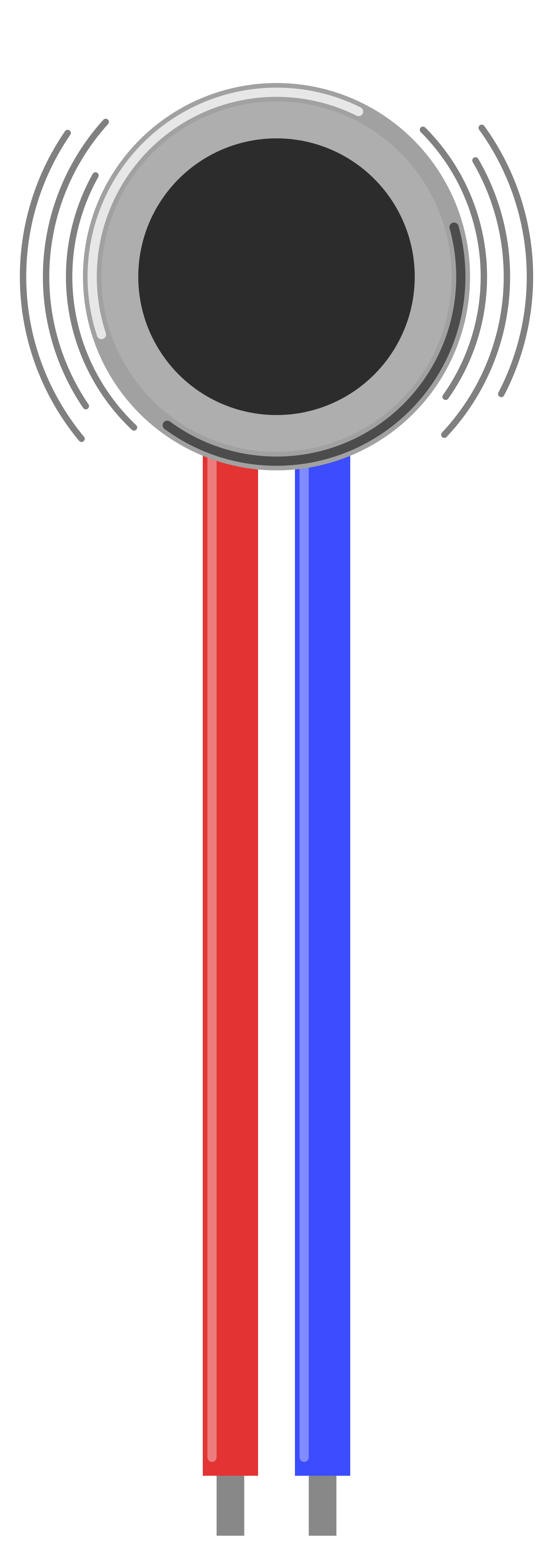

How to Use Vibration Motor: Examples, Pinouts, and Specs

Design with Vibration Motor in Cirkit Designer

Design with Vibration Motor in Cirkit DesignerIntroduction

A vibration motor is an electromechanical device designed to generate vibrations when an electrical current is applied. These vibrations can be used for a variety of applications, including haptic feedback in user interfaces, alert notifications in mobile devices, and as a tactile indicator in industrial and medical equipment. The compact size and ease of use make vibration motors suitable for a wide range of products.

Explore Projects Built with Vibration Motor

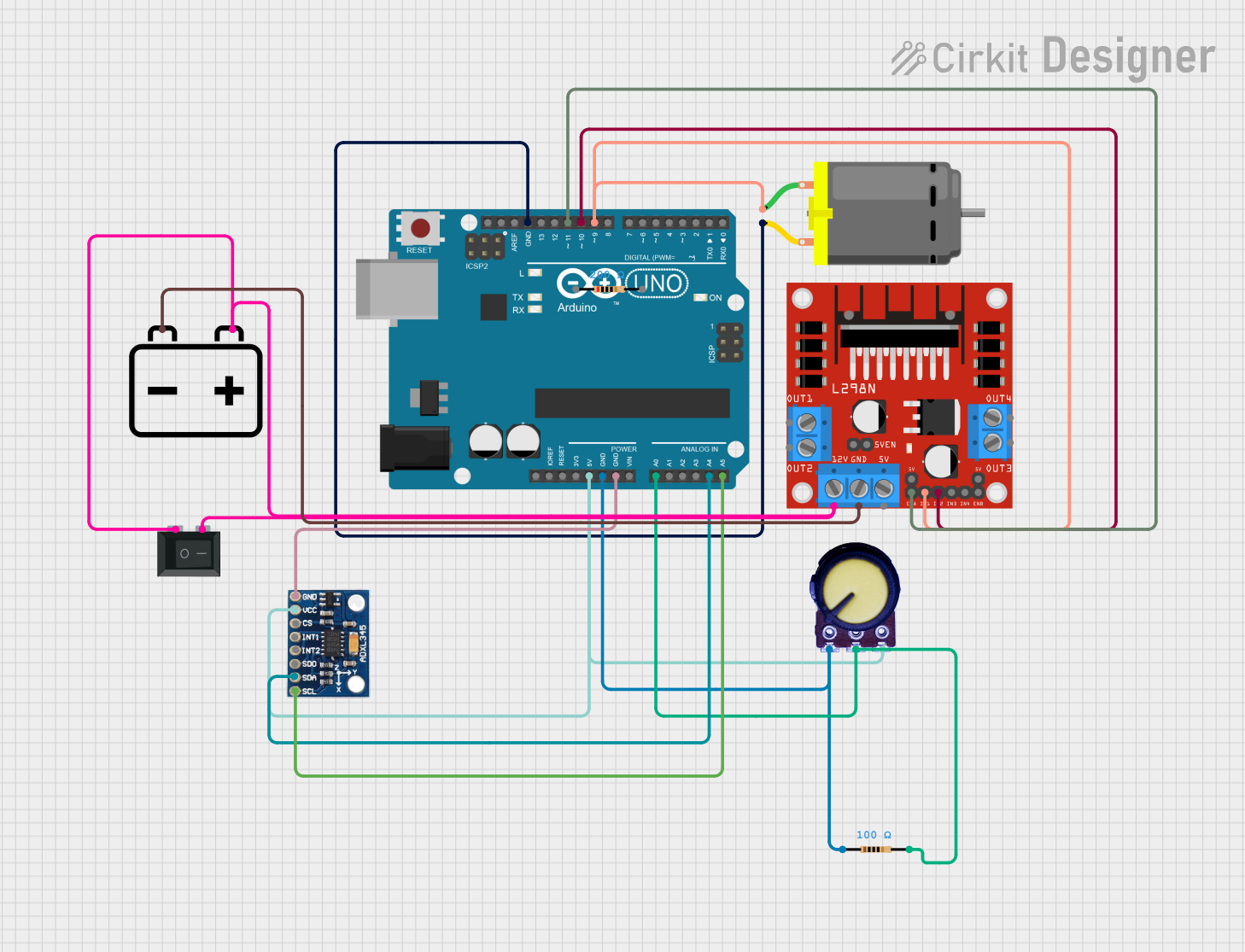

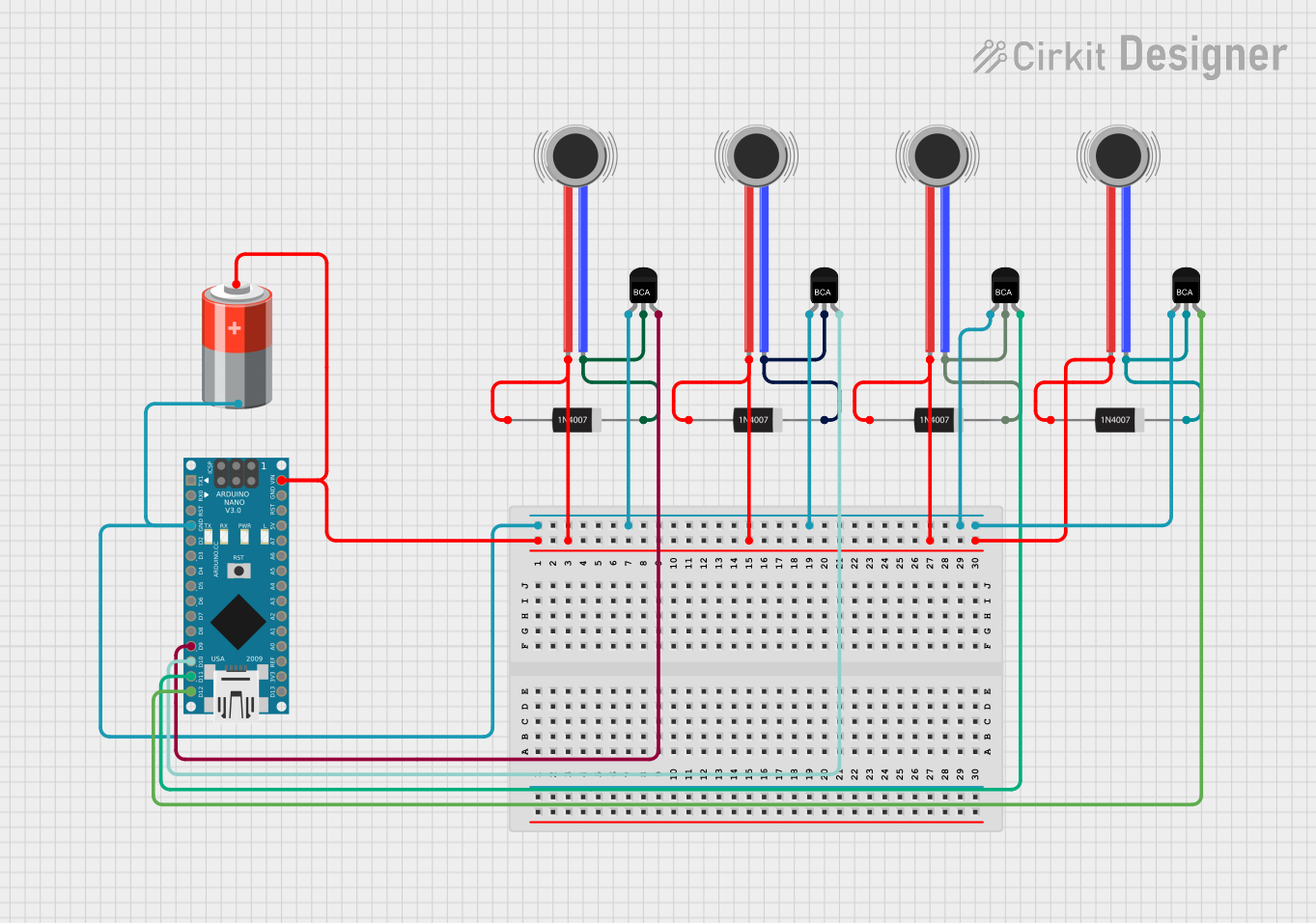

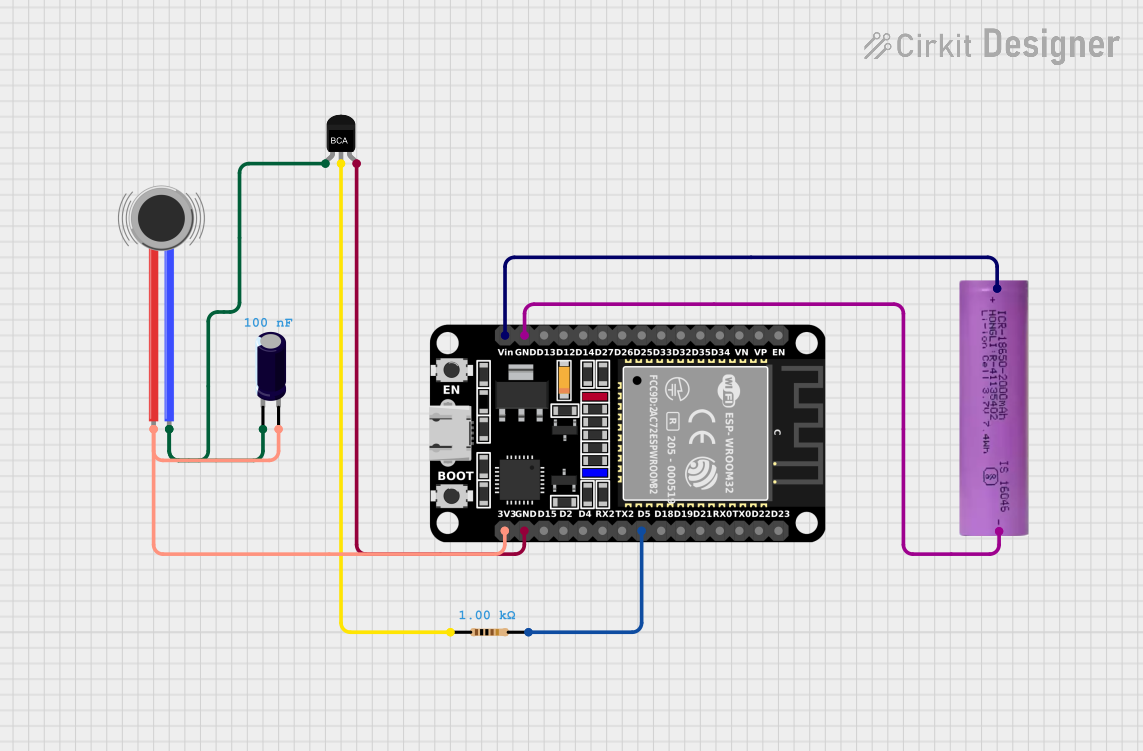

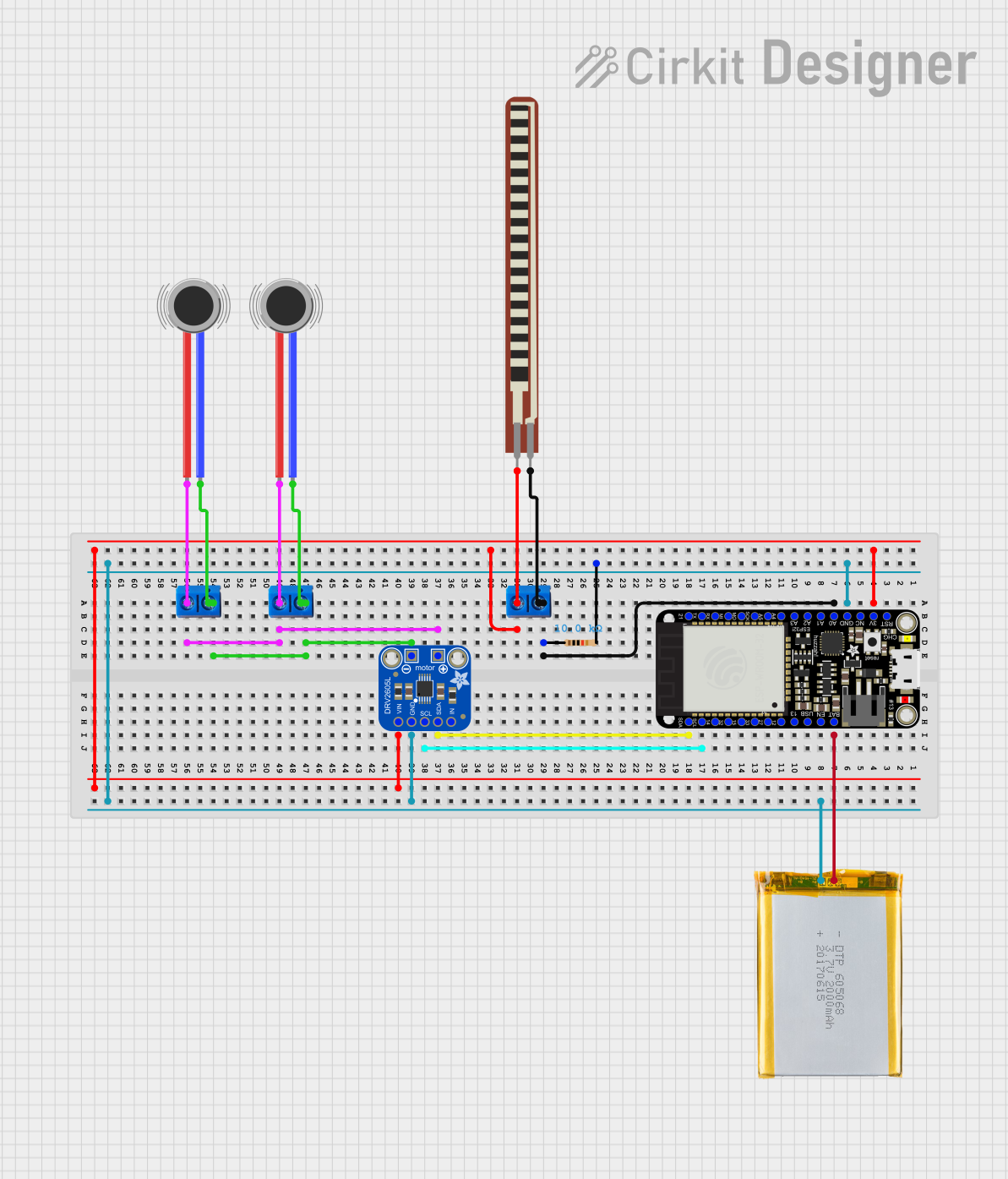

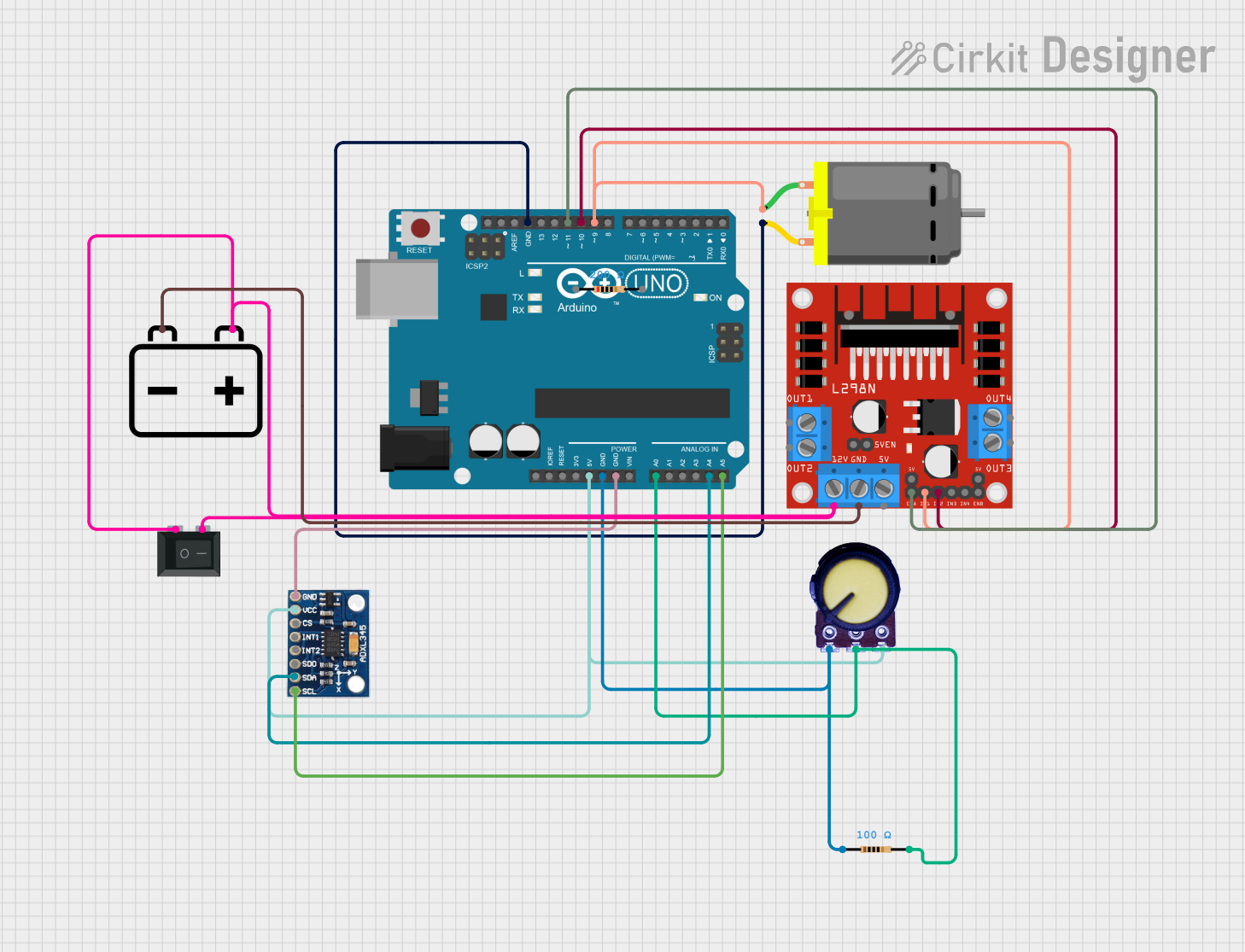

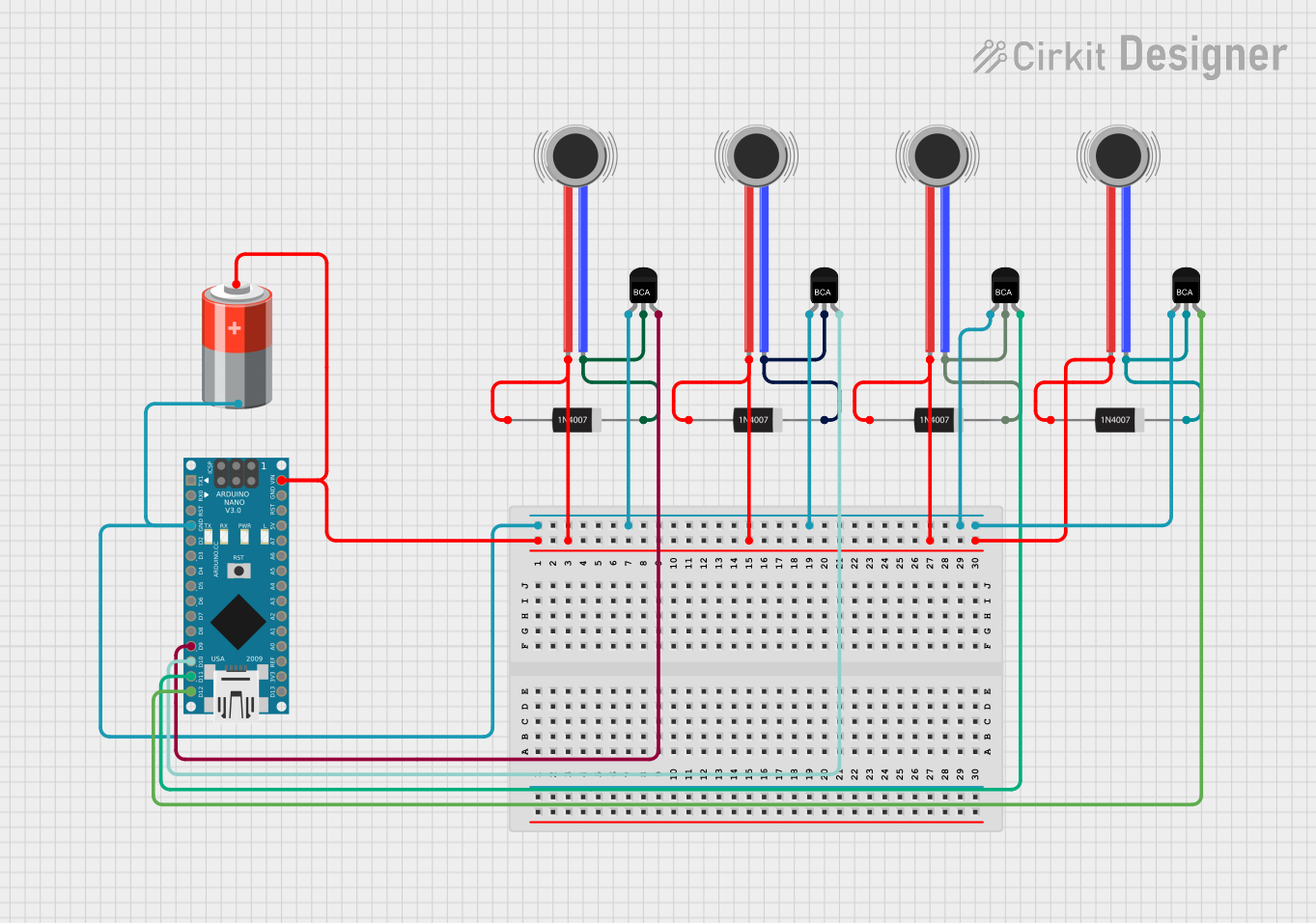

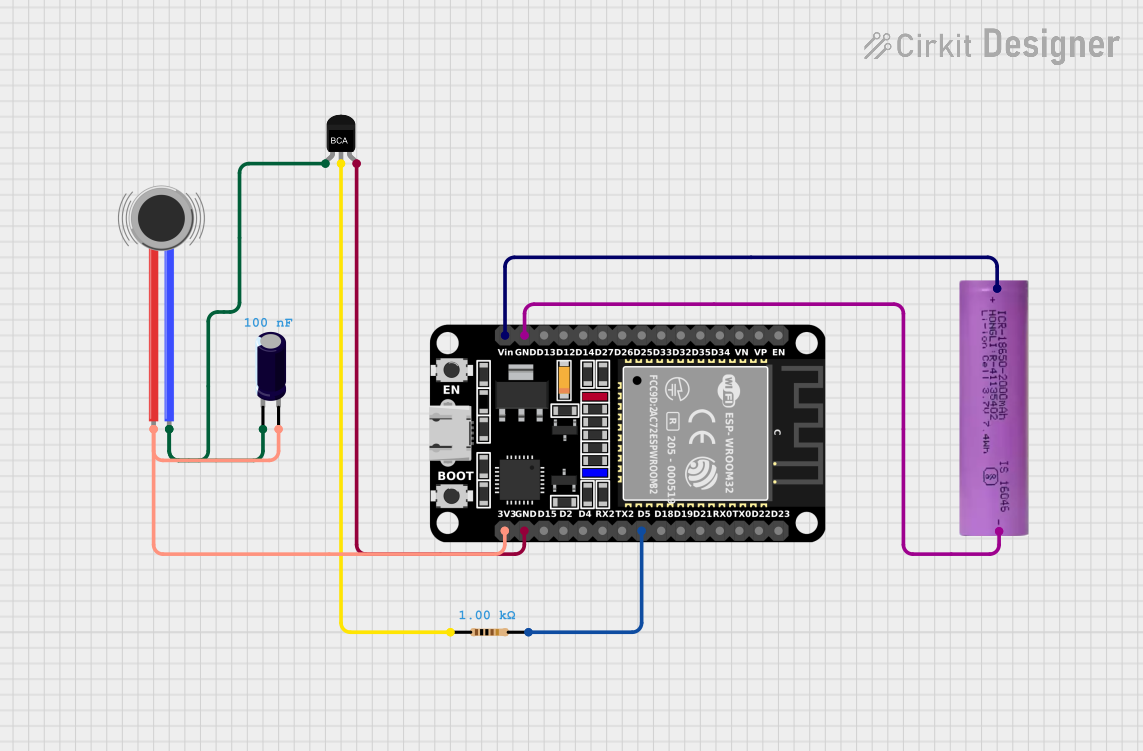

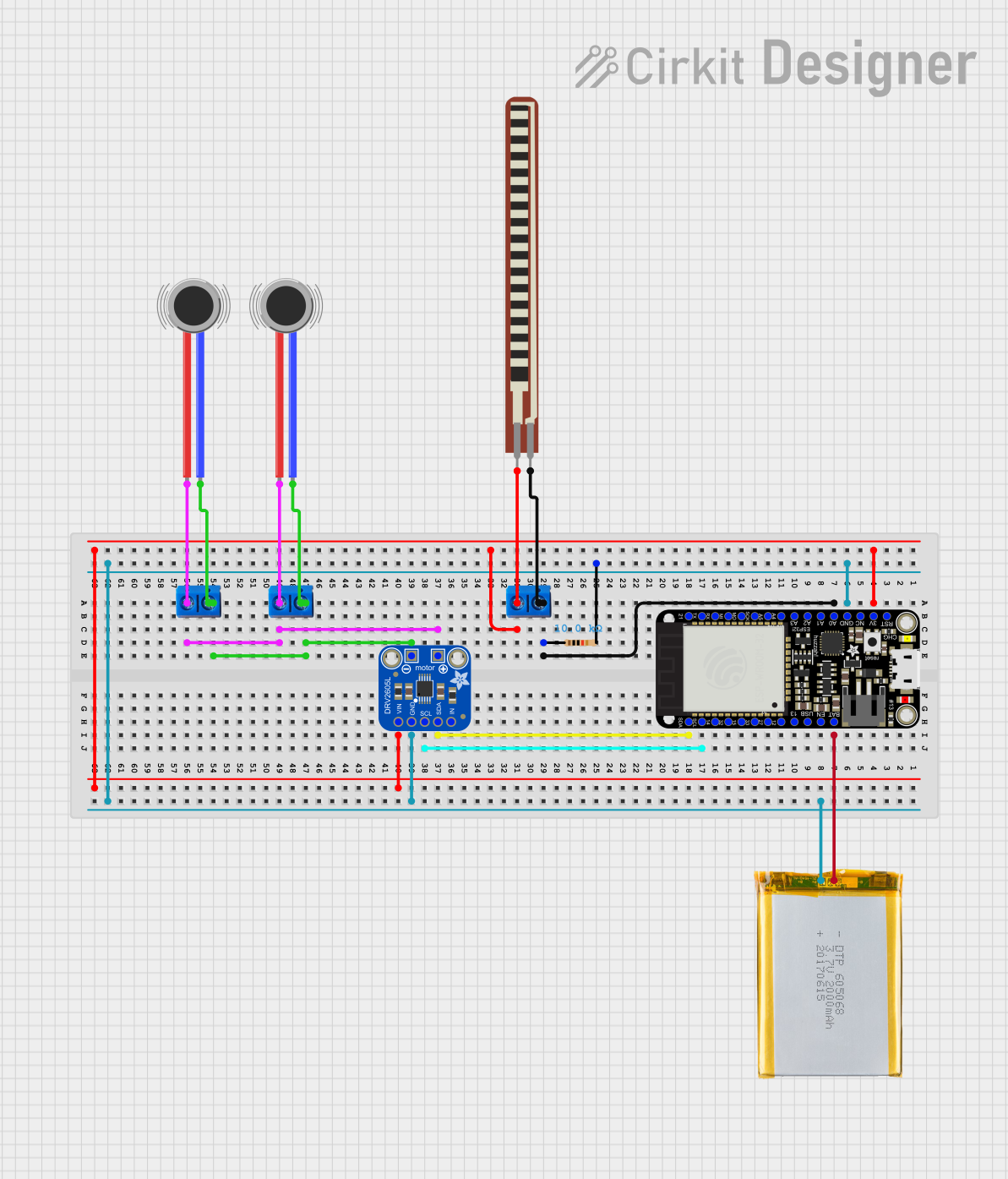

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Vibration Motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

General Characteristics

- Operating Voltage: Typically 1.5V to 3V for small motors, can vary for larger ones.

- Current Consumption: Varies with size and model, often in the range of 60mA to 100mA.

- Vibration Amplitude: Depends on the motor's weight and speed.

- Speed: Typically between 10,000 and 15,000 RPM (revolutions per minute).

- Lifetime: Varies, but often rated for several hours (e.g., 100-1000 hours) of continuous operation.

Pin Configuration and Descriptions

| Pin Number | Description |

|---|---|

| 1 | Positive Power Supply (V+) |

| 2 | Ground (GND) |

Usage Instructions

Integration into a Circuit

Power Supply: Connect the positive terminal of the vibration motor to a power source (e.g., battery) and the negative terminal to the ground. Ensure the power source matches the motor's rated voltage.

Control: To control the motor with a microcontroller like an Arduino UNO, you can use a transistor or a motor driver as a switch.

PWM Control: For variable vibration intensity, use Pulse Width Modulation (PWM) through a microcontroller.

Best Practices

- Isolation: Ensure the motor is securely mounted but with some form of isolation to prevent unwanted vibrations from affecting other components.

- Heat Dissipation: Avoid continuous operation at high currents to prevent overheating.

- Electrical Noise: Be aware that motors can generate electrical noise; use appropriate filtering if necessary.

Example Code for Arduino UNO

// Define the pin connected to the vibration motor

const int motorPin = 3; // Use a PWM pin for analog output

void setup() {

// Set the motor pin as an output

pinMode(motorPin, OUTPUT);

}

void loop() {

// Turn on the vibration motor at full speed

analogWrite(motorPin, 255); // Send a PWM signal of max duty cycle

delay(1000); // Vibrate for 1 second

// Turn off the motor

analogWrite(motorPin, 0); // Send a PWM signal of zero duty cycle

delay(1000); // Pause for 1 second

// Vibrate the motor at half speed

analogWrite(motorPin, 127); // Send a PWM signal of 50% duty cycle

delay(1000); // Vibrate for 1 second

// Turn off the motor

analogWrite(motorPin, 0); // Send a PWM signal of zero duty cycle

delay(1000); // Pause for 1 second

}

Troubleshooting and FAQs

Common Issues

- Motor not vibrating: Check the power supply and connections. Ensure the voltage matches the motor's specifications.

- Weak vibrations: Ensure the motor is not loosely mounted and that the power supply is adequate.

- Overheating: If the motor gets too hot, reduce the duty cycle or operating time.

FAQs

Q: Can I control the vibration intensity? A: Yes, by using PWM, you can control the intensity of the vibrations.

Q: How do I extend the life of my vibration motor? A: Avoid running the motor continuously at high currents and ensure it is mounted securely.

Q: Is it possible to use the vibration motor with a 5V Arduino pin directly? A: It is not recommended to connect the motor directly to an Arduino pin without a current-limiting resistor or a transistor, as it may draw more current than the pin can safely supply.

Q: Can I use the vibration motor with a 3.3V supply? A: Yes, but the vibration strength may be reduced compared to using a higher voltage within the motor's rated range.