How to Use servo motor: Examples, Pinouts, and Specs

Design with servo motor in Cirkit Designer

Design with servo motor in Cirkit DesignerIntroduction

A servo motor is a rotary actuator that allows for precise control of angular position, velocity, and acceleration. It consists of a motor coupled to a sensor for position feedback, along with a control circuit. Servo motors are widely used in applications requiring accurate movement and positioning, such as robotics, automation systems, RC vehicles, and industrial machinery. Their ability to maintain a specific position makes them ideal for tasks like steering, robotic arm movement, and camera stabilization.

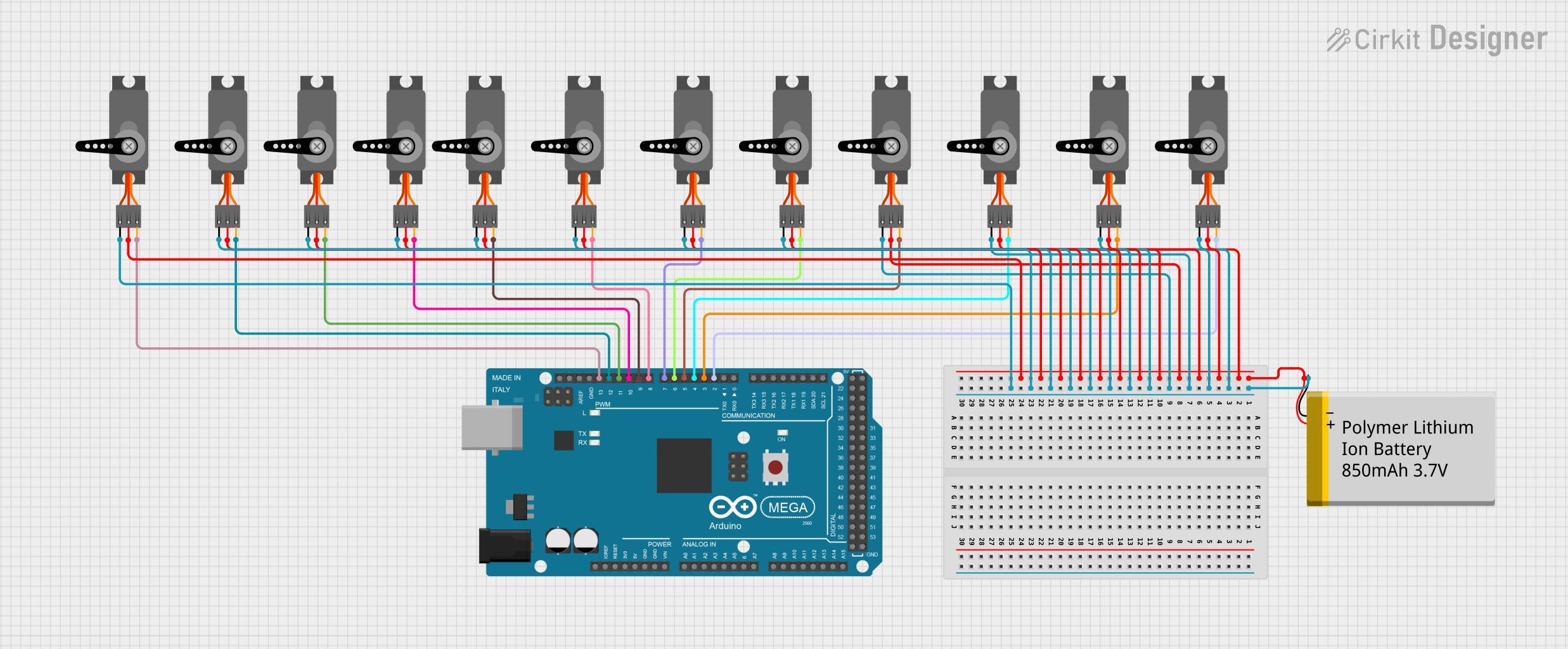

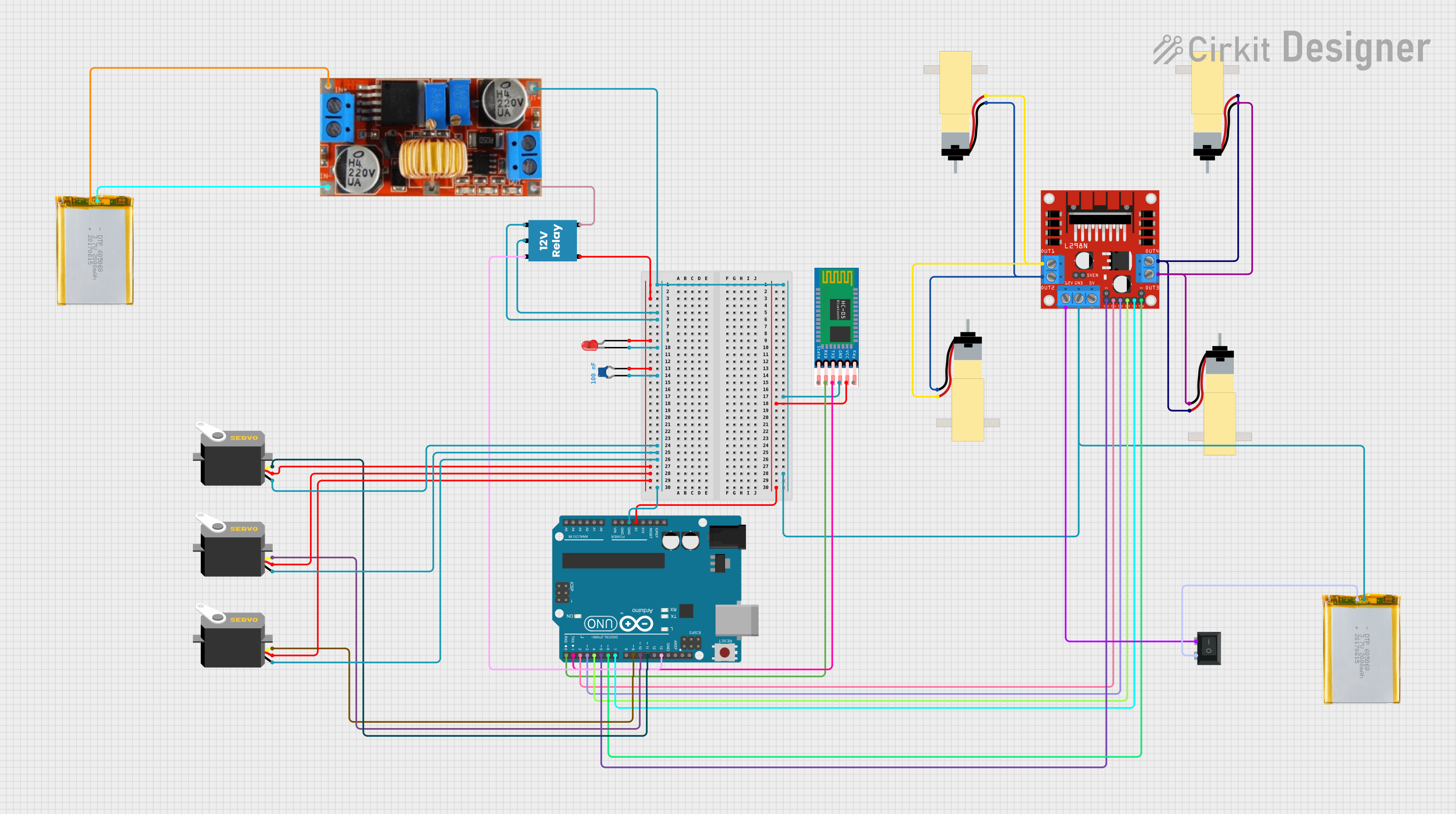

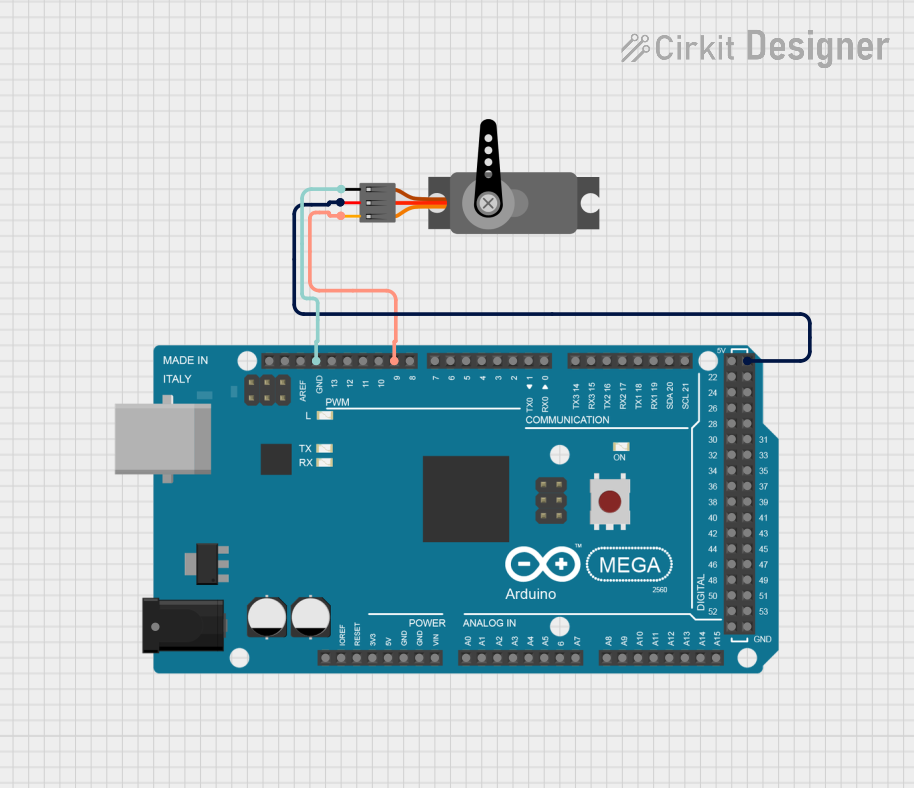

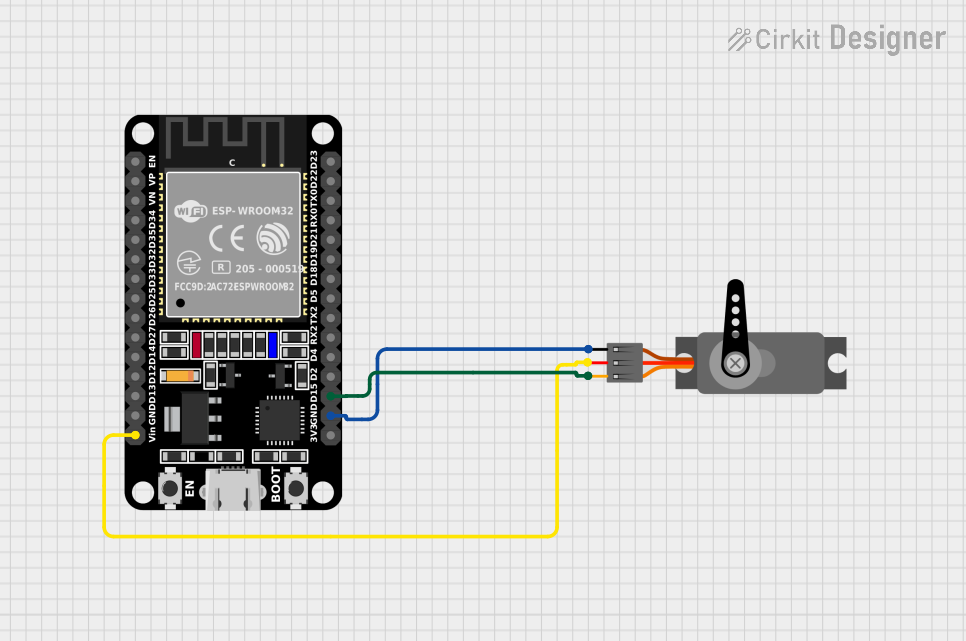

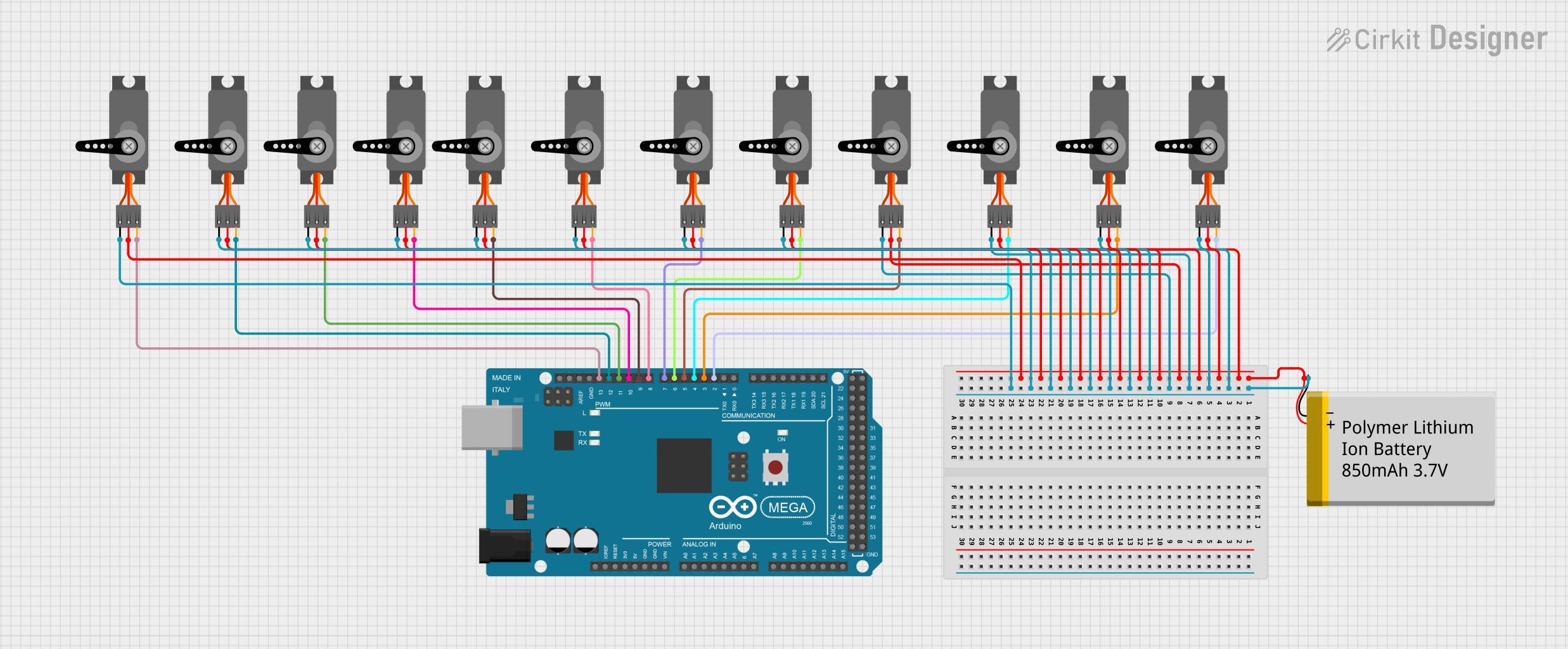

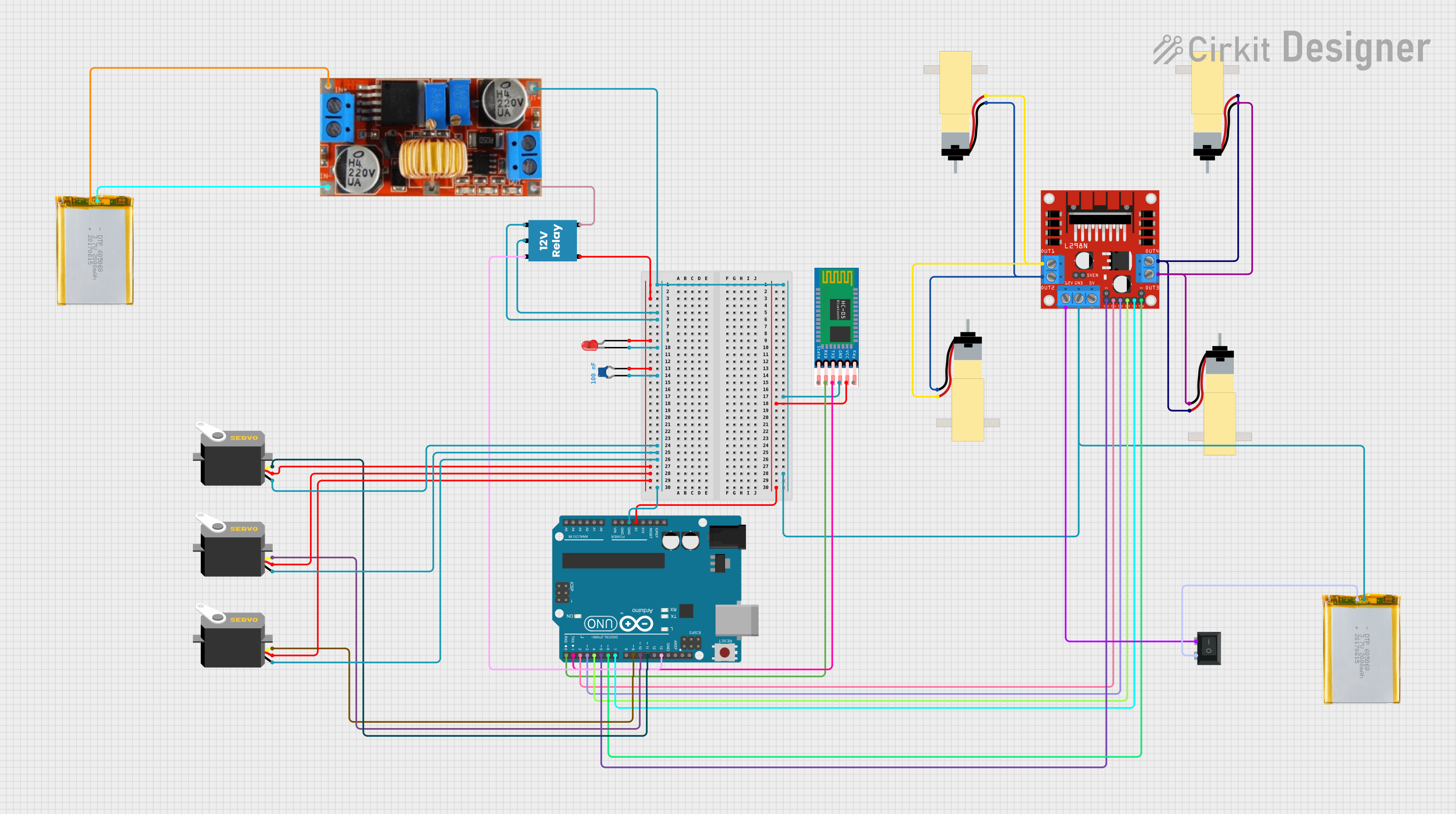

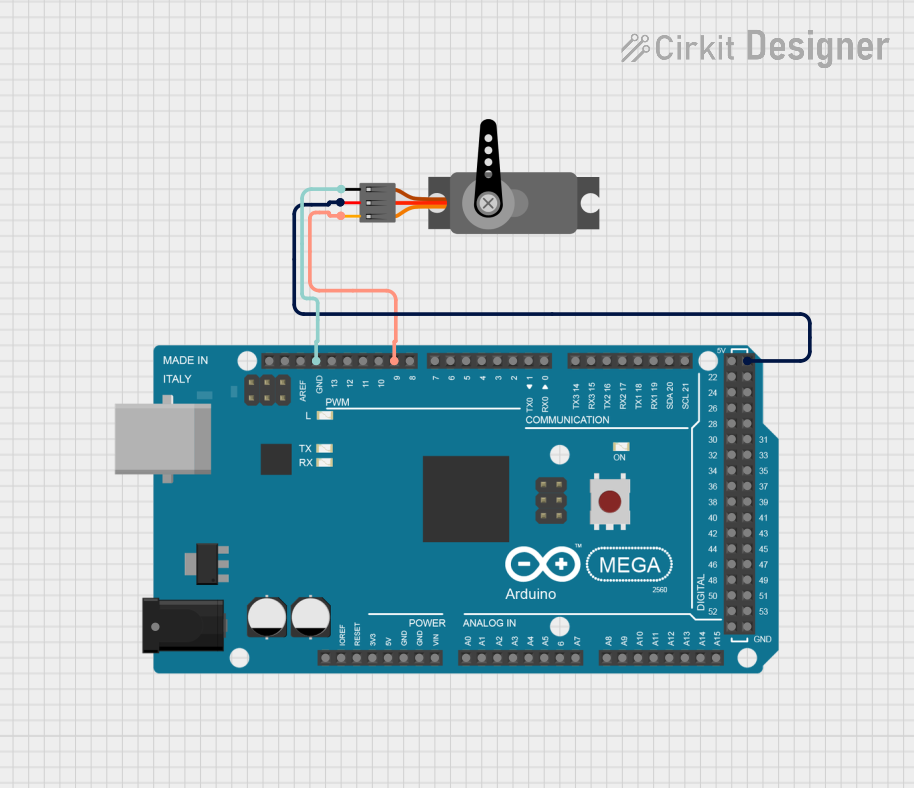

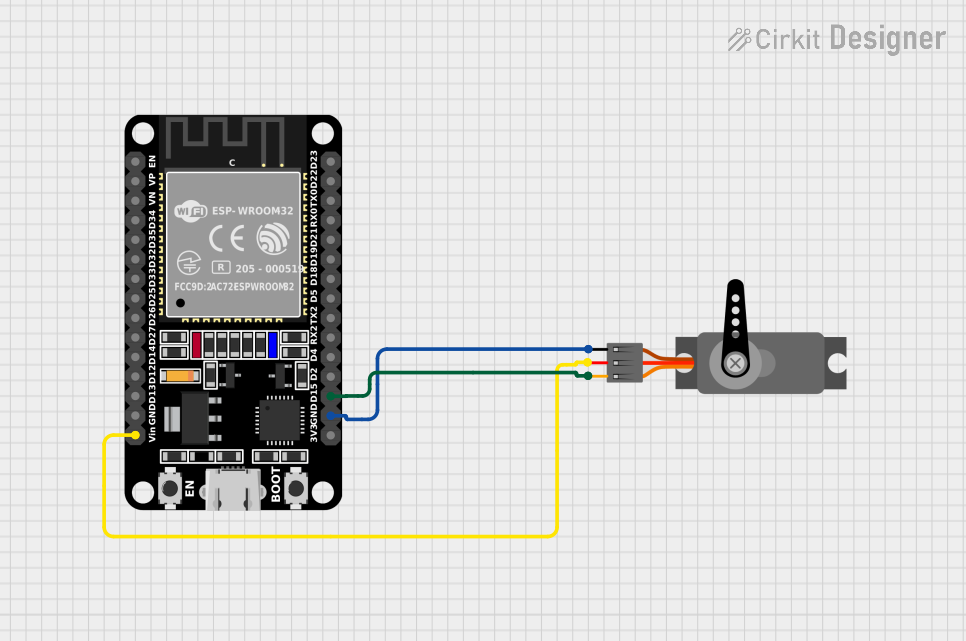

Explore Projects Built with servo motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with servo motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Below are the general technical specifications for a standard hobby servo motor (e.g., SG90 or MG996R). Specifications may vary depending on the specific model.

Key Technical Details

- Operating Voltage: 4.8V to 6V

- Operating Current: 100mA to 1A (depending on load)

- Torque:

- SG90: 1.8 kg·cm at 4.8V

- MG996R: 9.4 kg·cm at 6V

- Speed:

- SG90: 0.12 seconds/60° at 4.8V

- MG996R: 0.17 seconds/60° at 6V

- Control Signal: Pulse Width Modulation (PWM)

- Angle Range: 0° to 180° (typical for hobby servos)

- Weight:

- SG90: ~9g

- MG996R: ~55g

Pin Configuration and Descriptions

Servo motors typically have three wires for connection. The table below describes the pin configuration:

| Wire Color | Pin Name | Description |

|---|---|---|

| Red | VCC | Power supply input (4.8V to 6V). Connect to the positive terminal of the power source. |

| Brown/Black | GND | Ground connection. Connect to the negative terminal of the power source. |

| Orange/White | Signal (PWM) | Control signal input. Receives PWM signals to control the motor's position. |

Usage Instructions

How to Use the Servo Motor in a Circuit

Power the Servo Motor:

- Connect the red wire to a 5V or 6V power source (depending on the servo's specifications).

- Connect the black/brown wire to the ground (GND) of the power source.

- Ensure the power supply can provide sufficient current for the servo under load.

Connect the Signal Pin:

- Connect the signal wire (orange/white) to a PWM-capable pin on your microcontroller (e.g., Arduino UNO pin 9 or 10).

Control the Servo:

- Use PWM signals to control the servo's position. The pulse width determines the angle:

- 1ms pulse: ~0° position

- 1.5ms pulse: ~90° position (center)

- 2ms pulse: ~180° position

- Use PWM signals to control the servo's position. The pulse width determines the angle:

Important Considerations and Best Practices

- Power Supply: Use a separate power supply for the servo motor if it draws significant current, as powering it directly from the microcontroller may cause instability.

- PWM Signal: Ensure the PWM signal frequency is around 50Hz (20ms period) for standard hobby servos.

- Avoid Overloading: Do not exceed the torque rating of the servo, as this may damage the motor or reduce its lifespan.

- Mechanical Stops: Avoid forcing the servo beyond its physical limits (0° to 180°) to prevent damage.

Example Code for Arduino UNO

Below is an example of how to control a servo motor using an Arduino UNO and the Servo library:

#include <Servo.h> // Include the Servo library

Servo myServo; // Create a Servo object to control the servo motor

void setup() {

myServo.attach(9); // Attach the servo to pin 9 on the Arduino

}

void loop() {

myServo.write(0); // Move the servo to 0 degrees

delay(1000); // Wait for 1 second

myServo.write(90); // Move the servo to 90 degrees (center position)

delay(1000); // Wait for 1 second

myServo.write(180); // Move the servo to 180 degrees

delay(1000); // Wait for 1 second

}

Notes on the Code

- The

Servolibrary simplifies the process of generating PWM signals for the servo. - The

myServo.write(angle)function sets the servo to a specific angle (0° to 180°). - Ensure the servo is connected to a PWM-capable pin (e.g., pin 9 or 10 on the Arduino UNO).

Troubleshooting and FAQs

Common Issues and Solutions

Servo Motor Not Moving:

- Cause: Insufficient power supply.

- Solution: Use a power source that can provide adequate current (e.g., 4x AA batteries or a dedicated 5V power supply).

Servo Jitters or Unstable Movement:

- Cause: Electrical noise or insufficient power.

- Solution: Add a capacitor (e.g., 100µF) across the power supply terminals to stabilize the voltage.

Servo Overheating:

- Cause: Overloading or continuous operation at high torque.

- Solution: Reduce the load on the servo or allow it to rest periodically.

Servo Not Responding to PWM Signals:

- Cause: Incorrect wiring or incompatible PWM frequency.

- Solution: Verify the wiring and ensure the PWM frequency is set to 50Hz.

FAQs

Q: Can I control multiple servos with one Arduino?

- A: Yes, you can control multiple servos using the Servo library. However, ensure the power supply can handle the combined current draw of all servos.

Q: Can I rotate the servo beyond 180°?

- A: Standard hobby servos are limited to 0° to 180°. For continuous rotation, use a modified or continuous rotation servo.

Q: Why does my servo make a buzzing noise?

- A: This is normal when the servo is holding its position under load. However, excessive noise may indicate overloading or insufficient power.

By following this documentation, you can effectively integrate and troubleshoot a servo motor in your projects.