How to Use MT3608 Step-Up: Examples, Pinouts, and Specs

Design with MT3608 Step-Up in Cirkit Designer

Design with MT3608 Step-Up in Cirkit DesignerIntroduction

The MT3608 is a high-efficiency DC-DC boost converter designed to step up a lower input voltage to a higher output voltage. It is capable of delivering up to 2A of output current, making it suitable for a wide range of applications. This component is widely used in battery-powered devices to increase voltage levels for powering components such as microcontrollers, sensors, and displays.

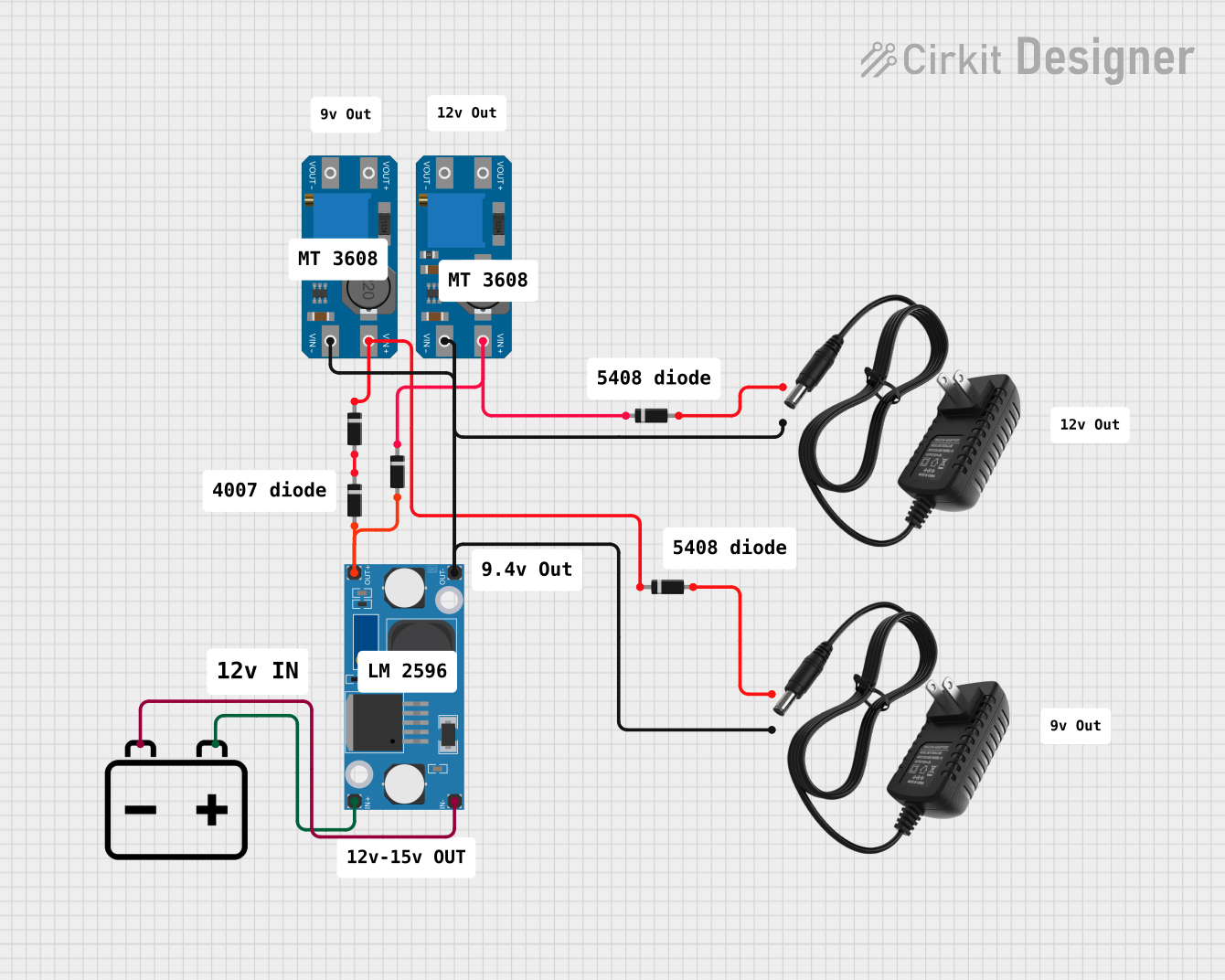

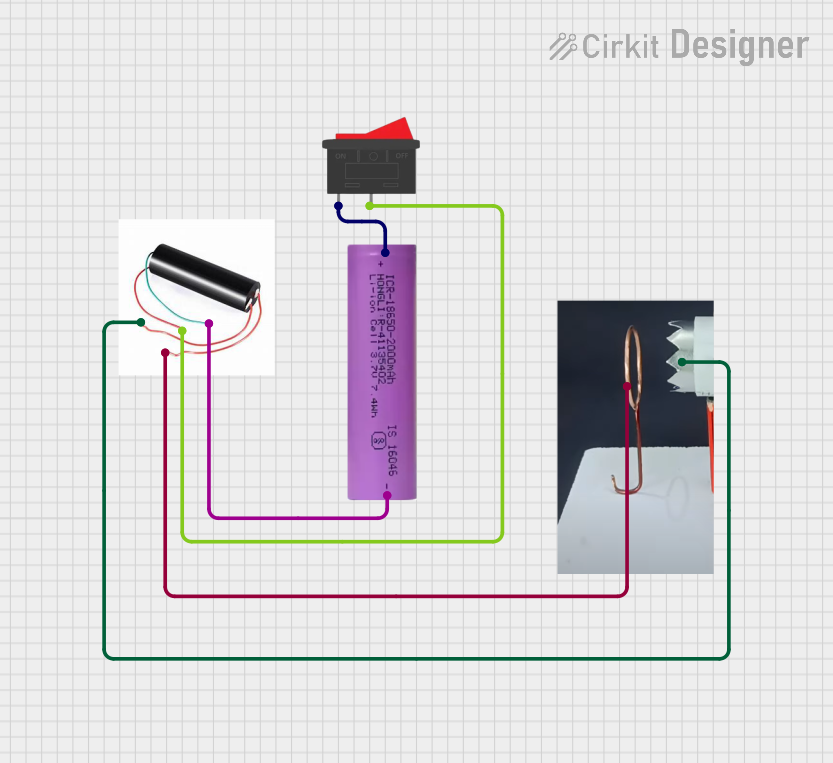

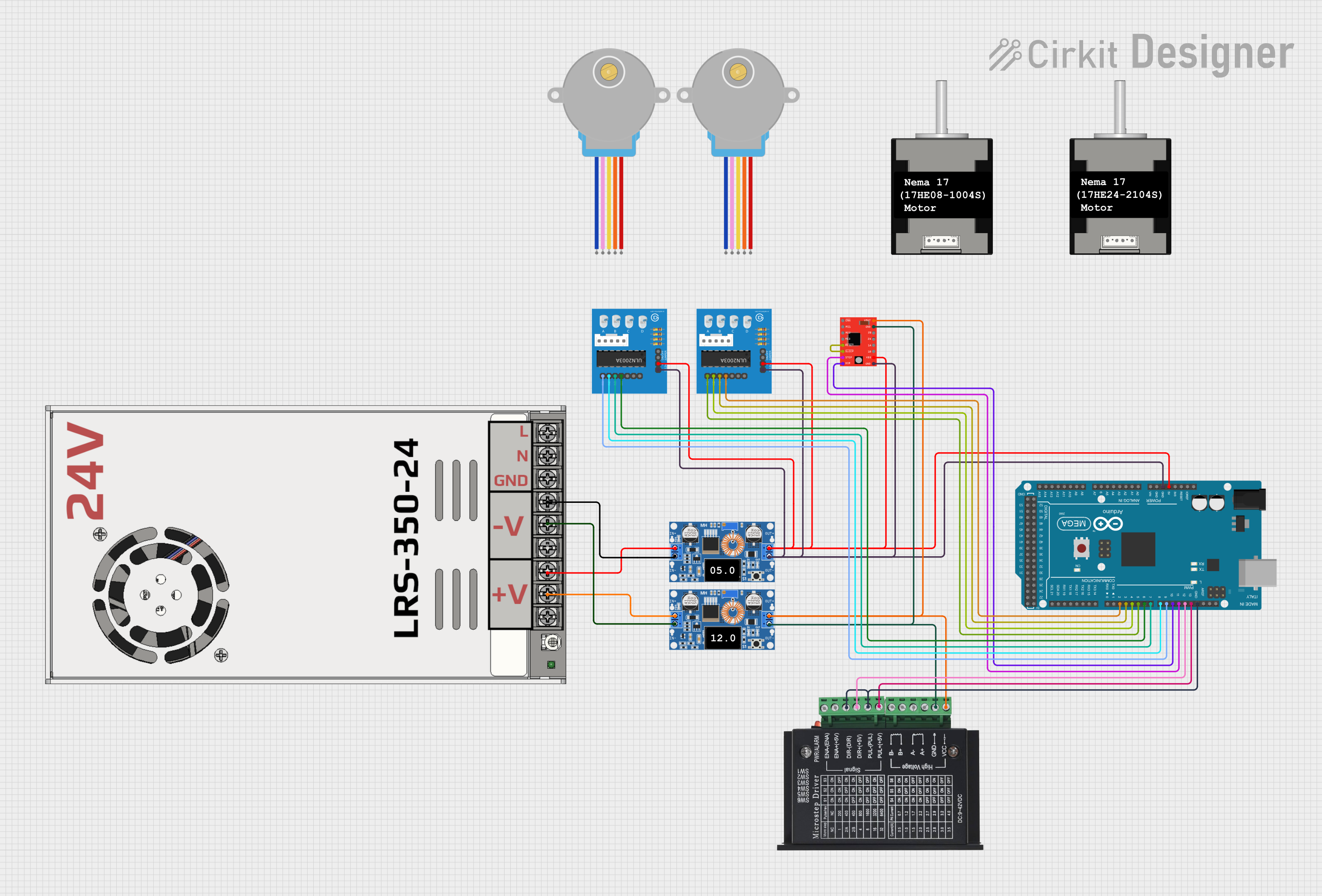

Explore Projects Built with MT3608 Step-Up

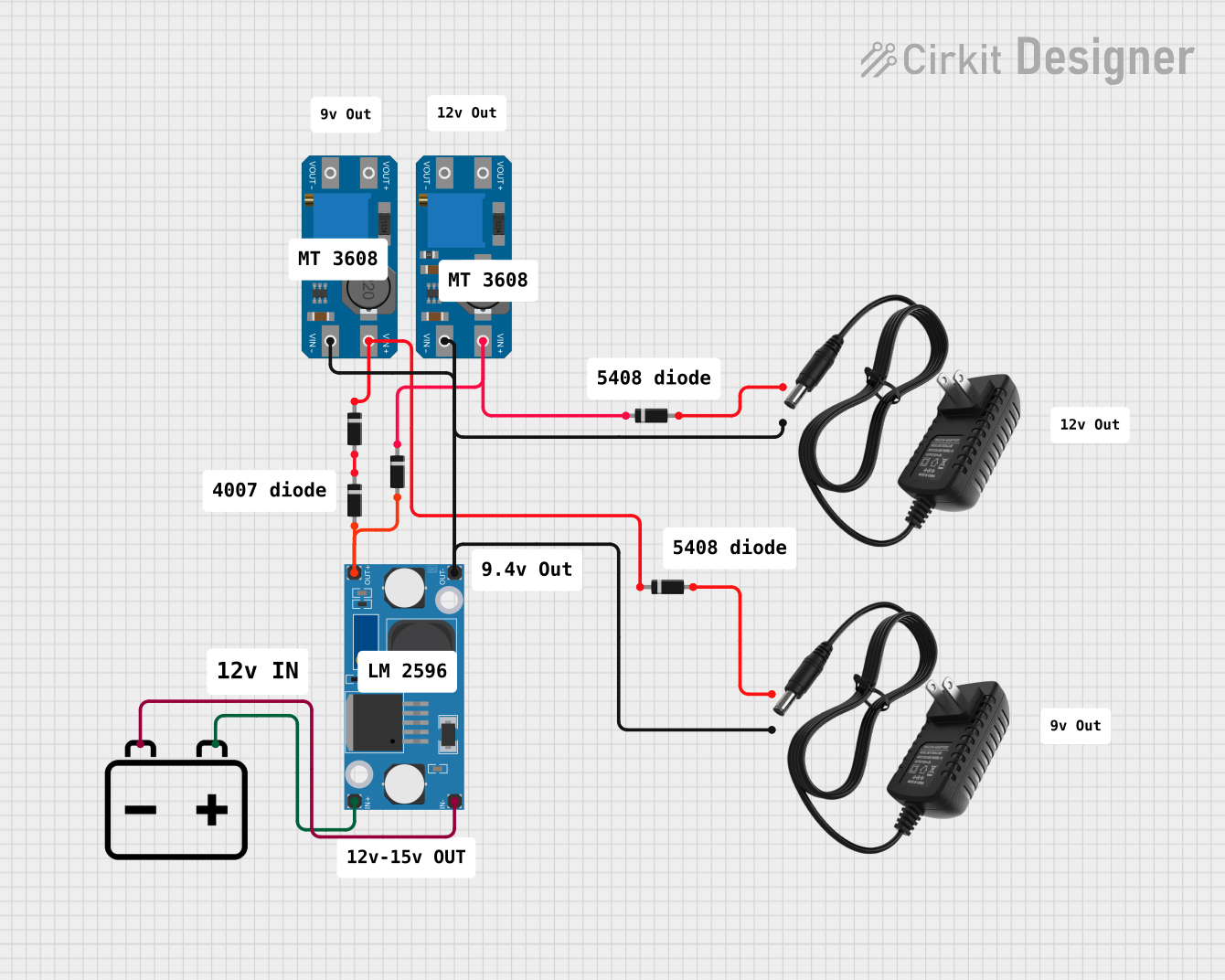

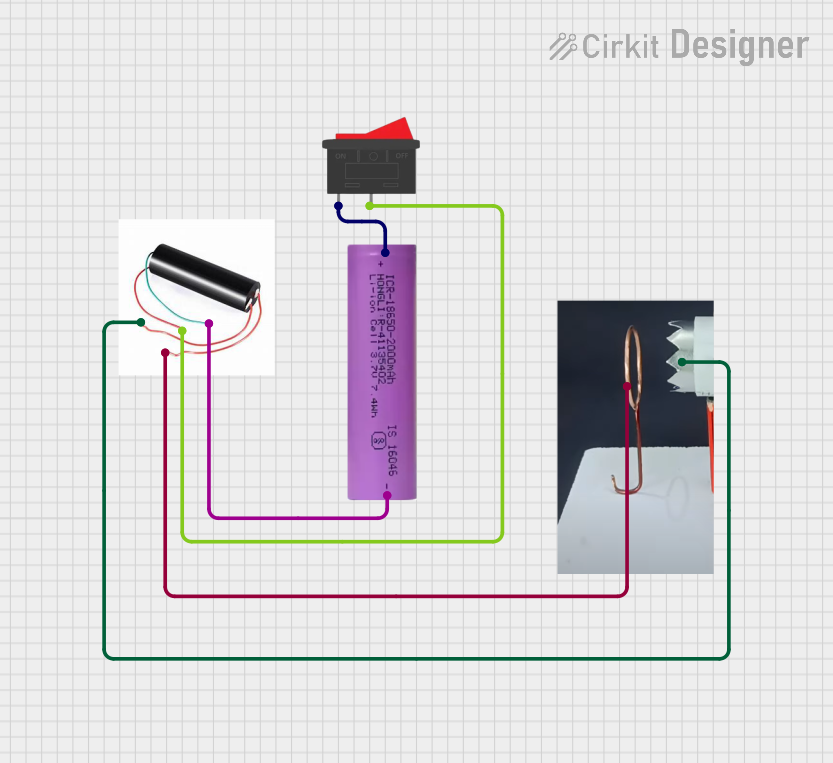

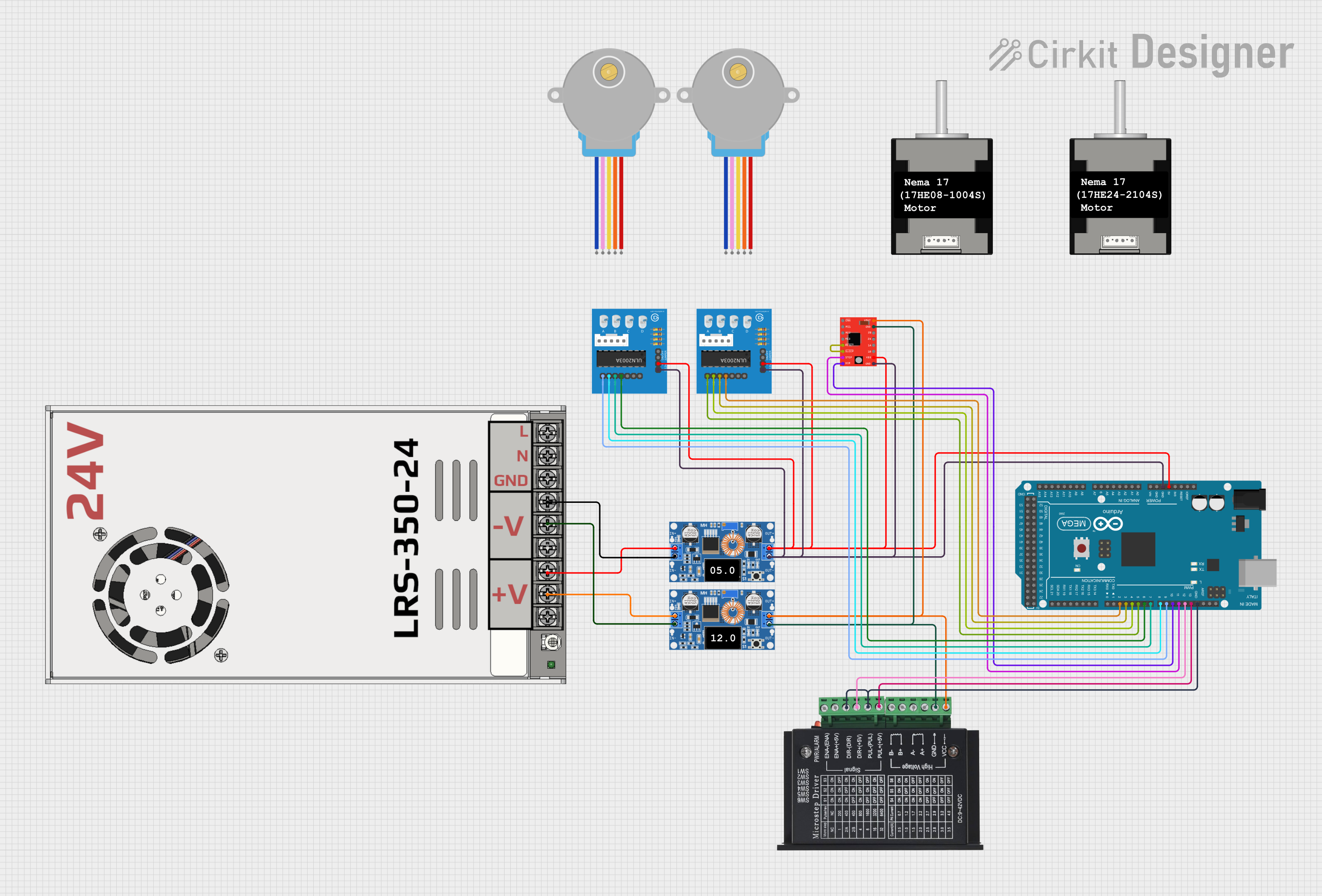

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with MT3608 Step-Up

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Powering microcontrollers and sensors from a single-cell Li-ion battery

- Boosting voltage for LED strips or lighting systems

- Portable power banks and USB chargers

- Audio amplifiers and other low-voltage devices requiring higher operating voltages

Technical Specifications

The MT3608 is a compact and efficient boost converter with the following key specifications:

| Parameter | Value |

|---|---|

| Input Voltage Range | 2V to 24V |

| Output Voltage Range | 5V to 28V (adjustable via potentiometer) |

| Maximum Output Current | 2A (depending on input voltage and load) |

| Efficiency | Up to 93% |

| Switching Frequency | 1.2 MHz |

| Dimensions | 36mm x 17mm x 6mm (module size) |

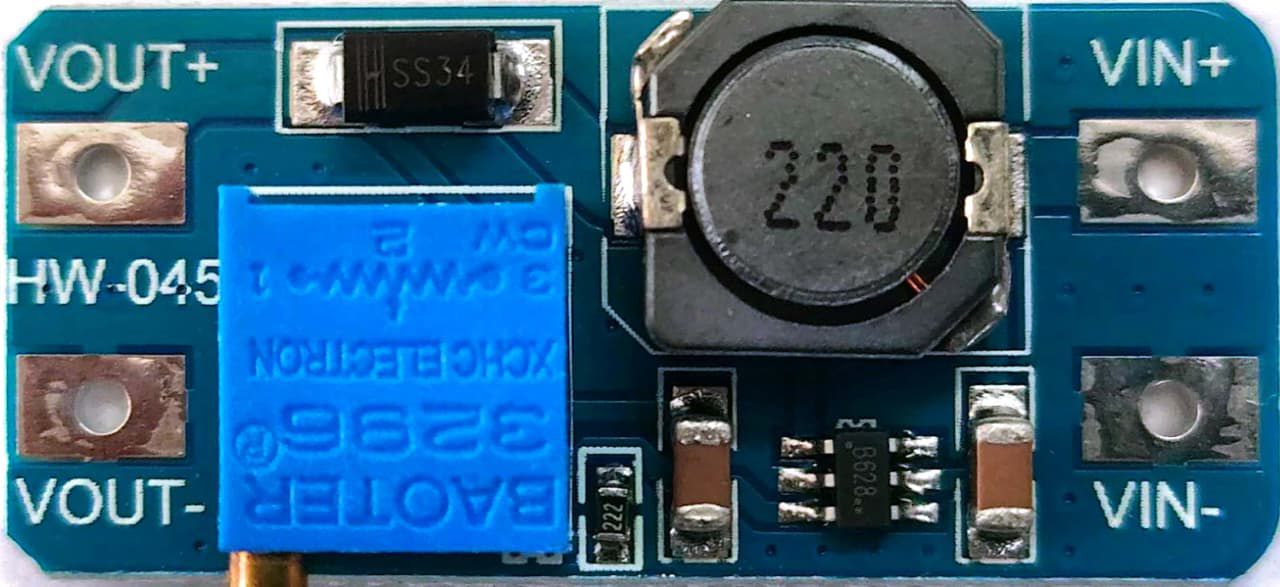

Pin Configuration and Descriptions

The MT3608 module typically has the following pinout:

| Pin Name | Description |

|---|---|

| VIN | Input voltage (2V to 24V). Connect to the power source. |

| GND | Ground. Connect to the negative terminal of the source. |

| VOUT | Boosted output voltage (5V to 28V). Connect to the load. |

Usage Instructions

How to Use the MT3608 in a Circuit

- Connect the Input Voltage:

- Connect the VIN pin to the positive terminal of your power source (e.g., a battery).

- Connect the GND pin to the negative terminal of the power source.

- Adjust the Output Voltage:

- Use the onboard potentiometer to set the desired output voltage. Turn the potentiometer clockwise to increase the voltage and counterclockwise to decrease it.

- Use a multimeter to measure the output voltage at the VOUT pin while adjusting.

- Connect the Load:

- Connect the VOUT pin to the positive terminal of your load.

- Connect the GND pin to the negative terminal of your load.

Important Considerations

- Input Voltage Range: Ensure the input voltage is within the specified range (2V to 24V). Exceeding this range may damage the module.

- Output Voltage Adjustment: Always adjust the output voltage without a load connected to avoid overvoltage damage to your components.

- Heat Dissipation: At higher currents, the module may generate heat. Consider adding a heatsink or ensuring proper ventilation.

- Current Limitations: The maximum output current depends on the input voltage and load. Exceeding 2A may cause instability or damage.

Example: Using MT3608 with Arduino UNO

The MT3608 can be used to power an Arduino UNO from a 3.7V Li-ion battery. Here's how to set it up:

- Connect the battery's positive terminal to the VIN pin and the negative terminal to the GND pin of the MT3608.

- Adjust the output voltage to 5V using the potentiometer.

- Connect the VOUT pin to the Arduino's 5V pin and the GND pin to the Arduino's GND pin.

Sample Code for Arduino UNO

// Example code to blink an LED using Arduino UNO powered by MT3608

// Ensure the MT3608 output is set to 5V before connecting to the Arduino

const int ledPin = 13; // Pin connected to the onboard LED

void setup() {

pinMode(ledPin, OUTPUT); // Set the LED pin as an output

}

void loop() {

digitalWrite(ledPin, HIGH); // Turn the LED on

delay(1000); // Wait for 1 second

digitalWrite(ledPin, LOW); // Turn the LED off

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output Voltage:

- Check the input voltage. Ensure it is within the 2V to 24V range.

- Verify all connections are secure and correct.

- Ensure the potentiometer is not set to the minimum output voltage.

Output Voltage is Unstable:

- Check if the load exceeds the module's current capacity (2A max).

- Ensure the input voltage is stable and sufficient for the desired output.

Module Overheating:

- Reduce the load current or improve ventilation.

- Ensure the input voltage is not too close to the output voltage, as this increases current draw.

Cannot Adjust Output Voltage:

- Verify the potentiometer is functioning correctly. If damaged, replace the module.

- Ensure no load is connected while adjusting the voltage.

FAQs

Q: Can the MT3608 be used to power a Raspberry Pi?

A: Yes, but ensure the output voltage is set to 5V and the current demand of the Raspberry Pi (including peripherals) does not exceed 2A.

Q: What happens if I exceed the input voltage range?

A: Exceeding the 24V input limit can permanently damage the module. Always use a regulated power source.

Q: Can I use the MT3608 to charge a battery?

A: No, the MT3608 is not designed for battery charging. Use a dedicated battery charging module for this purpose.