How to Use CT PZEM004T: Examples, Pinouts, and Specs

Design with CT PZEM004T in Cirkit Designer

Design with CT PZEM004T in Cirkit DesignerIntroduction

The CT PZEM004T is a multifunctional energy meter designed to measure key electrical parameters such as voltage, current, power, energy, and frequency. It is specifically built to work with current transformers (CTs), making it ideal for monitoring AC electrical systems. This component provides real-time data, enabling users to analyze energy consumption and improve energy efficiency.

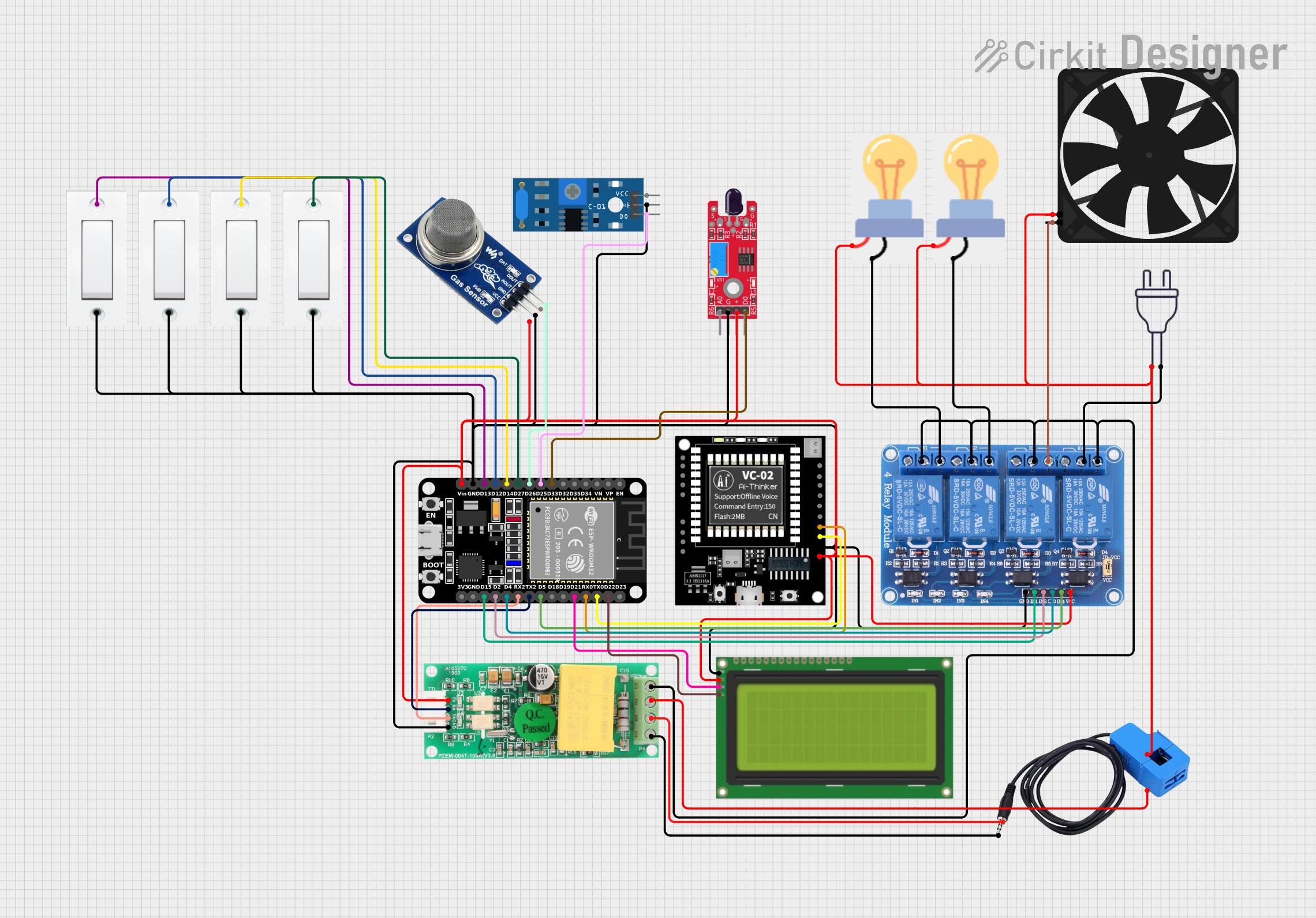

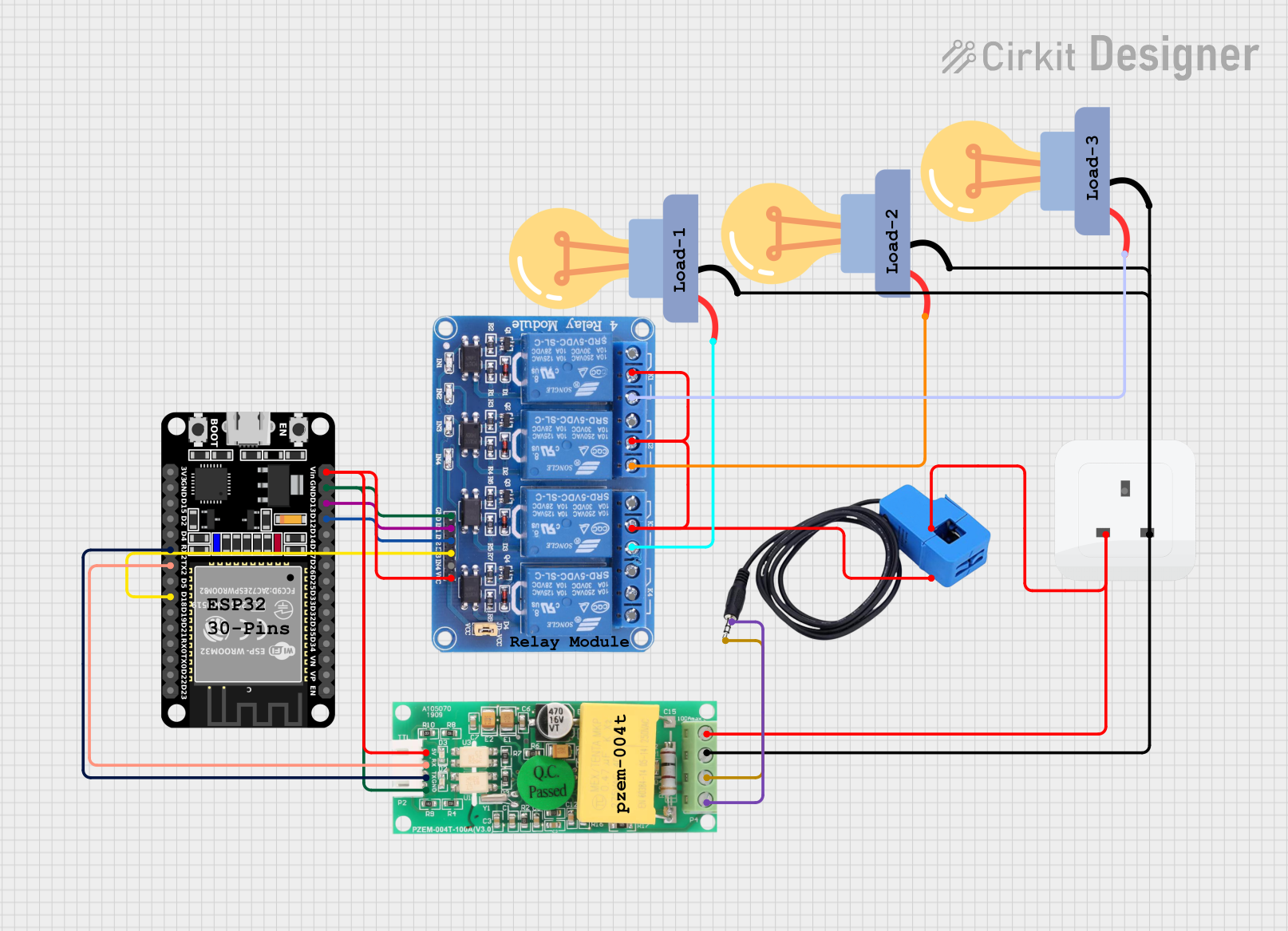

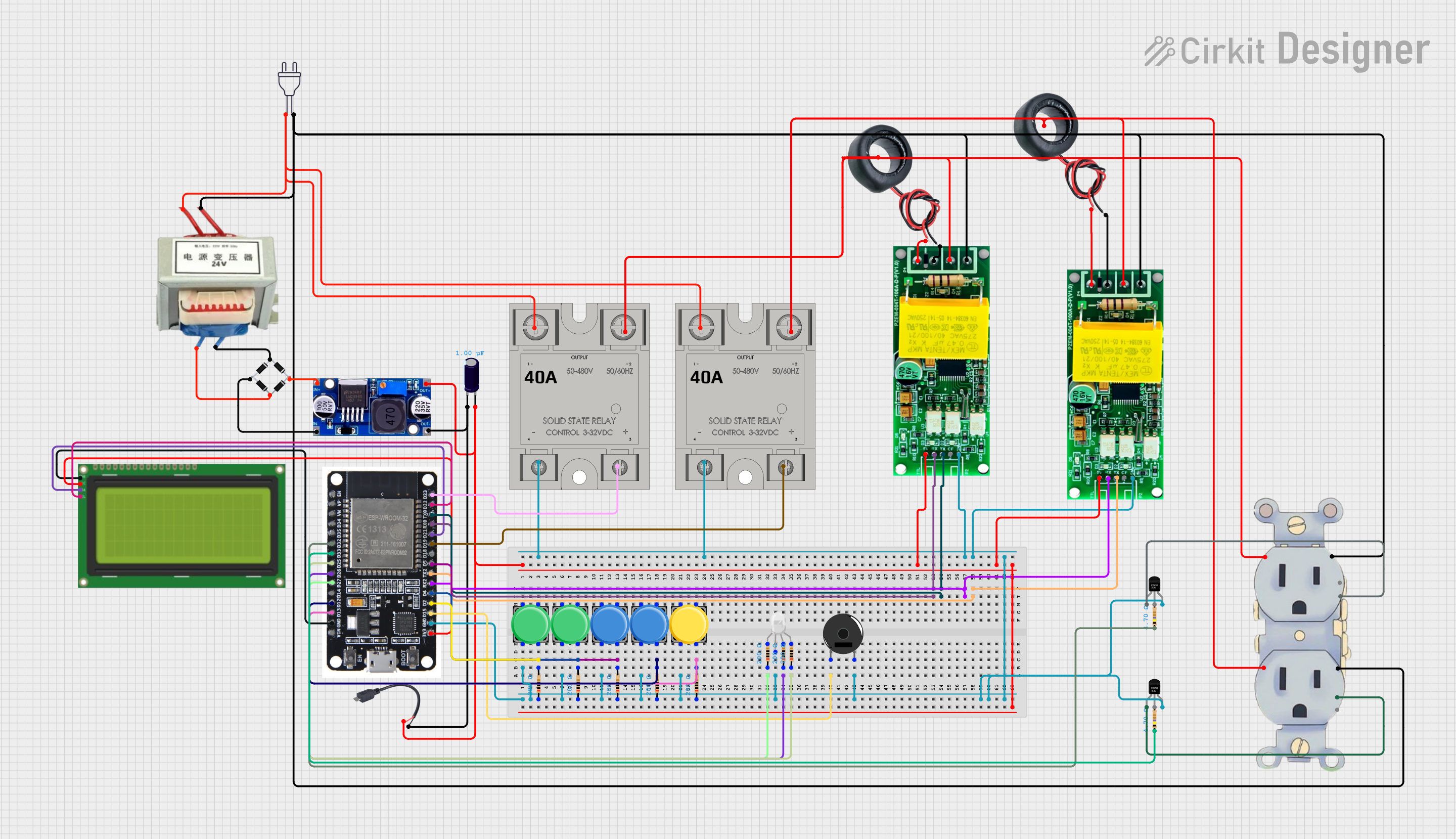

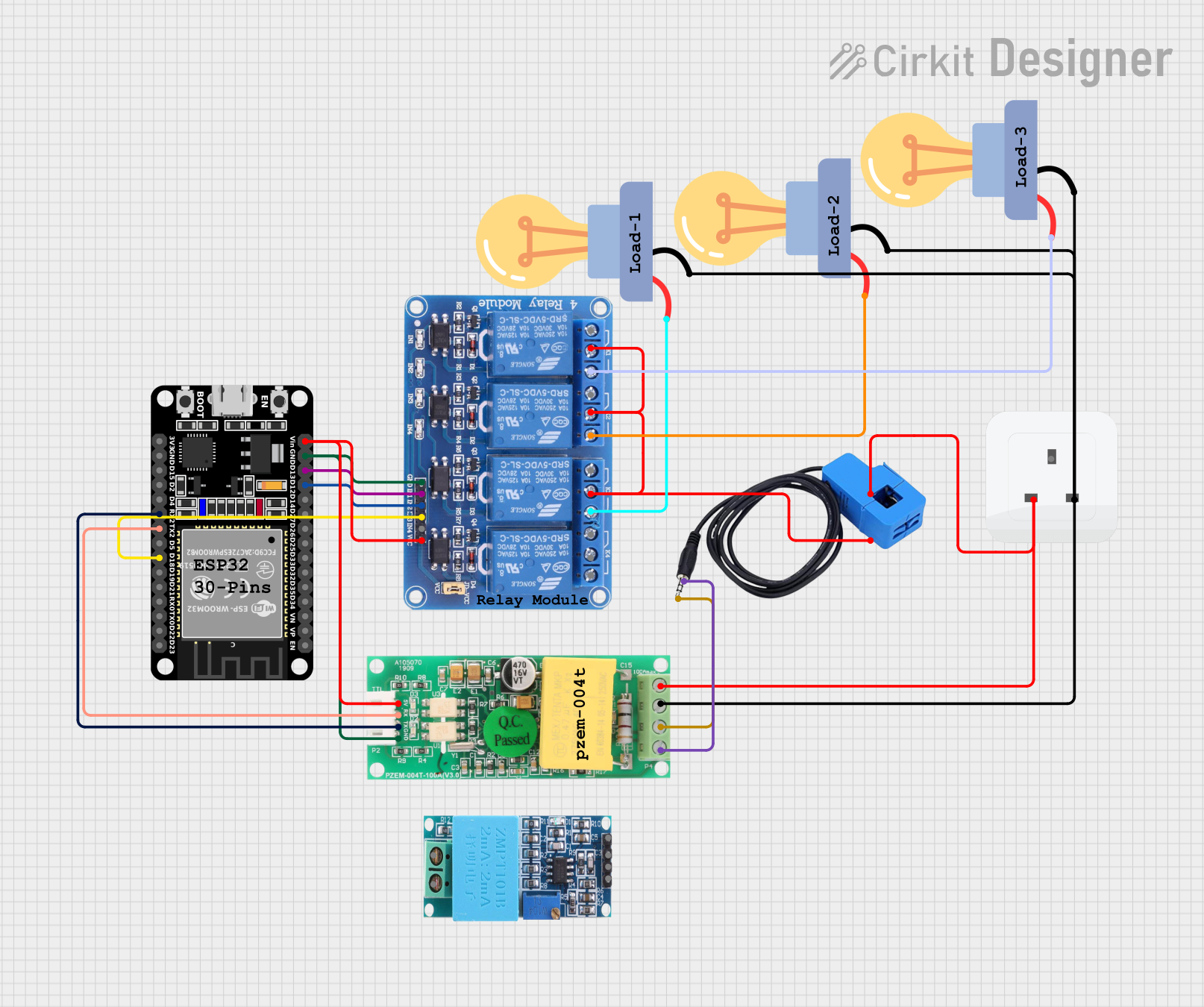

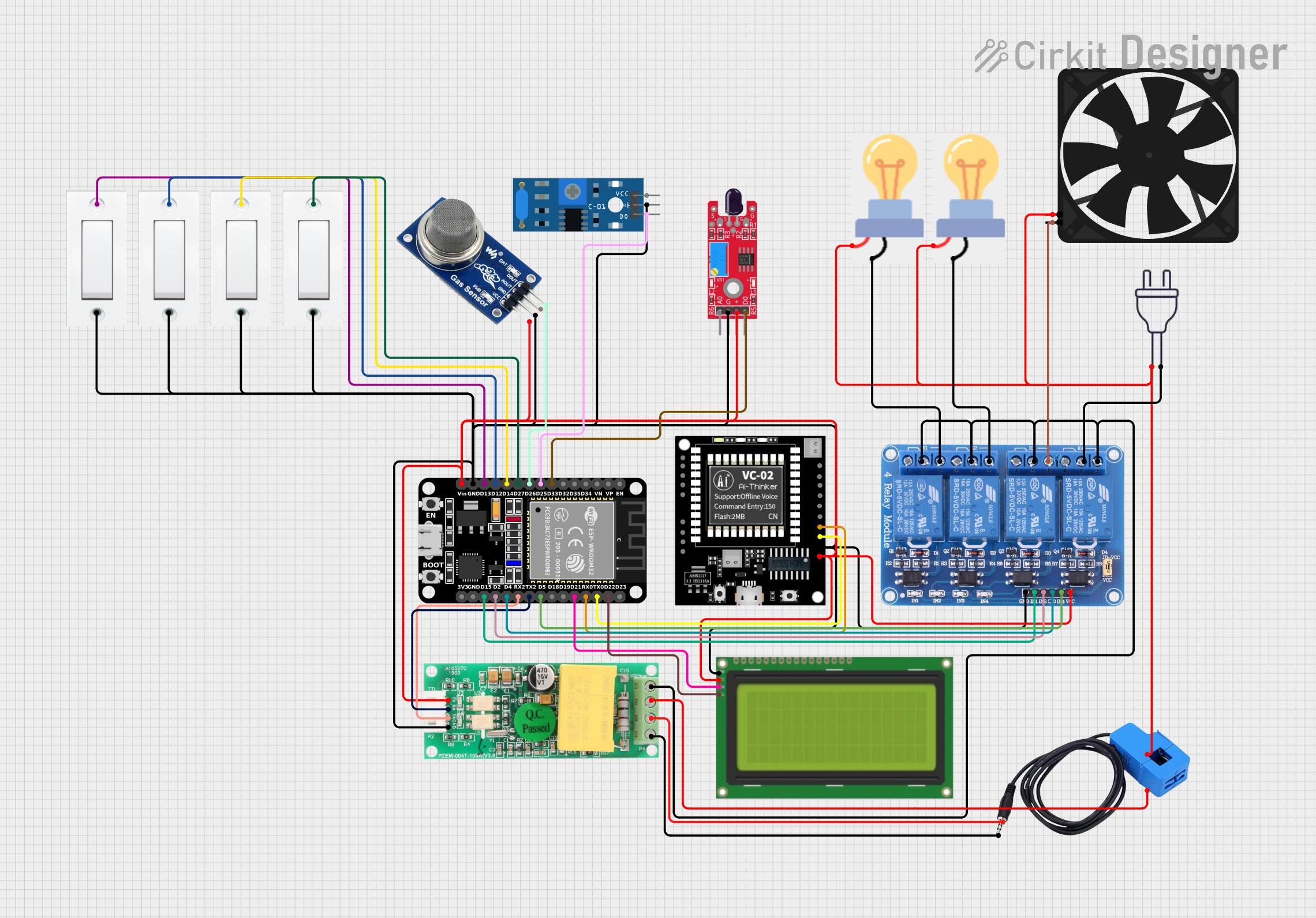

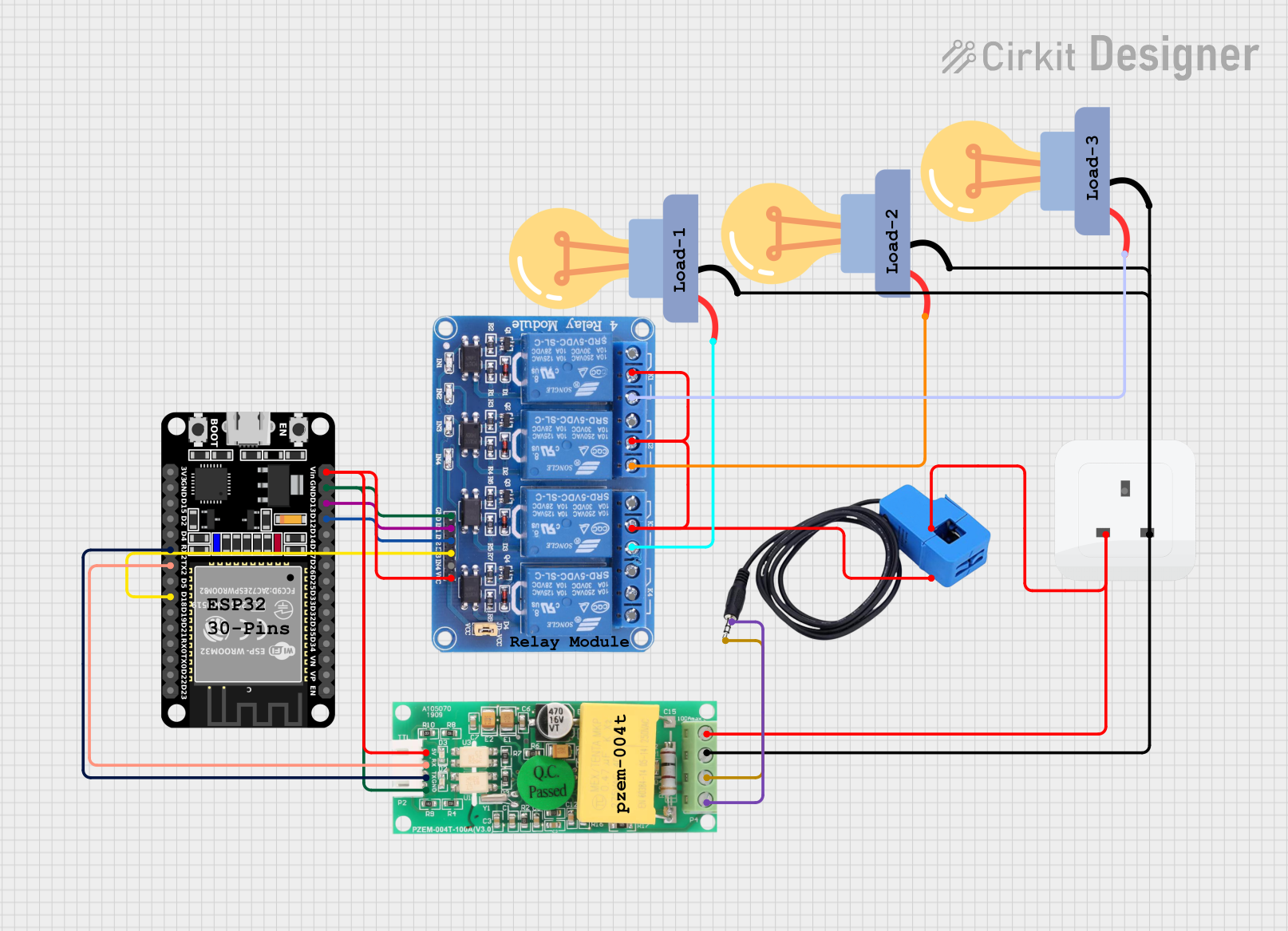

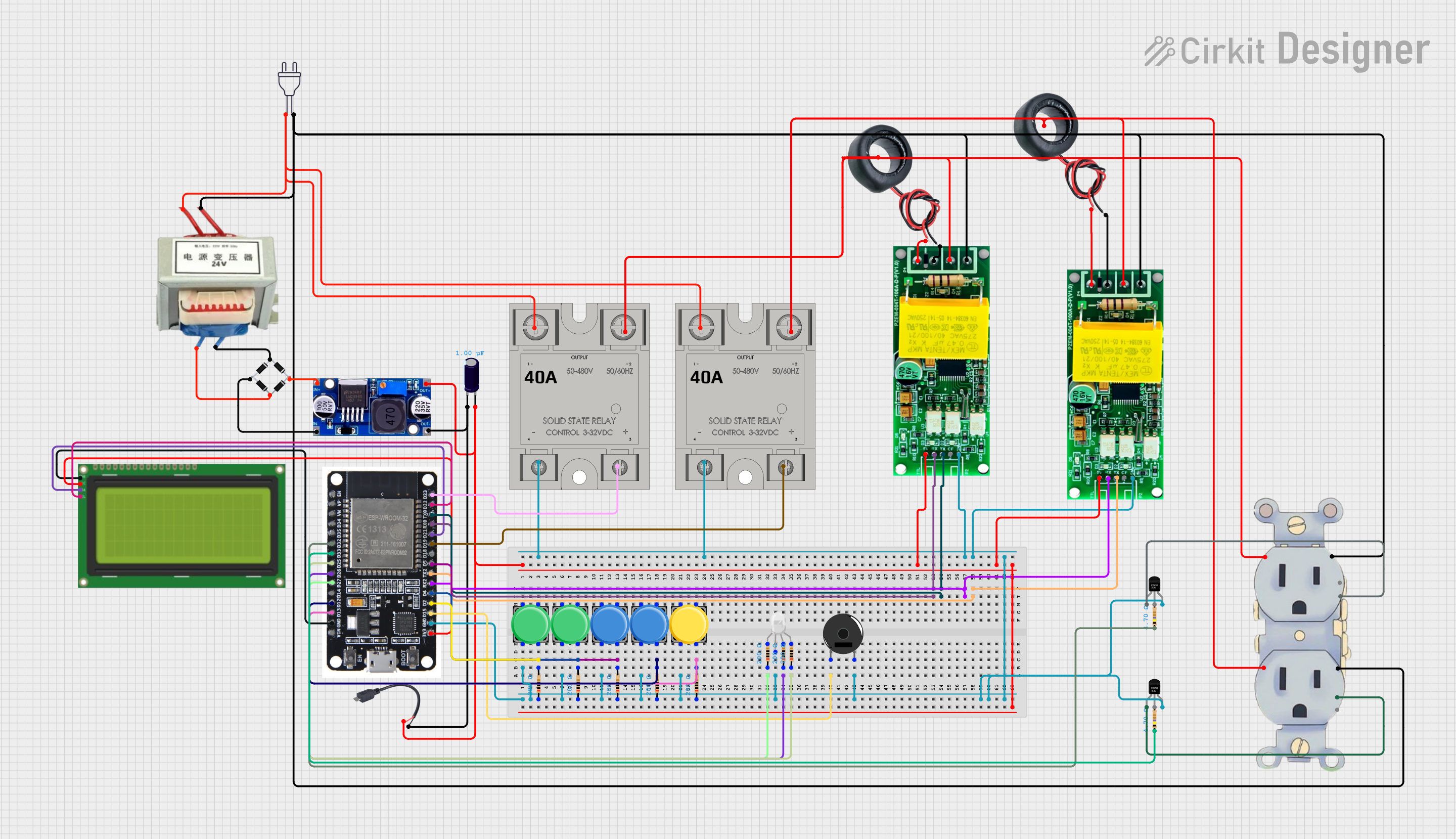

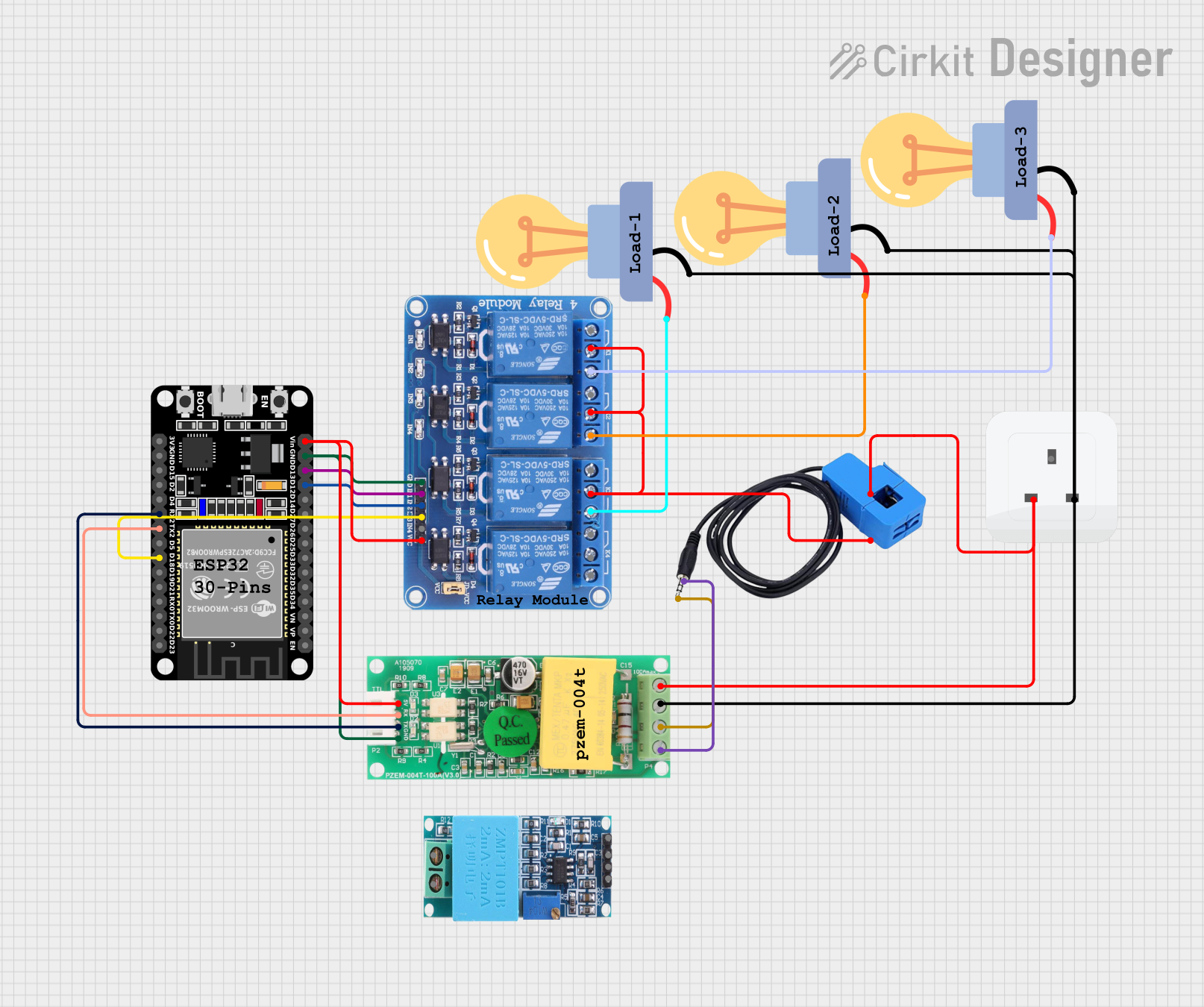

Explore Projects Built with CT PZEM004T

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with CT PZEM004T

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Home and industrial energy monitoring

- Smart energy management systems

- Renewable energy systems (e.g., solar inverters)

- Load analysis and optimization

- Electrical fault detection and diagnostics

Technical Specifications

The CT PZEM004T is a versatile and reliable energy meter with the following key specifications:

| Parameter | Specification |

|---|---|

| Voltage Range | 80V - 260V AC |

| Current Range | 0A - 100A (with external CT) |

| Power Range | 0W - 22kW |

| Energy Range | 0kWh - 9999kWh |

| Frequency Range | 45Hz - 65Hz |

| Communication Protocol | Modbus RTU (RS485) |

| Baud Rate | 9600 bps |

| Accuracy | ±0.5% |

| Operating Temperature | -10°C to 60°C |

| Power Supply | Self-powered (from measured AC voltage) |

Pin Configuration and Descriptions

The CT PZEM004T module has the following pinout:

| Pin Name | Description |

|---|---|

| V+ | AC voltage input (live wire) |

| V- | AC voltage input (neutral wire) |

| A+ | Current transformer (CT) input (primary side) |

| A- | Current transformer (CT) input (secondary side) |

| 5V | Optional 5V DC power input (for external power supply, if required) |

| GND | Ground connection for optional external power supply |

| TX | RS485 communication output (transmit) |

| RX | RS485 communication input (receive) |

Usage Instructions

How to Use the CT PZEM004T in a Circuit

Connect the Voltage Input:

- Connect the

V+pin to the live wire of the AC system. - Connect the

V-pin to the neutral wire of the AC system.

- Connect the

Connect the Current Transformer (CT):

- Attach the CT to the AC line you want to monitor.

- Connect the CT's output wires to the

A+andA-pins of the PZEM004T.

Power the Module:

- The module is self-powered from the AC voltage input. However, if needed, you can provide an external 5V DC power supply to the

5VandGNDpins.

- The module is self-powered from the AC voltage input. However, if needed, you can provide an external 5V DC power supply to the

Establish Communication:

- Use the

TXandRXpins to connect the module to a microcontroller or RS485-to-USB adapter for data communication. - Ensure the baud rate is set to 9600 bps for proper communication.

- Use the

Read Data:

- Use the Modbus RTU protocol to query the module for real-time measurements of voltage, current, power, energy, and frequency.

Important Considerations and Best Practices

- Ensure the CT is properly rated for the current range of your application (e.g., 100A CT for loads up to 100A).

- Avoid exposing the module to extreme temperatures or humidity to maintain accuracy and reliability.

- Use proper insulation and safety precautions when working with high-voltage AC systems.

- If connecting to an Arduino or other microcontroller, use an RS485-to-TTL converter for communication.

Example: Connecting to an Arduino UNO

Below is an example of how to interface the CT PZEM004T with an Arduino UNO using an RS485-to-TTL converter:

Wiring Diagram

- Connect the

TXpin of the PZEM004T to theDIpin of the RS485 module. - Connect the

RXpin of the PZEM004T to theROpin of the RS485 module. - Connect the

GNDpin of the PZEM004T to theGNDpin of the RS485 module. - Connect the

VCCpin of the RS485 module to the 5V pin of the Arduino. - Connect the

GNDpin of the RS485 module to the GND pin of the Arduino.

Arduino Code Example

#include <ModbusMaster.h>

// Create an instance of the ModbusMaster library

ModbusMaster node;

// Define the RS485 enable pin

#define MAX485_DE 2

#define MAX485_RE 3

void preTransmission() {

digitalWrite(MAX485_DE, HIGH); // Enable RS485 driver

digitalWrite(MAX485_RE, HIGH);

}

void postTransmission() {

digitalWrite(MAX485_DE, LOW); // Disable RS485 driver

digitalWrite(MAX485_RE, LOW);

}

void setup() {

// Initialize serial communication

Serial.begin(9600);

Serial.println("PZEM004T Energy Meter Test");

// Initialize Modbus communication

node.begin(1, Serial); // Set Modbus ID to 1

node.preTransmission(preTransmission);

node.postTransmission(postTransmission);

// Configure RS485 enable pins

pinMode(MAX485_DE, OUTPUT);

pinMode(MAX485_RE, OUTPUT);

digitalWrite(MAX485_DE, LOW);

digitalWrite(MAX485_RE, LOW);

}

void loop() {

uint8_t result;

uint16_t data[6];

// Read voltage (register 0x0000)

result = node.readInputRegisters(0x0000, 1);

if (result == node.ku8MBSuccess) {

Serial.print("Voltage: ");

Serial.print(node.getResponseBuffer(0) / 10.0); // Convert to volts

Serial.println(" V");

}

delay(1000); // Wait 1 second before the next reading

}

Troubleshooting and FAQs

Common Issues and Solutions

No Data Output:

- Ensure the module is properly powered (check voltage input or external 5V supply).

- Verify the RS485 connections and ensure the baud rate is set to 9600 bps.

Incorrect Readings:

- Check that the CT is securely clamped around the AC line and connected to the correct pins.

- Ensure the CT is rated for the current range of your application.

Communication Errors:

- Verify the Modbus ID of the PZEM004T (default is 1).

- Check the wiring between the RS485 module and the microcontroller.

FAQs

Q: Can the PZEM004T measure DC voltage or current?

A: No, the PZEM004T is designed specifically for AC systems and cannot measure DC parameters.

Q: How do I reset the energy counter?

A: The energy counter can be reset using a Modbus command. Refer to the module's datasheet for the specific command.

Q: Can I use multiple PZEM004T modules in the same system?

A: Yes, you can use multiple modules by assigning unique Modbus IDs to each device.

Q: What is the maximum cable length for RS485 communication?

A: RS485 supports cable lengths up to 1200 meters, but ensure proper termination resistors are used for long distances.