How to Use ADXL375 High G Accelerometer: Examples, Pinouts, and Specs

Design with ADXL375 High G Accelerometer in Cirkit Designer

Design with ADXL375 High G Accelerometer in Cirkit DesignerADXL375 High G Accelerometer Documentation

1. Introduction

The ADXL375 is a high-performance, 3-axis digital accelerometer designed to measure acceleration forces up to ±200g. It is ideal for applications requiring high sensitivity, precision, and the ability to withstand extreme acceleration forces. The device communicates via an SPI or I²C digital interface, making it easy to integrate into a wide range of systems.

Common Applications

- Impact and shock detection

- Sports equipment performance monitoring

- Industrial vibration analysis

- Automotive crash testing

- Aerospace and defense systems

- Wearable devices for motion tracking

The ADXL375 is a robust and versatile sensor, offering high-resolution acceleration data in a compact package.

2. Technical Specifications

The following table outlines the key technical details of the ADXL375:

| Parameter | Value |

|---|---|

| Measurement Range | ±200g |

| Sensitivity | 0.049 g/LSB |

| Supply Voltage (VDD) | 2.0V to 3.6V |

| Interface | SPI (4-wire) / I²C |

| Output Data Rate (ODR) | 0.1 Hz to 3200 Hz |

| Operating Temperature Range | -40°C to +85°C |

| Power Consumption | 140 µA (typical at 2.5V, 100 Hz) |

| Dimensions | 3 mm × 5 mm × 1 mm (LGA package) |

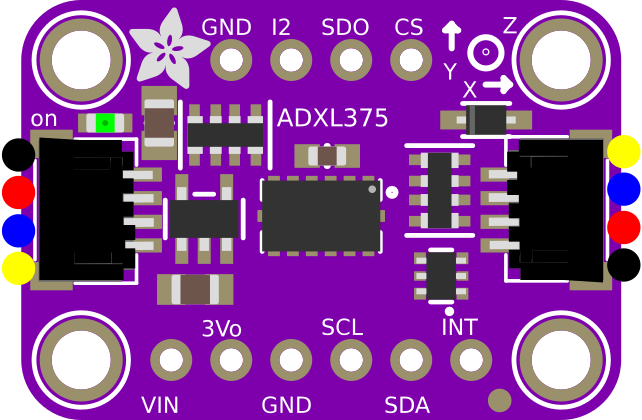

Pin Configuration and Descriptions

The ADXL375 is available in a 14-pin LGA package. The pinout and descriptions are as follows:

| Pin | Name | Description |

|---|---|---|

| 1 | VDD | Power supply input (2.0V to 3.6V). |

| 2 | GND | Ground reference. |

| 3 | CS | Chip Select (active low). Used to select the device in SPI mode. |

| 4 | SCL/SCLK | Serial Clock. Used for I²C or SPI communication. |

| 5 | SDA/SDI | Serial Data Input (I²C) or Data Input (SPI). |

| 6 | SDO/ALT | Serial Data Output (SPI) or Alternate Address Select (I²C). |

| 7-14 | NC | No connection. These pins should be left unconnected or tied to ground. |

3. Usage Instructions

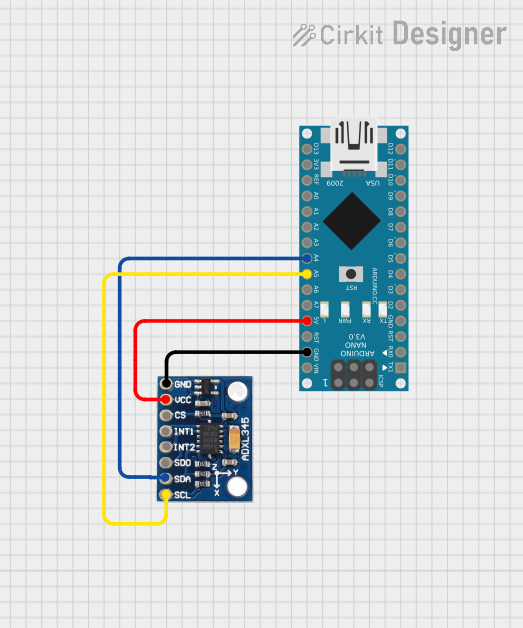

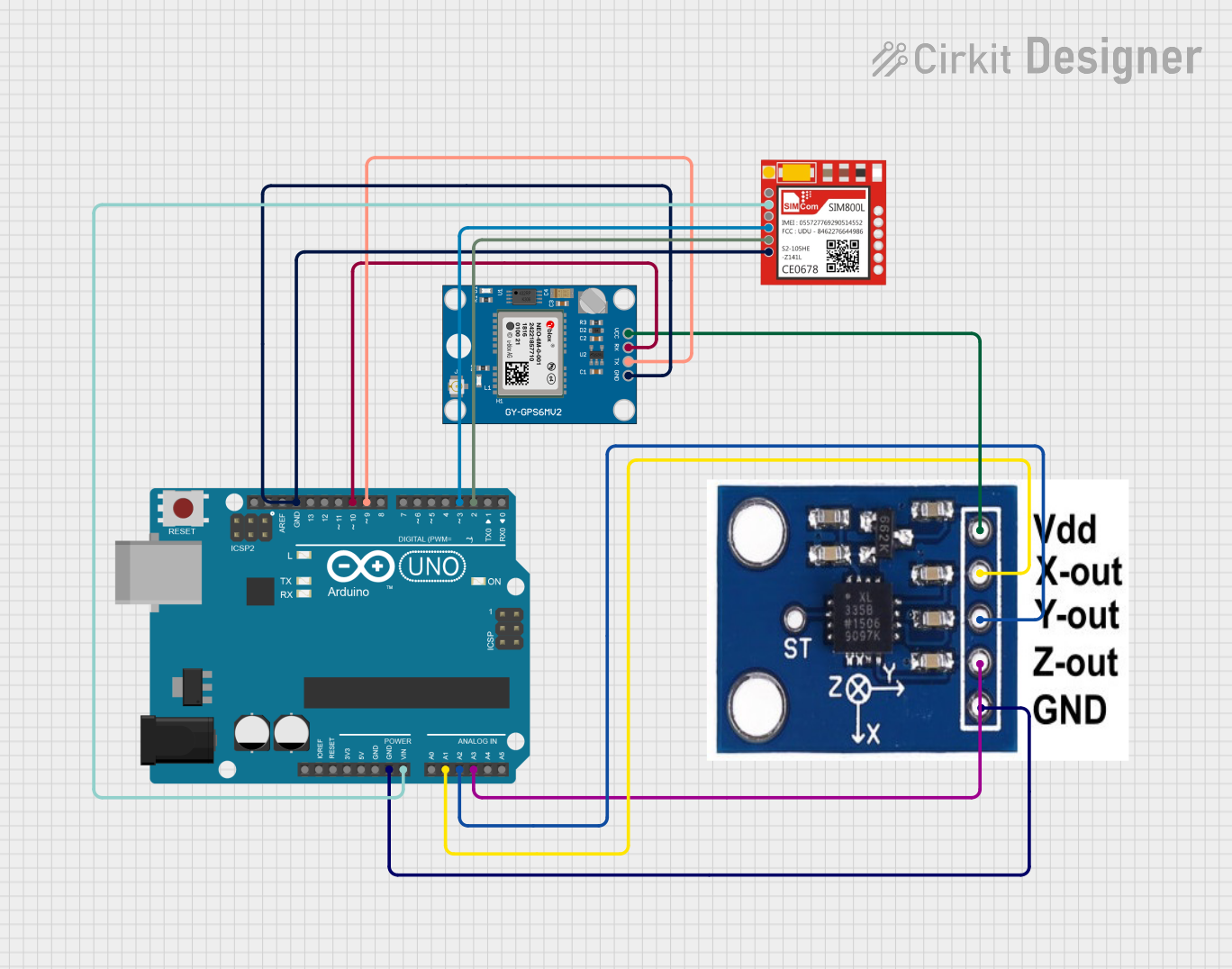

Connecting the ADXL375 to an Arduino UNO

The ADXL375 can be interfaced with an Arduino UNO using either SPI or I²C communication. Below is an example of how to connect the ADXL375 to the Arduino UNO using the SPI interface:

| ADXL375 Pin | Arduino UNO Pin |

|---|---|

| VDD | 3.3V |

| GND | GND |

| CS | Pin 10 |

| SCL/SCLK | Pin 13 |

| SDA/SDI | Pin 11 |

| SDO/ALT | Pin 12 |

Example Code: Reading Acceleration Data via SPI

The following Arduino sketch demonstrates how to read acceleration data from the ADXL375 using SPI:

#include <SPI.h>

// Define ADXL375 SPI pins

const int CS_PIN = 10; // Chip Select pin

// ADXL375 register addresses

#define POWER_CTL 0x2D

#define DATA_FORMAT 0x31

#define DATAX0 0x32

void setup() {

// Initialize serial communication

Serial.begin(9600);

// Set up SPI

SPI.begin();

pinMode(CS_PIN, OUTPUT);

digitalWrite(CS_PIN, HIGH); // Deselect the sensor

// Initialize ADXL375

initializeADXL375();

}

void loop() {

// Read acceleration data

int16_t x = readAxis(DATAX0);

int16_t y = readAxis(DATAX0 + 2);

int16_t z = readAxis(DATAX0 + 4);

// Convert raw data to g-force

float x_g = x * 0.049; // Sensitivity: 0.049 g/LSB

float y_g = y * 0.049;

float z_g = z * 0.049;

// Print acceleration data

Serial.print("X: ");

Serial.print(x_g);

Serial.print(" g, Y: ");

Serial.print(y_g);

Serial.print(" g, Z: ");

Serial.print(z_g);

Serial.println(" g");

delay(500); // Wait for 500ms

}

void initializeADXL375() {

// Set the device to measurement mode

writeRegister(POWER_CTL, 0x08);

// Set data format to full resolution, ±200g

writeRegister(DATA_FORMAT, 0x0B);

}

void writeRegister(byte reg, byte value) {

digitalWrite(CS_PIN, LOW); // Select the sensor

SPI.transfer(reg);

SPI.transfer(value);

digitalWrite(CS_PIN, HIGH); // Deselect the sensor

}

int16_t readAxis(byte reg) {

digitalWrite(CS_PIN, LOW); // Select the sensor

SPI.transfer(reg | 0x80); // Read command (MSB = 1)

byte lowByte = SPI.transfer(0x00);

byte highByte = SPI.transfer(0x00);

digitalWrite(CS_PIN, HIGH); // Deselect the sensor

// Combine high and low bytes

return (int16_t)((highByte << 8) | lowByte);

}

Important Considerations

- Power Supply: Ensure the ADXL375 is powered with a stable voltage between 2.0V and 3.6V. Using a voltage outside this range may damage the device.

- Communication Mode: Configure the device for SPI or I²C communication based on your application. Ensure proper pull-up resistors are used for I²C.

- Mounting: Securely mount the ADXL375 to minimize noise and vibration artifacts in the measurements.

- Data Rate: Select an appropriate output data rate (ODR) to balance power consumption and performance.

4. Troubleshooting and FAQs

Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| No data output | Incorrect wiring or communication settings | Verify connections and ensure SPI/I²C settings match the ADXL375 configuration. |

| Inconsistent or noisy readings | Excessive vibration or loose mounting | Securely mount the sensor and reduce external noise sources. |

| Device not responding to commands | Incorrect power supply voltage | Ensure the supply voltage is within the 2.0V to 3.6V range. |

| Incorrect acceleration values | Misconfigured data format or sensitivity | Verify the data format and sensitivity settings in the initialization code. |

Frequently Asked Questions

Can the ADXL375 measure static acceleration (e.g., gravity)?

- Yes, the ADXL375 can measure both static and dynamic acceleration, including gravity.

What is the maximum sampling rate of the ADXL375?

- The maximum output data rate (ODR) is 3200 Hz.

Can I use the ADXL375 with a 5V microcontroller?

- Yes, but you must use a logic level shifter to interface the 3.3V ADXL375 with a 5V microcontroller.

How do I switch between SPI and I²C modes?

- The communication mode is determined by the wiring of the SDO/ALT pin. Refer to the datasheet for details.

This documentation provides a comprehensive guide to using the ADXL375 High G Accelerometer. For further details, refer to the official datasheet or contact the manufacturer.

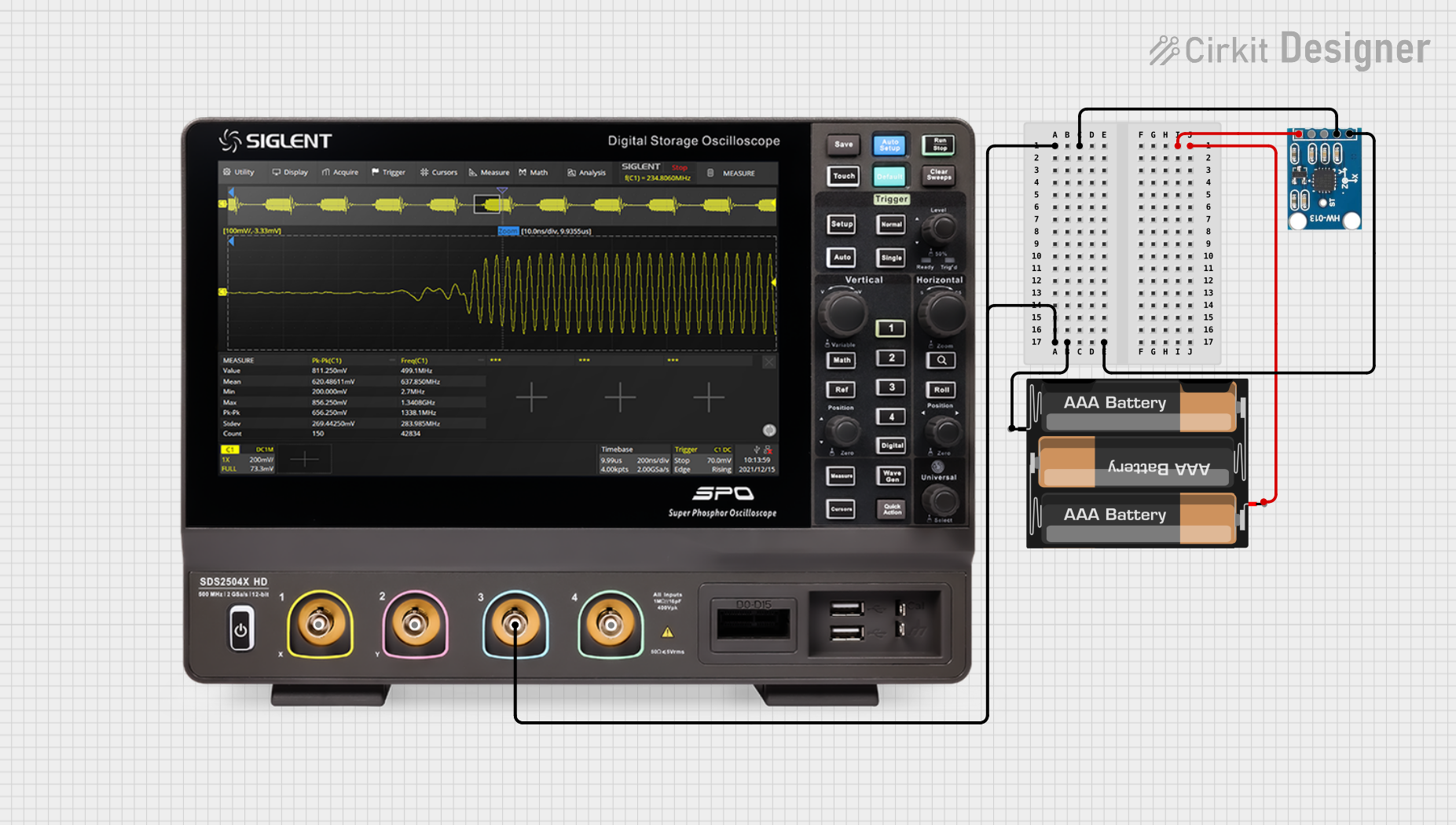

Explore Projects Built with ADXL375 High G Accelerometer

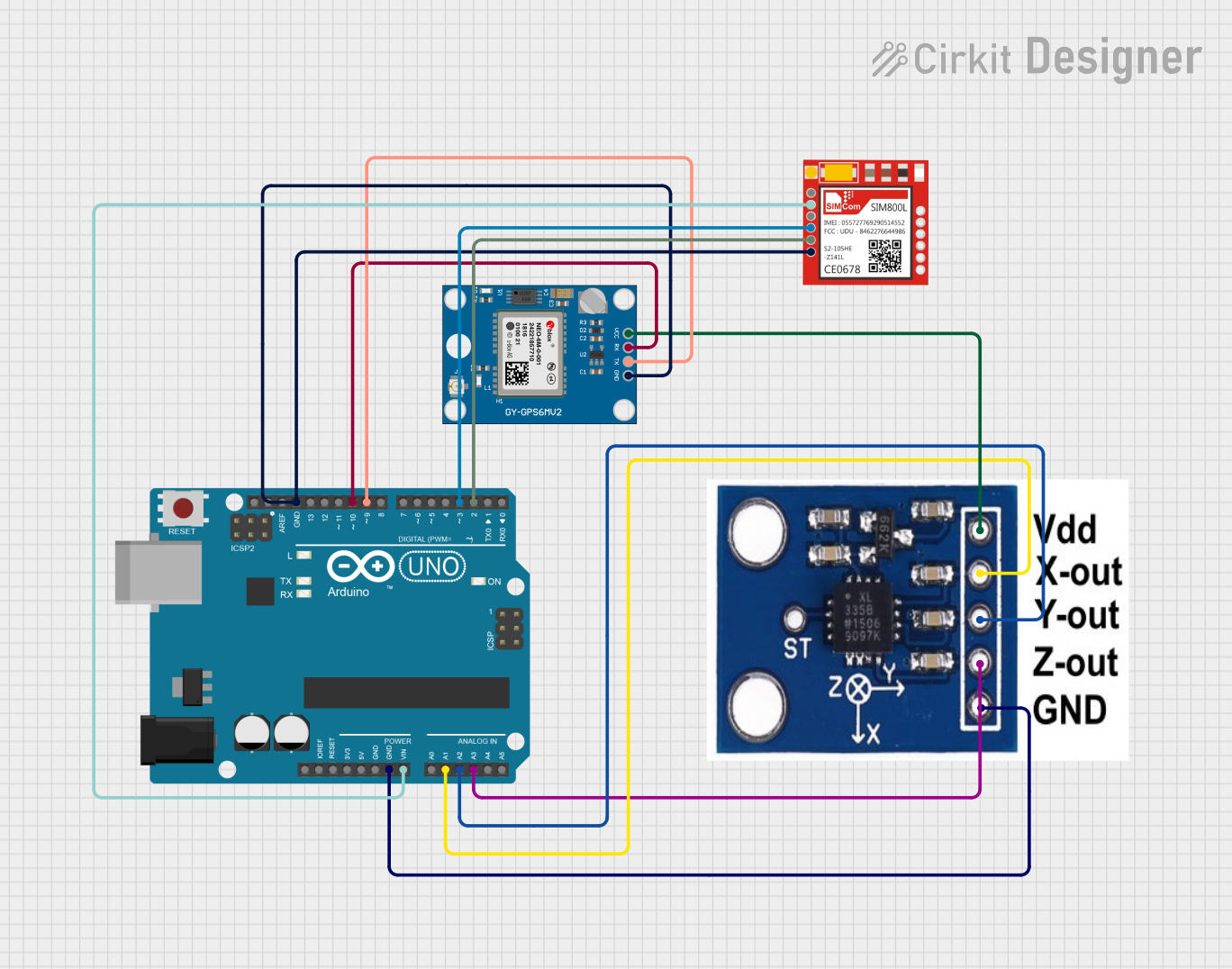

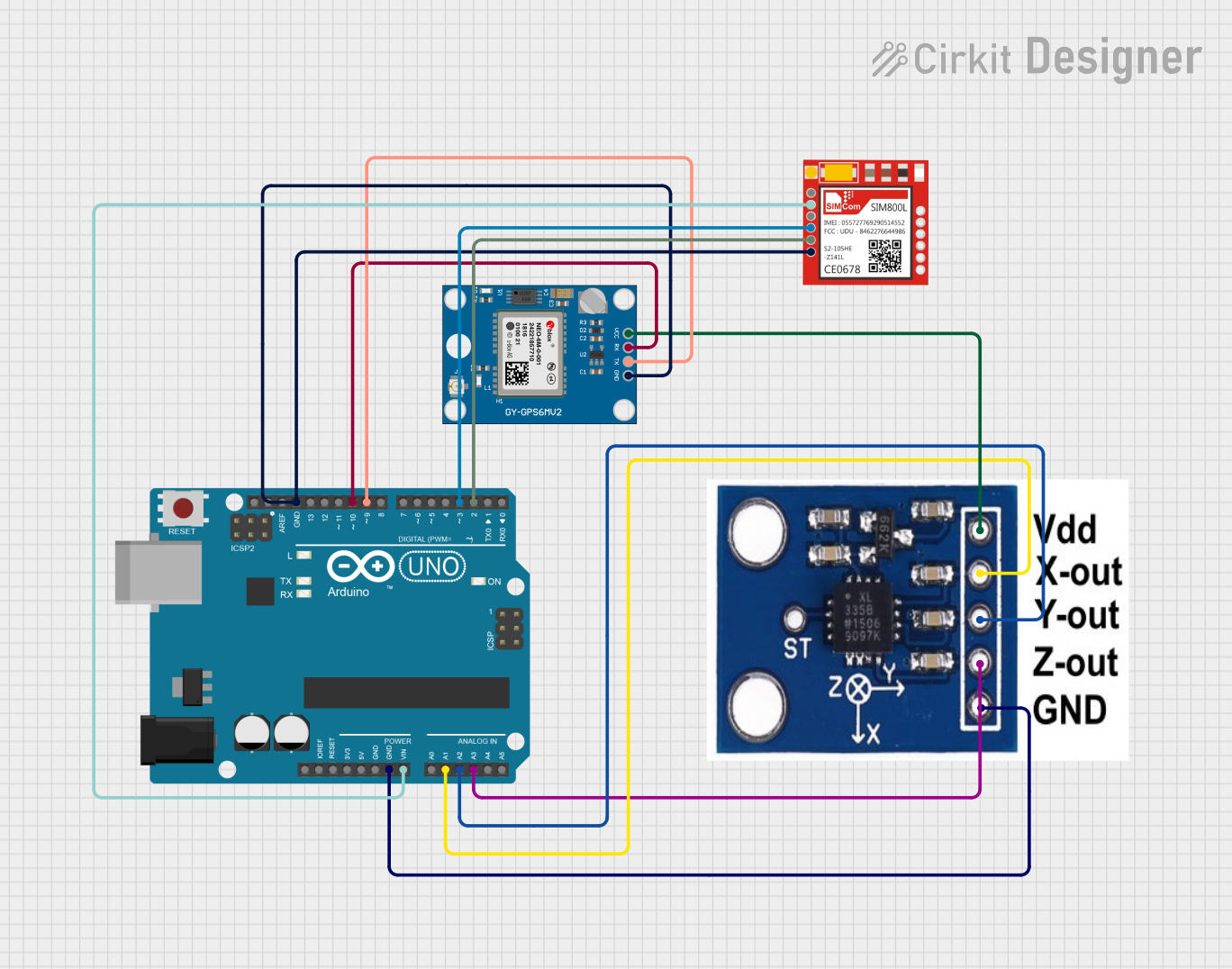

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

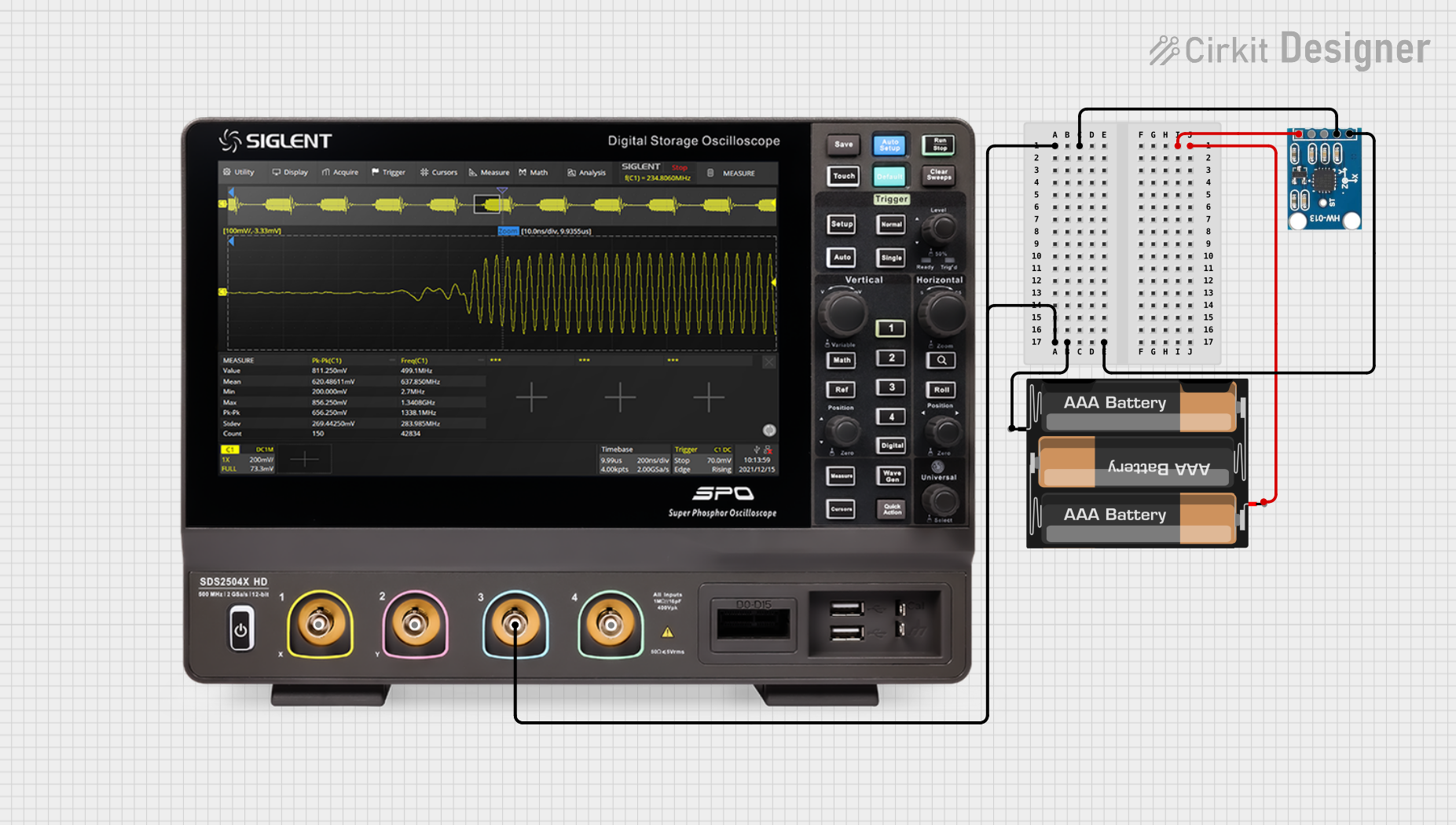

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with ADXL375 High G Accelerometer

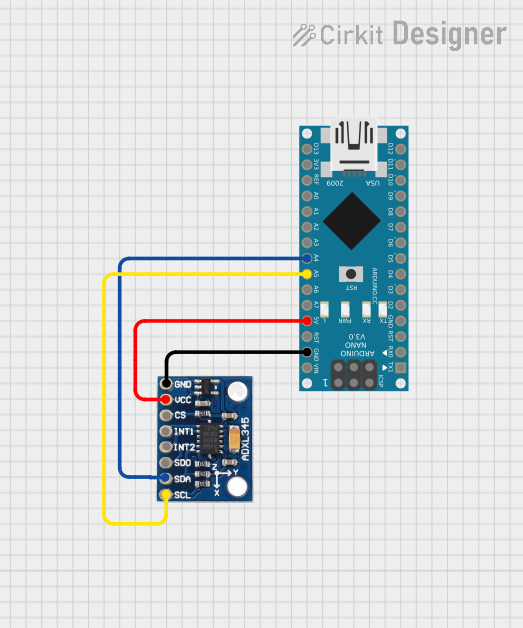

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

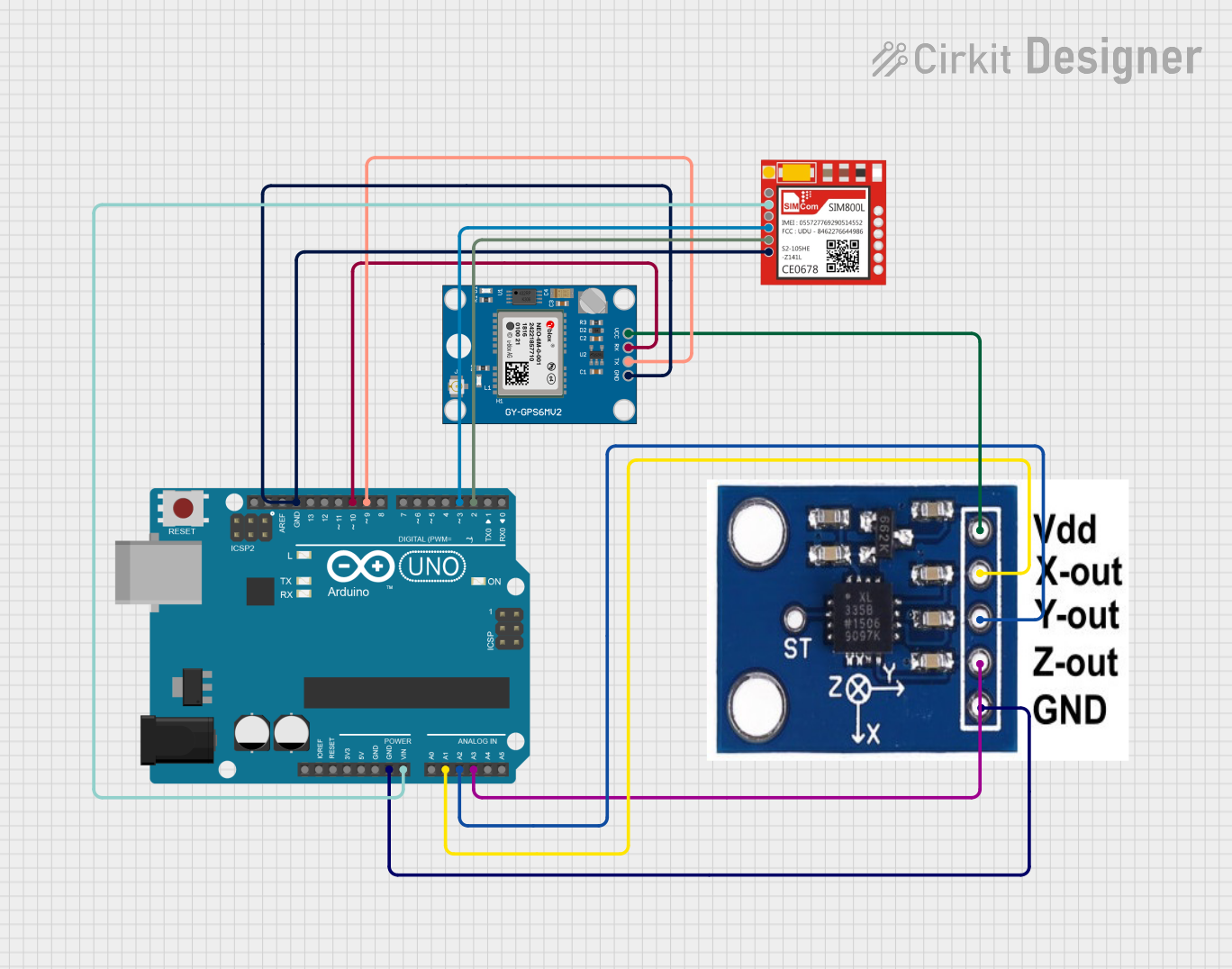

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer