How to Use IGUS.D9: Examples, Pinouts, and Specs

Design with IGUS.D9 in Cirkit Designer

Design with IGUS.D9 in Cirkit DesignerIntroduction

The IGUS.D9 is a high-quality drag chain designed for cable management in dynamic and moving applications. Manufactured by IGUS, this component ensures the protection and organization of cables and hoses in automated machinery. Its robust design allows it to withstand repetitive motion, making it ideal for industrial environments where reliability and durability are critical.

Explore Projects Built with IGUS.D9

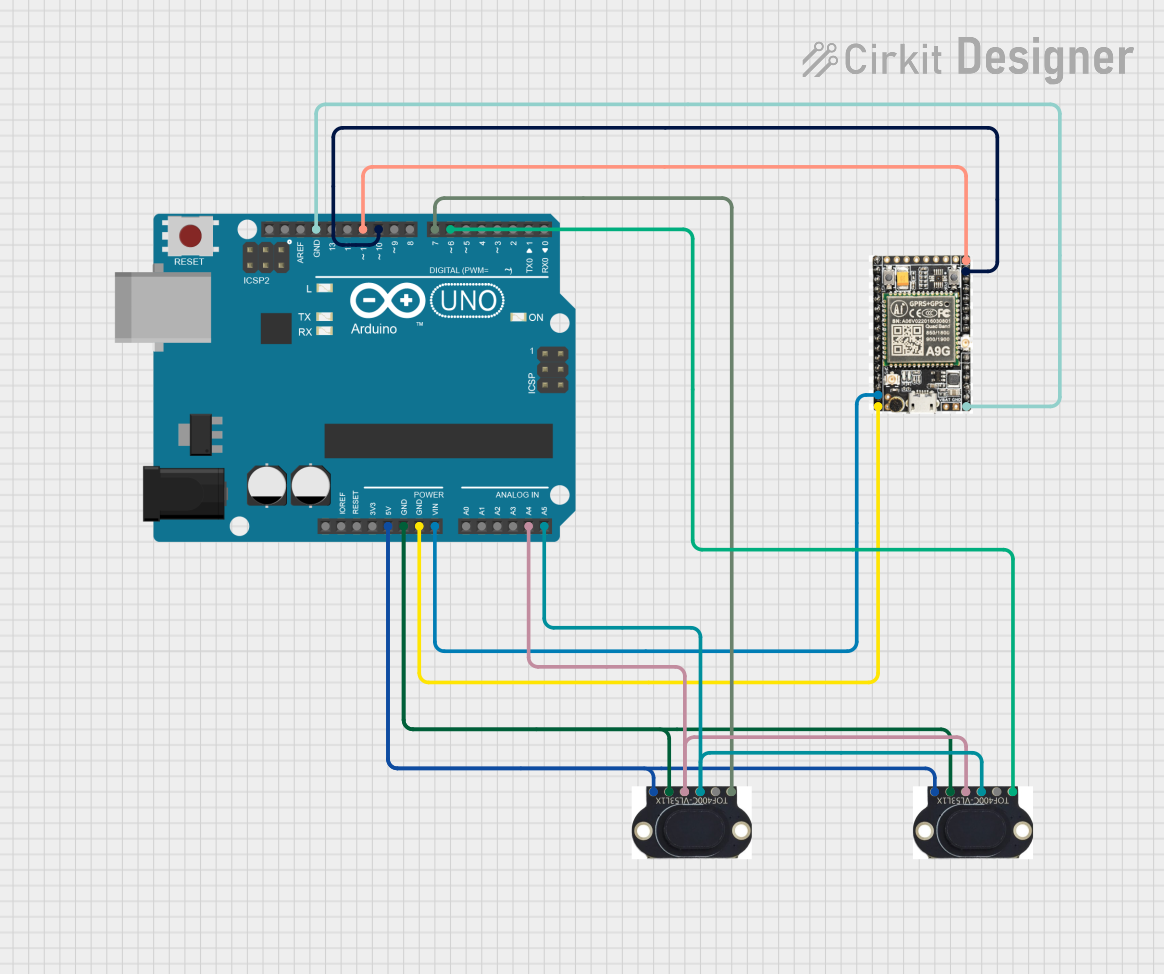

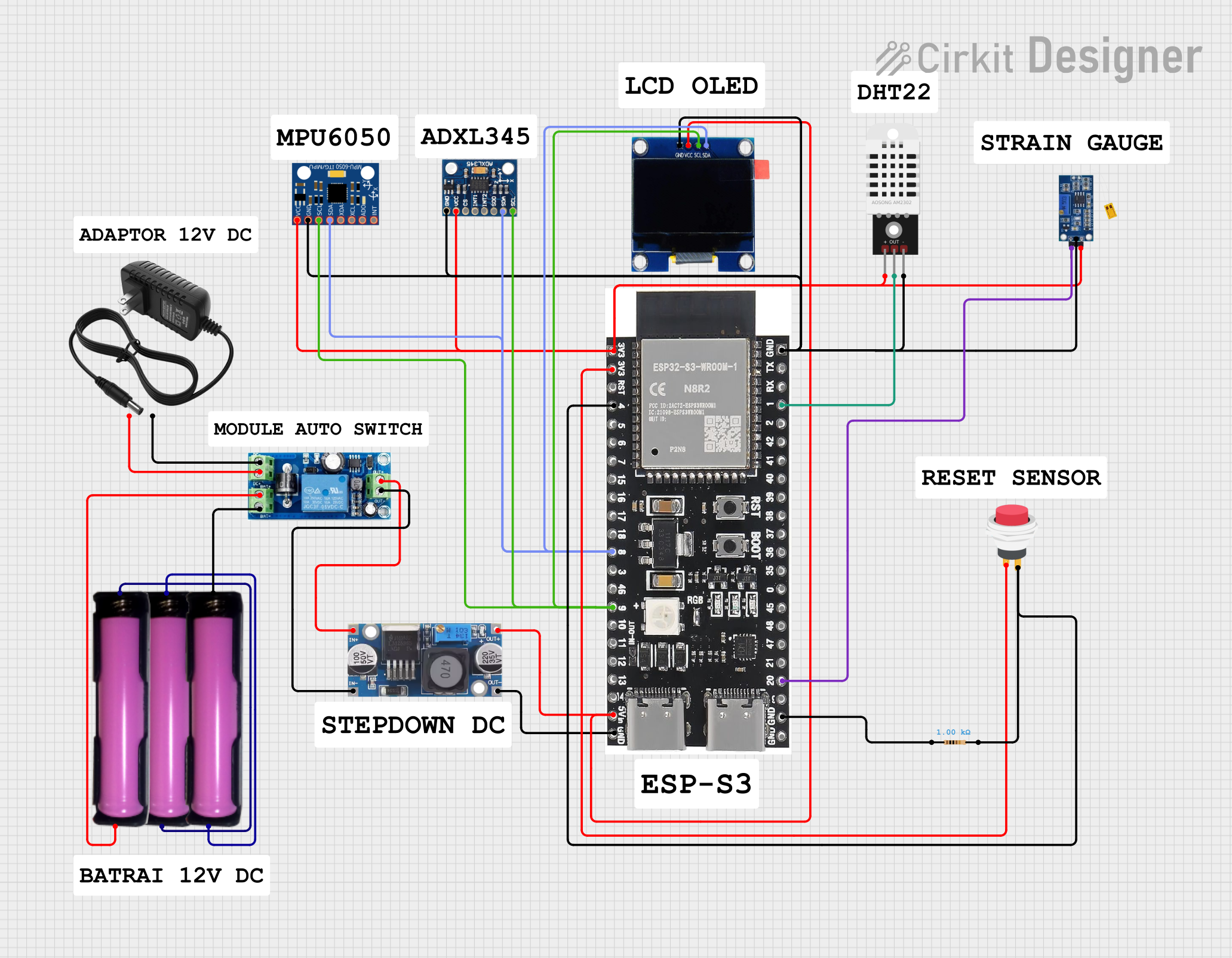

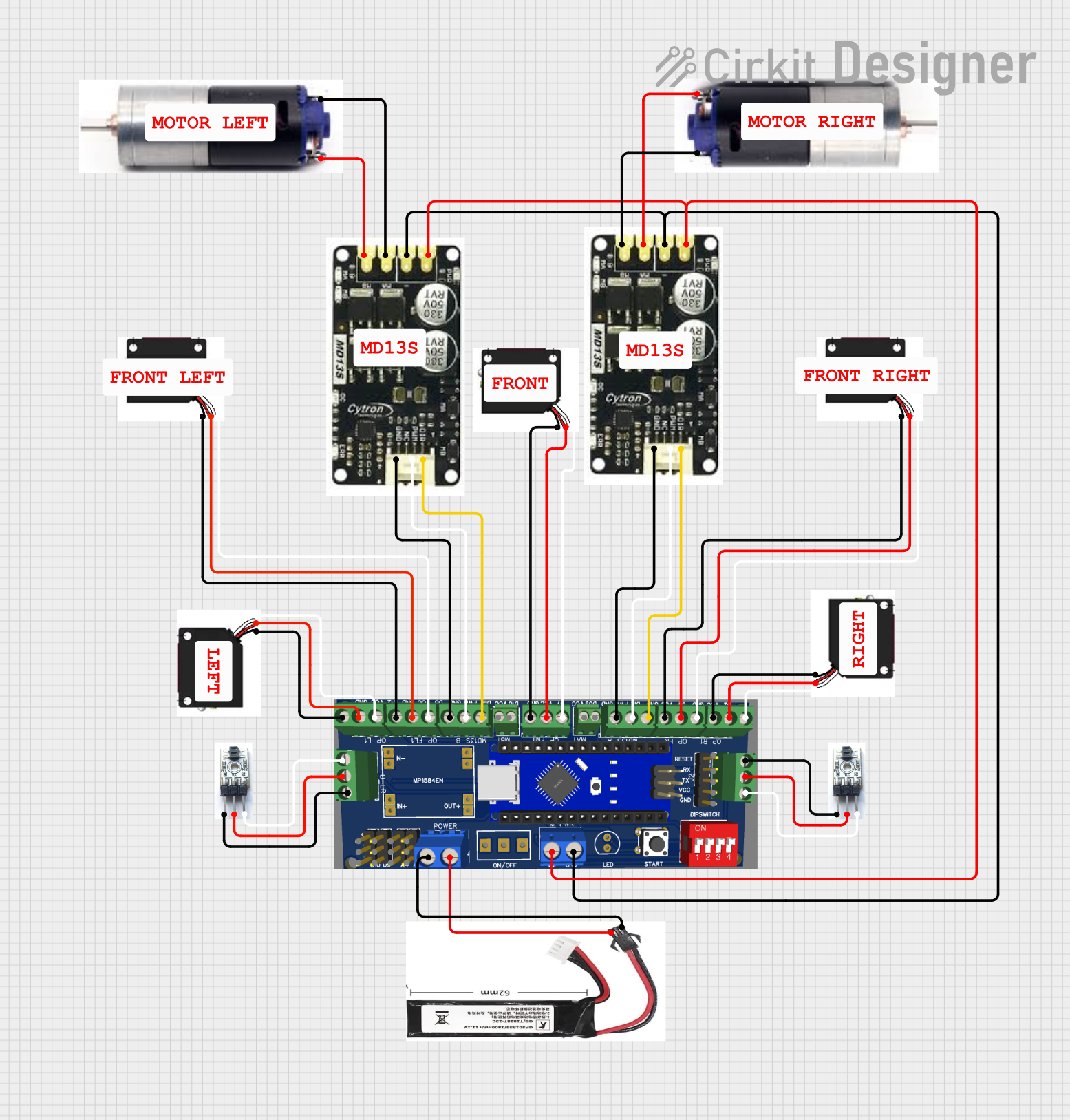

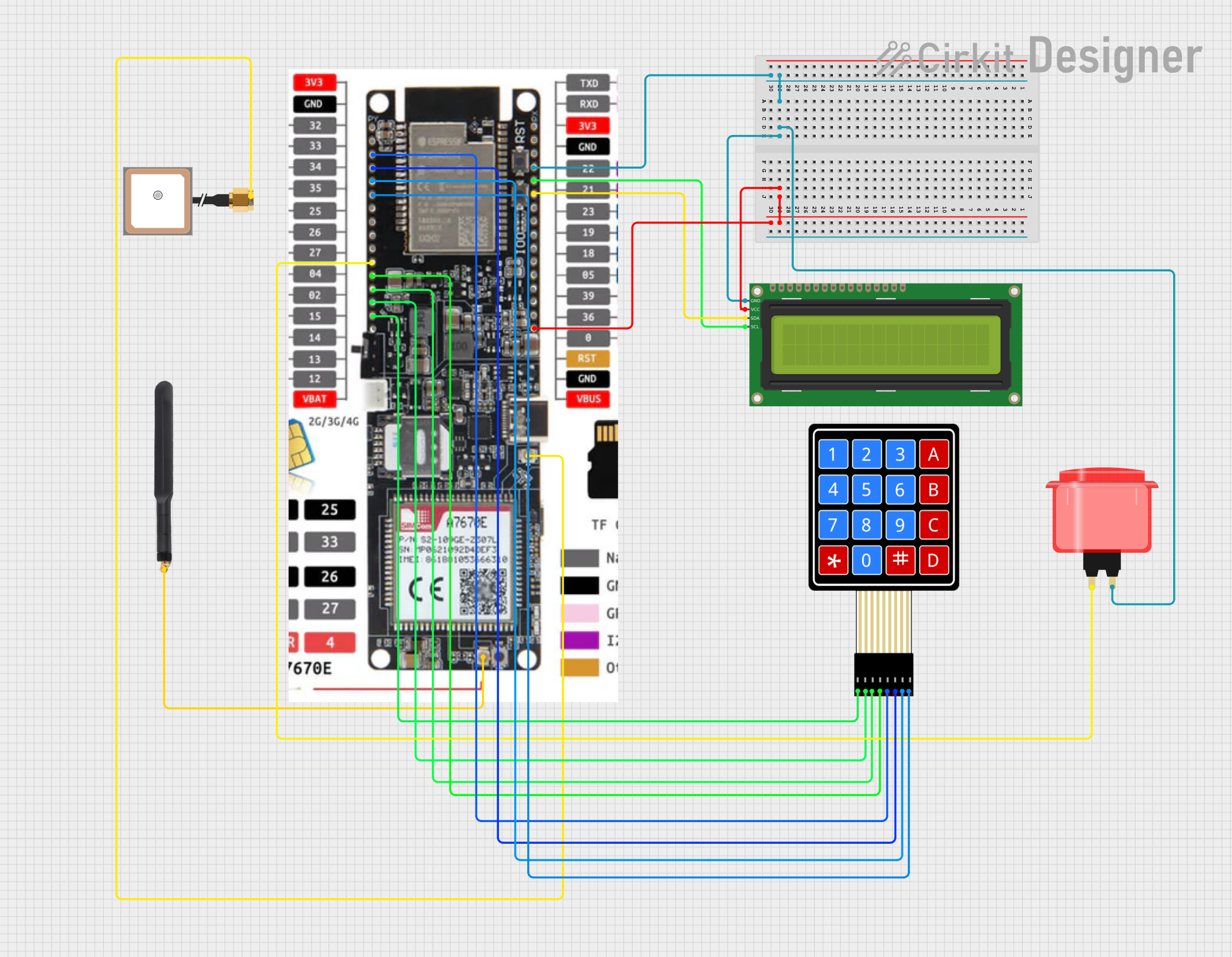

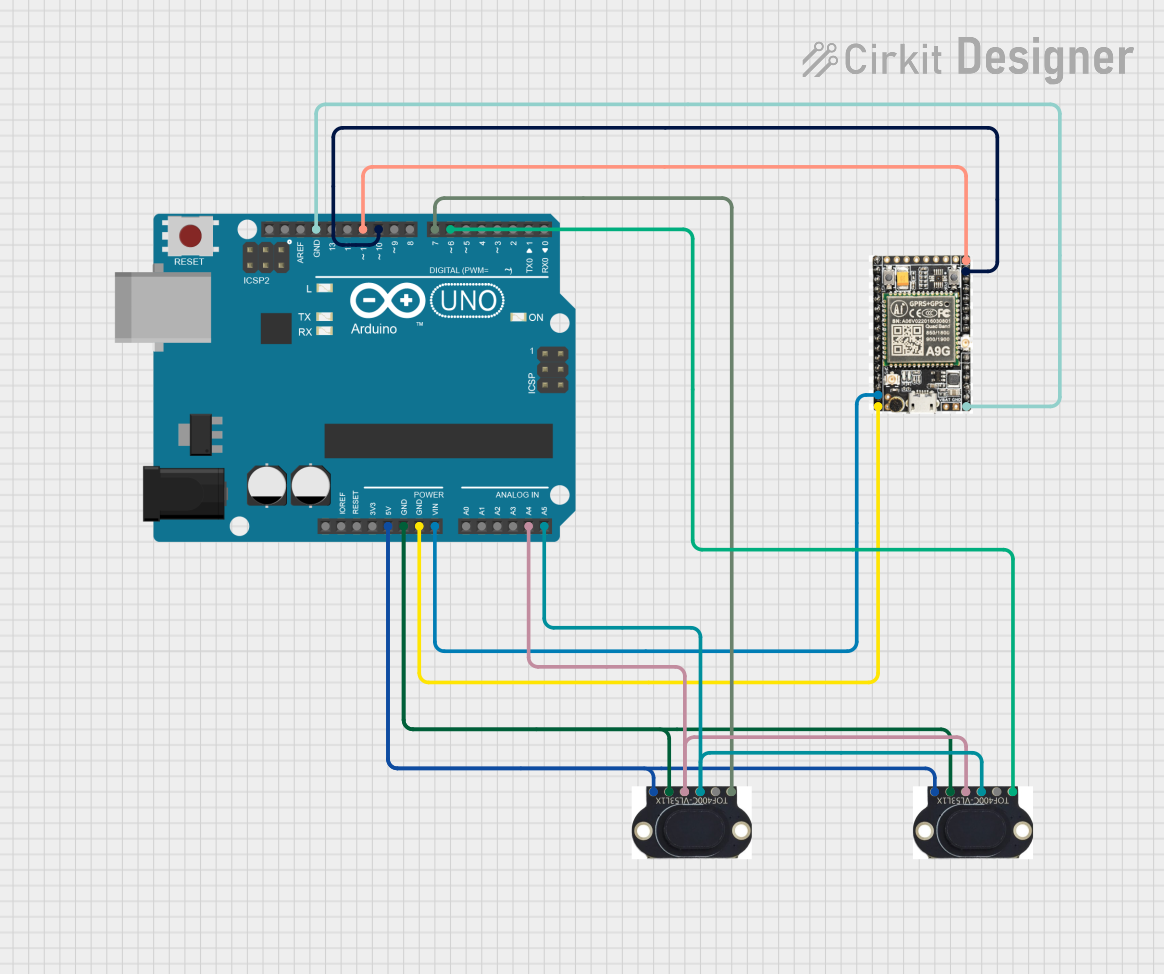

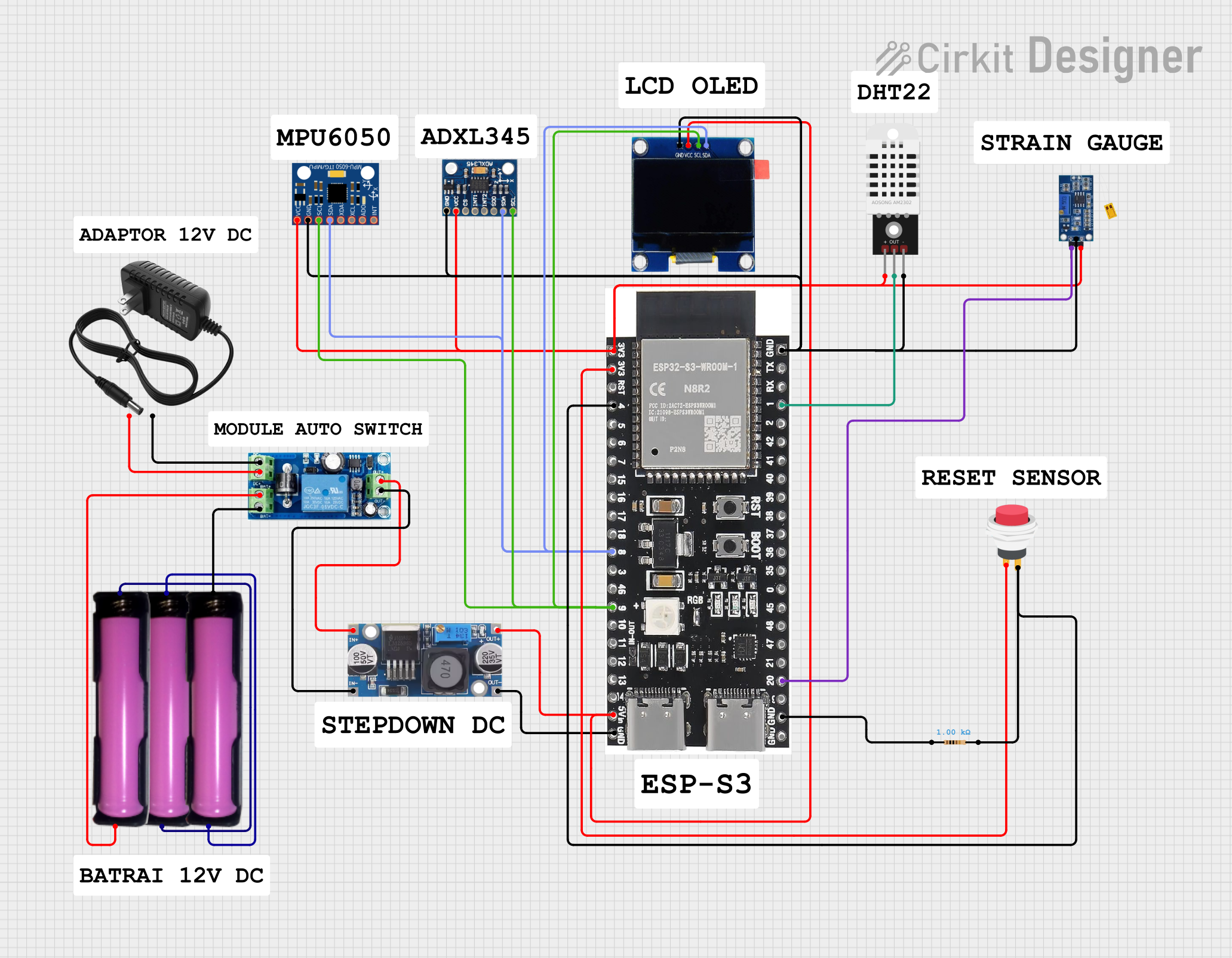

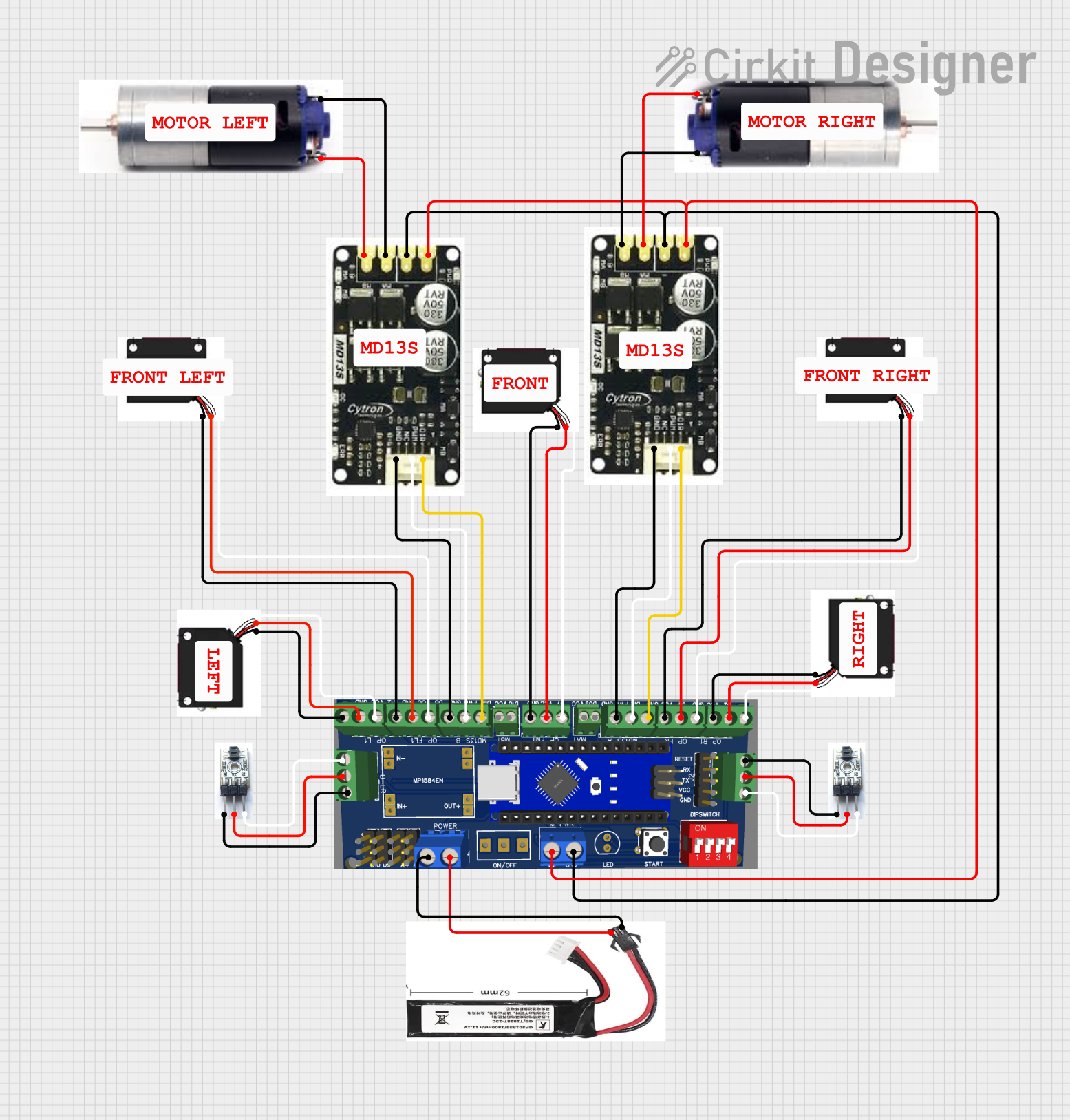

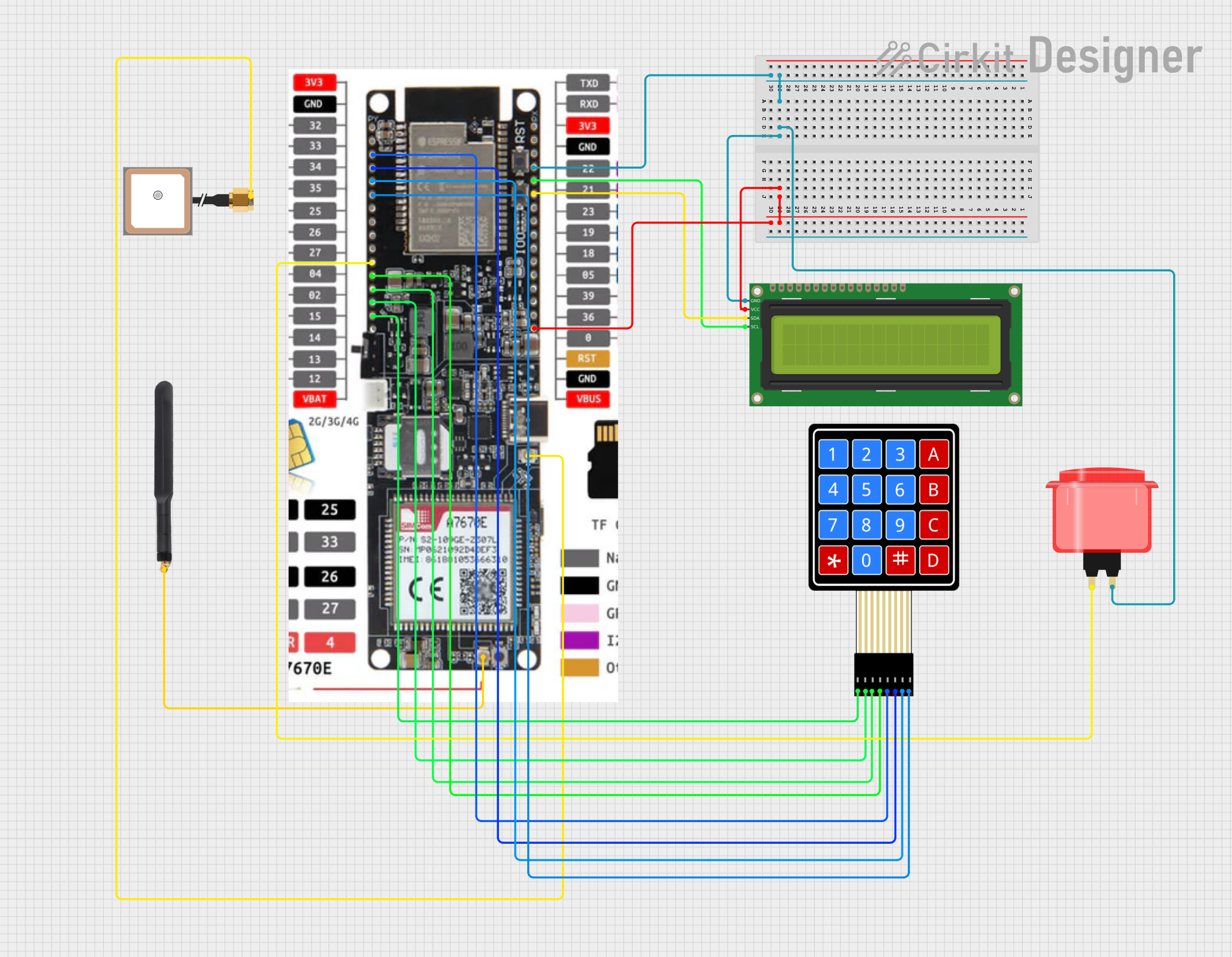

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with IGUS.D9

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Automated machinery: Protects cables and hoses in CNC machines, robotic arms, and conveyor systems.

- Industrial automation: Ensures smooth cable movement in assembly lines and production equipment.

- 3D printers: Manages cables for extruders and moving parts.

- Medical devices: Organizes and protects sensitive cables in diagnostic and treatment equipment.

- Material handling systems: Provides cable protection in cranes, lifts, and other moving systems.

Technical Specifications

The IGUS.D9 drag chain is designed to meet the demands of high-performance applications. Below are its key technical specifications:

General Specifications

| Parameter | Value |

|---|---|

| Manufacturer | IGUS |

| Part ID | D9 |

| Material | High-performance polymer |

| Operating Temperature | -40°C to +80°C |

| Inner Width | 9 mm |

| Outer Width | 15 mm |

| Inner Height | 10 mm |

| Bend Radius | 28 mm |

| Maximum Travel Speed | 10 m/s |

| Maximum Acceleration | 50 m/s² |

| Cable Capacity | Up to 3 cables (depending on size) |

Pin Configuration and Descriptions

The IGUS.D9 drag chain does not have electrical pins, as it is a mechanical component. However, its modular design includes the following key features:

| Feature | Description |

|---|---|

| Chain Links | Interlocking links that form the drag chain, allowing flexibility and strength. |

| Mounting Brackets | End brackets for securing the drag chain to stationary or moving parts. |

| Cable Compartments | Internal space for organizing and protecting cables or hoses. |

| Snap-Open Design | Allows easy access for cable installation and maintenance. |

Usage Instructions

The IGUS.D9 drag chain is straightforward to use and install. Follow these steps and best practices to ensure optimal performance:

Installation Steps

Determine the cable layout:

- Identify the cables or hoses to be routed through the drag chain.

- Ensure the cables are flexible and suitable for dynamic applications.

Assemble the drag chain:

- Connect the individual chain links to achieve the desired length.

- Use the snap-open feature to access the internal compartments.

Route the cables:

- Place the cables inside the drag chain, ensuring they are not twisted or overly tight.

- Leave some slack to accommodate movement and prevent strain.

Secure the drag chain:

- Attach the mounting brackets to the ends of the drag chain.

- Fix the brackets to the stationary and moving parts of the machinery.

Test the movement:

- Move the machinery through its full range of motion to ensure the drag chain operates smoothly.

- Check for any obstructions or excessive tension on the cables.

Important Considerations and Best Practices

- Cable selection: Use cables with a small bending radius and high flexibility to prevent damage.

- Avoid overloading: Do not exceed the drag chain's cable capacity or weight limits.

- Regular maintenance: Periodically inspect the drag chain for wear, damage, or debris.

- Proper alignment: Ensure the drag chain is aligned with the direction of movement to avoid twisting or binding.

Arduino UNO Integration

While the IGUS.D9 drag chain is not an electronic component, it can be used in projects involving Arduino UNO to manage cables for motors, sensors, or other peripherals. Below is an example of how to use the drag chain in a robotic arm project:

// Example: Controlling a robotic arm with cable management using IGUS.D9 drag chain

#include <Servo.h> // Include the Servo library for motor control

Servo baseServo; // Servo for the base rotation

Servo armServo; // Servo for the arm movement

void setup() {

baseServo.attach(9); // Attach base servo to pin 9

armServo.attach(10); // Attach arm servo to pin 10

// Initialize servos to their starting positions

baseServo.write(90); // Set base servo to 90 degrees

armServo.write(90); // Set arm servo to 90 degrees

}

void loop() {

// Example movement: Rotate base and move arm

baseServo.write(45); // Rotate base to 45 degrees

delay(1000); // Wait for 1 second

armServo.write(120); // Move arm to 120 degrees

delay(1000); // Wait for 1 second

// Return to starting position

baseServo.write(90); // Rotate base back to 90 degrees

armServo.write(90); // Move arm back to 90 degrees

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Drag chain is not moving smoothly | Misalignment or obstruction | Check alignment and remove any obstructions. |

| Cables are damaged | Excessive tension or improper routing | Ensure cables have enough slack and are properly routed. |

| Chain links are breaking | Overloading or excessive wear | Reduce cable weight and inspect for wear. |

| Mounting brackets are loose | Improper installation | Tighten the brackets and ensure secure attachment. |

FAQs

Q: Can the IGUS.D9 drag chain be used outdoors?

A: Yes, the IGUS.D9 is made of high-performance polymer that is resistant to UV and weather conditions, making it suitable for outdoor use.

Q: How do I determine the correct bend radius for my application?

A: The bend radius should be at least 10 times the diameter of the largest cable or hose in the drag chain.

Q: Can I cut the drag chain to a custom length?

A: Yes, the IGUS.D9 drag chain is modular and can be easily cut or extended to fit your specific requirements.

Q: What maintenance is required for the drag chain?

A: Regularly inspect the drag chain for wear, debris, and proper cable routing. Clean and replace any damaged links as needed.