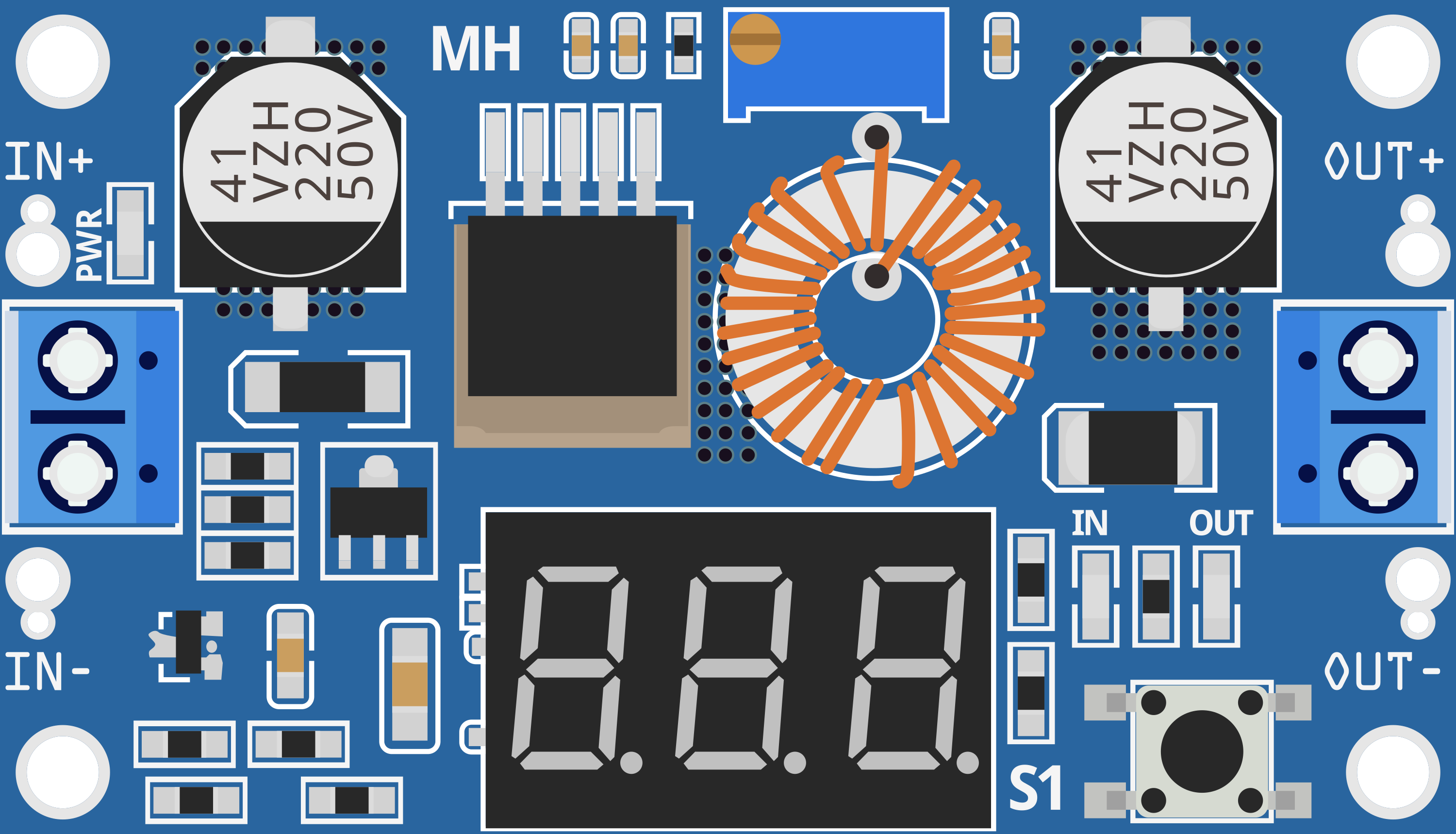

How to Use XL4015 5A DC Buck Step-down: Examples, Pinouts, and Specs

Design with XL4015 5A DC Buck Step-down in Cirkit Designer

Design with XL4015 5A DC Buck Step-down in Cirkit DesignerIntroduction

The XL4015 is a high-efficiency, step-down DC-DC converter module capable of handling up to 5A of current while maintaining a stable output voltage. This module is widely used in applications requiring voltage reduction from a higher voltage source to a lower voltage for various electronic devices, such as powering LEDs, battery charging, and as a power supply for embedded electronics.

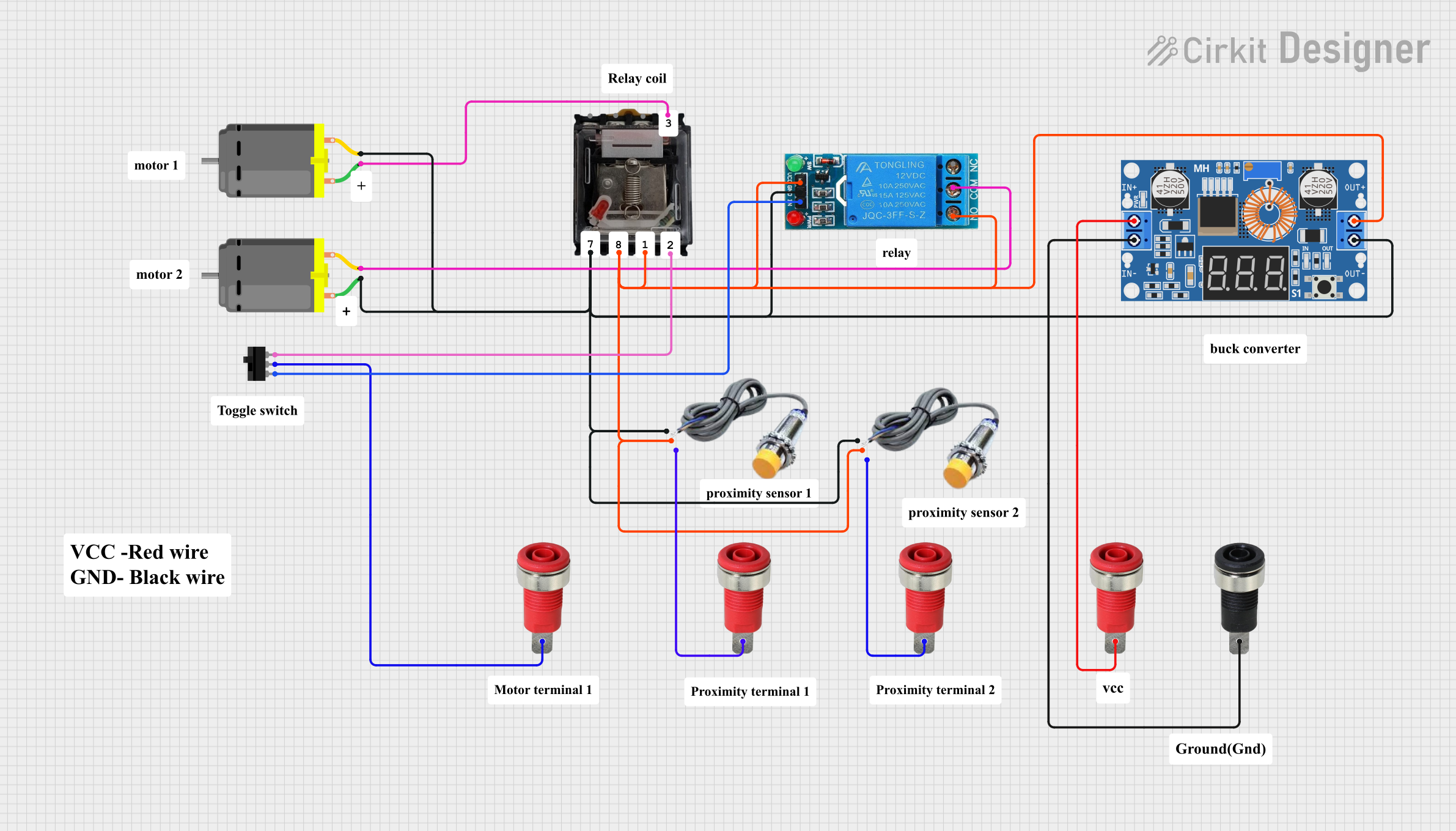

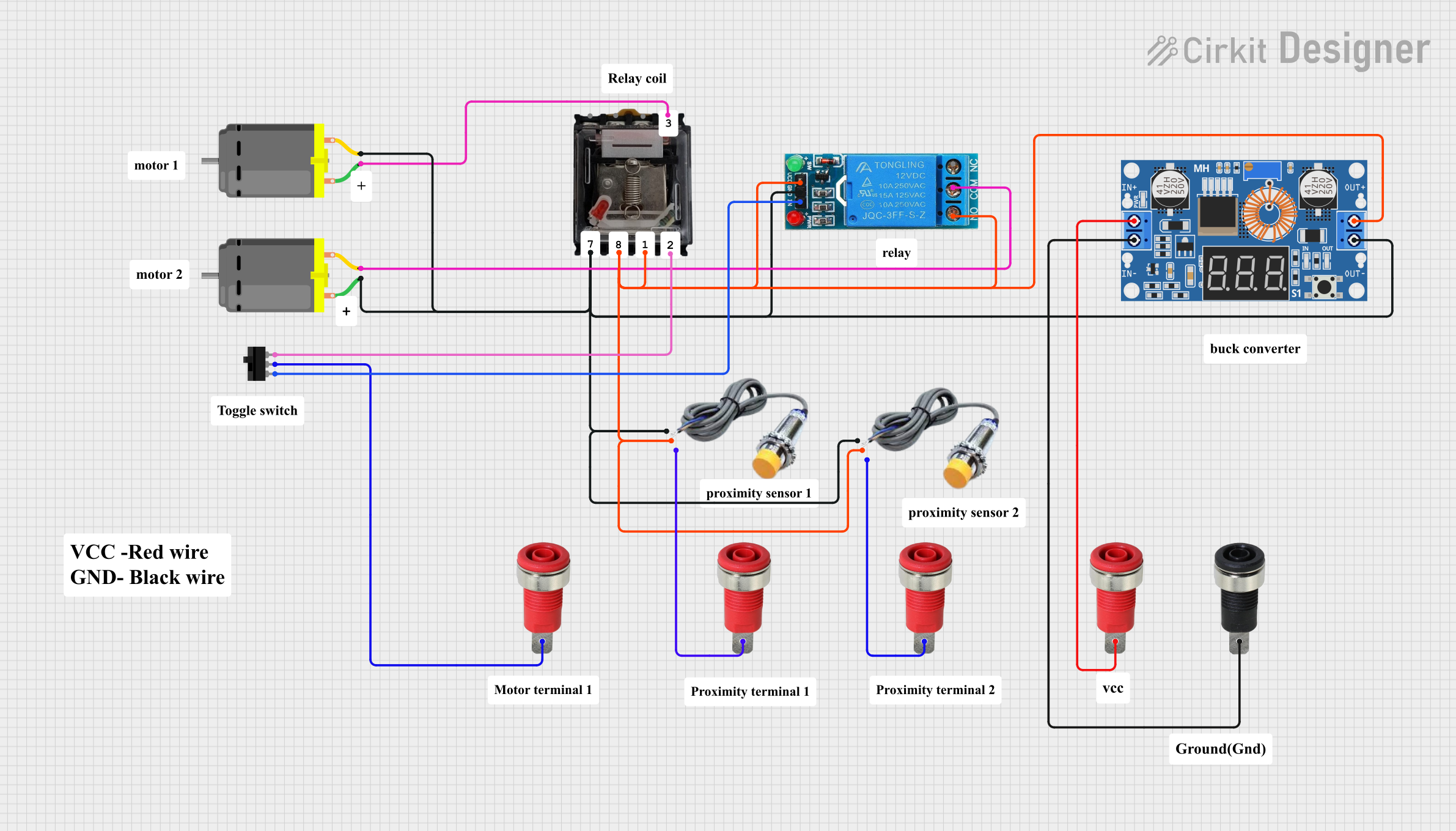

Explore Projects Built with XL4015 5A DC Buck Step-down

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with XL4015 5A DC Buck Step-down

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- LED drivers

- Battery chargers

- Power supplies for electronic devices

- Solar power supplies

- DIY electronics projects

Technical Specifications

Key Technical Details

- Input Voltage Range: 4V to 38V DC

- Output Voltage Range: 1.25V to 36V DC (adjustable via potentiometer)

- Output Current: Up to 5A (with proper heat sinking)

- Efficiency: Up to 96%

- Switching Frequency: 180kHz

- Operating Temperature: -40°C to +85°C

Pin Configuration and Descriptions

| Pin Number | Name | Description |

|---|---|---|

| 1 | IN+ | Input positive |

| 2 | IN- | Input negative |

| 3 | OUT+ | Output positive |

| 4 | OUT- | Output negative |

| 5 | ADJ | Adjustment potentiometer (built-in) |

Usage Instructions

How to Use the Component in a Circuit

- Connect the input voltage to the IN+ and IN- pins, ensuring that the voltage is within the specified range.

- Connect the load to the OUT+ and OUT- pins.

- Adjust the output voltage by turning the onboard potentiometer. Use a multimeter to measure the output voltage while adjusting.

- If the current draw is close to or at 5A, ensure that the module is mounted on a heat sink to dissipate heat effectively.

Important Considerations and Best Practices

- Always verify input and output voltages with a multimeter before connecting sensitive electronics.

- Avoid adjusting the potentiometer while the module is under load to prevent voltage spikes.

- For high-current applications, ensure adequate heat dissipation to prevent thermal shutdown or damage.

- Use thick wires for high-current connections to minimize voltage drop and heat generation.

Troubleshooting and FAQs

Common Issues Users Might Face

- Output voltage is not stable or does not match the setting: Ensure that the potentiometer is adjusted correctly and that the input voltage is stable and within the specified range.

- Module overheats: Check if the current draw is too high or if adequate heat sinking is in place.

- No output voltage: Verify connections and input voltage, and check for any signs of damage on the module.

Solutions and Tips for Troubleshooting

- If the output voltage is unstable, re-adjust the potentiometer and check the input voltage stability.

- For overheating issues, reduce the load current or improve heat dissipation with a larger heat sink or active cooling.

- If there is no output voltage, double-check all connections and replace the module if it appears damaged.

FAQs

Q: Can I use the XL4015 to charge batteries? A: Yes, but ensure that the output voltage is set correctly for the battery type and that the charging current does not exceed the battery's specifications.

Q: How do I know if I need a heat sink? A: If the module is running hot to the touch or if you are drawing more than 2A continuously, it is recommended to use a heat sink.

Q: Is the output voltage fixed or adjustable? A: The output voltage is adjustable via the onboard potentiometer.

Q: Can I use this module with an Arduino UNO? A: Yes, you can use it to step down the voltage for an Arduino UNO or any other compatible device, but ensure the output voltage is set to 5V or the appropriate level for your device.

Example Arduino UNO Connection Code

// No specific code is required for the XL4015 when used with an Arduino UNO.

// The XL4015 is a standalone power module and does not interface directly with

// the Arduino's digital or analog pins. However, you can use the Arduino to

// monitor the output voltage of the XL4015 if desired.

void setup() {

Serial.begin(9600);

pinMode(A0, INPUT); // Connect the output voltage of XL4015 to A0

}

void loop() {

int sensorValue = analogRead(A0);

float voltage = sensorValue * (5.0 / 1023.0); // Convert the reading to voltage

Serial.print("Output Voltage: ");

Serial.println(voltage);

delay(1000);

}

Note: The above code assumes that the output voltage of the XL4015 is within the 0-5V range that the Arduino can measure. If the voltage is higher, a voltage divider is required to bring the voltage into the measurable range.