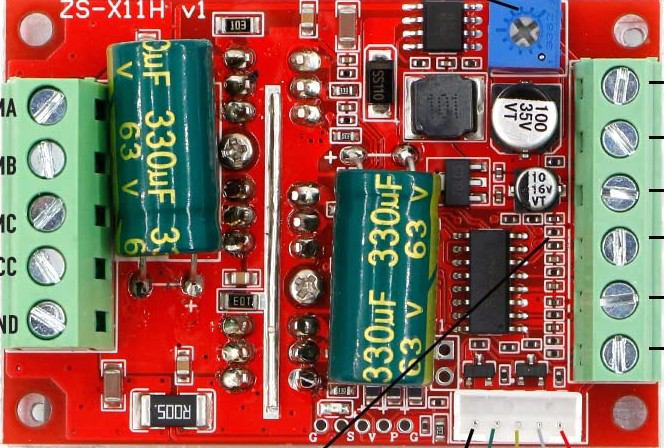

How to Use RioRand 350 W 6-60 V PWM DC: Examples, Pinouts, and Specs

Design with RioRand 350 W 6-60 V PWM DC in Cirkit Designer

Design with RioRand 350 W 6-60 V PWM DC in Cirkit DesignerIntroduction

The RioRand 350 W 6-60 V PWM DC Motor Controller (Part ID: UNO) is a versatile and efficient device designed for controlling the speed of DC motors. By utilizing Pulse Width Modulation (PWM) technology, this controller adjusts the duty cycle of the voltage supplied to the motor, enabling precise speed control. It supports a wide voltage range of 6 to 60 volts and can handle up to 350 watts of power, making it suitable for a variety of applications.

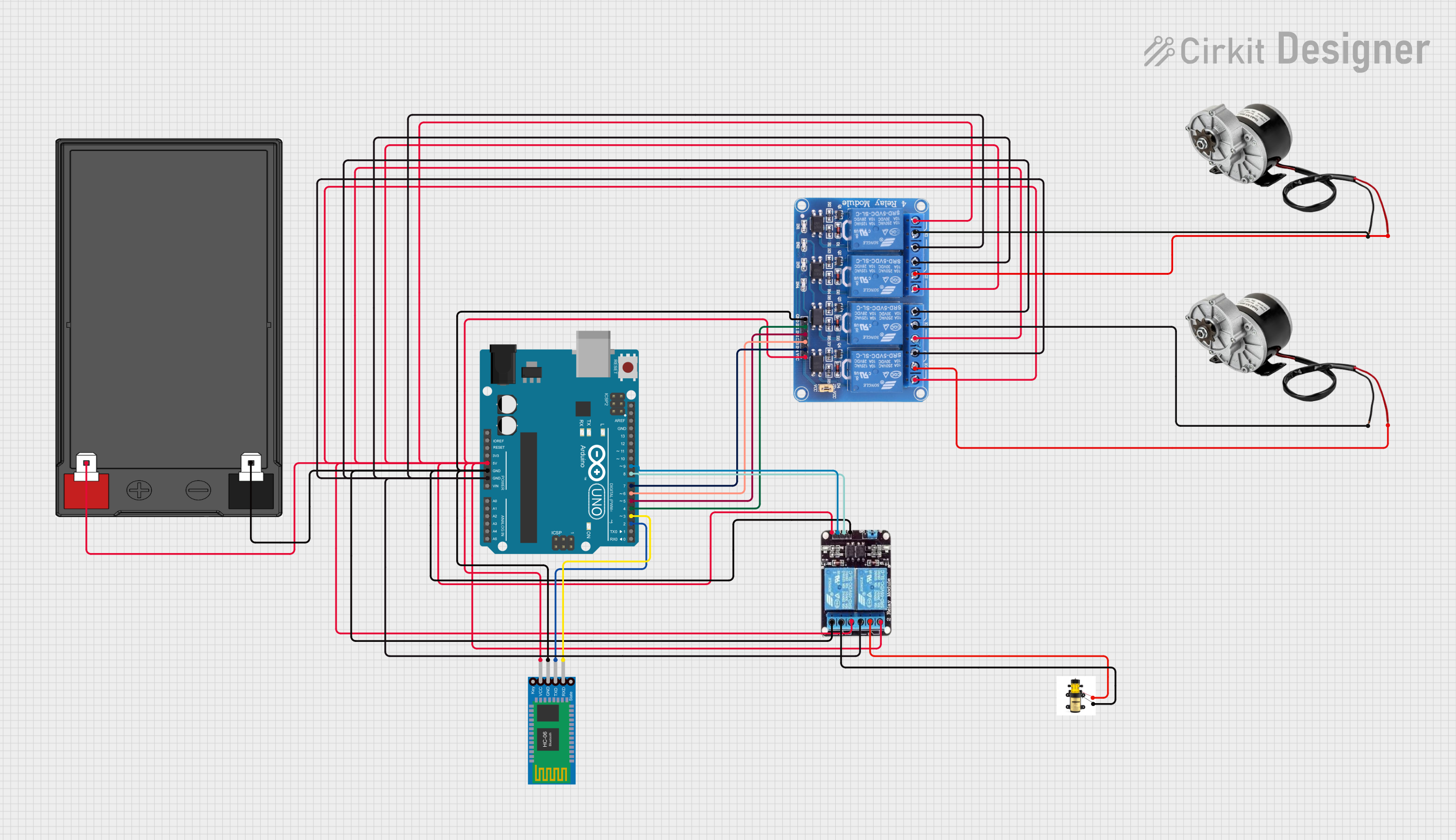

Explore Projects Built with RioRand 350 W 6-60 V PWM DC

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with RioRand 350 W 6-60 V PWM DC

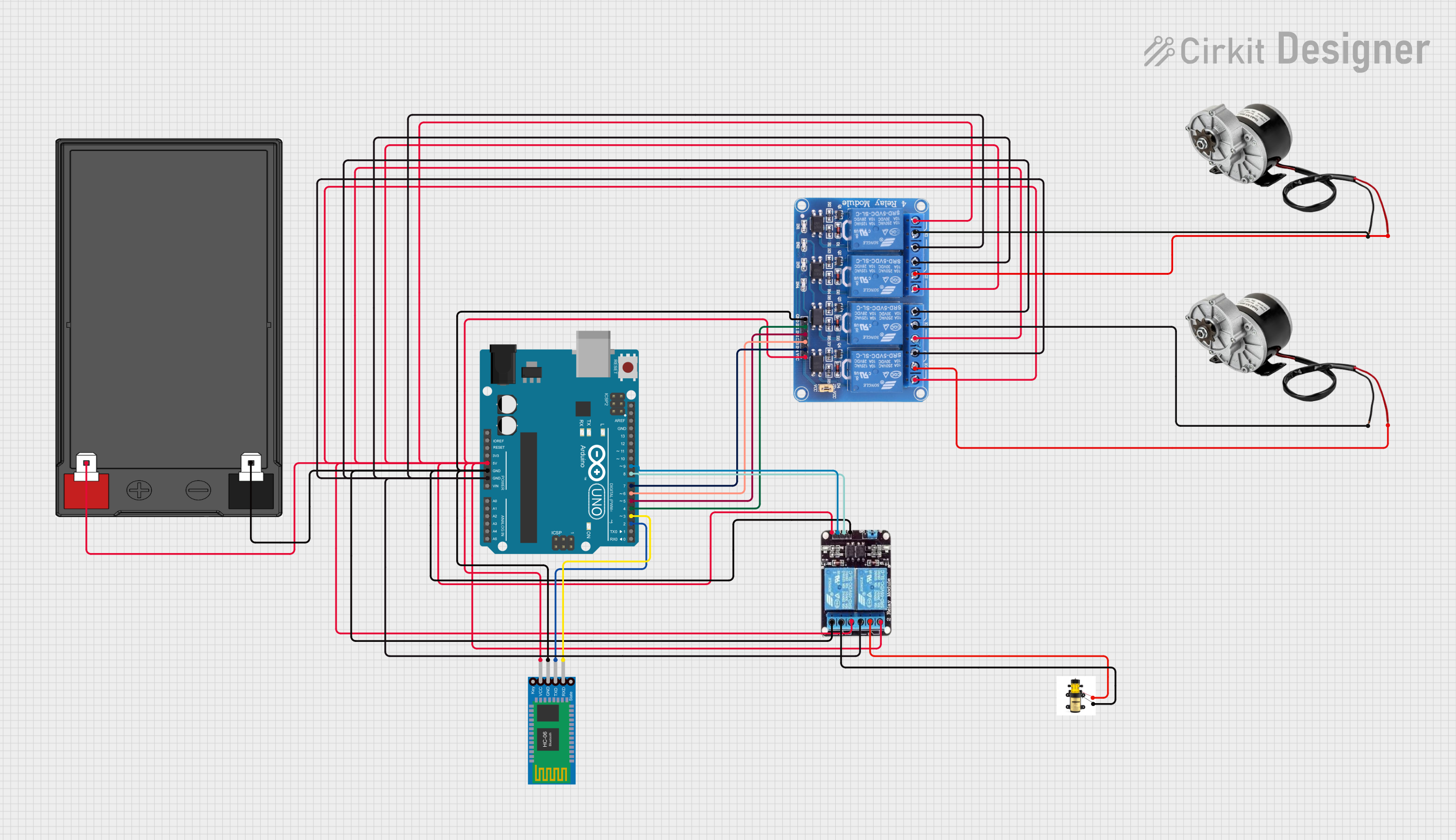

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Speed control for DC motors in robotics and automation systems

- Electric vehicle motor control

- Industrial conveyor belt systems

- Fan speed regulation

- DIY electronics and hobby projects

Technical Specifications

The following table outlines the key technical details of the RioRand 350 W 6-60 V PWM DC Motor Controller:

| Parameter | Specification |

|---|---|

| Input Voltage Range | 6 V to 60 V DC |

| Maximum Power Output | 350 W |

| Output Current | Up to 20 A (continuous) |

| PWM Frequency | 15 kHz |

| Duty Cycle Range | 0% to 100% |

| Control Method | Rotary potentiometer (speed control) |

| Dimensions | 70 mm x 40 mm x 30 mm |

| Weight | 50 g |

Pin Configuration and Descriptions

The RioRand PWM DC Motor Controller has the following input and output connections:

| Pin/Terminal | Description |

|---|---|

| VIN+ | Positive input terminal for the power supply (6-60 V DC). |

| VIN- | Negative input terminal for the power supply (ground). |

| MOTOR+ | Positive output terminal for the DC motor. |

| MOTOR- | Negative output terminal for the DC motor. |

| Potentiometer | Rotary knob for adjusting the PWM duty cycle and controlling motor speed. |

Usage Instructions

How to Use the Component in a Circuit

Connect the Power Supply:

- Attach the positive terminal of your DC power supply to the

VIN+pin. - Connect the negative terminal of your DC power supply to the

VIN-pin. - Ensure the power supply voltage is within the 6-60 V range.

- Attach the positive terminal of your DC power supply to the

Connect the DC Motor:

- Connect the positive terminal of the DC motor to the

MOTOR+pin. - Connect the negative terminal of the DC motor to the

MOTOR-pin.

- Connect the positive terminal of the DC motor to the

Adjust the Speed:

- Use the rotary potentiometer to adjust the motor speed. Turning the knob clockwise increases the speed, while turning it counterclockwise decreases the speed.

Power On:

- Turn on the power supply. The motor should start running, and its speed can be controlled using the potentiometer.

Important Considerations and Best Practices

- Voltage Compatibility: Ensure the input voltage matches the motor's rated voltage and falls within the controller's 6-60 V range.

- Current Limitations: Do not exceed the maximum continuous current rating of 20 A to avoid damaging the controller.

- Heat Dissipation: For high-power applications, ensure proper ventilation or use a heatsink to prevent overheating.

- Polarity: Double-check the polarity of all connections to avoid damaging the controller or motor.

- Load Testing: Test the motor with a light load before applying a full load to ensure proper operation.

Example: Connecting to an Arduino UNO

The RioRand PWM DC Motor Controller can be used with an Arduino UNO to automate motor speed control. Below is an example Arduino sketch:

// Example: Controlling the RioRand PWM DC Motor Controller with Arduino UNO

// This code generates a PWM signal on pin 9 to control motor speed.

const int pwmPin = 9; // PWM output pin connected to the controller's potentiometer input

void setup() {

pinMode(pwmPin, OUTPUT); // Set the PWM pin as an output

}

void loop() {

for (int dutyCycle = 0; dutyCycle <= 255; dutyCycle++) {

analogWrite(pwmPin, dutyCycle); // Increase motor speed gradually

delay(10); // Wait 10 ms between steps

}

for (int dutyCycle = 255; dutyCycle >= 0; dutyCycle--) {

analogWrite(pwmPin, dutyCycle); // Decrease motor speed gradually

delay(10); // Wait 10 ms between steps

}

}

Note: To use the Arduino UNO with this controller, you may need to modify the controller's potentiometer input to accept a PWM signal from the Arduino.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Start:

- Cause: Incorrect wiring or insufficient power supply voltage.

Solution: Verify all connections and ensure the power supply voltage is within the 6-60 V range.

- Cause: Incorrect wiring or insufficient power supply voltage.

Motor Runs at Full Speed Regardless of Potentiometer Position:

- Cause: Faulty potentiometer or damaged controller.

Solution: Check the potentiometer for proper operation. Replace the controller if necessary.

- Cause: Faulty potentiometer or damaged controller.

Controller Overheats:

- Cause: Excessive current draw or poor ventilation.

Solution: Ensure the motor's current draw does not exceed 20 A. Improve ventilation or add a heatsink.

- Cause: Excessive current draw or poor ventilation.

PWM Signal from Arduino Not Controlling Speed:

- Cause: Incompatible input or incorrect wiring.

Solution: Verify that the controller's potentiometer input is modified to accept a PWM signal.

- Cause: Incompatible input or incorrect wiring.

FAQs

Can this controller reverse the motor direction?

No, this controller does not support reversing motor direction. Use an H-bridge circuit for bidirectional control.What type of motors can this controller drive?

This controller is designed for brushed DC motors only. It is not compatible with brushless motors.Is the controller waterproof?

No, the controller is not waterproof. Use it in a dry environment or enclose it in a protective case.Can I use this controller with a 24 V battery?

Yes, as long as the battery voltage is within the 6-60 V range and the motor's current draw does not exceed 20 A.