How to Use Servo Tutorial Component: Examples, Pinouts, and Specs

Design with Servo Tutorial Component in Cirkit Designer

Design with Servo Tutorial Component in Cirkit DesignerIntroduction

The Servo Tutorial Component is a comprehensive guide designed to help users understand and utilize servo motors effectively in various electronic applications. Servo motors are widely used in robotics, automation, and control systems due to their precision and ease of use. This tutorial covers essential topics such as wiring, programming, and control techniques, making it suitable for both beginners and experienced users.

Explore Projects Built with Servo Tutorial Component

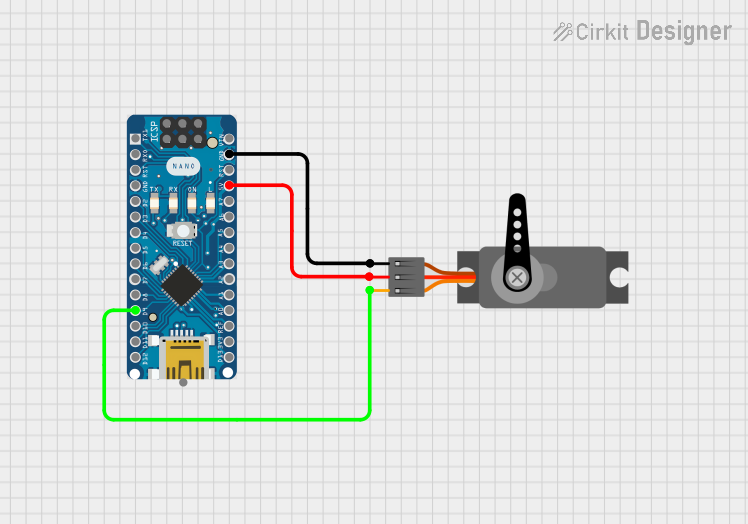

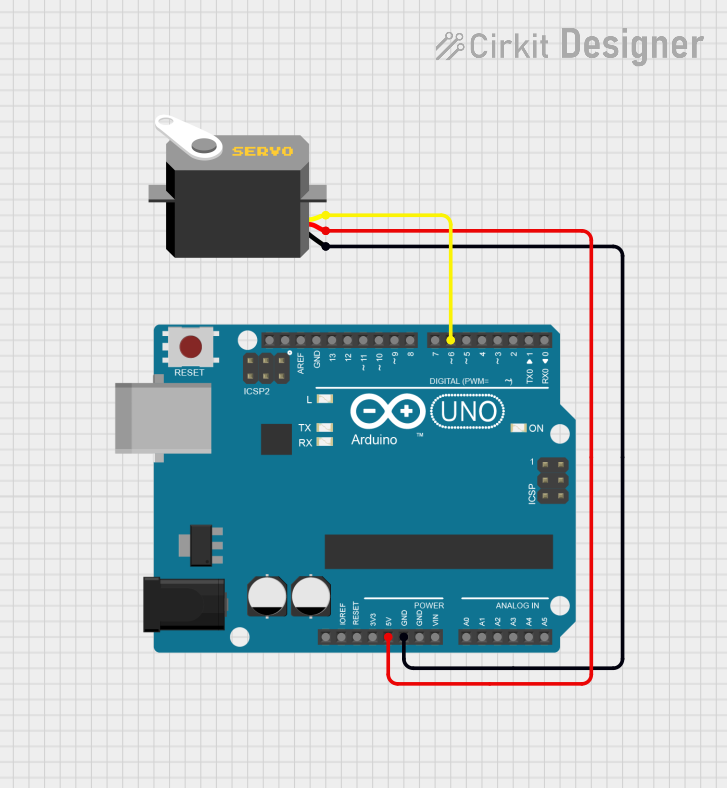

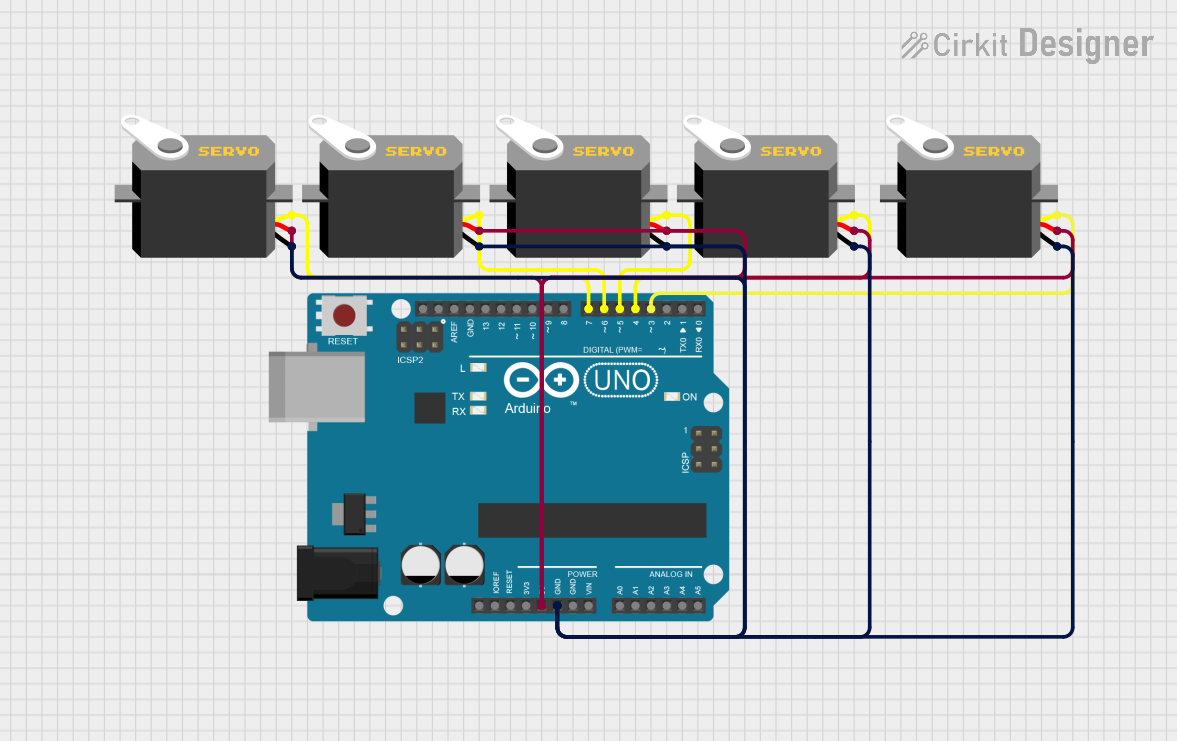

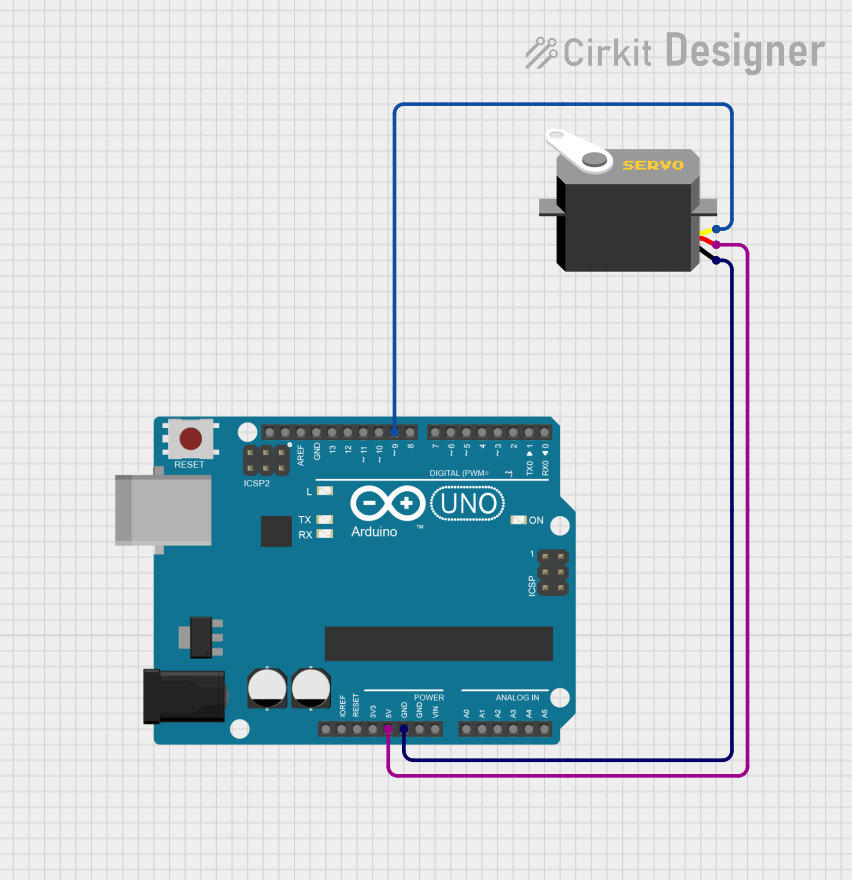

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Servo Tutorial Component

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Controlling robotic arms, grippers, and joints

- Automation: Positioning systems, such as camera gimbals or conveyor belts

- Remote-Controlled Devices: Steering mechanisms in RC cars, boats, and planes

- DIY Projects: Automated doors, pan-tilt camera mounts, and more

Technical Specifications

Servo motors come in various types and sizes, but the following specifications are typical for standard hobby servo motors:

| Specification | Details |

|---|---|

| Operating Voltage | 4.8V to 6V |

| Stall Torque | 1.5 kg-cm to 20 kg-cm (varies by model) |

| Operating Speed | ~0.1 to 0.2 seconds per 60° |

| Control Signal | PWM (Pulse Width Modulation) |

| PWM Signal Range | 1 ms to 2 ms (corresponds to 0° to 180°) |

| Connector Pins | 3 pins: Signal, VCC, GND |

Pin Configuration and Descriptions

| Pin | Name | Description |

|---|---|---|

| 1 | Signal | Receives the PWM signal to control the servo position |

| 2 | VCC | Power supply input (typically 5V) |

| 3 | GND | Ground connection |

Usage Instructions

How to Use the Component in a Circuit

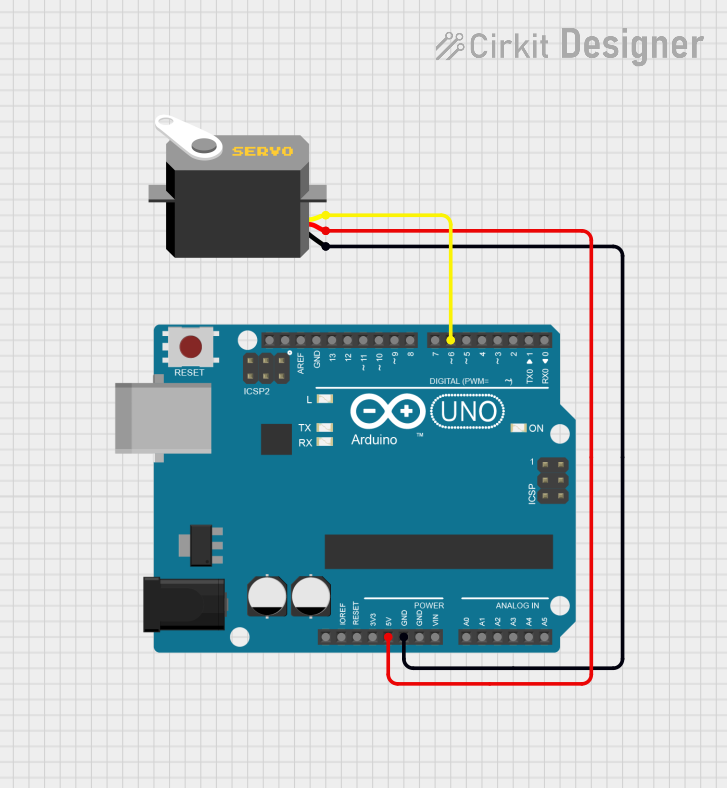

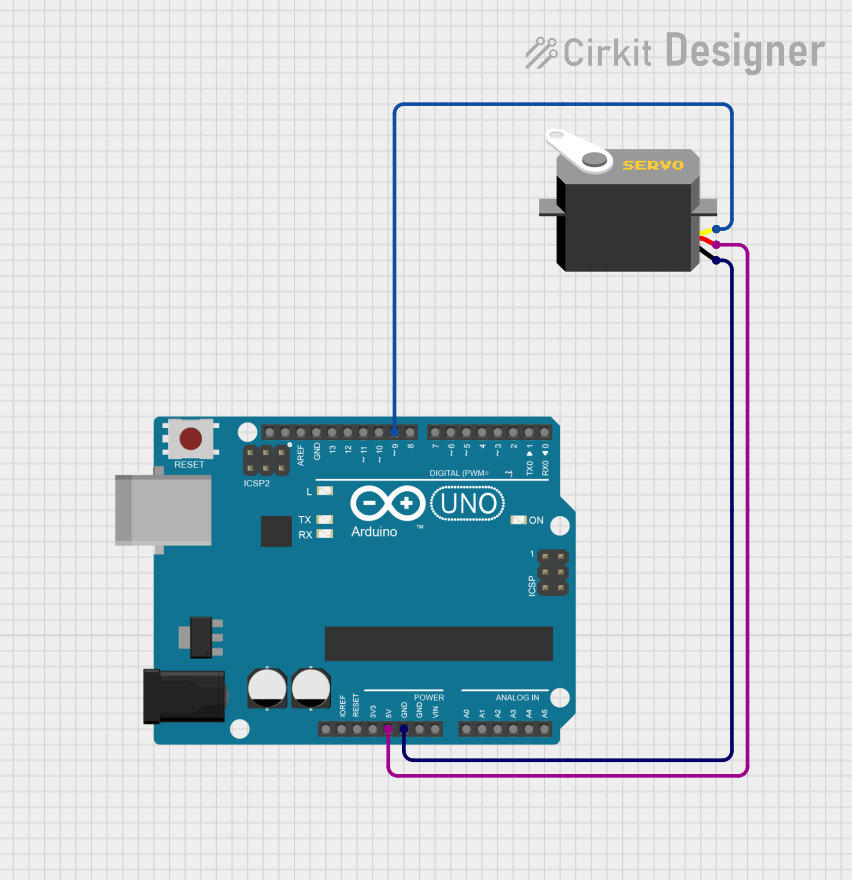

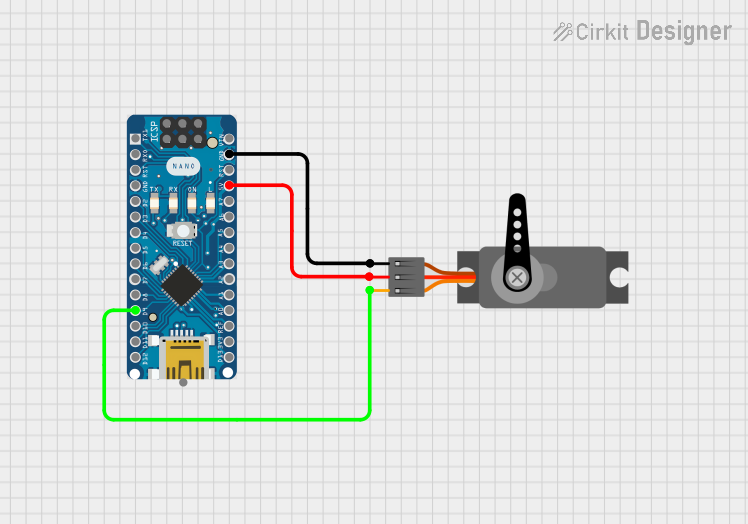

Wiring the Servo Motor:

- Connect the Signal pin of the servo to a PWM-capable pin on your microcontroller (e.g., Arduino UNO pin 9).

- Connect the VCC pin to a 5V power source.

- Connect the GND pin to the ground of your circuit.

Programming the Servo:

- Use a microcontroller (e.g., Arduino UNO) to send PWM signals to the servo.

- The position of the servo is determined by the width of the PWM signal:

- 1 ms corresponds to 0°.

- 1.5 ms corresponds to 90° (center position).

- 2 ms corresponds to 180°.

Example Circuit:

- Use a breadboard to connect the servo motor to the Arduino UNO.

- Ensure the power supply can handle the current requirements of the servo.

Arduino UNO Example Code

#include <Servo.h> // Include the Servo library

Servo myServo; // Create a Servo object to control the servo

void setup() {

myServo.attach(9); // Attach the servo to pin 9 on the Arduino

}

void loop() {

myServo.write(0); // Move the servo to 0 degrees

delay(1000); // Wait for 1 second

myServo.write(90); // Move the servo to 90 degrees

delay(1000); // Wait for 1 second

myServo.write(180); // Move the servo to 180 degrees

delay(1000); // Wait for 1 second

}

Important Considerations and Best Practices

- Power Supply: Ensure the power supply can provide sufficient current for the servo. A typical servo may draw up to 1A under load.

- Avoid Overloading: Do not exceed the torque rating of the servo to prevent damage.

- PWM Signal: Use a stable PWM signal to avoid erratic movements.

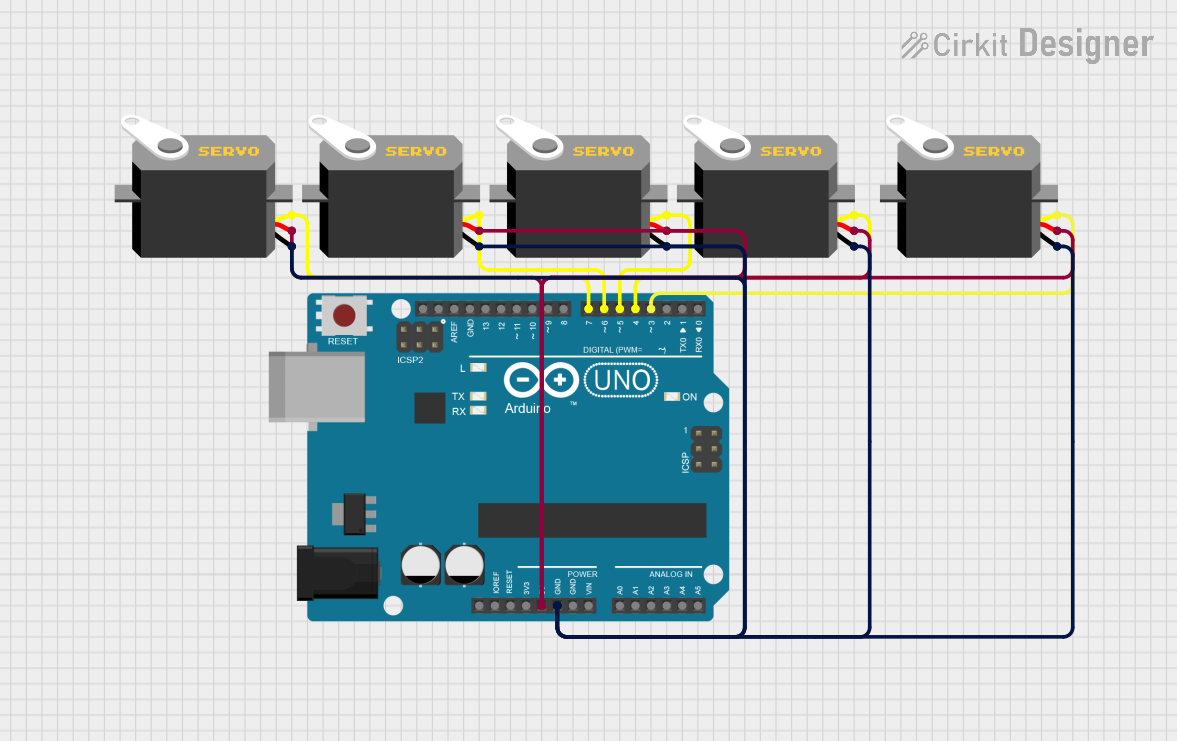

- External Power: For multiple servos, use an external power source to avoid overloading the microcontroller.

Troubleshooting and FAQs

Common Issues and Solutions

Servo Not Moving:

- Cause: Incorrect wiring or insufficient power supply.

- Solution: Double-check the connections and ensure the power supply meets the servo's requirements.

Erratic Movements:

- Cause: Unstable PWM signal or electrical noise.

- Solution: Use proper grounding and shield the signal wires if necessary.

Servo Overheating:

- Cause: Overloading or continuous operation at high torque.

- Solution: Reduce the load or allow the servo to rest periodically.

Limited Range of Motion:

- Cause: Incorrect PWM signal range.

- Solution: Verify the PWM signal width matches the servo's specifications.

FAQs

Q: Can I control multiple servos with one Arduino?

- A: Yes, you can control multiple servos using different PWM-capable pins. Use the Servo library to manage multiple servos.

Q: What happens if I exceed the servo's torque rating?

- A: Exceeding the torque rating can damage the servo's internal gears or motor. Always operate within the specified limits.

Q: Can I power the servo directly from the Arduino?

- A: While possible for small servos, it is recommended to use an external power source for reliable operation, especially for larger servos.

This Servo Tutorial Component provides a solid foundation for working with servo motors in various projects. By following the guidelines and best practices, users can achieve precise and reliable control in their applications.