How to Use TGS 822: Examples, Pinouts, and Specs

Design with TGS 822 in Cirkit Designer

Design with TGS 822 in Cirkit DesignerIntroduction

The TGS 822 is a gas sensor designed to detect various combustible gases, including methane, propane, and other hydrocarbons. It operates on the principle of conductivity change in its sensing element when exposed to target gases. This sensor is widely used in safety systems, environmental monitoring, and industrial applications where gas detection is critical. Its high sensitivity and reliability make it a popular choice for gas leak detection and air quality monitoring systems.

Explore Projects Built with TGS 822

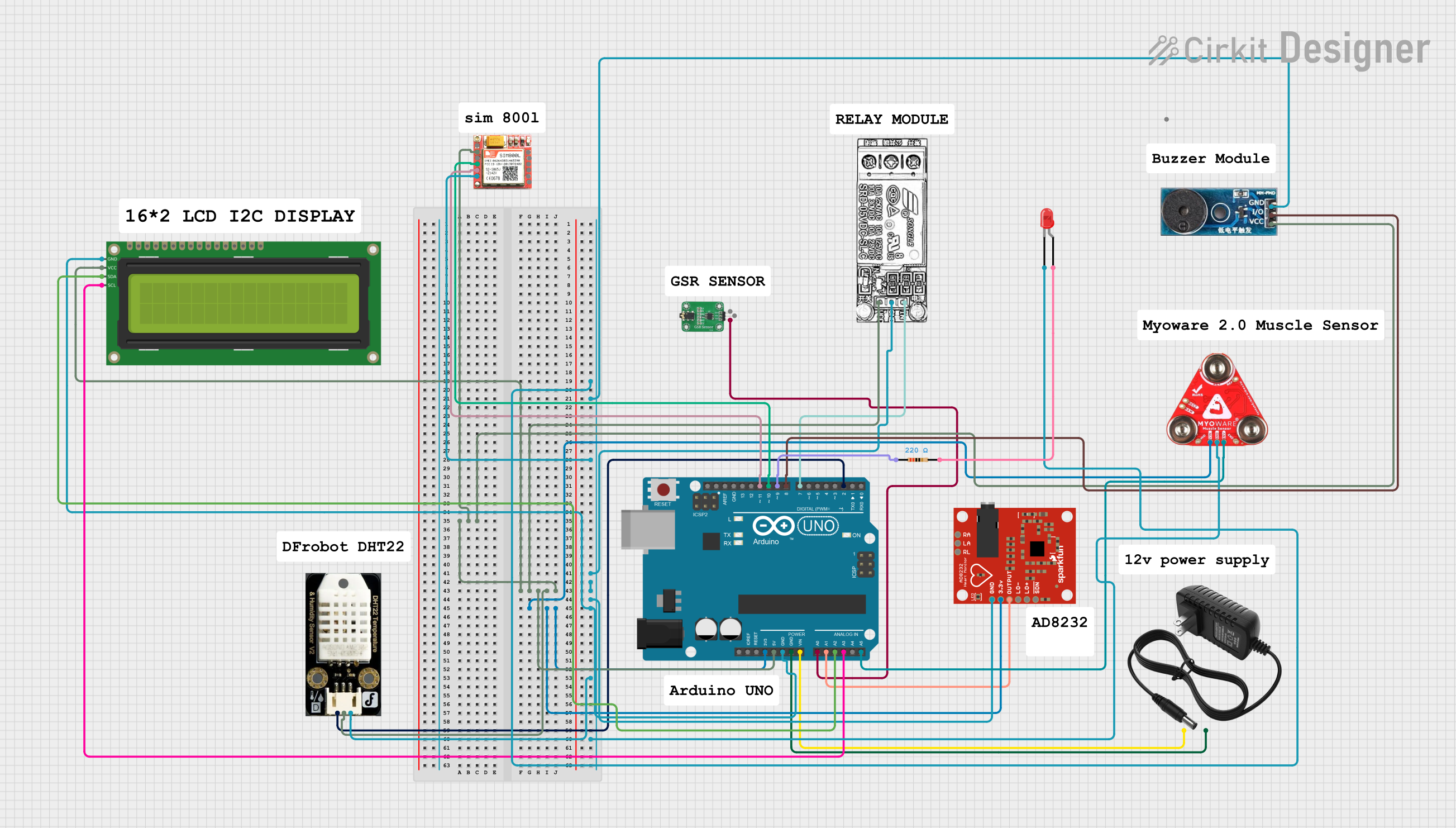

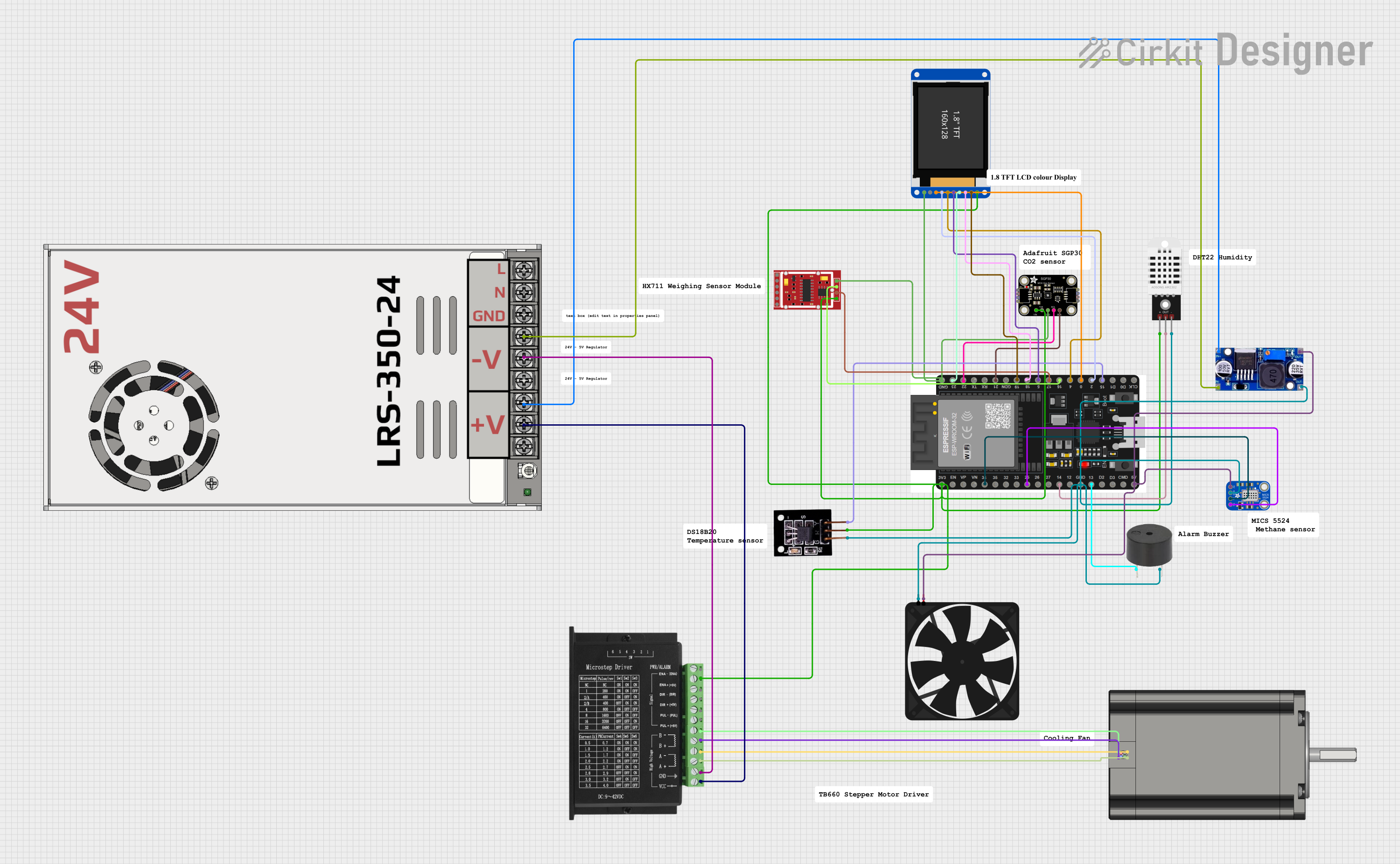

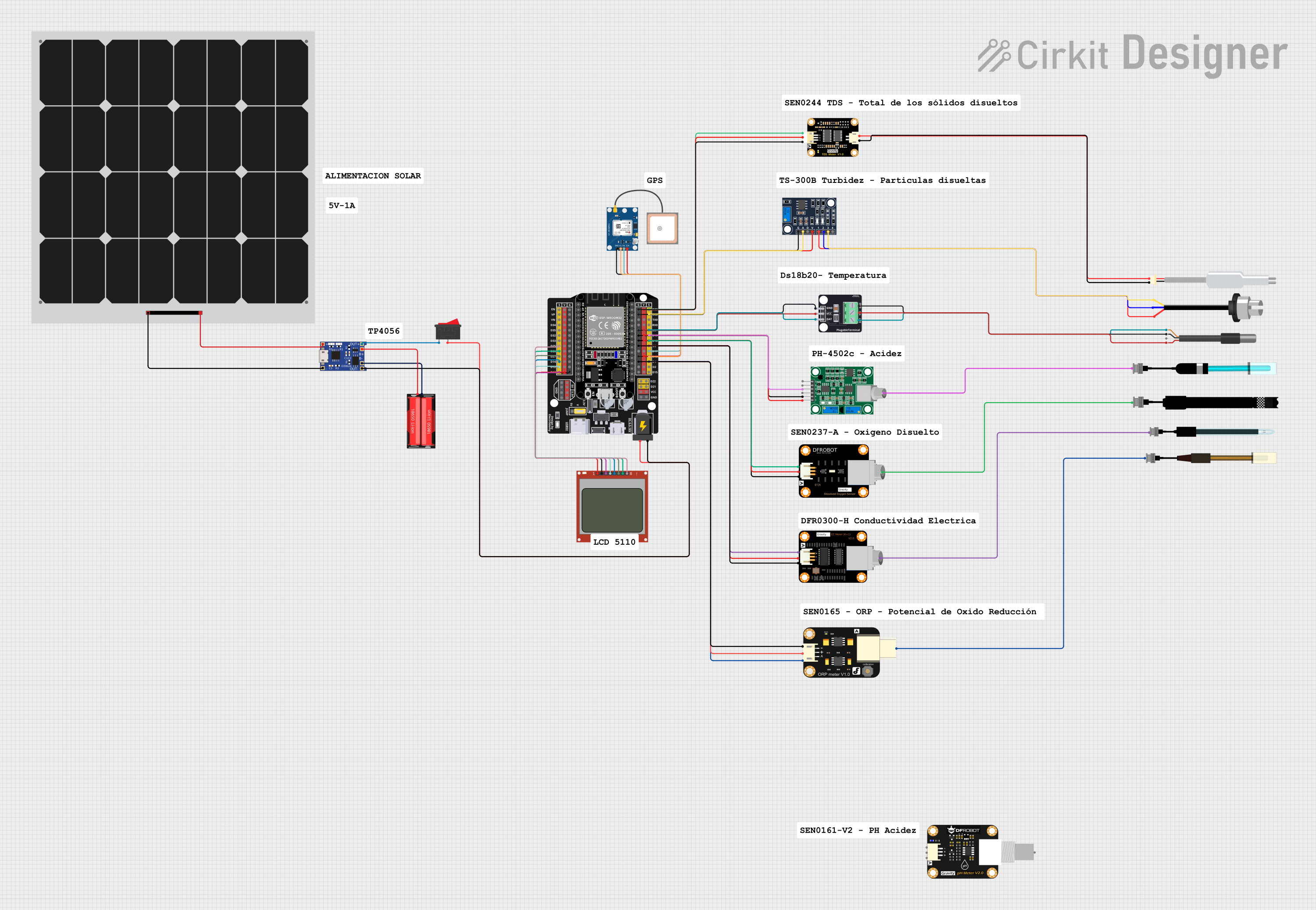

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

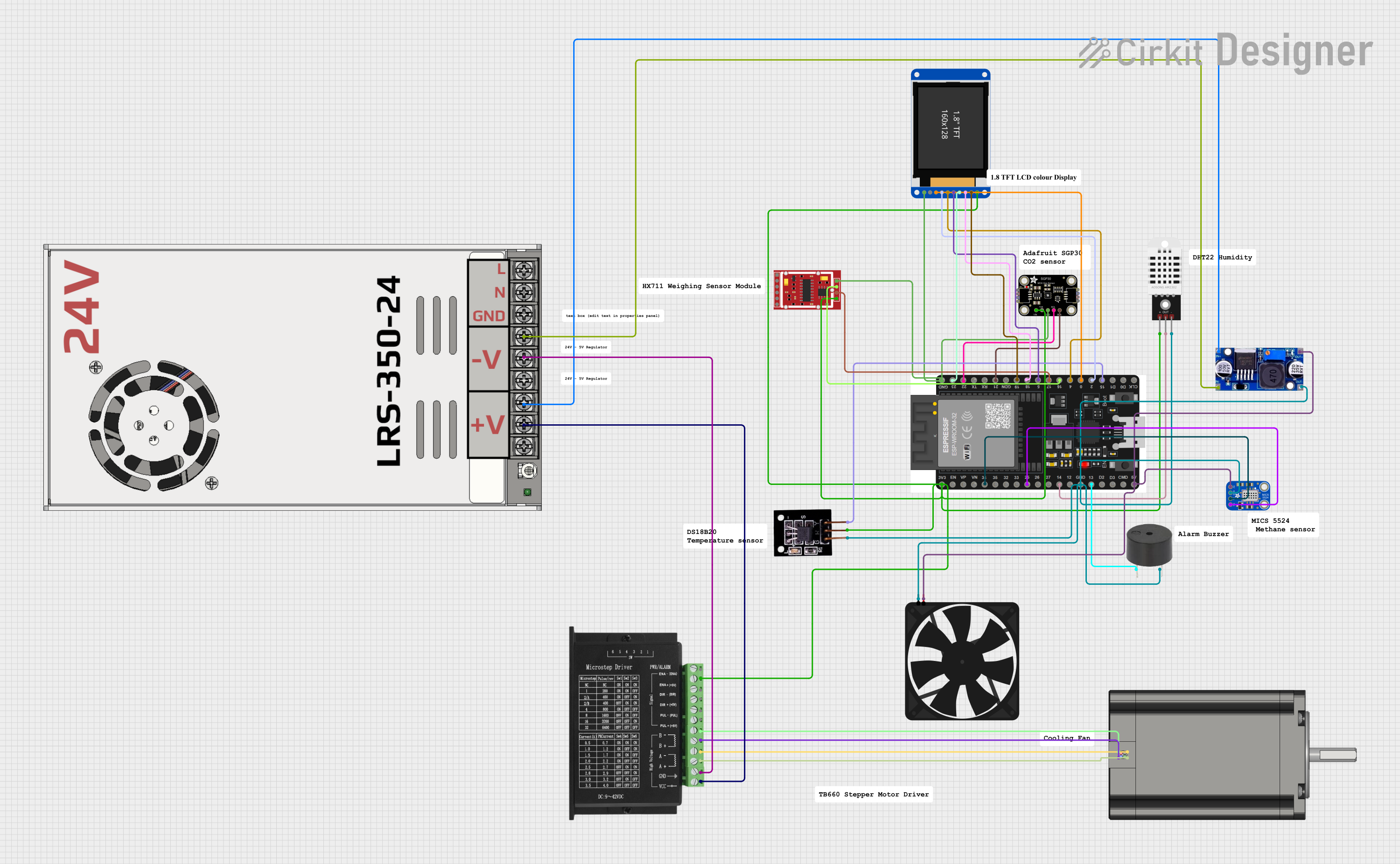

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with TGS 822

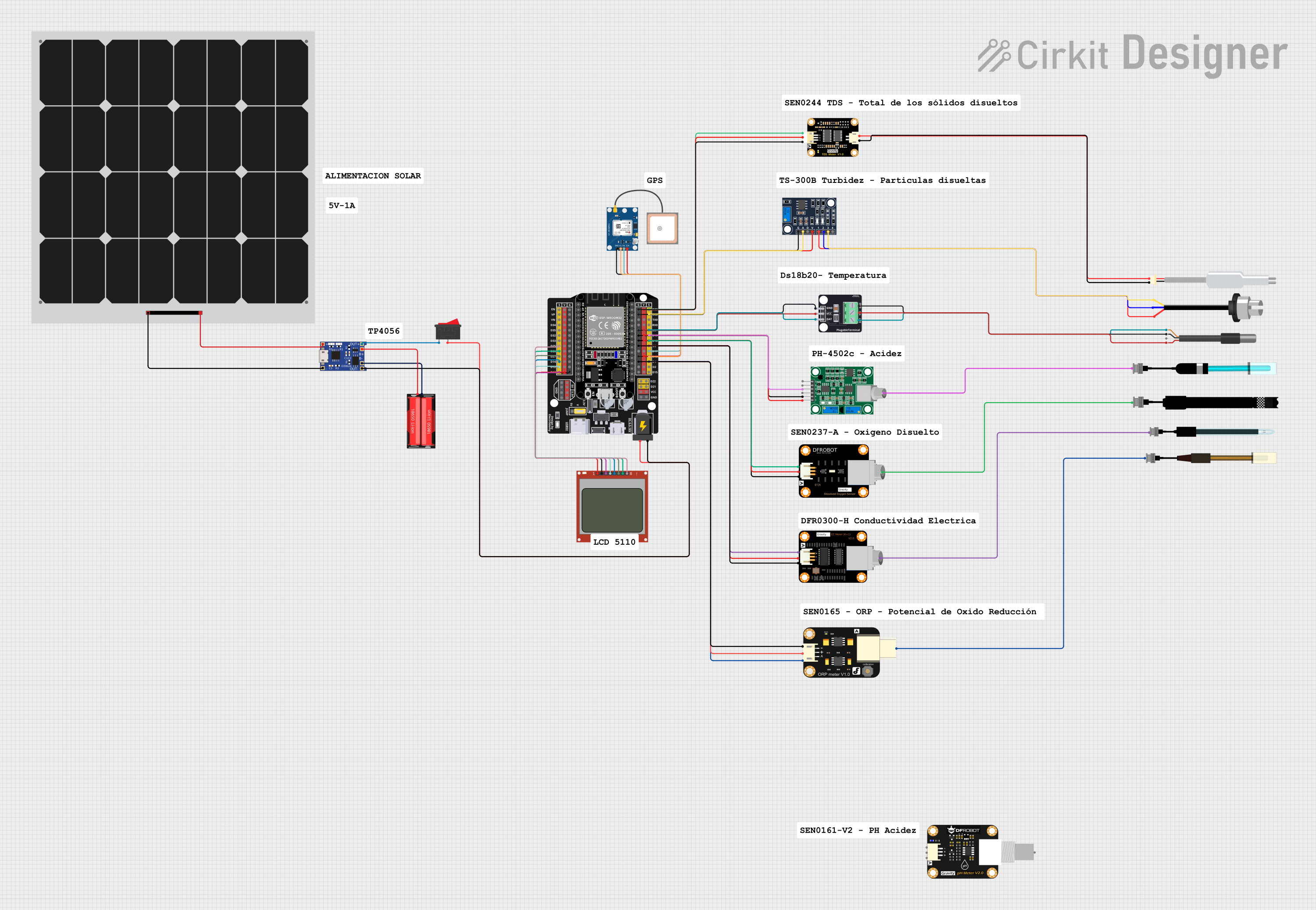

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

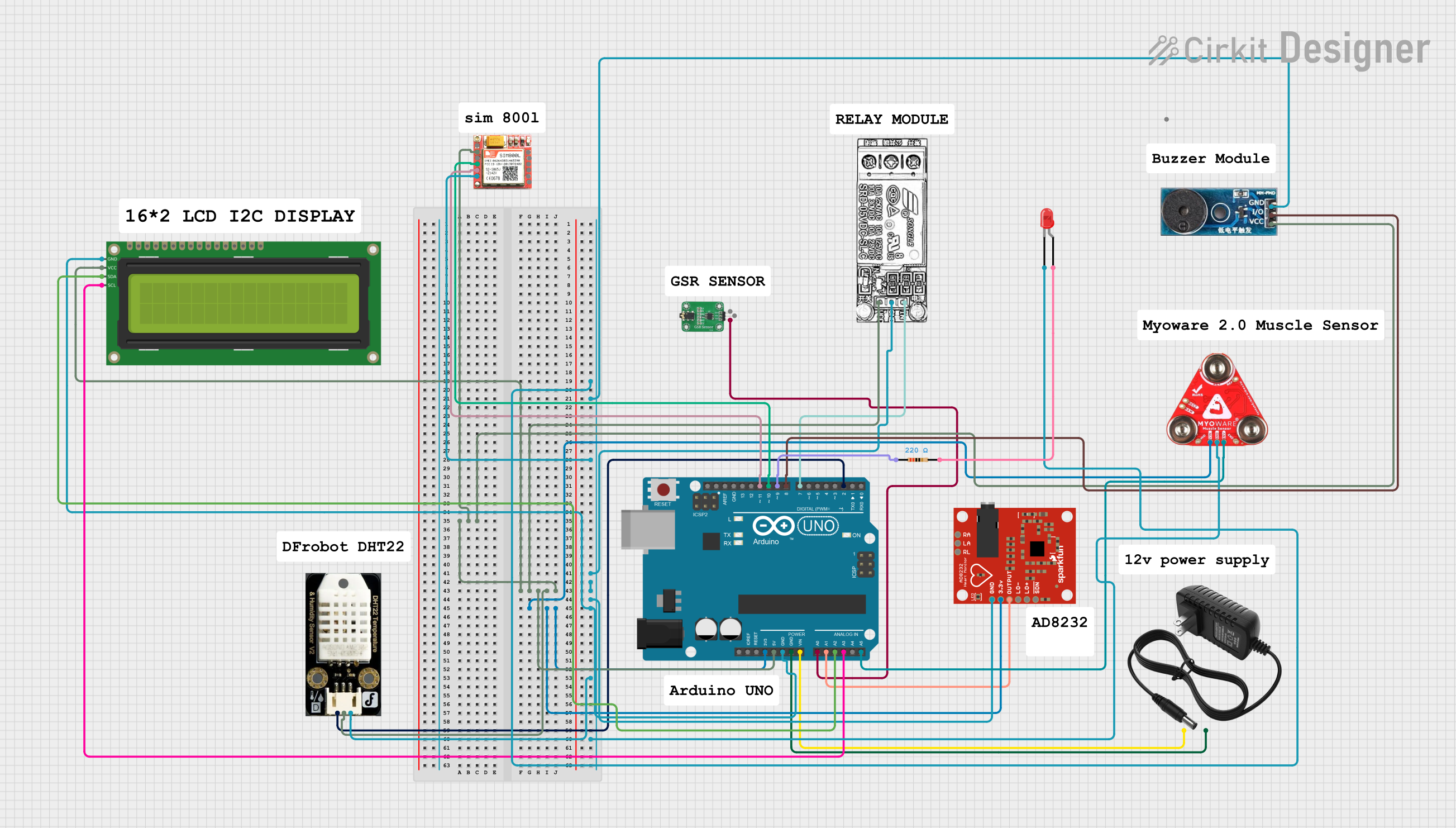

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Gas leak detection in residential and industrial environments

- Air quality monitoring systems

- Combustible gas detection in safety equipment

- Environmental monitoring for hazardous gases

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Target Gases | Methane, Propane, Combustible Gases |

| Operating Voltage | 5V DC |

| Heater Voltage (VH) | 5V ± 0.2V |

| Heater Current (IH) | 170mA (typical) |

| Sensing Resistance (Rs) | 10kΩ to 100kΩ (in clean air) |

| Preheat Time | Over 24 hours (recommended) |

| Operating Temperature | -10°C to 50°C |

| Humidity Range | 95% RH or less (non-condensing) |

| Dimensions | 16mm diameter, 17mm height |

Pin Configuration and Descriptions

The TGS 822 sensor has six pins, as shown in the table below:

| Pin Number | Label | Description |

|---|---|---|

| 1 | H1 | Heater pin 1 (connect to 5V supply) |

| 2 | A | Sensing element pin (connect to load resistor) |

| 3 | B | Sensing element pin (connect to load resistor) |

| 4 | H2 | Heater pin 2 (connect to ground) |

| 5, 6 | NC | Not connected |

Note: Pins 2 (A) and 3 (B) are interchangeable, as they are connected to the same sensing element.

Usage Instructions

How to Use the TGS 822 in a Circuit

- Power the Heater: Connect pin H1 to a 5V DC power supply and pin H2 to ground. This powers the internal heater, which is necessary for the sensor to operate.

- Connect the Sensing Element: Use a load resistor (typically 10kΩ) between pins A and B. The voltage across the load resistor will vary depending on the concentration of the target gas.

- Read the Output: Measure the voltage across the load resistor using an analog-to-digital converter (ADC) or a microcontroller. The output voltage decreases as the gas concentration increases.

- Calibrate the Sensor: Allow the sensor to preheat for at least 24 hours before use. Perform calibration in clean air to determine the baseline resistance (Rs in clean air).

Important Considerations and Best Practices

- Preheat Time: Ensure the sensor is preheated for at least 24 hours before initial use to stabilize its performance.

- Load Resistor Selection: Choose an appropriate load resistor value (typically 10kΩ) based on your application and the expected gas concentration range.

- Ventilation: Install the sensor in a well-ventilated area to avoid saturation and ensure accurate readings.

- Avoid Contaminants: Protect the sensor from exposure to water, dust, and corrosive gases, as these can degrade its performance.

- Arduino Integration: The TGS 822 can be easily interfaced with an Arduino UNO for gas detection applications.

Example Arduino Code

// TGS 822 Gas Sensor Example Code

// This code reads the analog output of the TGS 822 and prints the gas level

// to the serial monitor. Ensure the sensor is connected to the correct pins.

const int sensorPin = A0; // Analog pin connected to the sensor's output

const int loadResistor = 10000; // Load resistor value in ohms (10kΩ)

void setup() {

Serial.begin(9600); // Initialize serial communication at 9600 baud

pinMode(sensorPin, INPUT); // Set the sensor pin as input

}

void loop() {

int sensorValue = analogRead(sensorPin); // Read the analog value

float voltage = sensorValue * (5.0 / 1023.0); // Convert to voltage

float gasConcentration = (voltage / loadResistor) * 1000;

// Estimate gas concentration (arbitrary units)

Serial.print("Sensor Voltage: ");

Serial.print(voltage);

Serial.println(" V");

Serial.print("Gas Concentration: ");

Serial.print(gasConcentration);

Serial.println(" (arbitrary units)");

delay(1000); // Wait 1 second before the next reading

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output or Incorrect Readings:

- Cause: The sensor may not have been preheated for the recommended 24 hours.

- Solution: Allow the sensor to preheat for the full duration before use.

Fluctuating Readings:

- Cause: Electrical noise or unstable power supply.

- Solution: Use a decoupling capacitor (e.g., 0.1µF) across the power supply pins to stabilize the voltage.

Sensor Saturation:

- Cause: Exposure to high concentrations of gas for extended periods.

- Solution: Ventilate the area and allow the sensor to recover in clean air.

Sensor Not Responding to Gas:

- Cause: Incorrect wiring or damaged sensor.

- Solution: Verify the wiring and ensure the sensor is not physically damaged.

FAQs

Q: Can the TGS 822 detect gases other than methane and propane?

A: Yes, the TGS 822 can detect a range of combustible gases, but its sensitivity varies depending on the gas type.

Q: How long does the sensor last?

A: The sensor has a typical lifespan of 5 years under normal operating conditions.

Q: Can I use the TGS 822 outdoors?

A: While the sensor can operate outdoors, it should be protected from water, dust, and extreme environmental conditions to ensure reliable performance.

Q: What is the recommended load resistor value?

A: A 10kΩ resistor is commonly used, but the value can be adjusted based on the application and desired sensitivity.