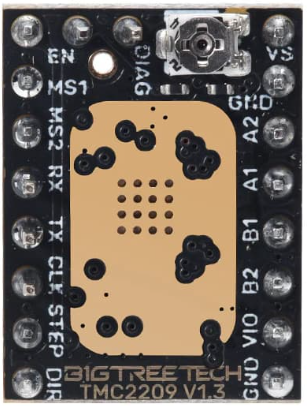

How to Use TMC 2209: Examples, Pinouts, and Specs

Design with TMC 2209 in Cirkit Designer

Design with TMC 2209 in Cirkit DesignerIntroduction

The TMC 2209 is a highly efficient and versatile stepper motor driver designed for applications requiring precise motion control. It is widely used in 3D printers, CNC machines, and other automation systems. This driver is known for its silent operation, thanks to Trinamic's StealthChop2 technology, and advanced features such as sensorless homing, microstepping control, and dynamic current adjustment. The TMC 2209 is an excellent choice for reducing noise and improving the performance of stepper motor-driven systems.

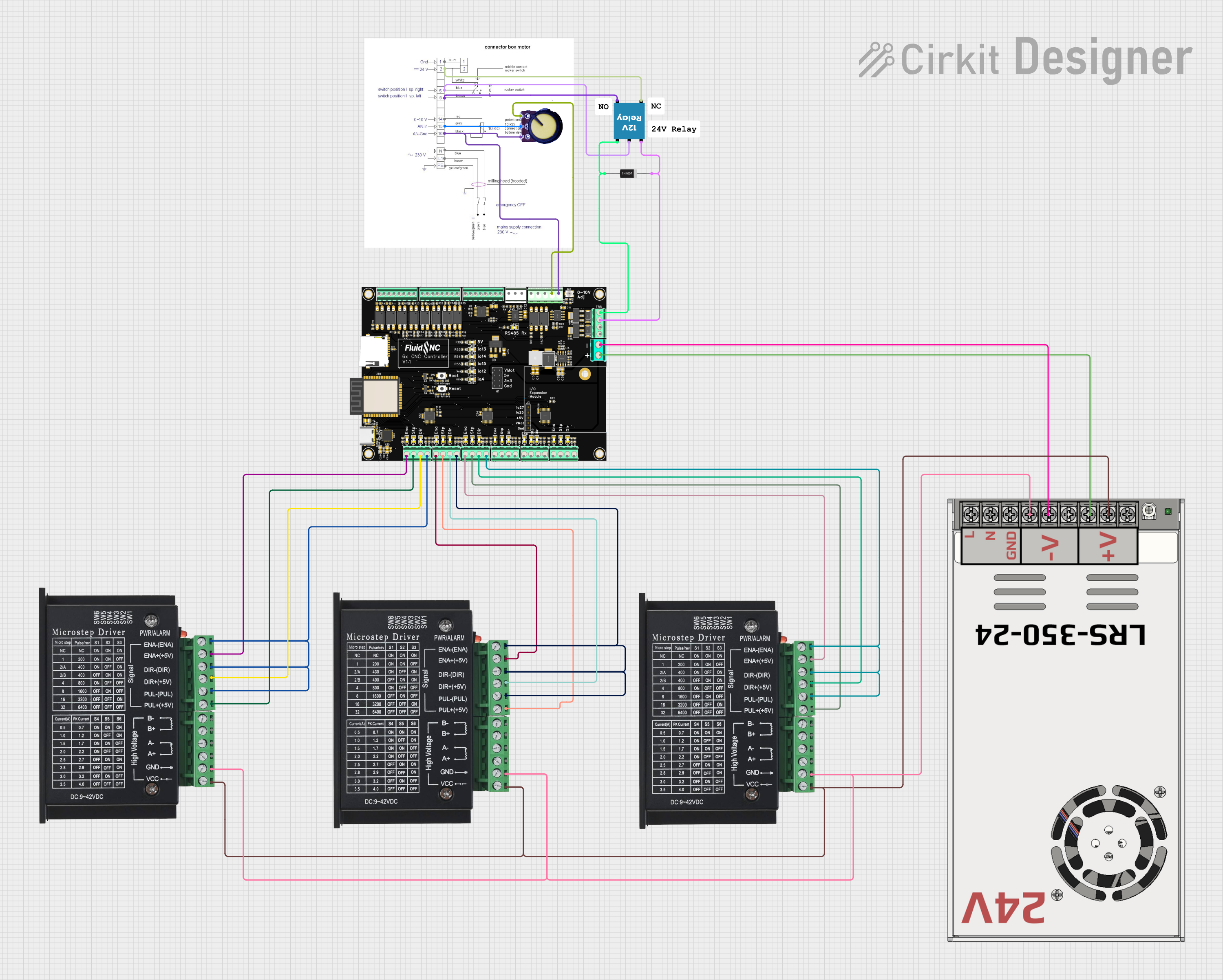

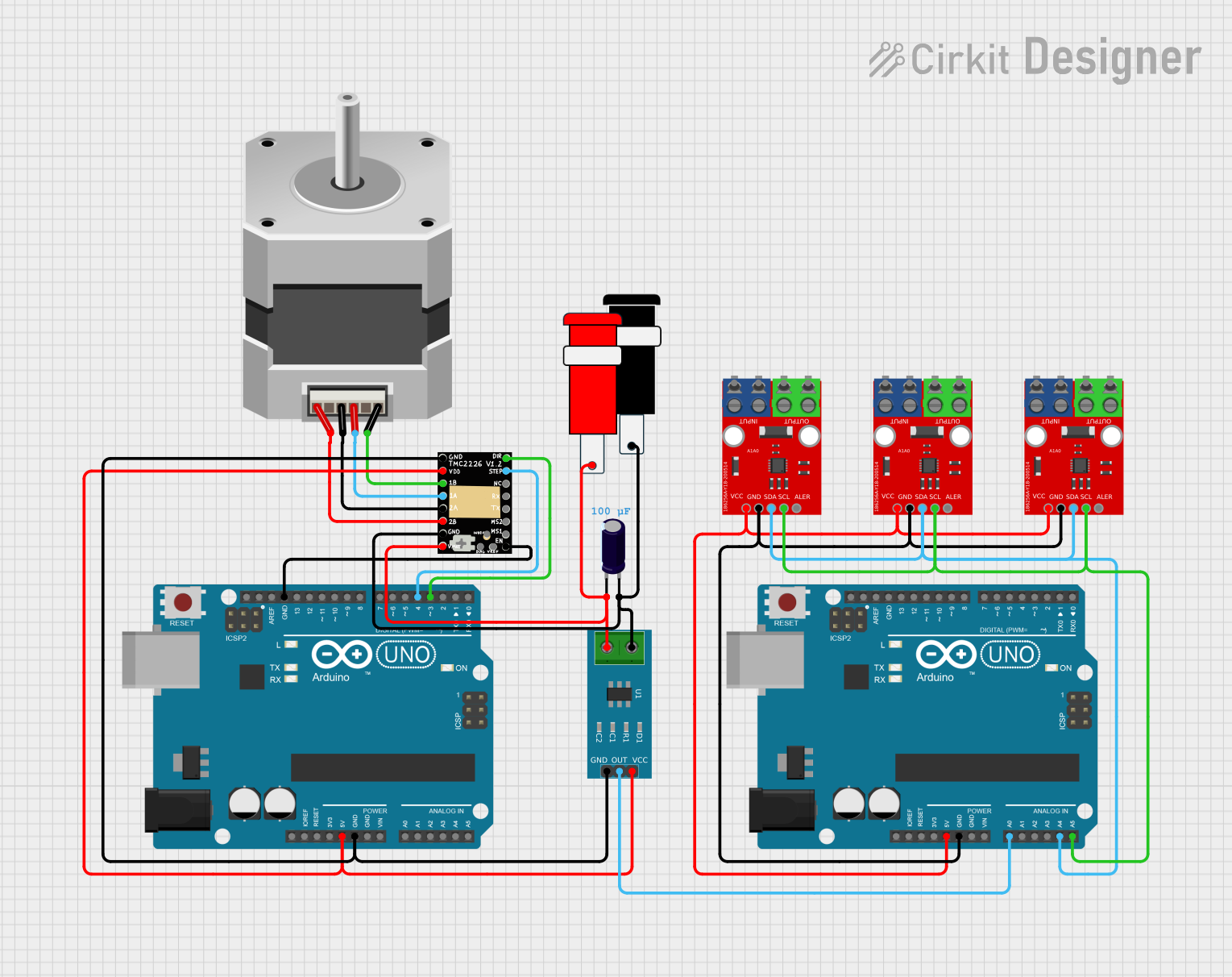

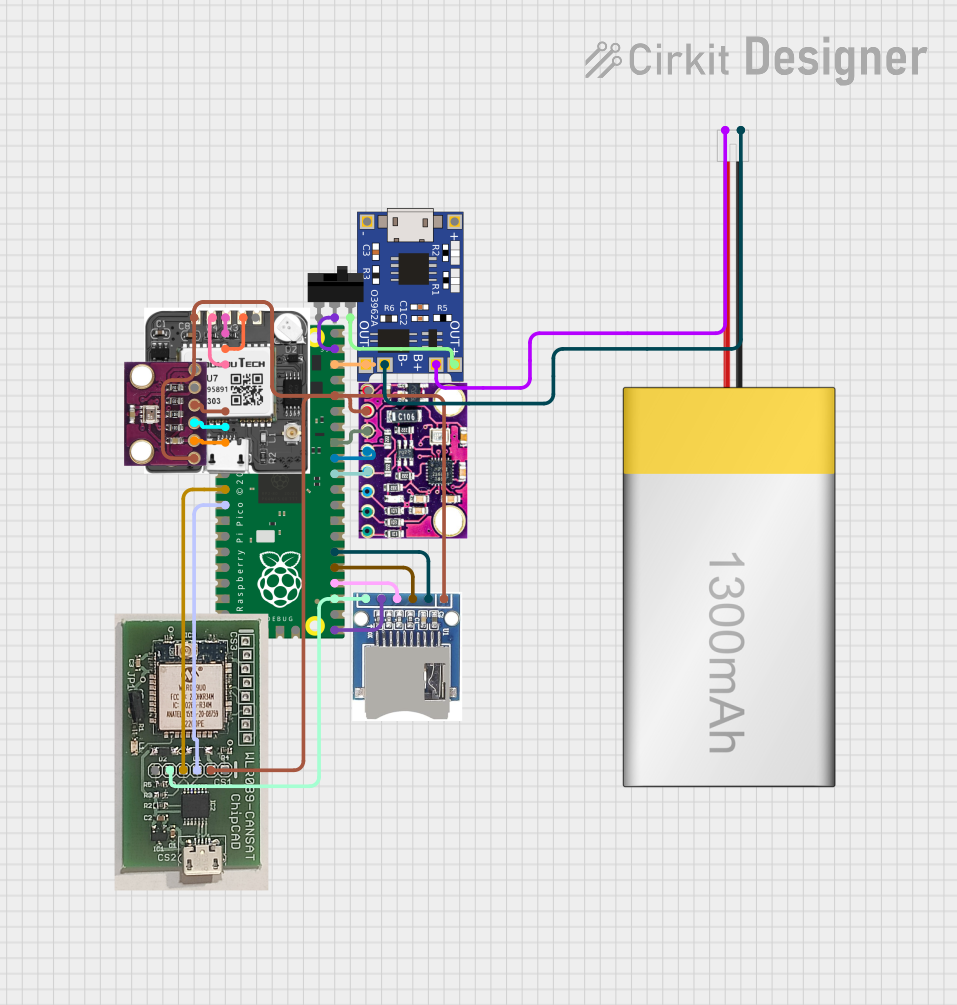

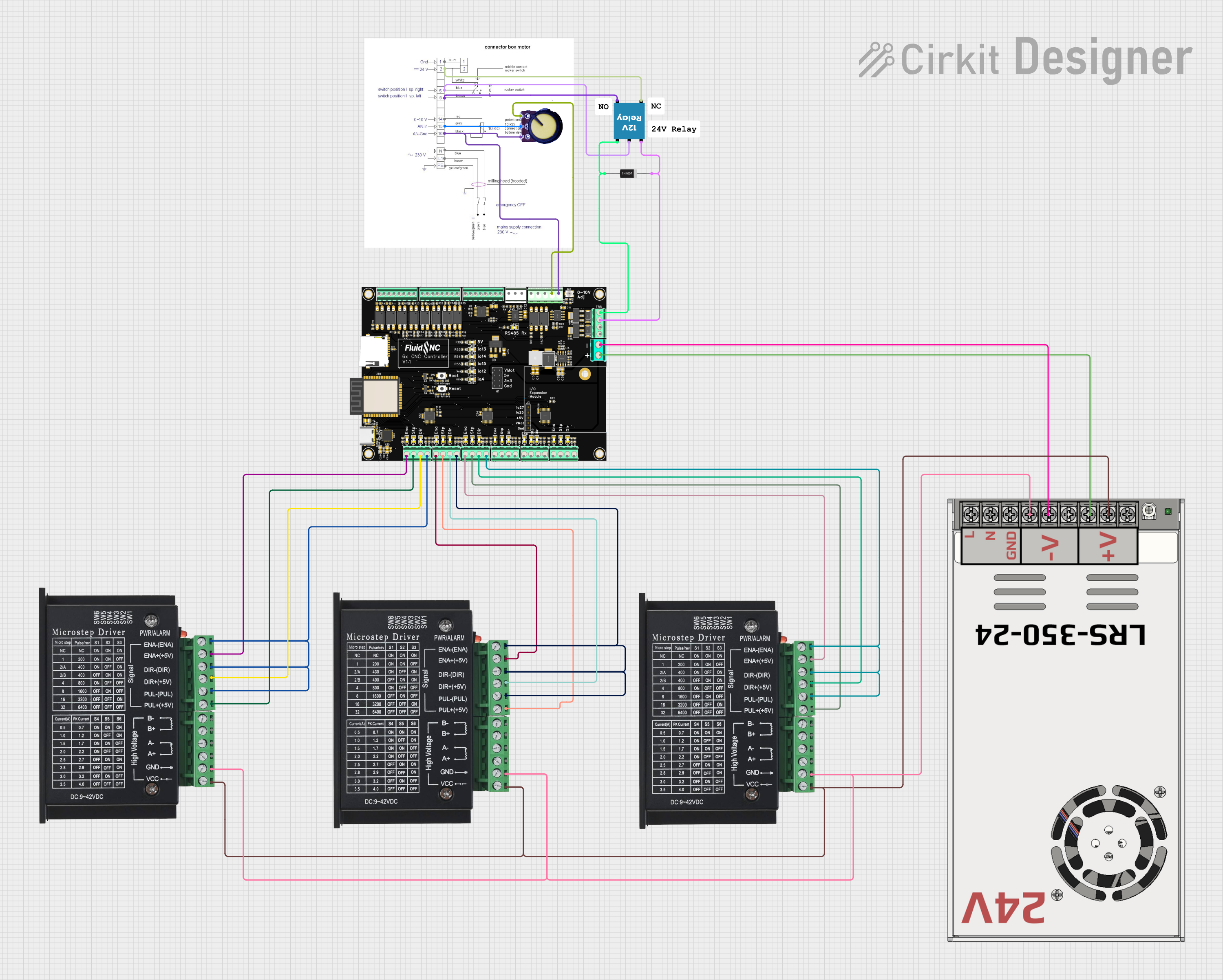

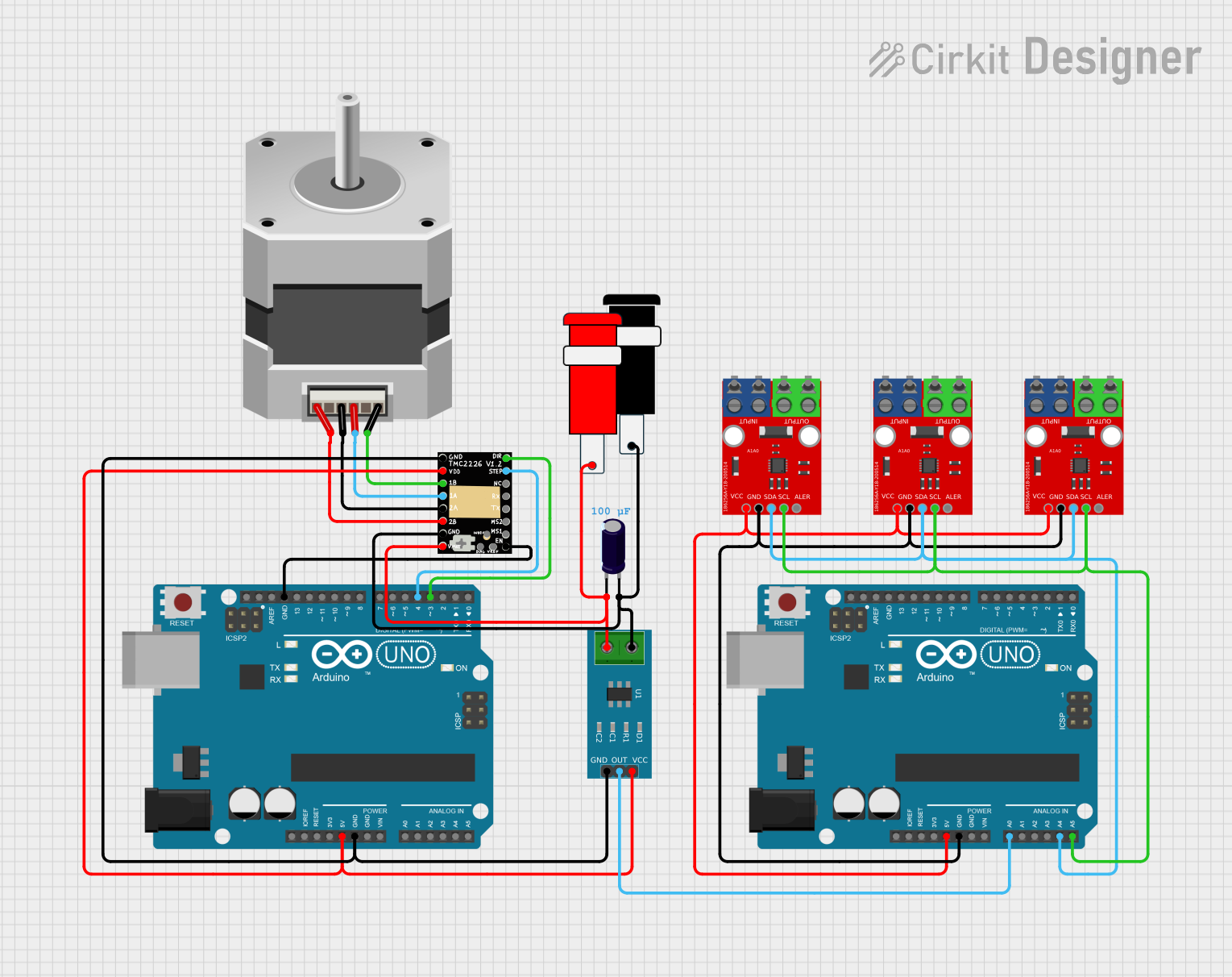

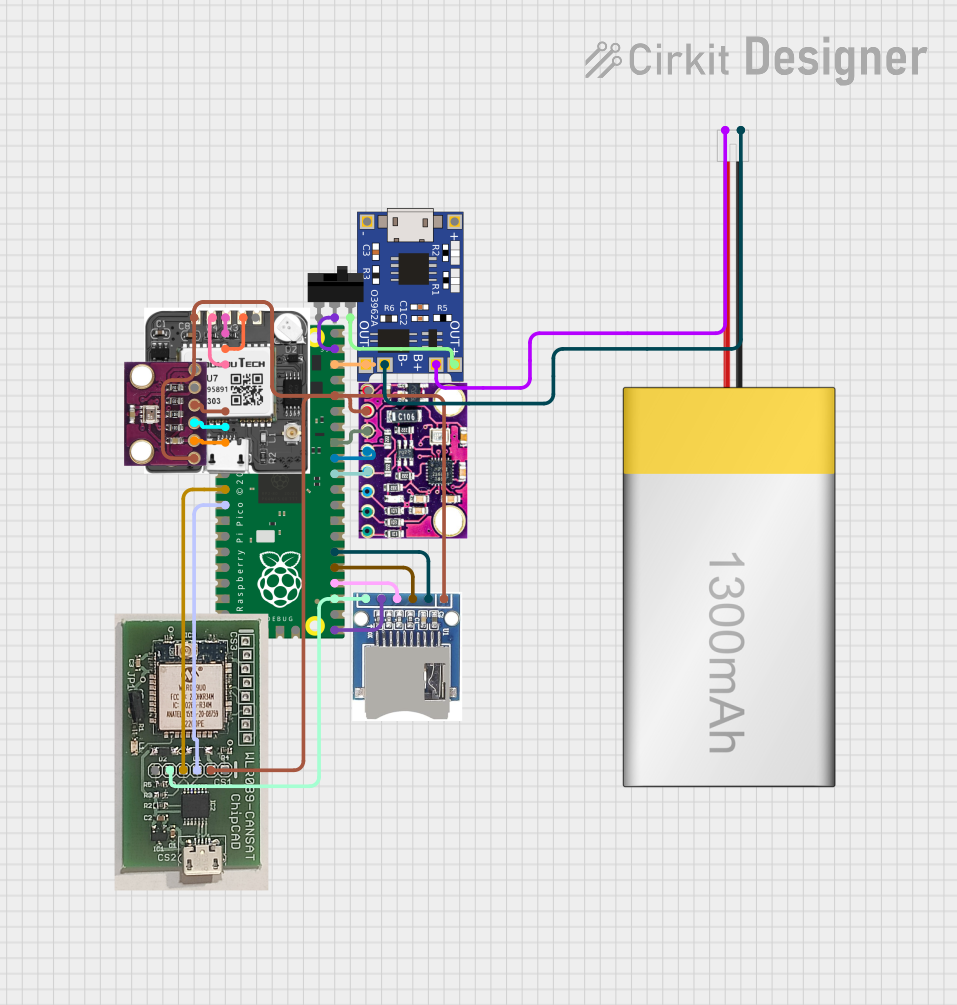

Explore Projects Built with TMC 2209

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with TMC 2209

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- 3D printers for smooth and quiet axis movement

- CNC machines for precise motion control

- Robotics and automation systems

- Laser engravers and plotters

- Any application requiring silent and efficient stepper motor operation

Technical Specifications

The TMC 2209 offers a range of features and specifications that make it suitable for demanding applications. Below are the key technical details:

Key Specifications

| Parameter | Value |

|---|---|

| Operating Voltage Range | 4.75V to 29V |

| Maximum Motor Current | 2.0A RMS (2.8A peak) |

| Microstepping Resolution | Up to 256 microsteps per step |

| Communication Interface | UART |

| Logic Voltage | 3.3V or 5V compatible |

| Features | StealthChop2, SpreadCycle, |

| CoolStep, StallGuard4 |

Pin Configuration

The TMC 2209 is typically available in a 28-pin package. Below is the pinout and description:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | GND | Ground connection |

| 2 | VM | Motor power supply (4.75V to 29V) |

| 3 | VCC_IO | Logic voltage input (3.3V or 5V) |

| 4 | ENN | Enable pin (active low) |

| 5 | DIR | Direction control input |

| 6 | STEP | Step pulse input |

| 7 | UART | UART communication pin for configuration and diagnostics |

| 8 | MS1 | Microstep resolution selection pin 1 |

| 9 | MS2 | Microstep resolution selection pin 2 |

| 10 | DIAG | Diagnostic output (e.g., for StallGuard4) |

| 11 | INDEX | Step position indicator |

| 12 | NC | Not connected |

| 13-28 | Motor Outputs | Connections for the stepper motor coils (A1, A2, B1, B2) |

Usage Instructions

The TMC 2209 can be used in a variety of circuits to drive stepper motors. Below are the steps and best practices for using this component effectively:

Basic Circuit Setup

- Power Supply: Connect the motor power supply (VM) to a voltage source within the range of 4.75V to 29V. Ensure the power supply can handle the current requirements of your stepper motor.

- Logic Voltage: Connect the VCC_IO pin to the logic voltage of your microcontroller (3.3V or 5V).

- Motor Connections: Connect the stepper motor coils to the motor output pins (A1, A2, B1, B2).

- Control Pins: Connect the STEP and DIR pins to your microcontroller for step and direction control.

- UART Communication: If advanced features like sensorless homing or dynamic current adjustment are required, connect the UART pin to your microcontroller's UART interface.

Arduino UNO Example Code

Below is an example of how to control the TMC 2209 using an Arduino UNO:

#include <TMCStepper.h>

// Define pins for TMC2209

#define EN_PIN 8 // Enable pin

#define DIR_PIN 5 // Direction pin

#define STEP_PIN 2 // Step pin

#define SERIAL_PORT Serial // UART communication port

#define DRIVER_ADDRESS 0b00 // TMC2209 driver address (set via jumpers)

// Initialize TMC2209 driver

TMC2209Stepper driver(&SERIAL_PORT, DRIVER_ADDRESS);

void setup() {

pinMode(EN_PIN, OUTPUT);

digitalWrite(EN_PIN, LOW); // Enable the driver (active low)

SERIAL_PORT.begin(115200); // Initialize UART communication

driver.begin(); // Initialize the driver

driver.toff(5); // Enable driver with a toff value

driver.rms_current(800); // Set motor current to 800mA

driver.microsteps(16); // Set microstepping to 1/16

}

void loop() {

digitalWrite(DIR_PIN, HIGH); // Set direction

for (int i = 0; i < 200; i++) {

digitalWrite(STEP_PIN, HIGH); // Generate step pulse

delayMicroseconds(500); // Delay for step timing

digitalWrite(STEP_PIN, LOW);

delayMicroseconds(500);

}

delay(1000); // Wait before reversing direction

digitalWrite(DIR_PIN, LOW); // Reverse direction

for (int i = 0; i < 200; i++) {

digitalWrite(STEP_PIN, HIGH);

delayMicroseconds(500);

digitalWrite(STEP_PIN, LOW);

delayMicroseconds(500);

}

delay(1000);

}

Best Practices

- Use decoupling capacitors near the VM and VCC_IO pins to reduce noise and ensure stable operation.

- Ensure proper heat dissipation by using a heatsink or active cooling if the driver operates at high currents.

- Configure the UART interface for advanced features like StallGuard4 and CoolStep for optimal performance.

- Avoid exceeding the maximum current and voltage ratings to prevent damage to the driver.

Troubleshooting and FAQs

Common Issues

Motor Not Moving:

- Check the power supply connections and ensure the voltage is within the specified range.

- Verify the STEP and DIR signals from the microcontroller.

- Ensure the ENN pin is set to LOW to enable the driver.

Overheating:

- Ensure proper cooling with a heatsink or fan.

- Reduce the motor current using the

rms_current()function in the code.

No UART Communication:

- Verify the UART connections and ensure the correct baud rate is set.

- Check the driver address and ensure it matches the configuration in the code.

Motor Vibrations or Noise:

- Enable StealthChop2 mode for silent operation.

- Check the microstepping configuration and adjust as needed.

FAQs

Q: Can the TMC 2209 be used without UART?

A: Yes, the TMC 2209 can operate in standalone mode using the STEP and DIR pins. However, UART is required for advanced features like sensorless homing and dynamic current adjustment.

Q: How do I enable sensorless homing?

A: Sensorless homing requires configuring the StallGuard4 feature via UART. Refer to the TMC 2209 datasheet for detailed instructions.

Q: What is the maximum microstepping resolution?

A: The TMC 2209 supports up to 256 microsteps per step, providing extremely smooth motor operation.

Q: Can I use the TMC 2209 with a 12V or 24V power supply?

A: Yes, the TMC 2209 supports a wide voltage range of 4.75V to 29V, making it compatible with 12V and 24V systems.