How to Use XR2206 HLF 224A8: Examples, Pinouts, and Specs

Design with XR2206 HLF 224A8 in Cirkit Designer

Design with XR2206 HLF 224A8 in Cirkit DesignerIntroduction

The XR2206 is a monolithic function generator integrated circuit (IC) capable of producing high-quality sine, square, triangle, ramp, and pulse waveforms of high stability and accuracy. The versatility of the XR2206 makes it an ideal solution for applications in communication systems, signal processing, instrumentation, and function generator equipment.

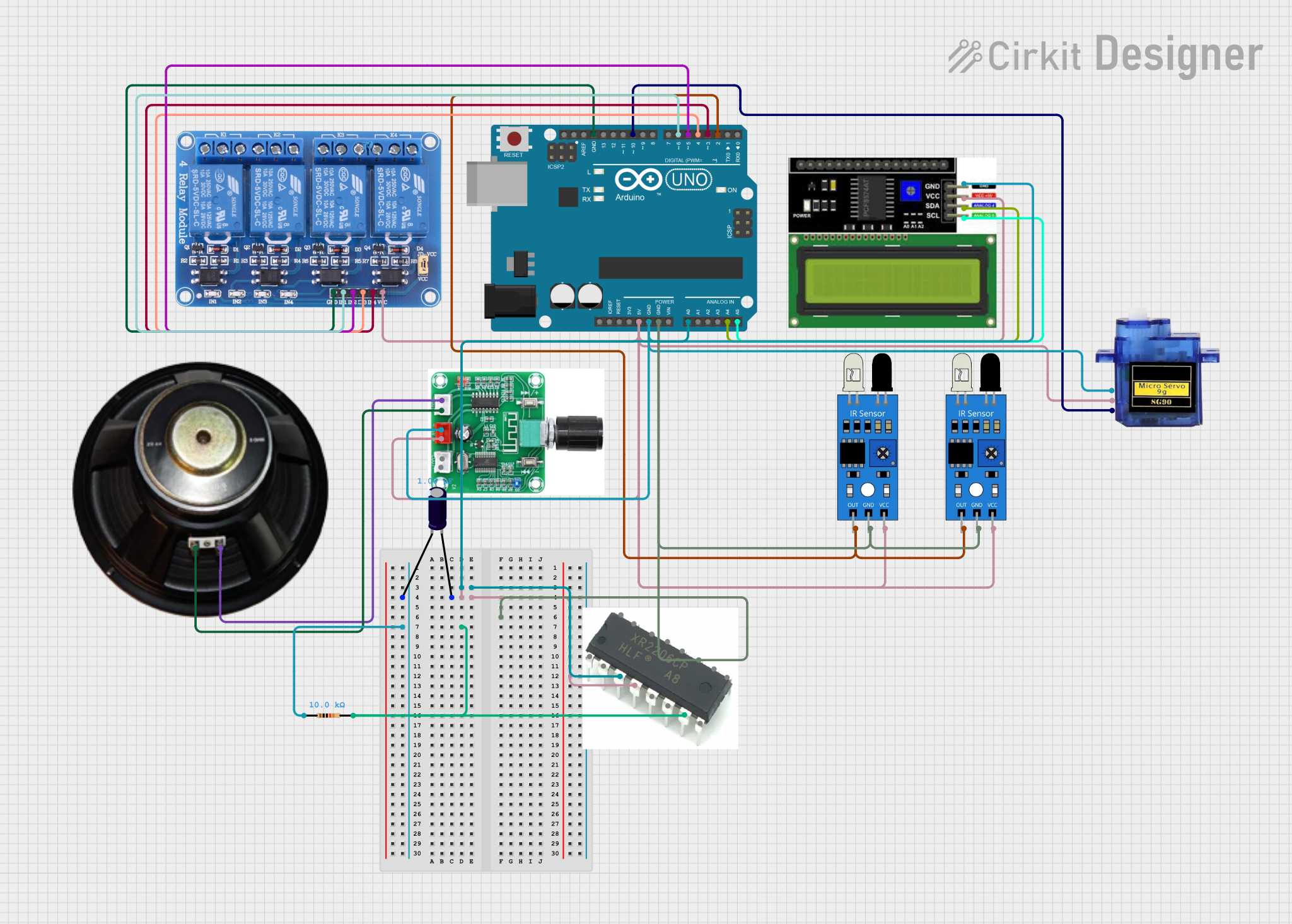

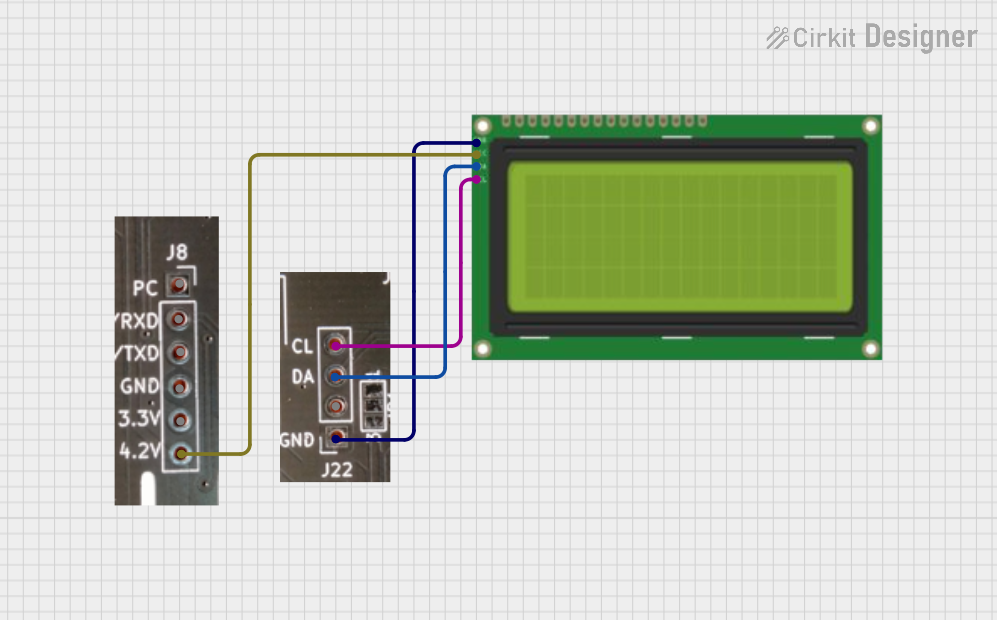

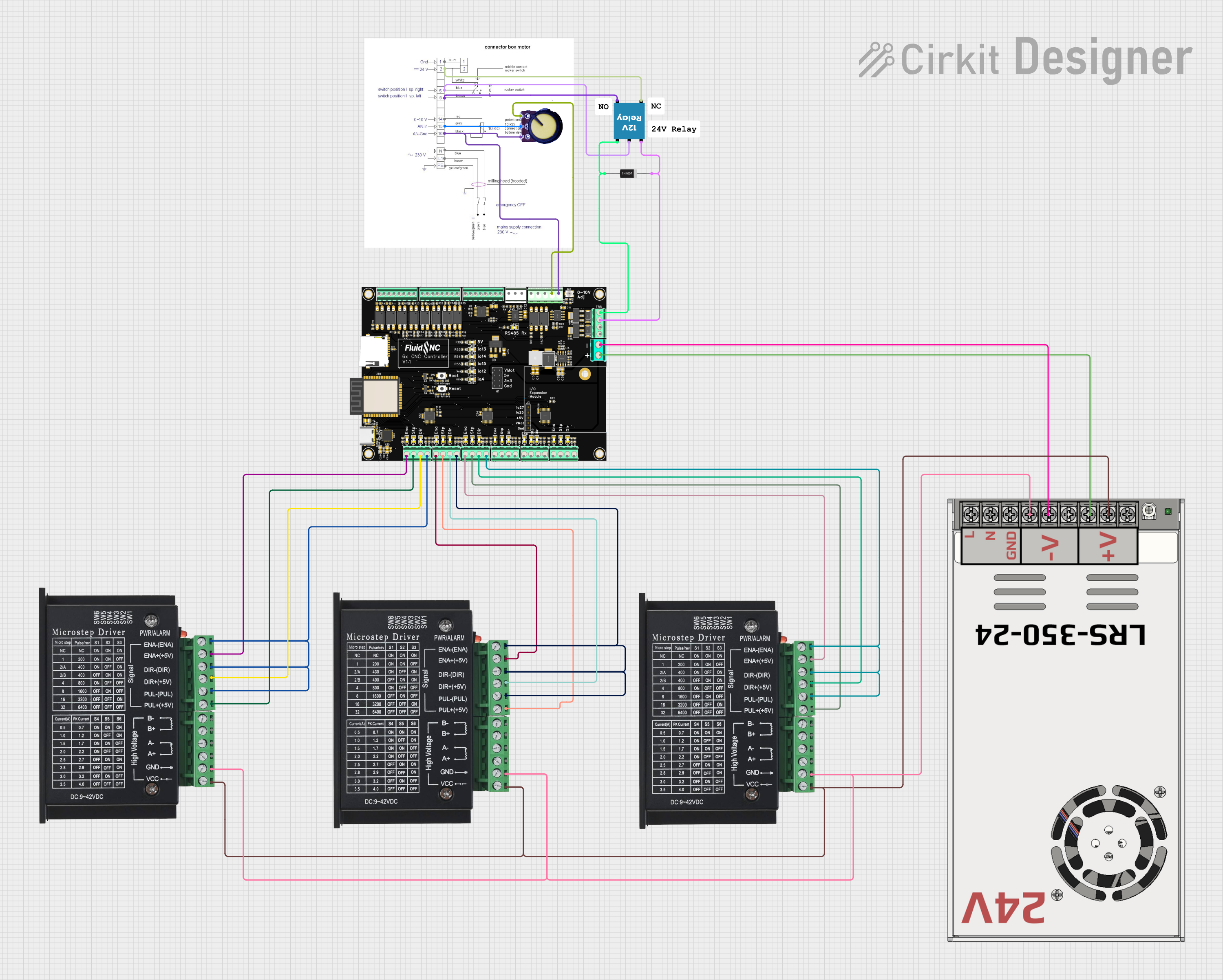

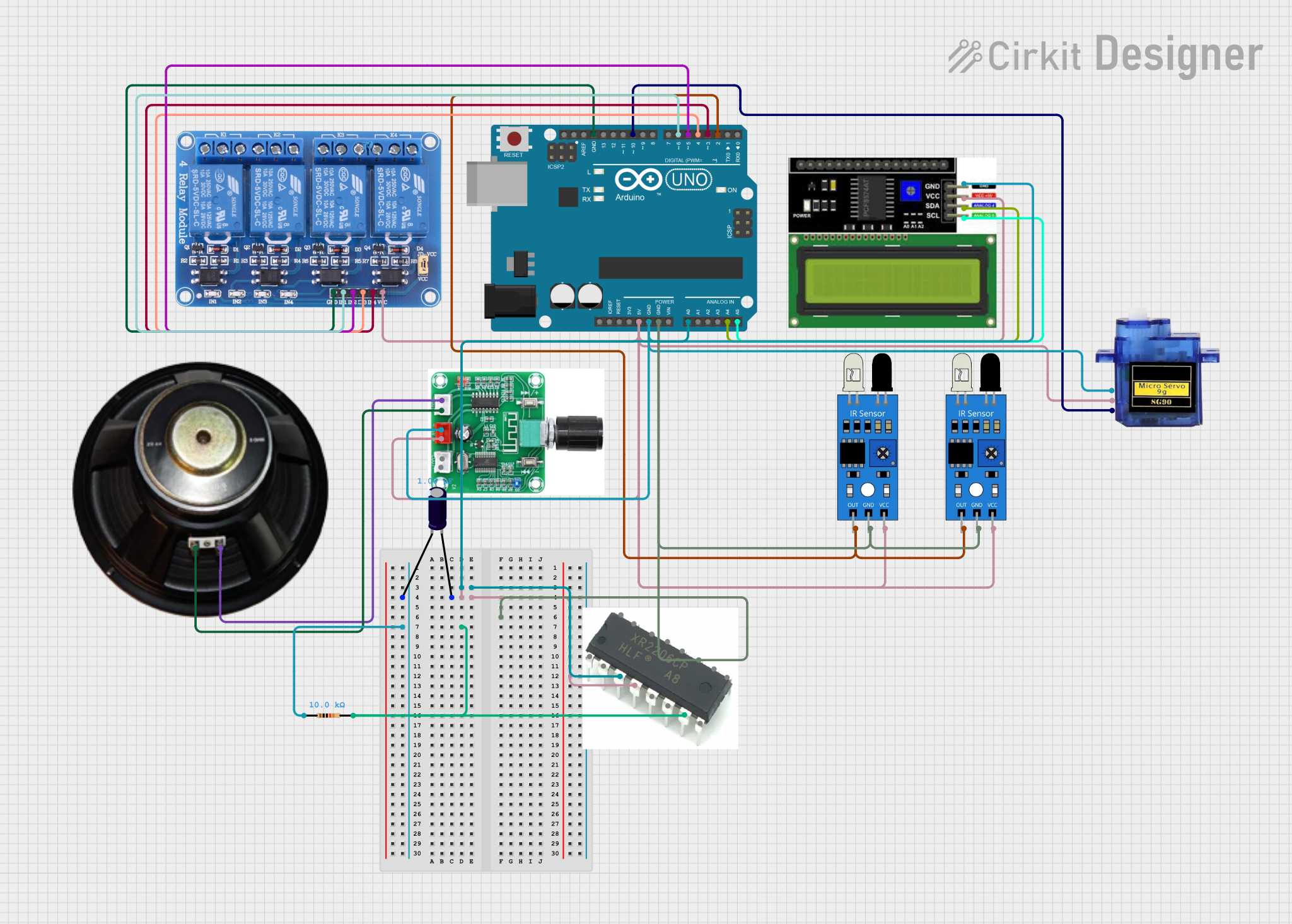

Explore Projects Built with XR2206 HLF 224A8

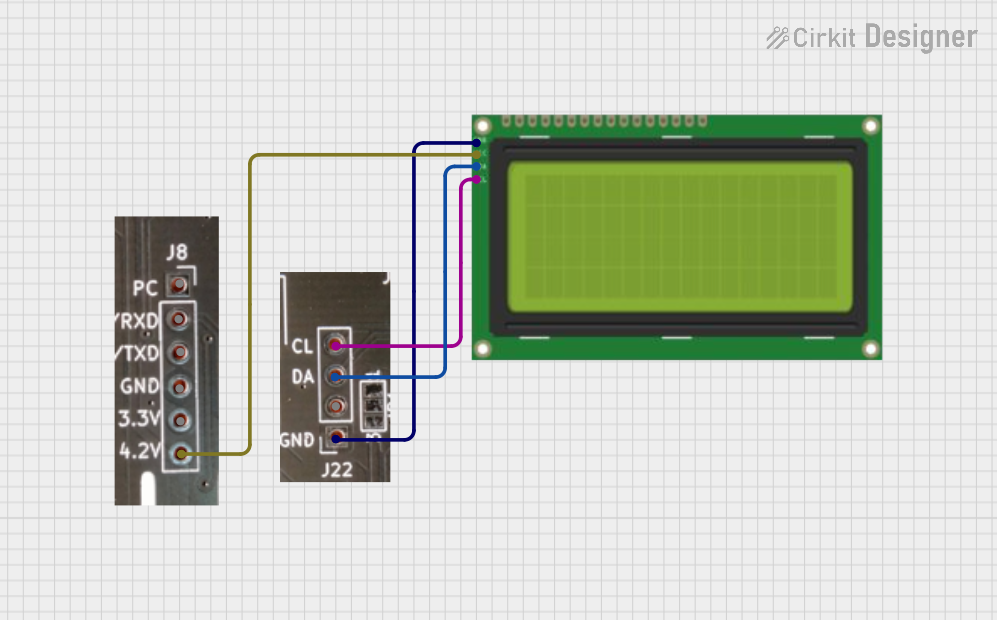

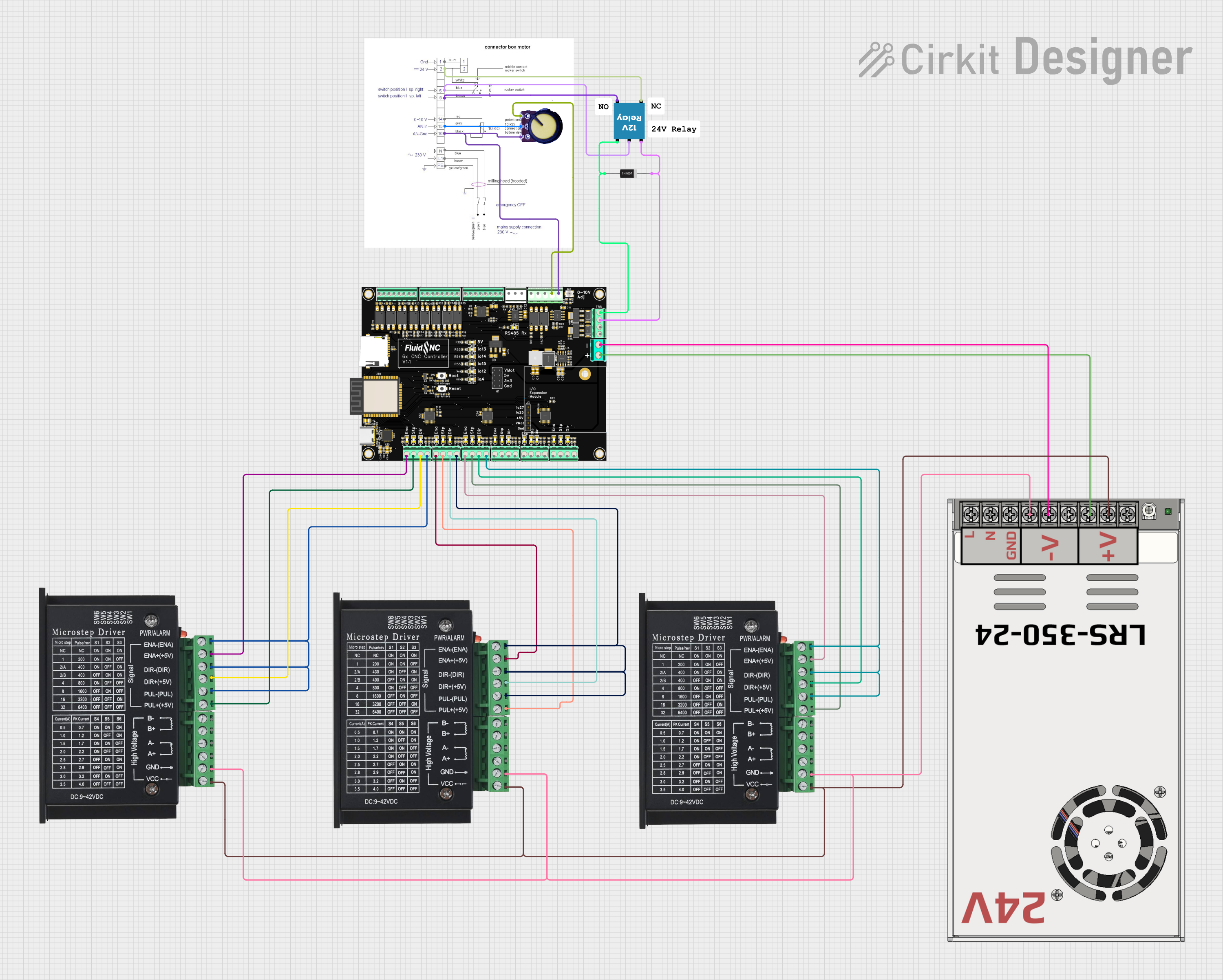

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with XR2206 HLF 224A8

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Signal generation for testing and troubleshooting

- Educational tools for electronic laboratories

- Function generators in electronic test equipment

- Modulation and demodulation in communication systems

Technical Specifications

Key Technical Details

- Supply Voltage (Vcc): 10V to 26V

- Output Frequency Range: 0.01Hz to 1MHz

- Frequency Adjustment Range: 2000:1

- Temperature Stability: 20ppm/°C

- Line Regulation: 0.05%/V

- Output Waveforms: Sine, Square, Triangle, Ramp, and Pulse

Pin Configuration and Descriptions

| Pin Number | Name | Description |

|---|---|---|

| 1 | GND | Ground reference for the IC |

| 2 | WAVE | Shape control for waveform output |

| 3 | SYNC | Synchronization output |

| 4 | V+ | Positive supply voltage |

| 5 | OFFSET | DC Offset control |

| 6 | FM | Frequency modulation input |

| 7 | AM | Amplitude modulation input |

| 8 | INV | Inverter input |

| 9 | TIMING | Timing resistor/capacitor connection |

| 10 | OUT | Output waveform |

| 11 | GND | Ground reference for the IC |

| 12 | V- | Negative supply voltage |

| 13 | SWEEP | Sweep control input |

| 14 | GND | Ground reference for the IC |

| 15 | GND | Ground reference for the IC |

| 16 | GND | Ground reference for the IC |

Usage Instructions

How to Use the Component in a Circuit

- Connect the power supply to pins 4 (V+) and 12 (V-) with the appropriate voltage levels.

- Attach a timing resistor to pin 9 and a timing capacitor to ground to set the frequency range.

- Set the desired waveform shape by adjusting the voltage on pin 2 (WAVE).

- Use pin 10 (OUT) to obtain the output waveform.

- Optionally, use pins 6 (FM) and 7 (AM) for frequency and amplitude modulation, respectively.

Important Considerations and Best Practices

- Ensure that the power supply voltage is within the specified range to prevent damage.

- Use a heat sink if operating near maximum power ratings to dissipate heat.

- Keep the timing capacitor and resistor close to the IC to minimize noise and interference.

- Use a decoupling capacitor near the power supply pins to filter out voltage spikes.

Troubleshooting and FAQs

Common Issues Users Might Face

- No Output Signal: Check power supply connections and ensure that the timing components are properly connected.

- Distorted Waveforms: Verify that the load connected to the output is within the IC's driving capability.

- Unstable Frequency: Ensure that the timing capacitor and resistor values are correct and that there is no interference.

Solutions and Tips for Troubleshooting

- Double-check all connections and component values.

- Use an oscilloscope to monitor the output waveform for troubleshooting.

- Replace timing components if the frequency is not within the expected range.

FAQs

Q: Can the XR2206 be used with a single supply voltage? A: Yes, the XR2206 can operate with a single supply voltage, but a dual supply can provide a greater output swing and better performance.

Q: What is the maximum frequency that can be generated? A: The XR2206 can generate frequencies up to 1MHz.

Q: How can I adjust the frequency range? A: The frequency range can be adjusted by changing the values of the timing resistor and capacitor connected to pin 9.

Example Code for Arduino UNO

Below is an example code snippet for controlling the XR2206 with an Arduino UNO to produce a 1kHz sine wave. This assumes additional circuitry to interface the Arduino with the XR2206.

// Define the XR2206 control pins

const int wavePin = 3; // Connected to pin 2 (WAVE) of XR2206

void setup() {

pinMode(wavePin, OUTPUT);

// Set the waveform shape to sine wave

analogWrite(wavePin, 128); // 128 corresponds to mid-range for sine wave

}

void loop() {

// The XR2206 will continuously output the 1kHz sine wave

// Additional code can be added here to change the waveform dynamically

}

Note: The above code is a simple illustration. In practice, you would need a digital-to-analog converter (DAC) or a PWM to analog filter circuit to properly control the WAVE pin for waveform selection.