How to Use mcp2551: Examples, Pinouts, and Specs

Design with mcp2551 in Cirkit Designer

Design with mcp2551 in Cirkit DesignerIntroduction

The MCP2551 is a high-speed CAN (Controller Area Network) transceiver manufactured by Analog. It serves as the interface between a CAN protocol controller and the physical CAN bus, enabling robust communication in automotive and industrial environments. The MCP2551 is designed to support data rates of up to 1 Mbps, making it suitable for high-speed applications. Its low power consumption, high noise immunity, and fault-tolerant design make it a reliable choice for demanding applications.

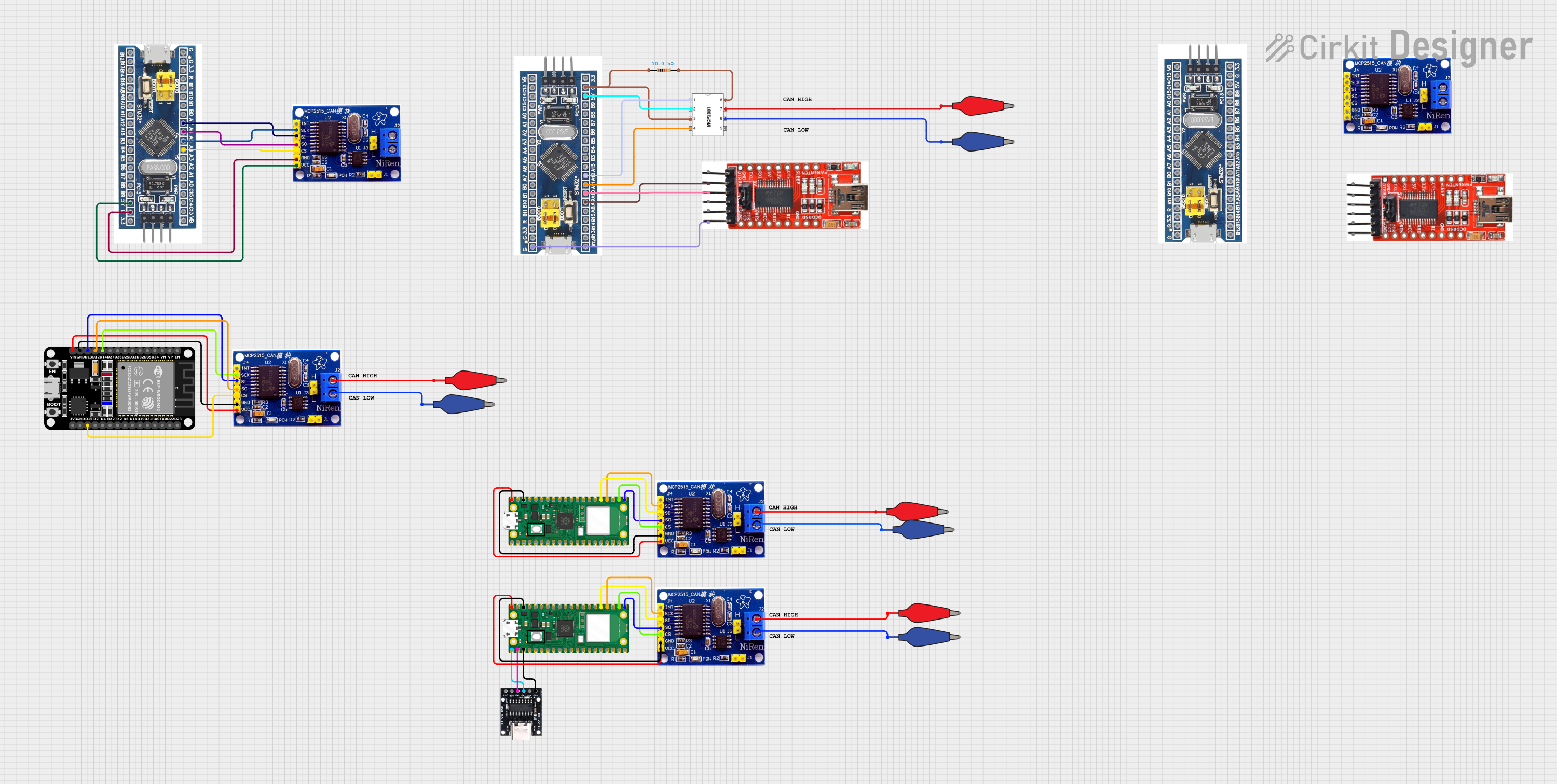

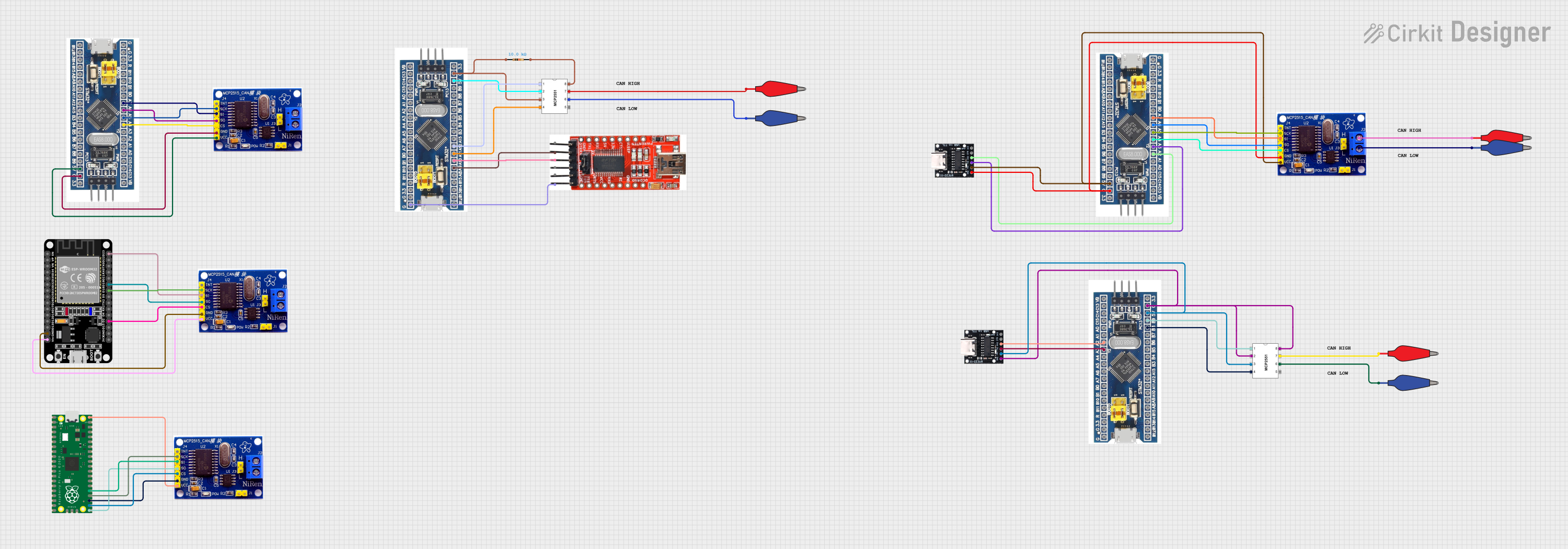

Explore Projects Built with mcp2551

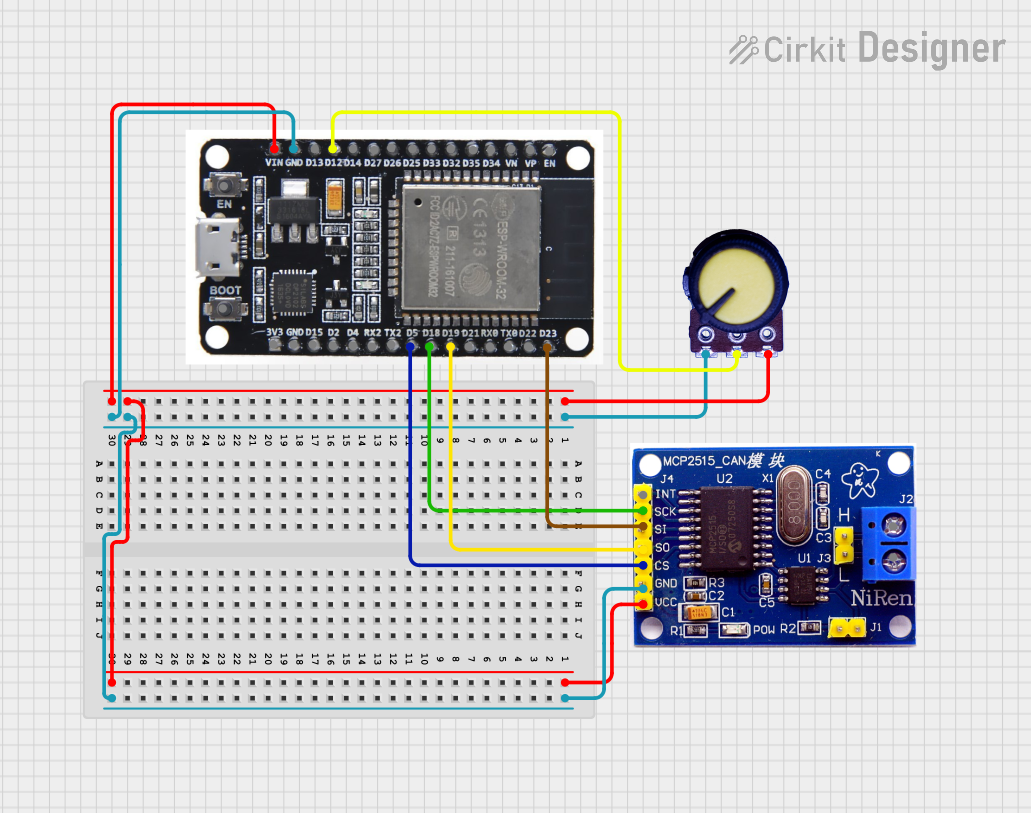

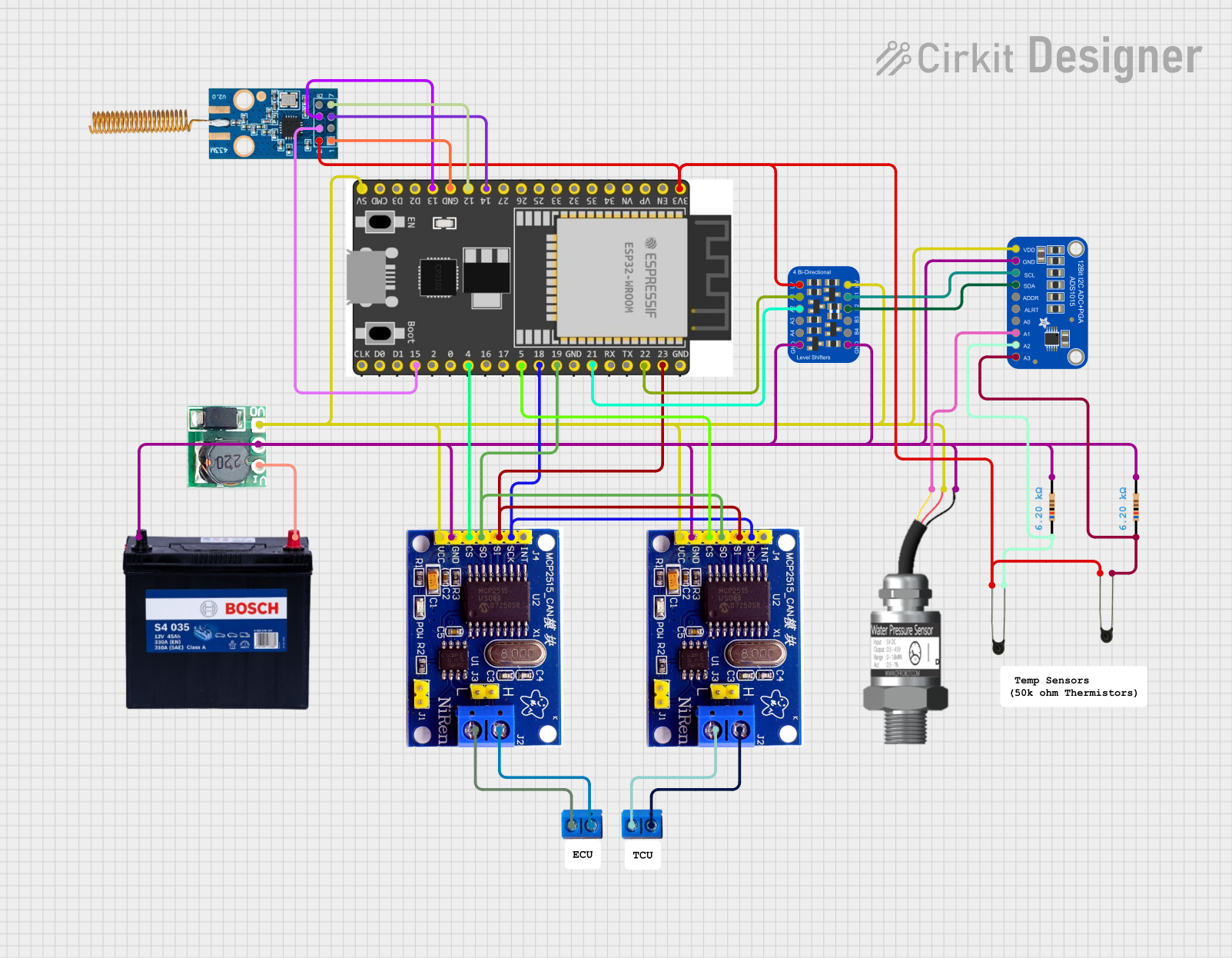

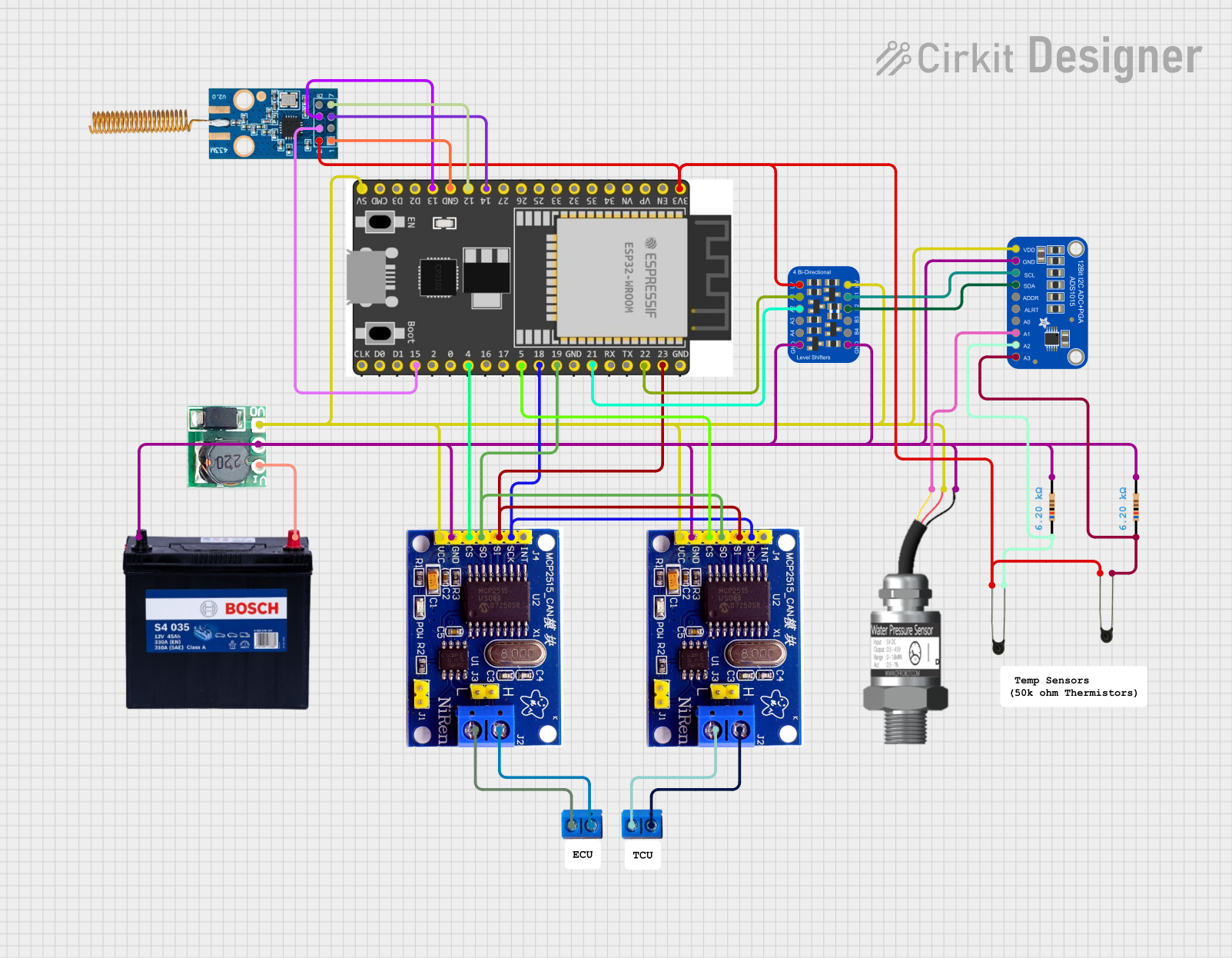

Open Project in Cirkit Designer

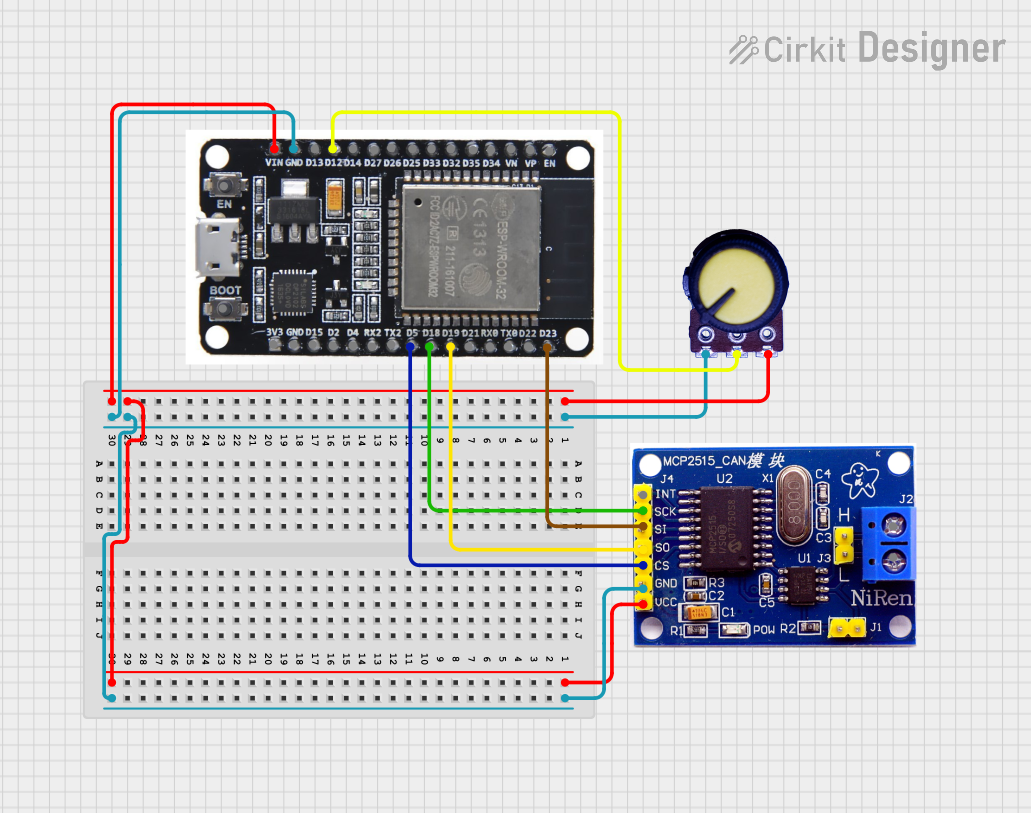

Open Project in Cirkit Designer

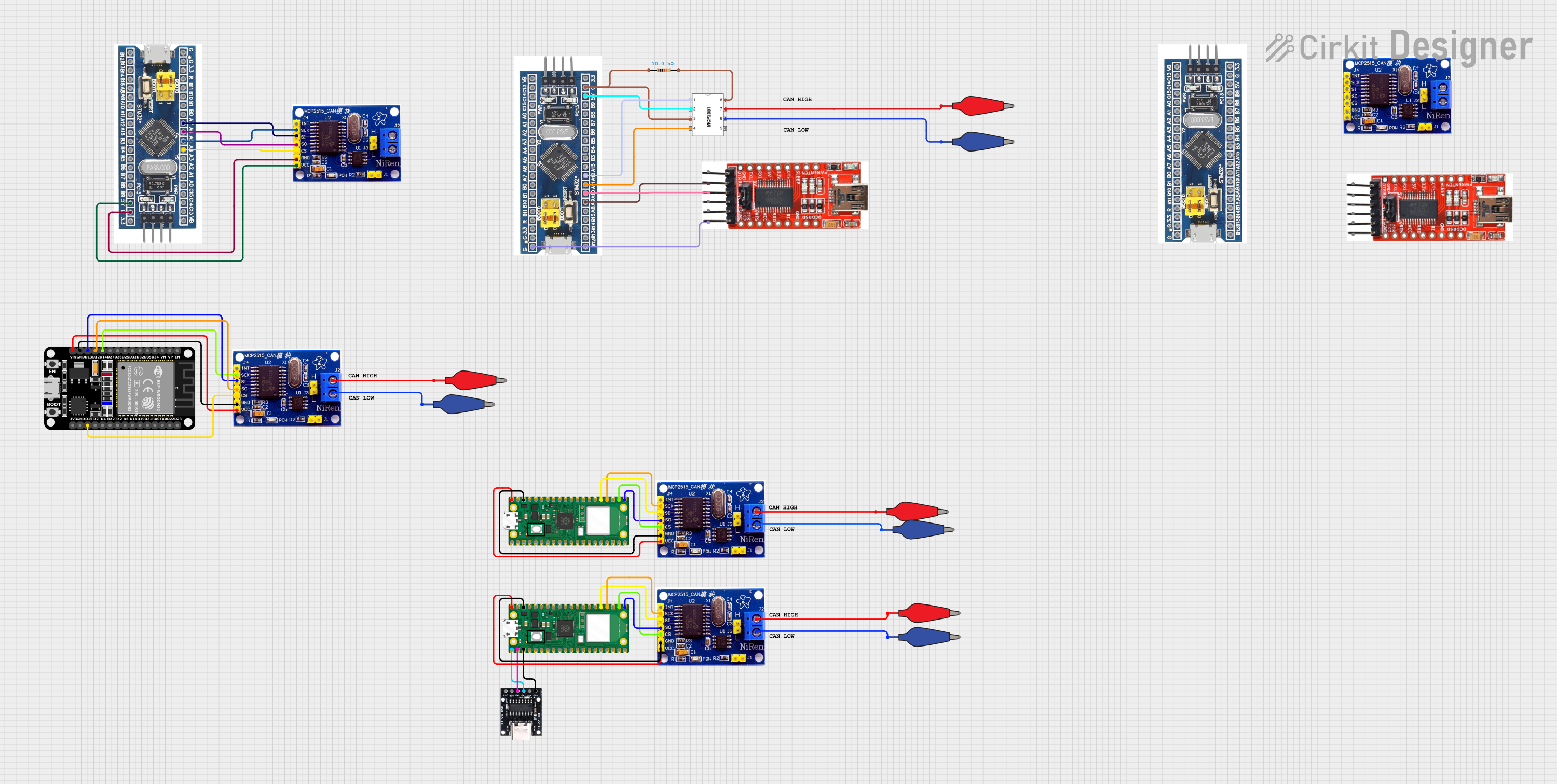

Open Project in Cirkit Designer

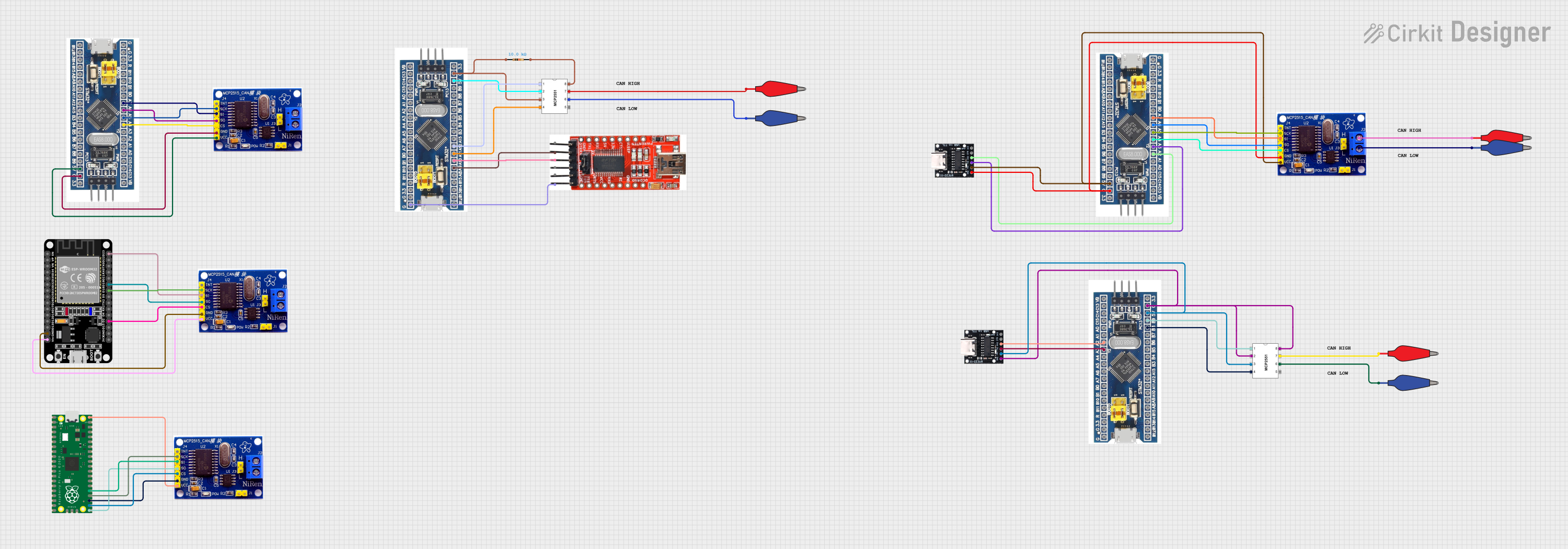

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with mcp2551

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Automotive systems (e.g., engine control units, body control modules)

- Industrial automation and control

- Building automation systems

- Medical equipment

- Robotics and embedded systems requiring CAN communication

Technical Specifications

Key Technical Details

- Supply Voltage (VDD): 4.5V to 5.5V

- Data Rate: Up to 1 Mbps

- Bus Voltage Range: -7V to +12V

- Standby Current: 1 µA (typical)

- Operating Temperature Range: -40°C to +125°C

- ESD Protection: ±4 kV (Human Body Model)

- Propagation Delay (High-Speed Mode): 120 ns (typical)

- Package Options: PDIP, SOIC, and others

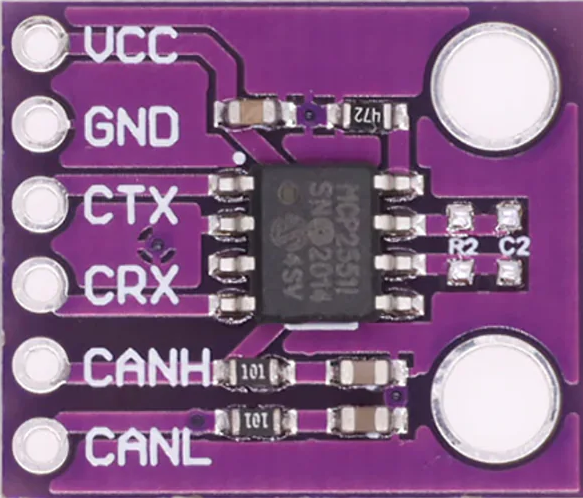

Pin Configuration and Descriptions

The MCP2551 is typically available in an 8-pin package. Below is the pinout and description:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | TXD | Transmit Data Input: Connected to the CAN controller's transmit output. |

| 2 | VSS | Ground: Connect to system ground. |

| 3 | VDD | Supply Voltage: Connect to a 5V power supply. |

| 4 | RXD | Receive Data Output: Outputs data received from the CAN bus. |

| 5 | VREF | Reference Voltage Output: Provides a reference voltage (typically 2.5V). |

| 6 | CANL | CAN Low: Connect to the CAN bus low line. |

| 7 | CANH | CAN High: Connect to the CAN bus high line. |

| 8 | RS | Slope Control Input: Controls the slew rate of the CAN signals. |

Usage Instructions

How to Use the MCP2551 in a Circuit

Power Supply:

- Connect the VDD pin to a regulated 5V power supply.

- Connect the VSS pin to the system ground.

CAN Bus Connection:

- Connect the CANH and CANL pins to the CAN bus lines.

- Use a 120-ohm termination resistor between CANH and CANL at each end of the bus.

Controller Interface:

- Connect the TXD pin to the CAN controller's transmit output.

- Connect the RXD pin to the CAN controller's receive input.

Slope Control:

- Use the RS pin to control the slew rate of the CAN signals. For high-speed operation, connect RS to ground. For reduced EMI, connect RS to a resistor to ground.

Reference Voltage:

- The VREF pin provides a reference voltage (typically 2.5V) that can be used for external circuits if needed.

Important Considerations and Best Practices

- Ensure proper decoupling by placing a 0.1 µF ceramic capacitor close to the VDD pin.

- Use twisted-pair cables for the CANH and CANL lines to minimize noise and improve signal integrity.

- Avoid long stubs on the CAN bus to reduce signal reflections.

- Ensure the total bus length and node count comply with the CAN standard for the desired data rate.

Example: Connecting MCP2551 to an Arduino UNO

Below is an example of how to connect the MCP2551 to an Arduino UNO for CAN communication:

Circuit Connections

- MCP2551 TXD → Arduino Digital Pin 10 (CAN Controller TX)

- MCP2551 RXD → Arduino Digital Pin 11 (CAN Controller RX)

- MCP2551 CANH → CAN Bus High Line

- MCP2551 CANL → CAN Bus Low Line

- MCP2551 VDD → 5V

- MCP2551 VSS → GND

- MCP2551 RS → GND (for high-speed mode)

Arduino Code Example

#include <SPI.h>

#include <mcp2515.h> // Include the MCP2515 CAN controller library

struct can_frame canMsg; // Define a CAN message structure

MCP2515 mcp2515(10); // Initialize MCP2515 with CS pin 10

void setup() {

Serial.begin(9600);

mcp2515.reset(); // Reset the MCP2515

mcp2515.setBitrate(CAN_500KBPS); // Set CAN bus speed to 500 kbps

mcp2515.setNormalMode(); // Set MCP2515 to normal mode

Serial.println("MCP2551 CAN Transceiver Initialized");

}

void loop() {

// Example: Sending a CAN message

canMsg.can_id = 0x100; // Set CAN ID

canMsg.can_dlc = 2; // Set data length (2 bytes)

canMsg.data[0] = 0x55; // First byte of data

canMsg.data[1] = 0xAA; // Second byte of data

if (mcp2515.sendMessage(&canMsg) == MCP2515::ERROR_OK) {

Serial.println("Message Sent Successfully");

} else {

Serial.println("Error Sending Message");

}

delay(1000); // Wait 1 second before sending the next message

}

Troubleshooting and FAQs

Common Issues and Solutions

No Communication on the CAN Bus:

- Verify that the CANH and CANL lines are properly connected and terminated with 120-ohm resistors at both ends of the bus.

- Ensure the MCP2551 is powered correctly (5V on VDD and GND on VSS).

- Check the TXD and RXD connections between the MCP2551 and the CAN controller.

High Error Rate or Noise on the Bus:

- Use twisted-pair cables for the CANH and CANL lines to reduce noise.

- Ensure the RS pin is configured correctly for the desired slew rate.

MCP2551 Overheating:

- Check for short circuits on the CANH and CANL lines.

- Ensure the bus voltage does not exceed the specified range (-7V to +12V).

FAQs

Q: Can the MCP2551 operate at 3.3V?

A: No, the MCP2551 requires a supply voltage of 4.5V to 5.5V. For 3.3V systems, consider using a level shifter or a different transceiver designed for 3.3V operation.

Q: What is the maximum number of nodes supported on the CAN bus?

A: The maximum number of nodes depends on the bus length, data rate, and transceiver characteristics. Typically, up to 120 nodes can be supported.

Q: How do I reduce EMI in my design?

A: Use the RS pin to control the slew rate of the CAN signals. Adding a resistor between RS and ground can reduce EMI by slowing down the signal transitions.