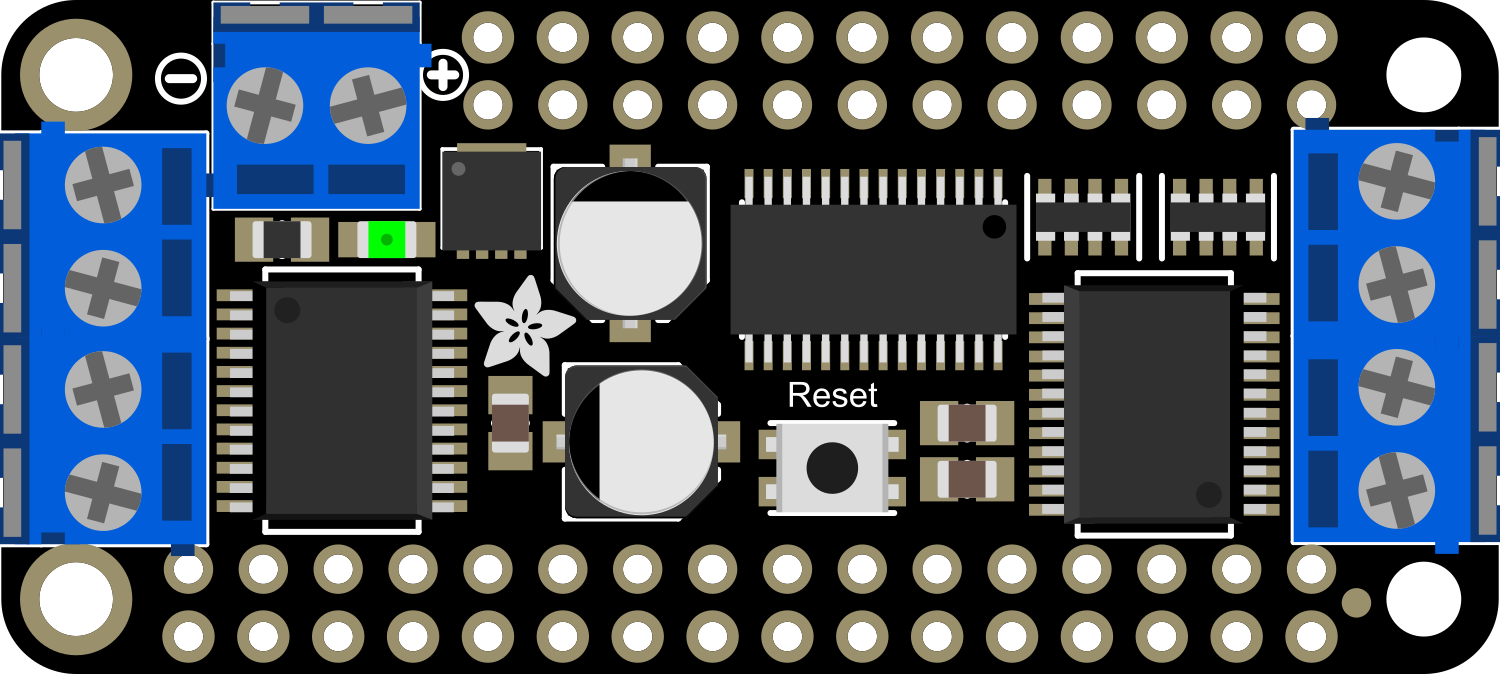

How to Use Adafruit DC+Stepper FeatherWing: Examples, Pinouts, and Specs

Design with Adafruit DC+Stepper FeatherWing in Cirkit Designer

Design with Adafruit DC+Stepper FeatherWing in Cirkit DesignerIntroduction

The Adafruit DC+Stepper FeatherWing is a versatile motor driver add-on board designed for use with the Adafruit Feather development boards. This component allows users to control up to 2 stepper motors or 4 DC motors with PWM speed control. It is an ideal choice for hobbyists and engineers who are looking to create projects that require precise motor control, such as robotic arms, automated tools, or custom vehicles.

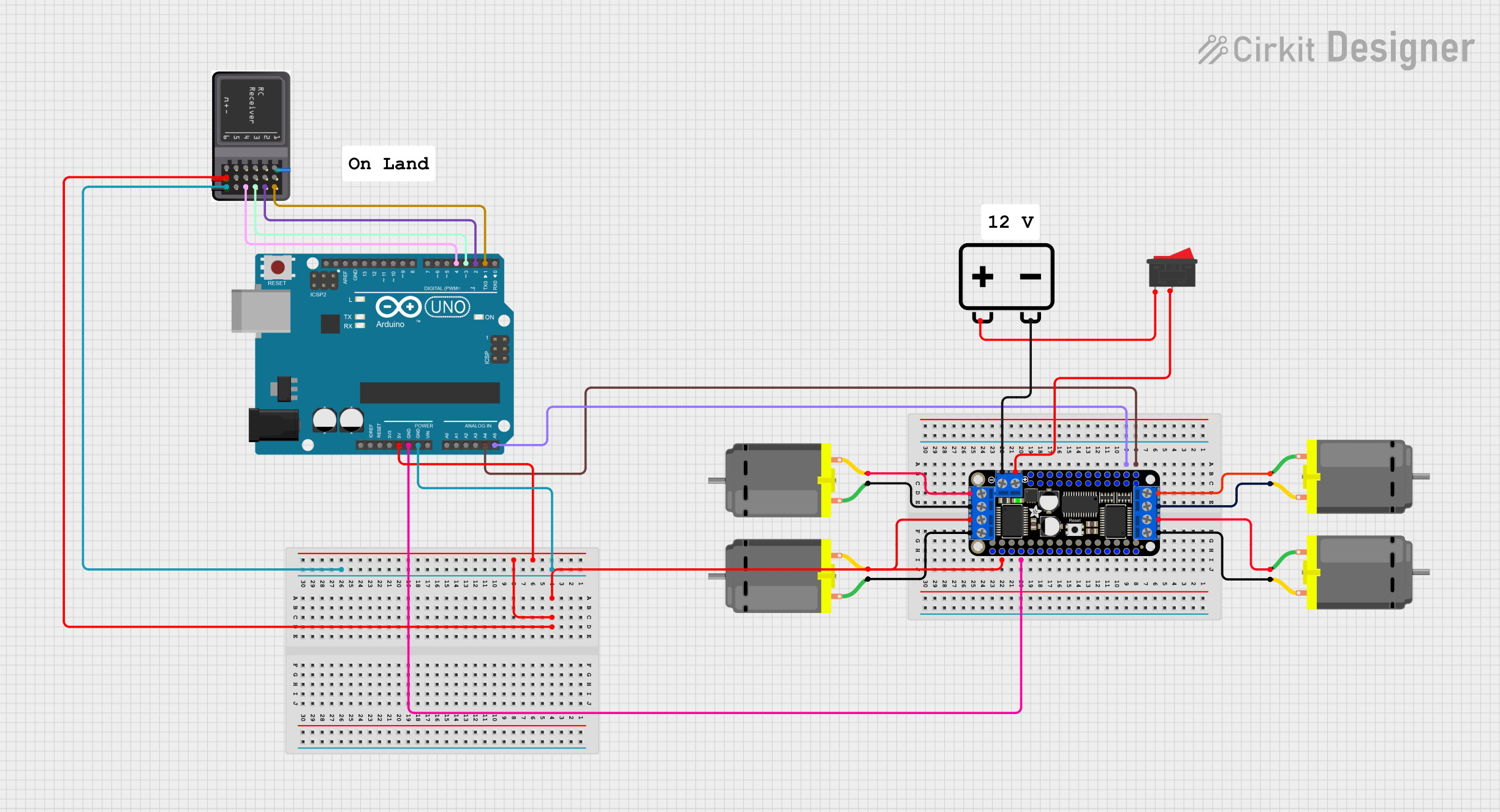

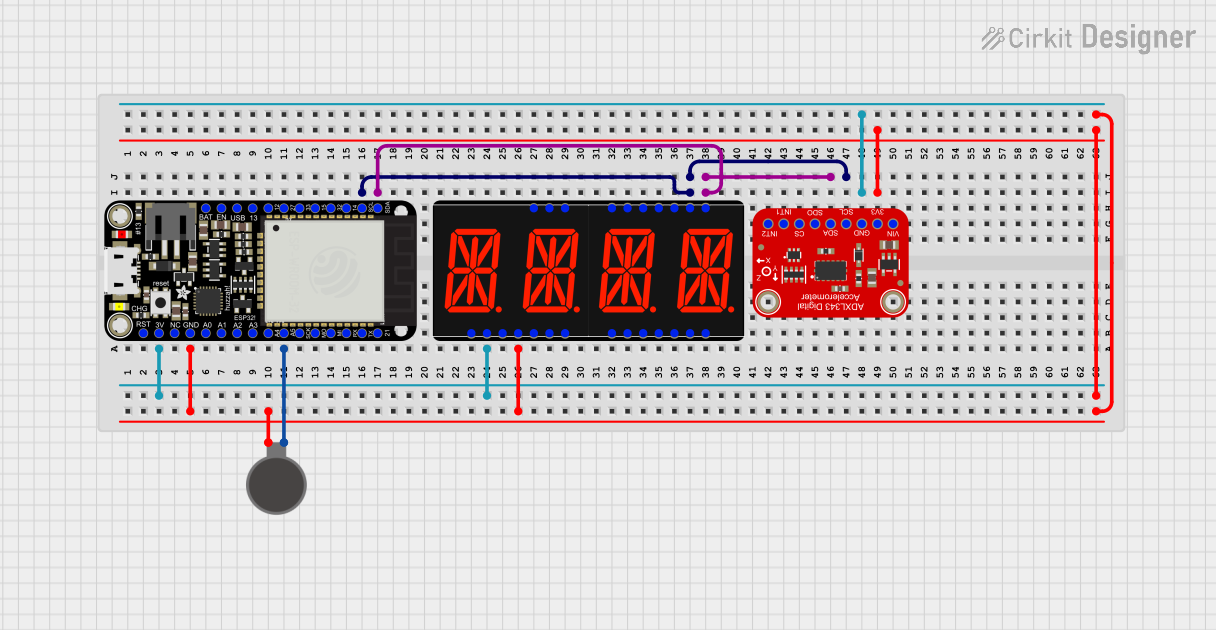

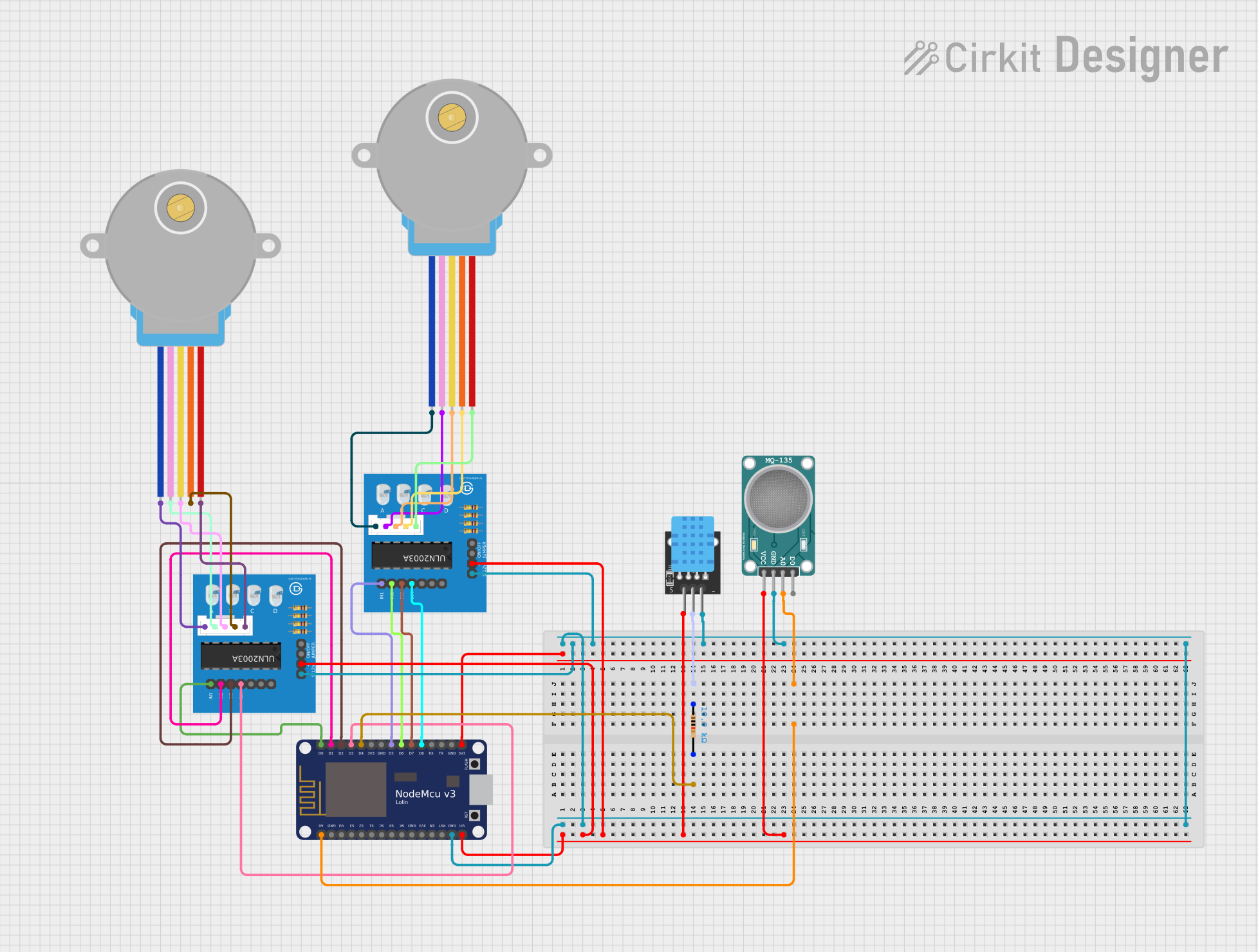

Explore Projects Built with Adafruit DC+Stepper FeatherWing

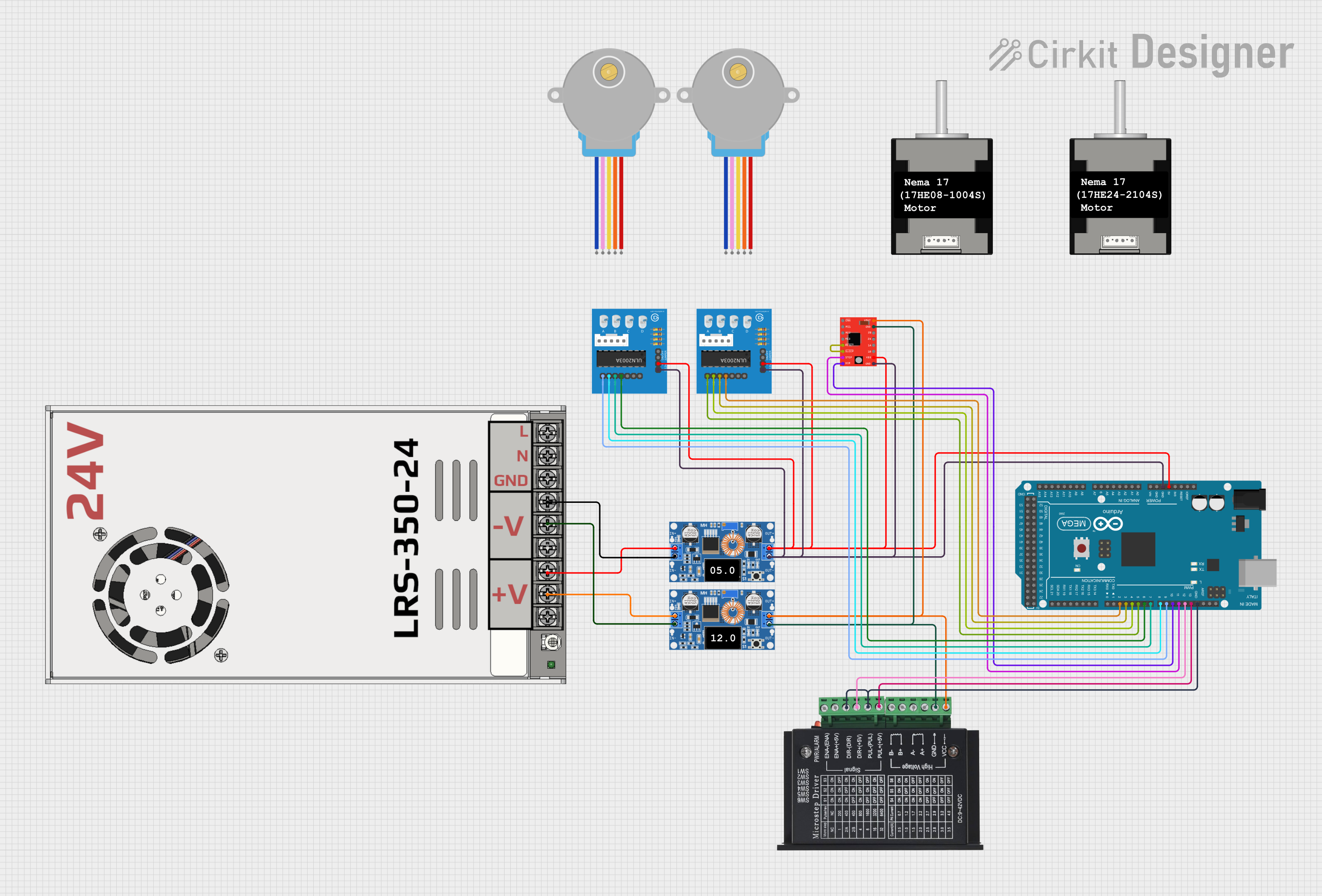

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

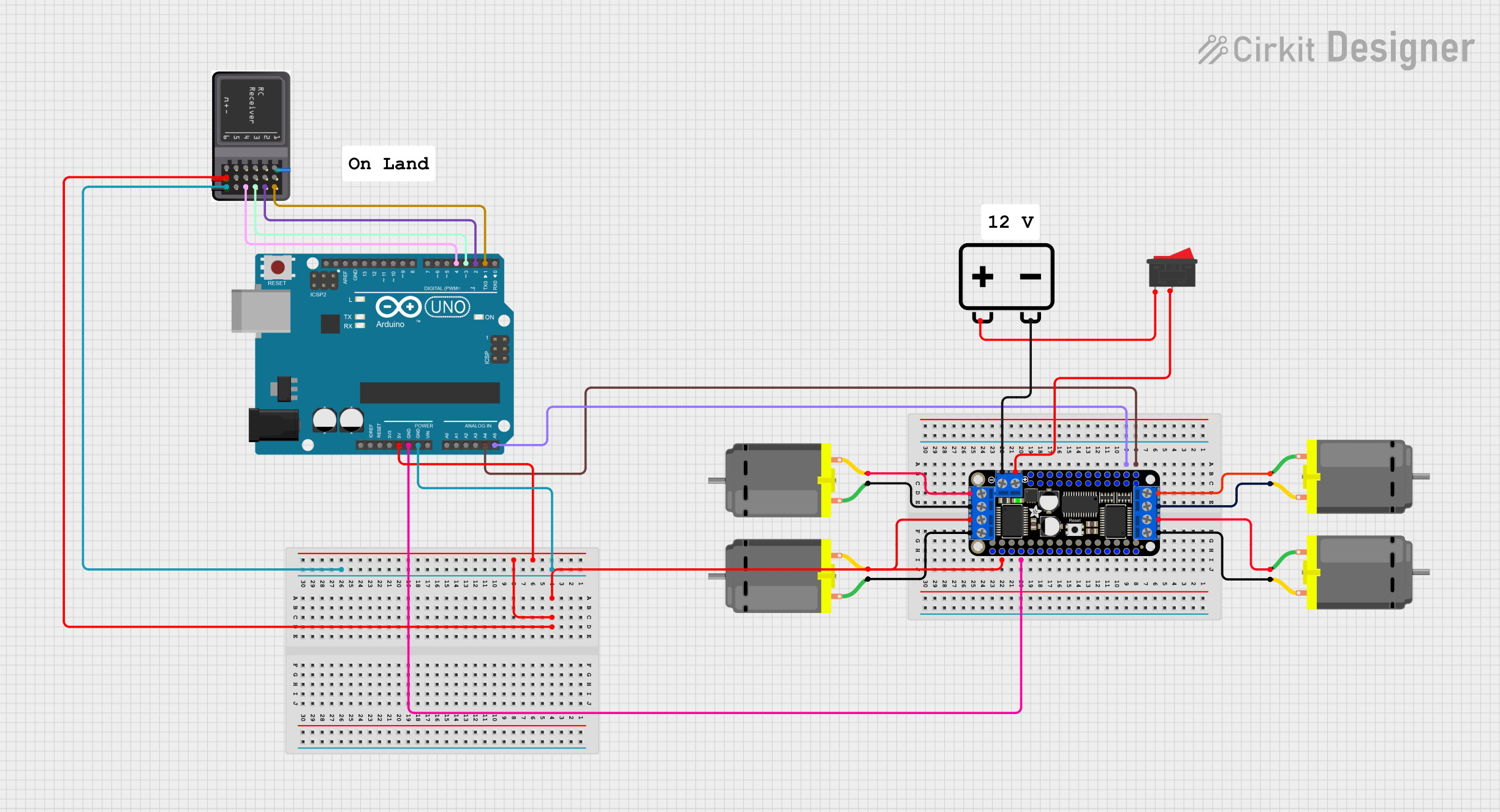

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Adafruit DC+Stepper FeatherWing

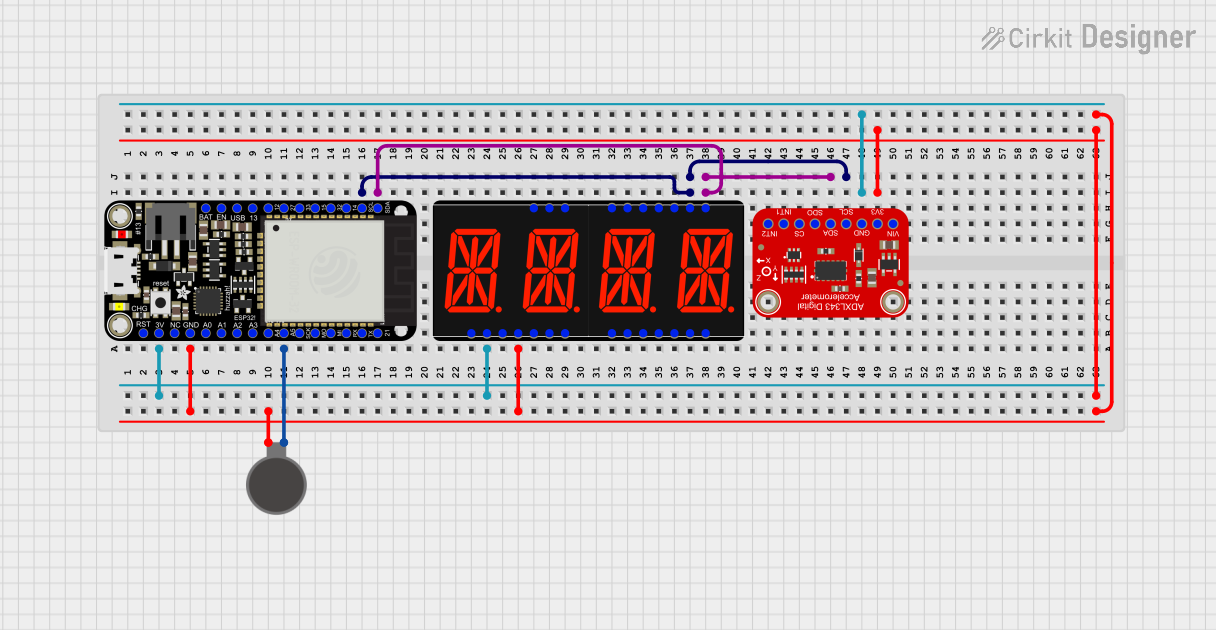

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

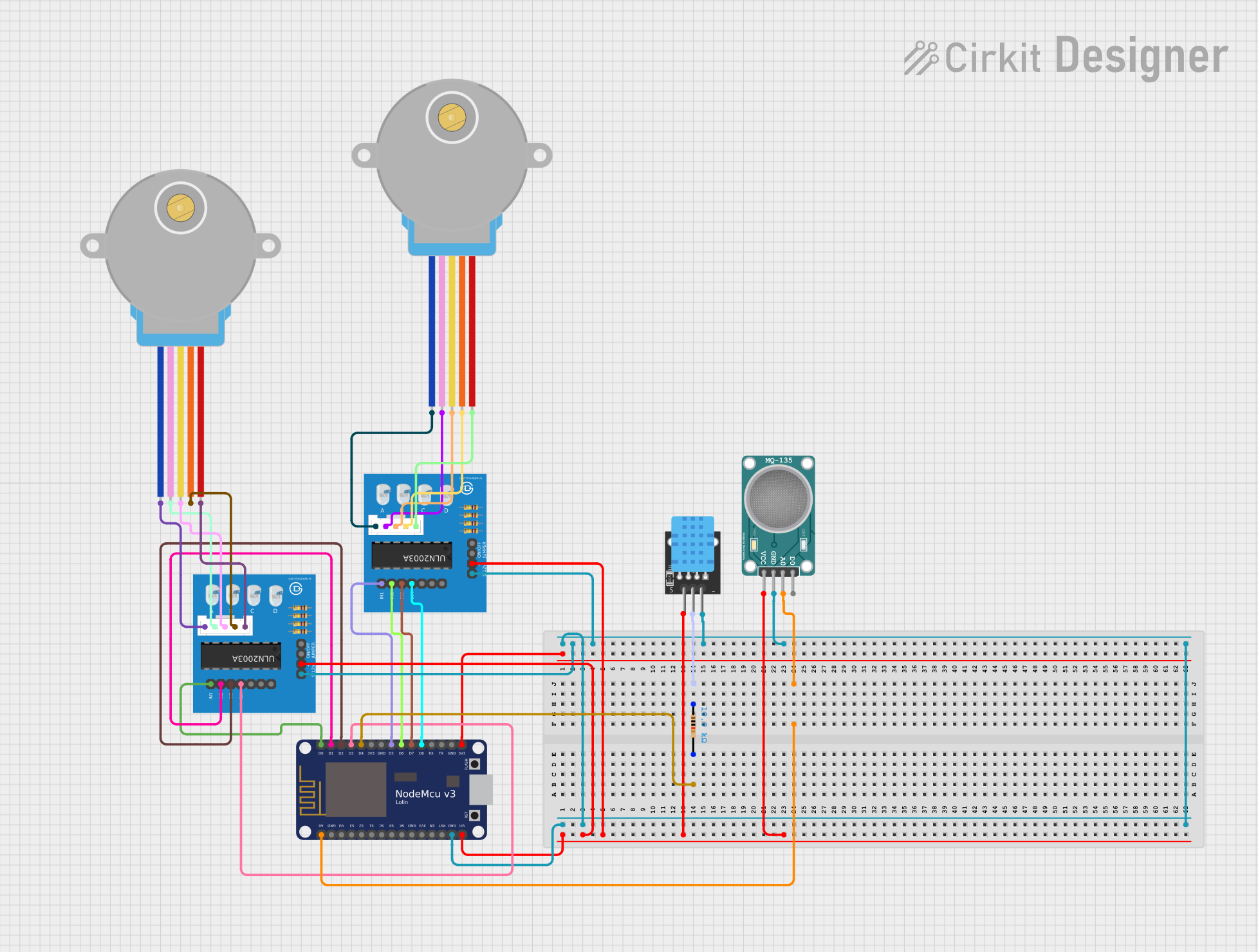

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics

- CNC machines

- Automated art installations

- Educational projects

- Prototyping motor-driven mechanisms

Technical Specifications

Key Technical Details

- Motor Voltage: 4.5V to 13.5V

- Logic Voltage: 3V to 5V

- Output Current: Up to 1.2A per channel (with proper heat-sinking, up to 3A peak)

- PWM Frequency: 1.6 kHz

Pin Configuration and Descriptions

| Pin | Function | Description |

|---|---|---|

| A1, A2 | Motor A Terminals | Connect to motor A or coil 1 of a stepper motor |

| B1, B2 | Motor B Terminals | Connect to motor B or coil 2 of a stepper motor |

| C1, C2 | Motor C Terminals | Connect to motor C (DC motor use only) |

| D1, D2 | Motor D Terminals | Connect to motor D (DC motor use only) |

| GND | Ground | Common ground for logic and motor power |

| VIN | Motor Power Supply | Input for motor power (4.5V to 13.5V) |

| 3Vo | Logic Power Output | 3.3V output (from Feather board) |

| SDA, SCL | I2C Data/Clock | I2C communication pins |

| PWM | PWM Input | Pulse Width Modulation input for speed control |

Usage Instructions

How to Use the Component in a Circuit

Power Connections:

- Connect the motor power supply to the VIN and GND terminals.

- Ensure that the logic power is supplied from the Feather board to the 3Vo pin.

Motor Connections:

- Connect your DC or stepper motors to the appropriate terminals (A1, A2 for Motor A/Stepper Coil 1, etc.).

Control Interface:

- Use the I2C interface (SDA and SCL pins) to communicate with the FeatherWing from your Feather board.

PWM Speed Control:

- Apply PWM signals to the PWM pin for speed control of DC motors.

Important Considerations and Best Practices

- Always ensure that the power supply voltage and current do not exceed the specified limits.

- Use proper heat-sinking for currents above 1.2A per channel.

- Avoid running motors at full speed for extended periods to prevent overheating.

- When using stepper motors, ensure that the stepping sequence is correctly programmed for smooth operation.

Example Code for Arduino UNO

#include <Wire.h>

#include <Adafruit_MotorShield.h>

// Create the motor shield object with the default I2C address

Adafruit_MotorShield AFMS = Adafruit_MotorShield();

// Connect a stepper motor with 200 steps per revolution (1.8 degree)

// to motor port #2 (M3 and M4)

Adafruit_StepperMotor *myMotor = AFMS.getStepper(200, 2);

void setup() {

Serial.begin(9600); // Start serial communication.

AFMS.begin(); // Create with the default frequency 1.6KHz.

myMotor->setSpeed(10); // Set the speed to 10 rpm.

}

void loop() {

myMotor->step(100, FORWARD, SINGLE);

Serial.println("Stepped 100 steps forward, single coil steps.");

delay(1000);

}

Note: This example assumes the use of an Adafruit Motor Shield library, which may need to be modified for direct use with the FeatherWing. The code provided is for illustrative purposes and may require adjustments for specific Feather boards.

Troubleshooting and FAQs

Common Issues

- Motor not responding: Check connections and ensure that the power supply is adequate.

- Overheating: Ensure proper heat-sinking and avoid running motors at high currents for extended periods.

- Inaccurate motor movement: Verify that the stepping sequence and speed settings are correct for stepper motors.

Solutions and Tips for Troubleshooting

- Double-check wiring against the pin configuration table.

- Use a multimeter to verify power supply voltage and motor resistance.

- Review your code to ensure that the I2C address and motor configurations are correct.

- Consult the Adafruit forums and support channels for assistance.

FAQs

Q: Can I control more than one FeatherWing at a time? A: Yes, you can stack multiple FeatherWings, but you will need to manage different I2C addresses for each one.

Q: What is the maximum number of motors I can control with one FeatherWing? A: You can control up to 4 DC motors or 2 stepper motors with a single FeatherWing.

Q: Can I use this FeatherWing with other development boards besides Feather? A: While designed for Feather boards, it is possible to use the FeatherWing with other development boards that support I2C communication and meet the logic voltage requirements. However, additional wiring and code adjustments may be necessary.