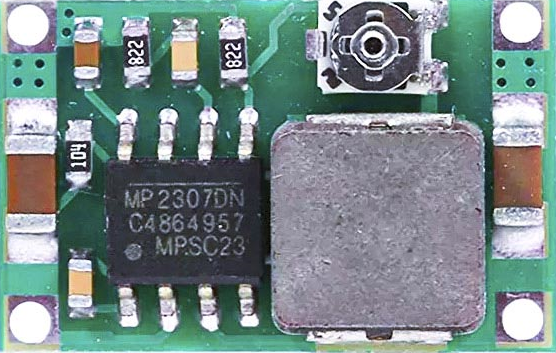

How to Use Mini-360 DC-DC Step Down Buck Converter: Examples, Pinouts, and Specs

Design with Mini-360 DC-DC Step Down Buck Converter in Cirkit Designer

Design with Mini-360 DC-DC Step Down Buck Converter in Cirkit DesignerIntroduction

The Mini-360 DC-DC Step Down Buck Converter is a compact, high-efficiency voltage regulator designed to step down voltage from a higher level to a lower level, using the principles of buck conversion. This component is widely used in battery-powered devices, power supplies, and DIY electronics projects where a specific lower voltage is required from a higher voltage source.

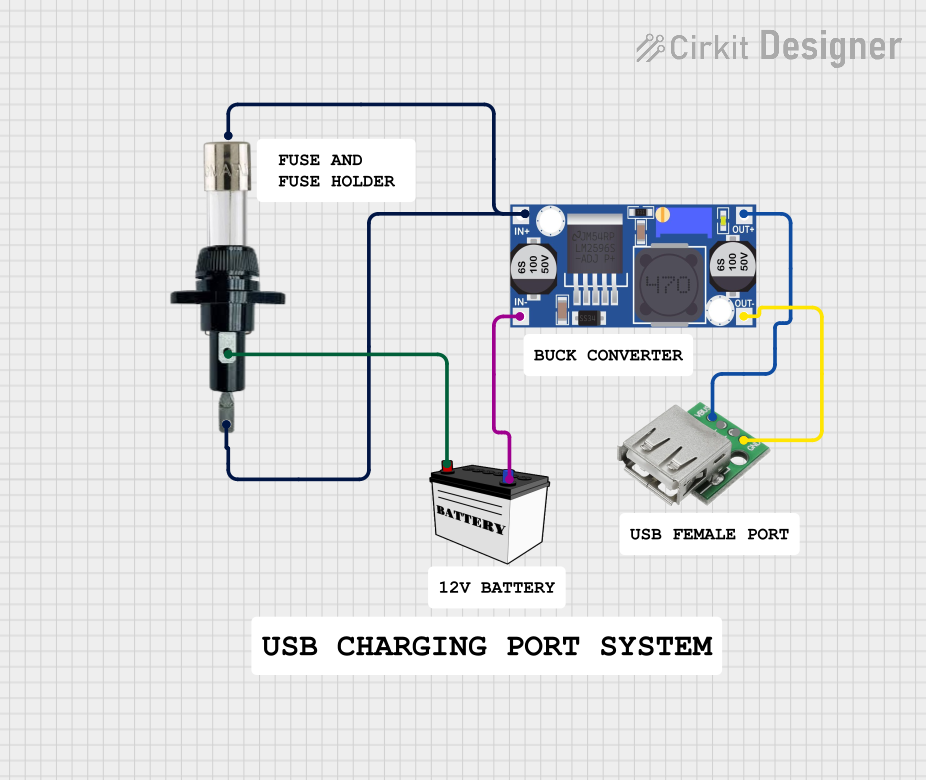

Explore Projects Built with Mini-360 DC-DC Step Down Buck Converter

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Mini-360 DC-DC Step Down Buck Converter

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Powering microcontrollers and sensors from a higher voltage source

- Battery-powered applications where extending battery life is crucial

- Providing variable voltage outputs for testing electronic circuits

- Portable electronic devices requiring regulated power supply

Technical Specifications

Key Technical Details

- Input Voltage Range: 4.75V to 23V

- Output Voltage Range: 1V to 17V (adjustable via onboard potentiometer)

- Maximum Output Current: Up to 3A (adequate heat sinking is necessary for currents above 1.5A)

- Conversion Efficiency: Up to 96%

- Switching Frequency: 340kHz

- Operating Temperature: -40°C to +85°C

Pin Configuration and Descriptions

| Pin Number | Name | Description |

|---|---|---|

| 1 | VIN | Input voltage (4.75V to 23V) |

| 2 | GND | Ground connection |

| 3 | VOUT | Output voltage (1V to 17V) |

| 4 | GND | Ground connection for the output side |

Usage Instructions

How to Use the Component in a Circuit

- Connect the input voltage source to the VIN and GND pins, ensuring that the voltage is within the specified range.

- Connect the load to the VOUT and GND pins.

- Adjust the onboard potentiometer to set the desired output voltage. Use a multimeter to monitor the output voltage while adjusting.

- Ensure that the input voltage is always higher than the desired output voltage.

Important Considerations and Best Practices

- Always verify input and output voltages with a multimeter before connecting sensitive components.

- Do not exceed the maximum input voltage of 23V to prevent damage to the converter.

- For currents above 1.5A, ensure adequate heat sinking to prevent overheating.

- Avoid adjusting the potentiometer while the converter is under load to prevent voltage spikes.

- Keep the converter away from high-temperature sources and ensure proper ventilation.

Troubleshooting and FAQs

Common Issues Users Might Face

- Output voltage is too high or too low: Ensure the potentiometer is correctly adjusted. If the issue persists, check for any damage to the potentiometer or the converter itself.

- Converter is overheating: Reduce the load or improve heat dissipation with a heat sink or by improving airflow.

- No output voltage: Check all connections, ensure the input voltage is within the specified range, and that the converter is not damaged.

Solutions and Tips for Troubleshooting

- If the output voltage cannot be adjusted, replace the potentiometer or the entire converter.

- In case of overheating, temporarily reduce the load to allow the converter to cool down and assess the need for better heat dissipation.

- If there is no output voltage, double-check the wiring, especially the polarity of the connections, and ensure the input voltage is present and within the specified range.

Example Code for Arduino UNO

If you're using the Mini-360 DC-DC Step Down Buck Converter to power an Arduino UNO, here's an example of how you might set up the converter and a simple code snippet to demonstrate functionality.

// This example assumes you are powering an Arduino UNO with the Mini-360 Buck Converter

void setup() {

// Initialize the Serial communication at 9600 baud rate

Serial.begin(9600);

}

void loop() {

// Read the input voltage on analog pin A0

int sensorValue = analogRead(A0);

// Convert the analog reading (which goes from 0 - 1023) to a voltage (0 - 5V)

float voltage = sensorValue * (5.0 / 1023.0);

// Print out the voltage to the Serial Monitor

Serial.println(voltage);

// Wait for a second

delay(1000);

}

Note: In this example, the Arduino is powered through the 5V pin, which bypasses the onboard voltage regulator. The Mini-360 Buck Converter must be adjusted to provide a stable 5V output before connecting to the Arduino.

Remember to adjust the potentiometer on the Mini-360 to output exactly 5V before connecting it to the Arduino's 5V pin. Use a multimeter to verify the voltage.