How to Use Hc-020k: Examples, Pinouts, and Specs

Design with Hc-020k in Cirkit Designer

Design with Hc-020k in Cirkit DesignerIntroduction

The HC-020K is a relay or contactor designed for controlling high voltage or high current circuits using a low voltage signal. It acts as an electrically operated switch, allowing small control signals to manage larger electrical loads safely and efficiently. This component is widely used in automation systems, industrial equipment, home appliances, and other applications where electrical isolation and high-power control are required.

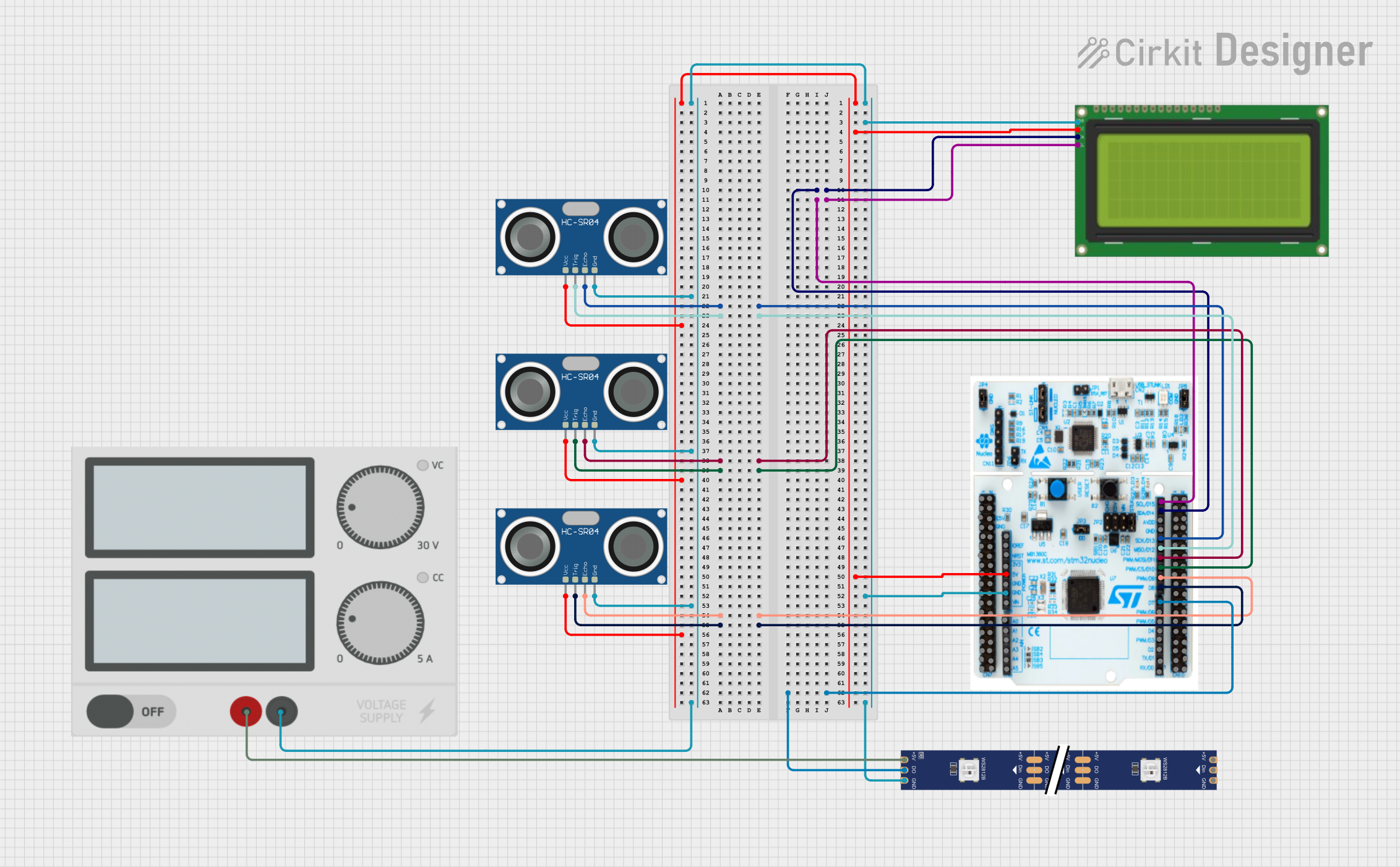

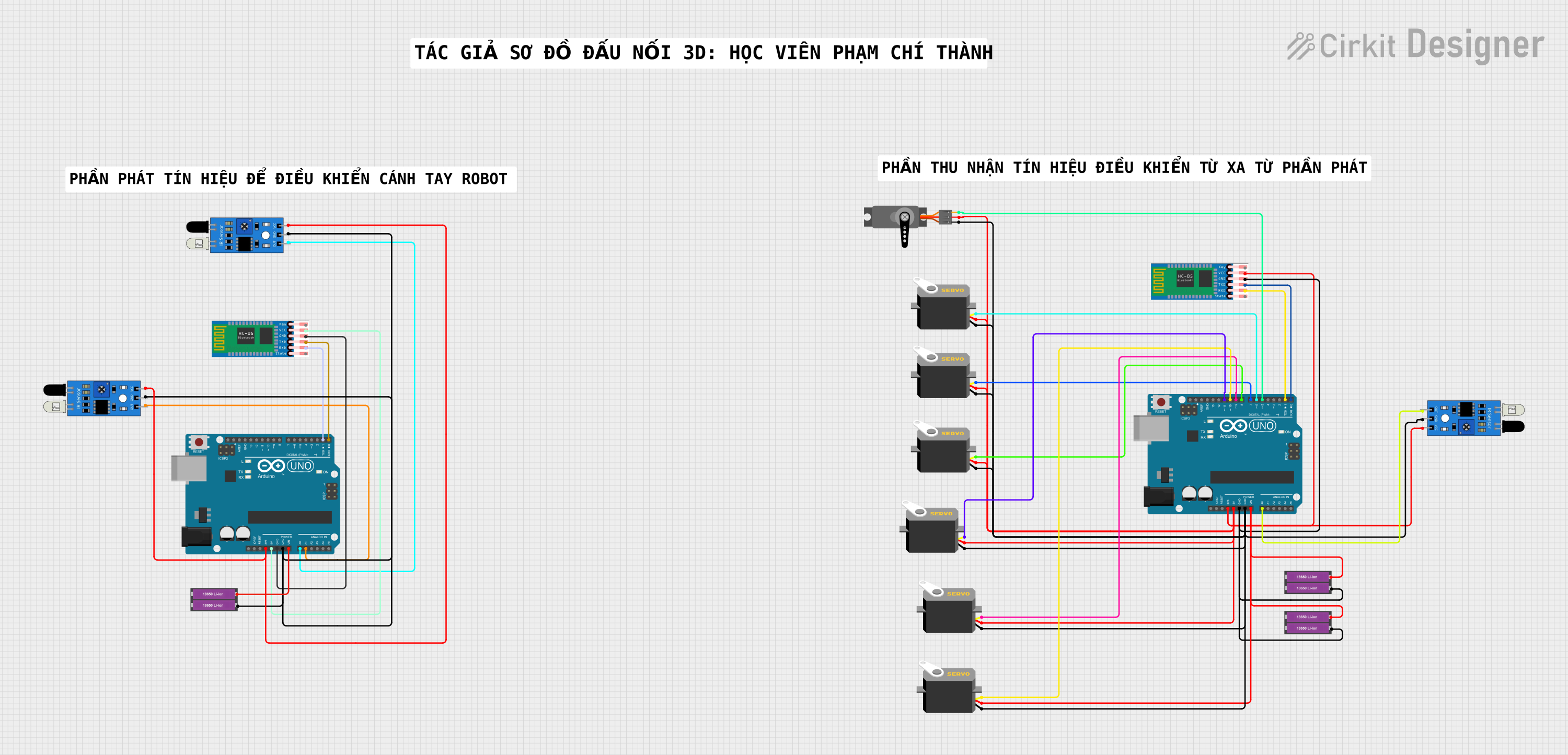

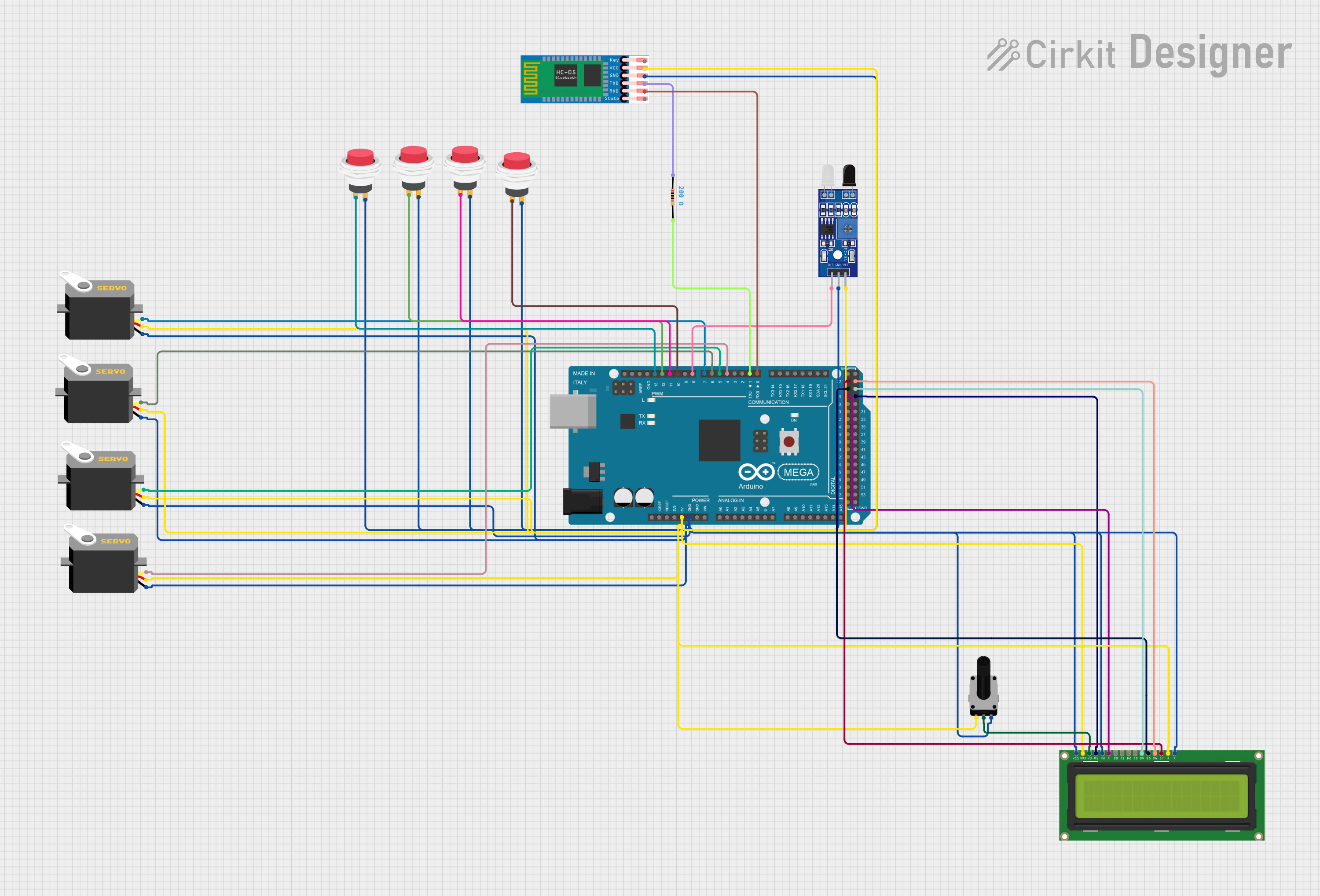

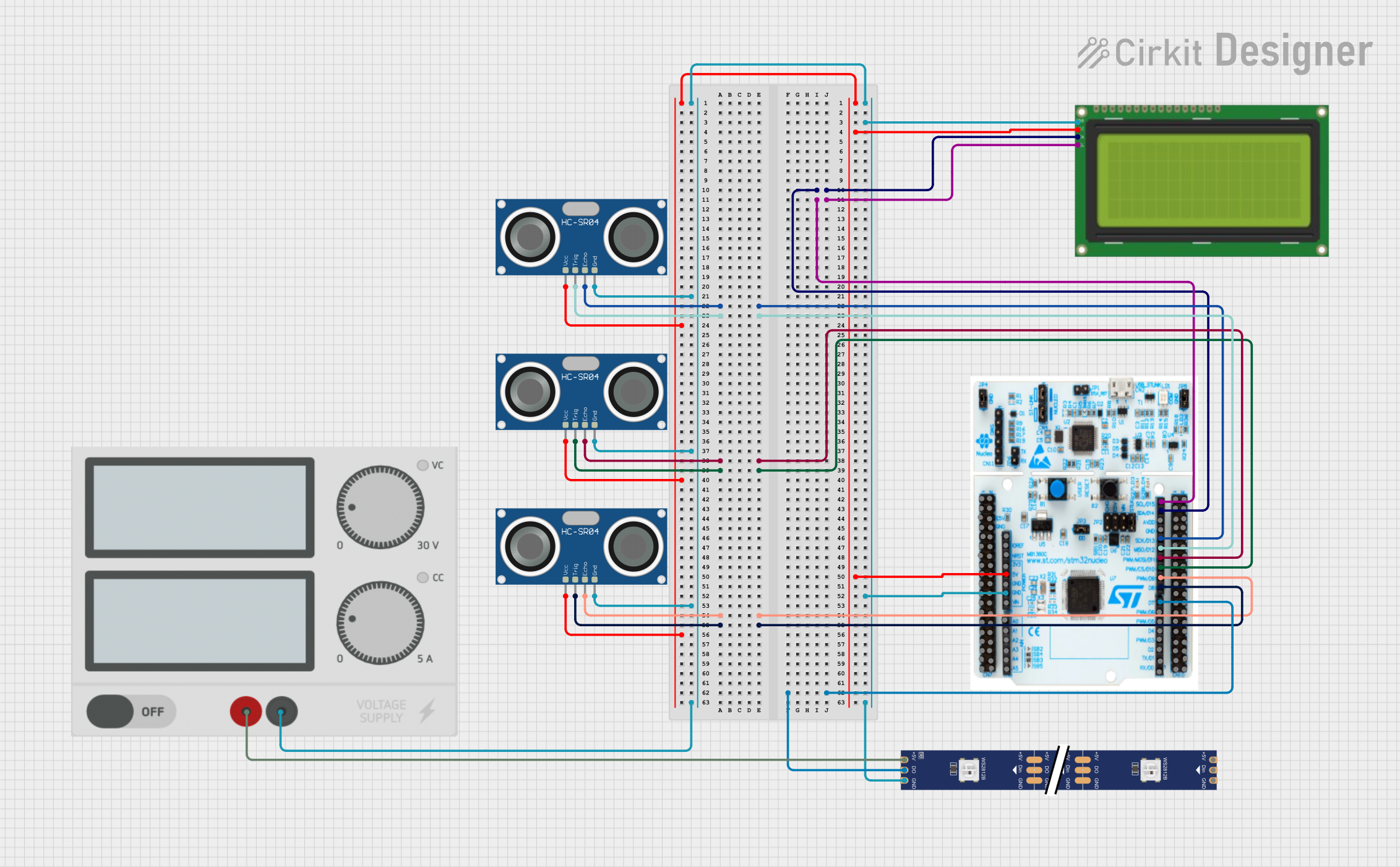

Explore Projects Built with Hc-020k

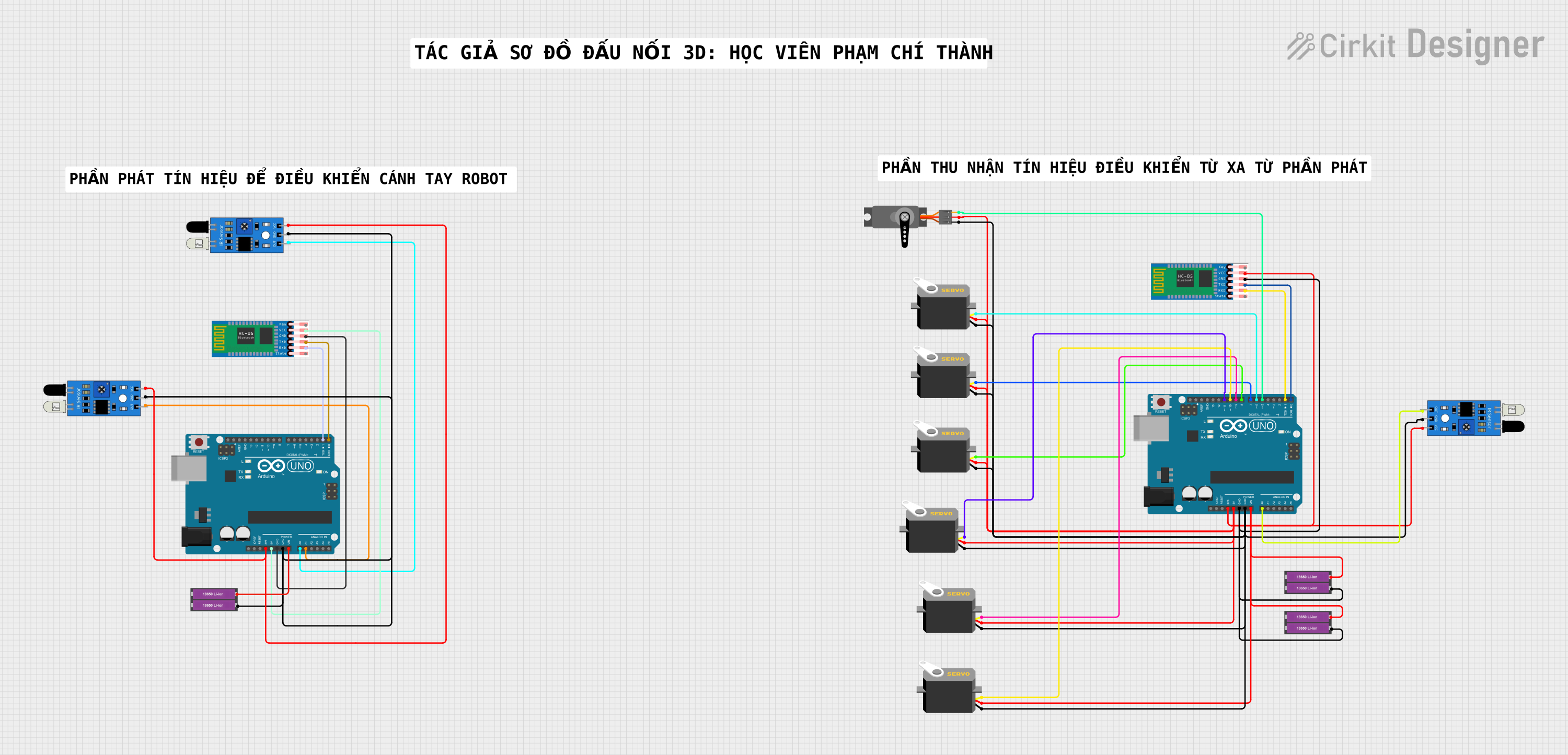

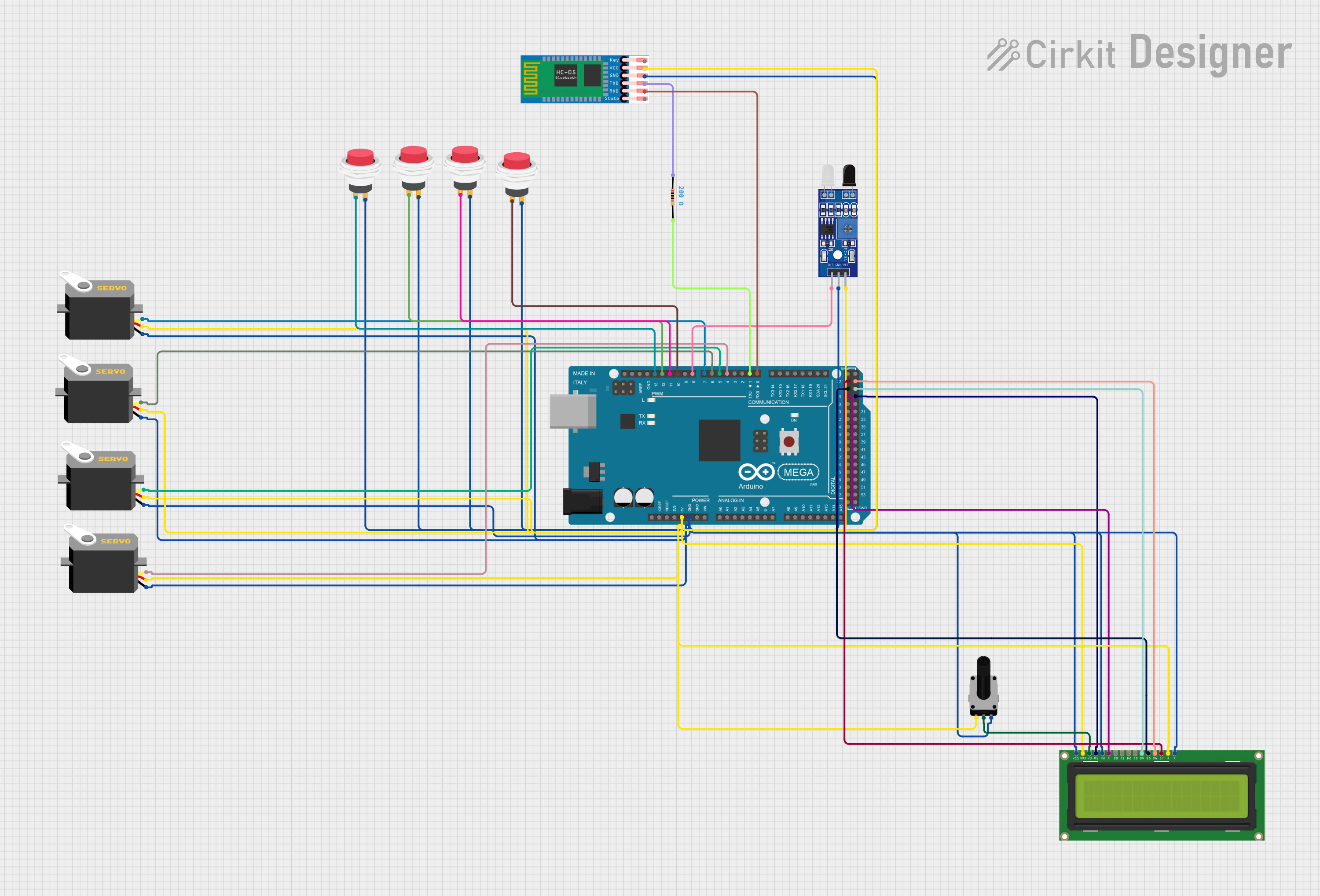

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Hc-020k

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Industrial motor control systems

- Home automation (e.g., controlling lights or appliances)

- Power distribution systems

- Automotive electronics

- Safety circuits requiring electrical isolation

Technical Specifications

Key Technical Details

- Operating Voltage (Control Signal): 5V DC

- Coil Resistance: 70Ω ± 10%

- Switching Voltage (Load): Up to 250V AC or 30V DC

- Switching Current (Load): Up to 10A

- Contact Type: SPDT (Single Pole Double Throw)

- Insulation Resistance: ≥ 100MΩ at 500V DC

- Dielectric Strength: 1500V AC (between coil and contacts)

- Response Time: ≤ 10ms

- Release Time: ≤ 5ms

- Operating Temperature Range: -40°C to 85°C

- Mechanical Life: 10 million operations (no load)

- Electrical Life: 100,000 operations (rated load)

Pin Configuration and Descriptions

The HC-020K typically has 5 pins, as described in the table below:

| Pin Number | Name | Description |

|---|---|---|

| 1 | Coil (+) | Positive terminal of the relay coil. Connect to the control signal (e.g., 5V). |

| 2 | Coil (-) | Negative terminal of the relay coil. Connect to ground. |

| 3 | Common (COM) | Common terminal for the load circuit. |

| 4 | Normally Open (NO) | Load terminal that is disconnected when the relay is inactive. |

| 5 | Normally Closed (NC) | Load terminal that is connected when the relay is inactive. |

Usage Instructions

How to Use the HC-020K in a Circuit

Power the Relay Coil:

- Connect the coil pins (1 and 2) to a low voltage DC source (e.g., 5V DC).

- Use a transistor or MOSFET to drive the relay if the control signal comes from a microcontroller like an Arduino.

Connect the Load:

- Identify the load you want to control (e.g., a light bulb or motor).

- Connect one side of the load to the Common (COM) pin (Pin 3).

- Connect the other side of the load to either:

- Normally Open (NO) pin (Pin 4) if you want the load to turn on when the relay is activated.

- Normally Closed (NC) pin (Pin 5) if you want the load to turn off when the relay is activated.

Control the Relay:

- Apply a control signal (e.g., 5V DC) to the coil pins to activate the relay.

- When the relay is activated, the NO pin connects to COM, and the NC pin disconnects from COM.

Important Considerations and Best Practices

- Use a Flyback Diode: Always connect a flyback diode across the relay coil to protect the driving circuit from voltage spikes when the relay is turned off.

- Avoid Overloading: Ensure the load does not exceed the relay's rated voltage and current.

- Isolation: If using the relay with a microcontroller, consider using an optocoupler for additional electrical isolation.

- Mounting: Secure the relay properly to avoid mechanical vibrations that could affect its operation.

Example: Connecting the HC-020K to an Arduino UNO

Below is an example of how to control the HC-020K relay using an Arduino UNO:

Circuit Connections

- Connect the relay's Coil (+) pin to a digital output pin on the Arduino (e.g., Pin 7) through a 1kΩ resistor.

- Connect the relay's Coil (-) pin to the Arduino's GND.

- Connect a flyback diode (e.g., 1N4007) across the relay coil, with the cathode connected to Coil (+) and the anode to Coil (-).

- Connect the load to the COM and NO pins of the relay.

Arduino Code

// Define the pin connected to the relay

const int relayPin = 7;

void setup() {

// Set the relay pin as an output

pinMode(relayPin, OUTPUT);

// Ensure the relay is off initially

digitalWrite(relayPin, LOW);

}

void loop() {

// Turn the relay on

digitalWrite(relayPin, HIGH);

delay(1000); // Keep the relay on for 1 second

// Turn the relay off

digitalWrite(relayPin, LOW);

delay(1000); // Keep the relay off for 1 second

}

Notes:

- The above code toggles the relay on and off every second.

- Ensure the Arduino's 5V pin can supply enough current to drive the relay coil. If not, use an external power source with a transistor or MOSFET.

Troubleshooting and FAQs

Common Issues and Solutions

Relay Not Activating:

- Cause: Insufficient control signal voltage or current.

- Solution: Verify the control signal is 5V DC and can supply enough current (typically 70mA). Use a transistor or MOSFET if needed.

Load Not Switching:

- Cause: Incorrect wiring of the load to the relay pins.

- Solution: Double-check the connections to the COM, NO, and NC pins.

Relay Buzzing or Chattering:

- Cause: Unstable control signal or insufficient power supply.

- Solution: Ensure the control signal is stable and the power supply can handle the relay's current requirements.

Microcontroller Resetting When Relay Activates:

- Cause: Voltage spikes from the relay coil affecting the microcontroller.

- Solution: Add a flyback diode across the relay coil and use a separate power supply for the relay if possible.

FAQs

Q: Can the HC-020K handle DC loads?

A: Yes, the relay can handle DC loads up to 30V and 10A.Q: Can I use the HC-020K with a 3.3V microcontroller?

A: Not directly. Use a transistor or MOSFET to drive the relay coil with a 5V signal.Q: What is the purpose of the flyback diode?

A: The flyback diode protects the driving circuit from voltage spikes generated when the relay coil is turned off.Q: How do I know if the relay is working?

A: You should hear a clicking sound when the relay activates. Additionally, you can measure continuity between the COM and NO pins when the relay is on.