How to Use WCS1700: Examples, Pinouts, and Specs

Design with WCS1700 in Cirkit Designer

Design with WCS1700 in Cirkit DesignerIntroduction

The WCS1700 is a capacitive touch sensor designed to detect touch input through a capacitive sensing mechanism. It is widely used in applications such as touch screens, touch-sensitive controls, and other user interface systems where a reliable and responsive touch detection is required. The WCS1700 offers high sensitivity, low power consumption, and ease of integration, making it an ideal choice for modern touch-based designs.

Explore Projects Built with WCS1700

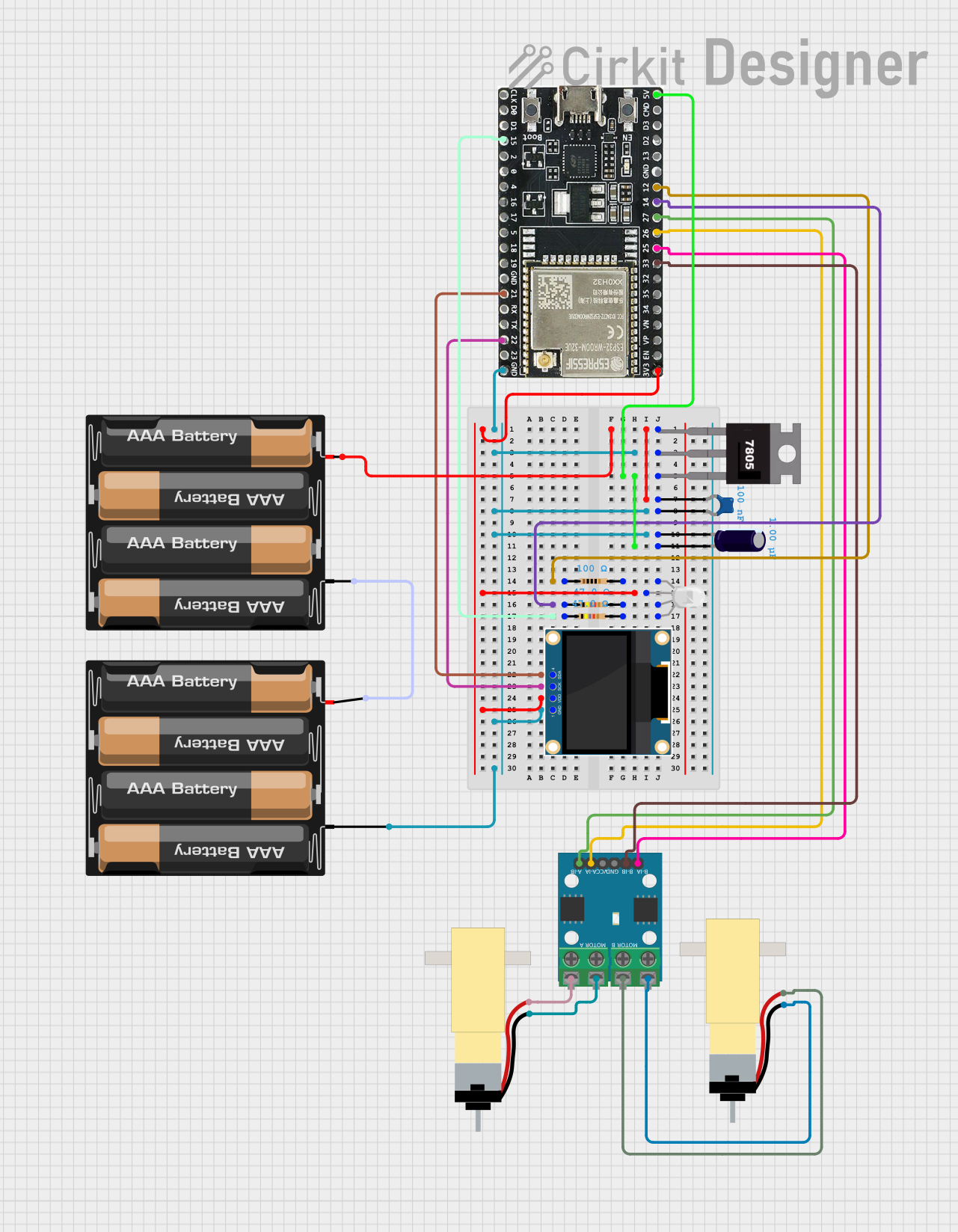

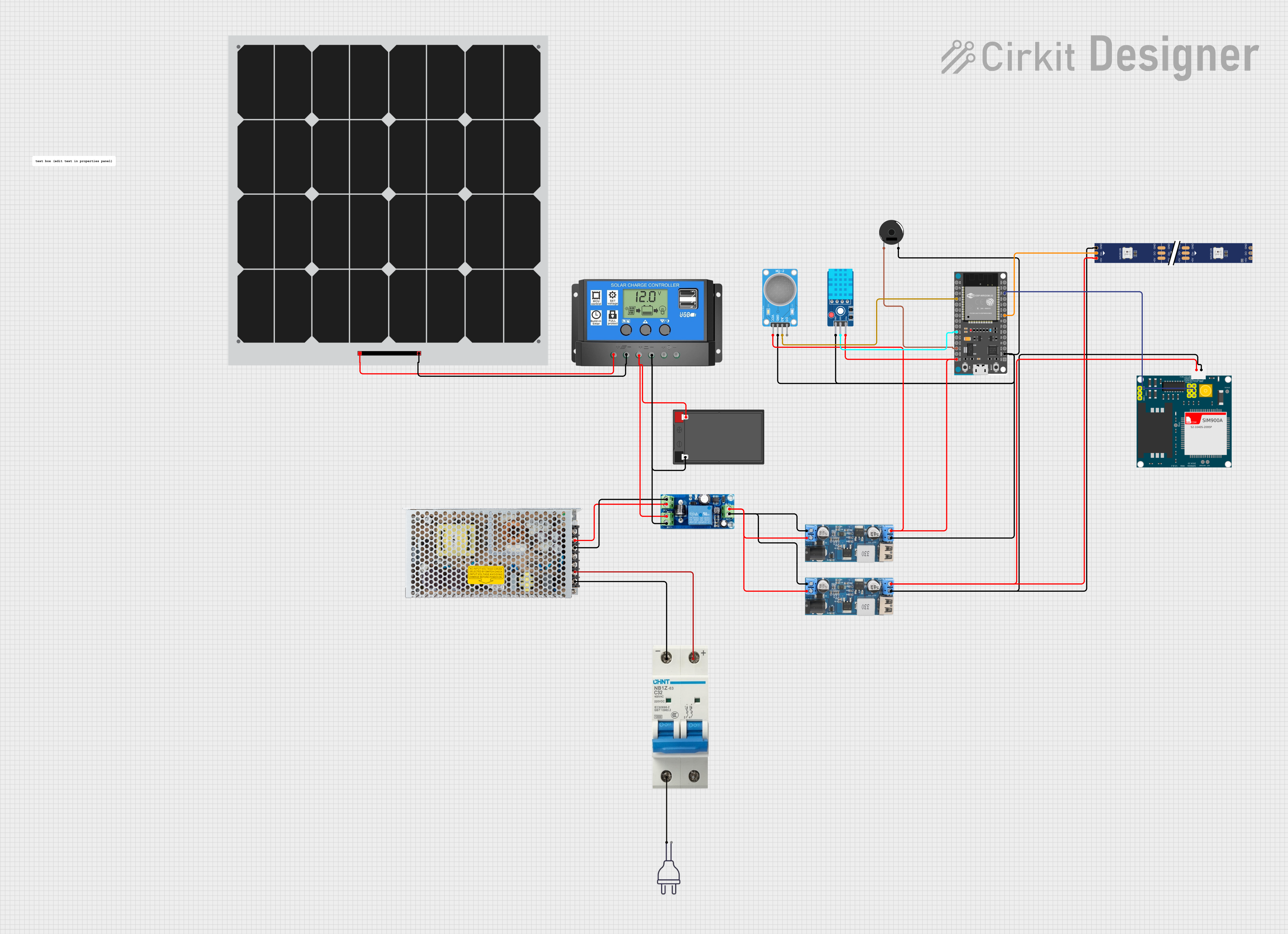

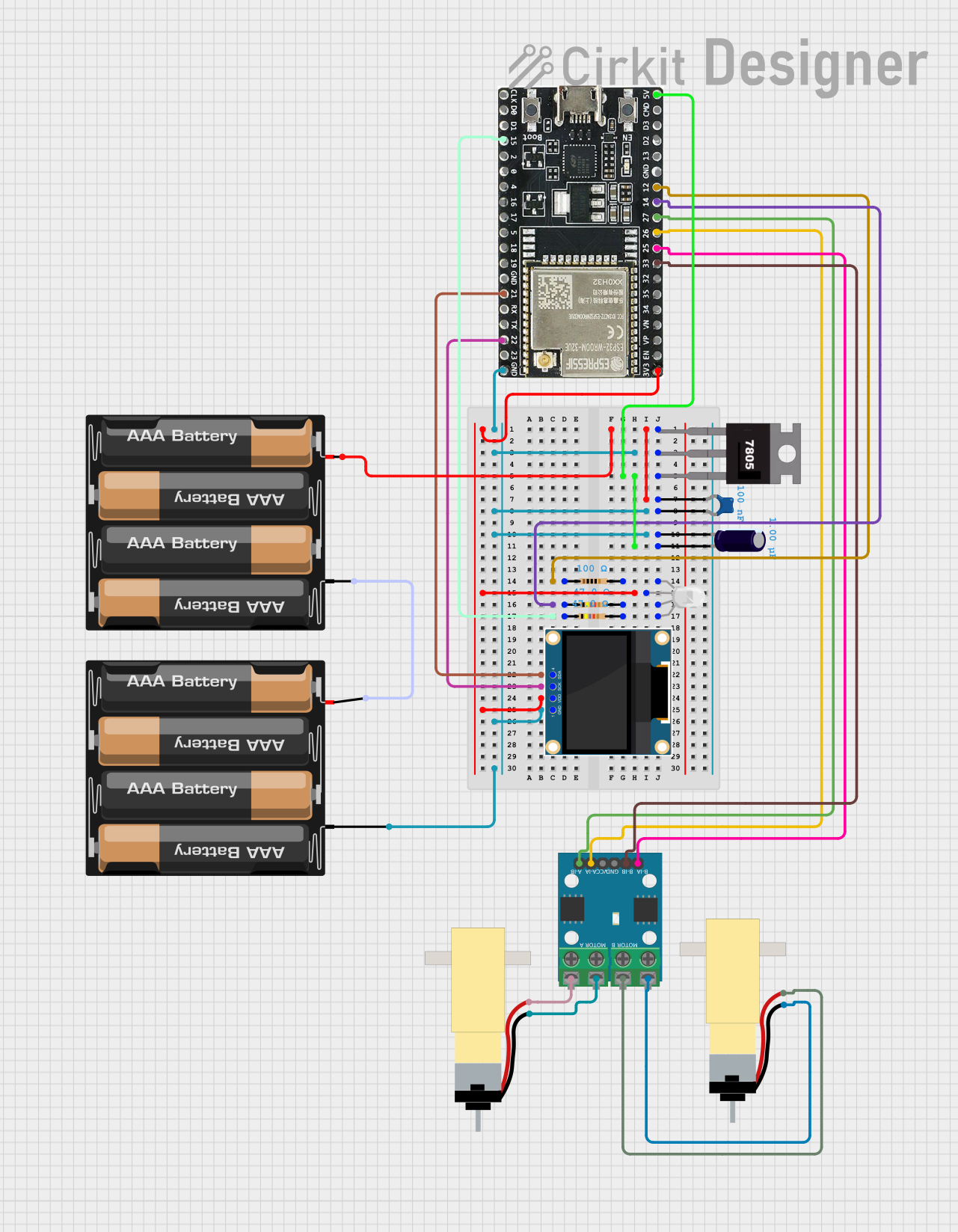

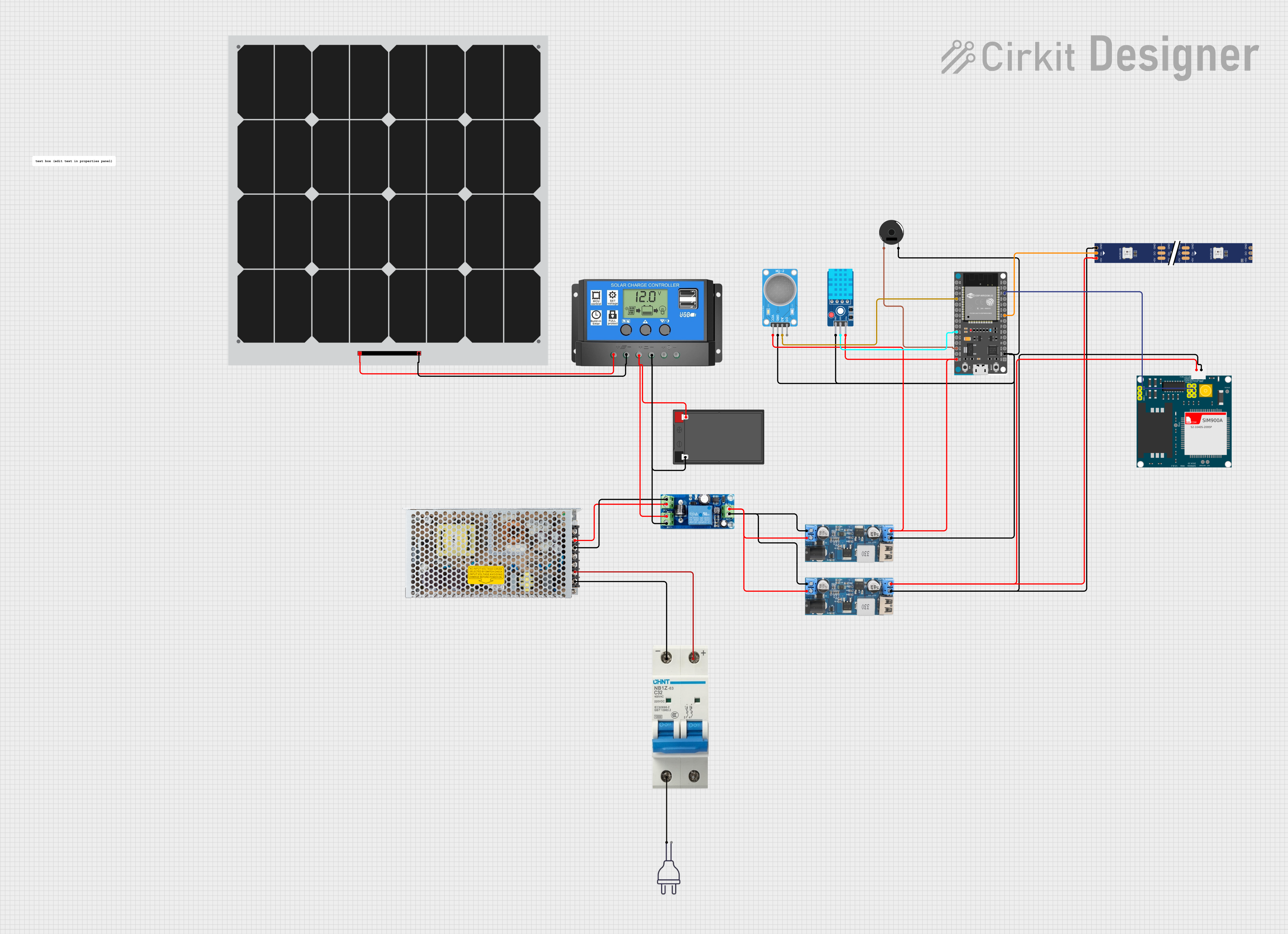

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with WCS1700

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Touch-sensitive control panels

- Touch screens for consumer electronics

- Home automation systems

- Wearable devices

- Industrial control interfaces

Technical Specifications

Key Technical Details

- Operating Voltage: 2.7V to 5.5V

- Operating Current: < 10 µA (standby mode), ~1 mA (active mode)

- Response Time: < 100 ms

- Touch Sensitivity: Adjustable via external components

- Interface: Digital output (active low or high, depending on configuration)

- Operating Temperature: -40°C to 85°C

- Package Type: SOP-8 or DIP-8

Pin Configuration and Descriptions

The WCS1700 is typically available in an 8-pin package. Below is the pinout and description:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (2.7V to 5.5V). |

| 2 | OUT | Digital output pin. Indicates touch detection. |

| 3 | GND | Ground connection. |

| 4 | SEN | Sensitivity adjustment pin. Connect to a resistor or capacitor to adjust sensitivity. |

| 5 | NC | No connection. Leave unconnected. |

| 6 | NC | No connection. Leave unconnected. |

| 7 | NC | No connection. Leave unconnected. |

| 8 | NC | No connection. Leave unconnected. |

Note: Some variants of the WCS1700 may have slightly different pin configurations. Always refer to the specific datasheet for your component.

Usage Instructions

How to Use the WCS1700 in a Circuit

- Power Supply: Connect the VCC pin to a stable power source (2.7V to 5.5V) and the GND pin to ground.

- Output Connection: Connect the OUT pin to a microcontroller or other digital input device to read the touch detection signal.

- Sensitivity Adjustment: Use an external resistor or capacitor on the SEN pin to adjust the touch sensitivity. Refer to the datasheet for recommended values.

- Touch Pad Design: Connect the touch pad (sensor electrode) to the appropriate input. Ensure the touch pad is properly designed for optimal sensitivity and noise immunity.

Important Considerations

- Debouncing: Implement software debouncing in your microcontroller to filter out false triggers caused by noise or rapid touch events.

- PCB Design: Ensure proper grounding and shielding to minimize interference and false triggering.

- Environmental Factors: The WCS1700 is sensitive to environmental conditions such as humidity and temperature. Design your system to account for these variations.

- Pull-up Resistor: If the OUT pin is open-drain, use an appropriate pull-up resistor to ensure proper signal levels.

Example: Connecting WCS1700 to Arduino UNO

Below is an example of how to connect the WCS1700 to an Arduino UNO and read touch input:

Circuit Connections

- VCC: Connect to the 5V pin on the Arduino.

- GND: Connect to the GND pin on the Arduino.

- OUT: Connect to digital pin 2 on the Arduino.

- SEN: Connect a 10 kΩ resistor to ground for sensitivity adjustment.

Arduino Code

// WCS1700 Capacitive Touch Sensor Example

// This code reads the touch input from the WCS1700 and prints the status to the Serial Monitor.

#define TOUCH_PIN 2 // Define the digital pin connected to the OUT pin of WCS1700

void setup() {

pinMode(TOUCH_PIN, INPUT); // Set the touch pin as input

Serial.begin(9600); // Initialize serial communication at 9600 baud

}

void loop() {

int touchState = digitalRead(TOUCH_PIN); // Read the touch sensor state

if (touchState == LOW) {

// The sensor outputs LOW when a touch is detected

Serial.println("Touch detected!");

} else {

Serial.println("No touch detected.");

}

delay(100); // Add a small delay to avoid flooding the Serial Monitor

}

Note: Adjust the

TOUCH_PINdefinition if you connect the OUT pin to a different Arduino pin.

Troubleshooting and FAQs

Common Issues and Solutions

No Response from the Sensor

- Cause: Incorrect power supply or loose connections.

- Solution: Verify that the VCC and GND pins are properly connected and the supply voltage is within the specified range.

False Touch Detection

- Cause: Noise or improper grounding.

- Solution: Ensure proper grounding and shielding. Add a decoupling capacitor (e.g., 0.1 µF) near the VCC pin.

Low Sensitivity

- Cause: Incorrect sensitivity adjustment.

- Solution: Adjust the resistor or capacitor connected to the SEN pin to increase sensitivity.

Interference from Nearby Components

- Cause: Electromagnetic interference (EMI) from other components.

- Solution: Use proper PCB layout techniques, such as separating the touch sensor traces from high-frequency signals.

FAQs

Q: Can the WCS1700 detect multiple touches simultaneously?

A: No, the WCS1700 is designed to detect a single touch at a time.Q: What is the maximum size of the touch pad?

A: The size of the touch pad depends on the sensitivity adjustment and the application. Refer to the datasheet for guidelines.Q: Can the WCS1700 be used with a 3.3V system?

A: Yes, the WCS1700 operates within a voltage range of 2.7V to 5.5V, making it compatible with 3.3V systems.Q: How do I prevent accidental touches?

A: Use proper sensitivity adjustment and implement software filtering to ignore brief or weak touch signals.

By following this documentation, you can effectively integrate the WCS1700 into your touch-sensitive applications.