How to Use line tracking: Examples, Pinouts, and Specs

Design with line tracking in Cirkit Designer

Design with line tracking in Cirkit DesignerIntroduction

The Line Tracking Sensor (Manufacturer: Arduinno, Part ID: UNO) is a compact and efficient module designed for robotics applications. It enables robots to detect and follow a line or path, typically using infrared (IR) or optical sensors to distinguish between the line and the surrounding surface. This sensor is widely used in autonomous vehicles, line-following robots, and industrial automation systems.

Explore Projects Built with line tracking

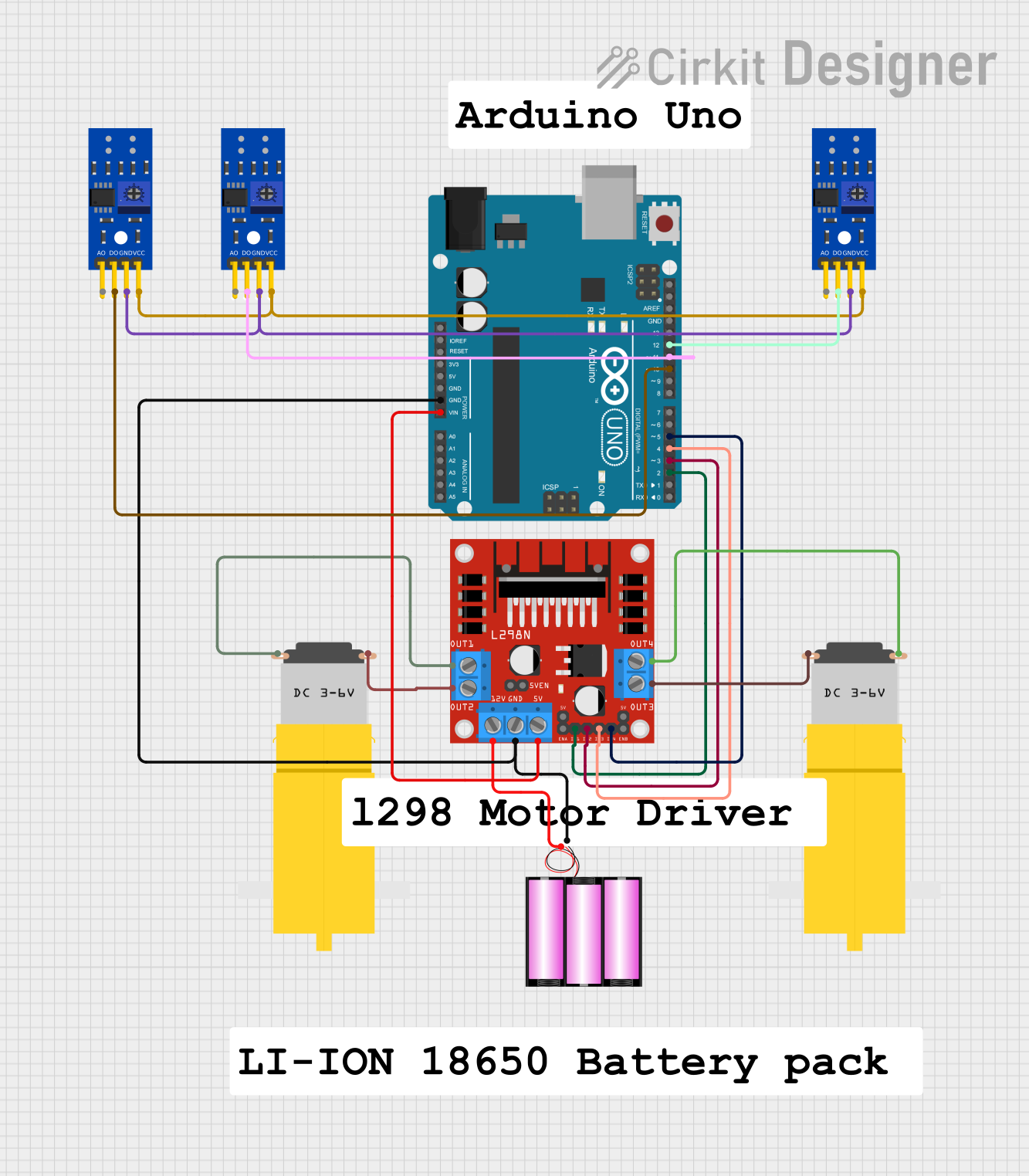

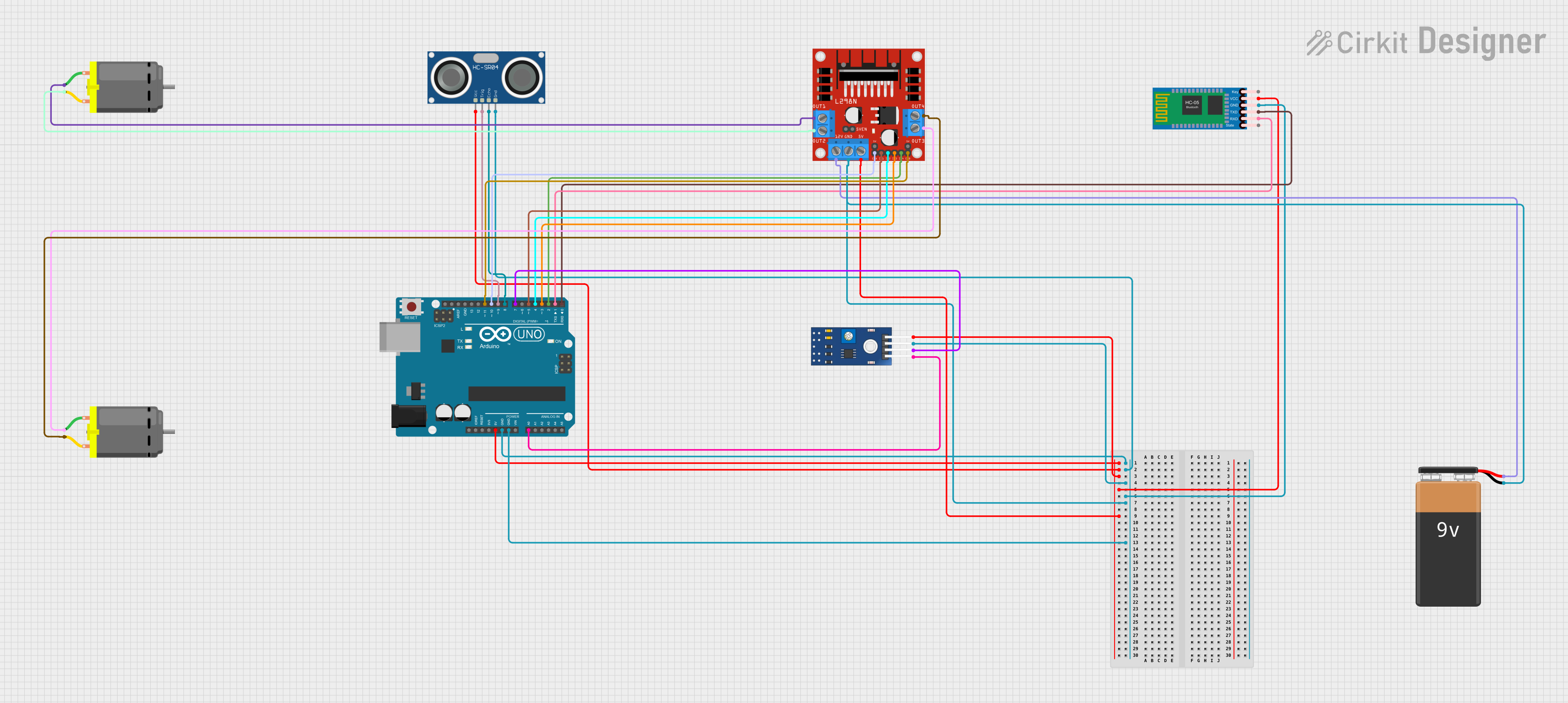

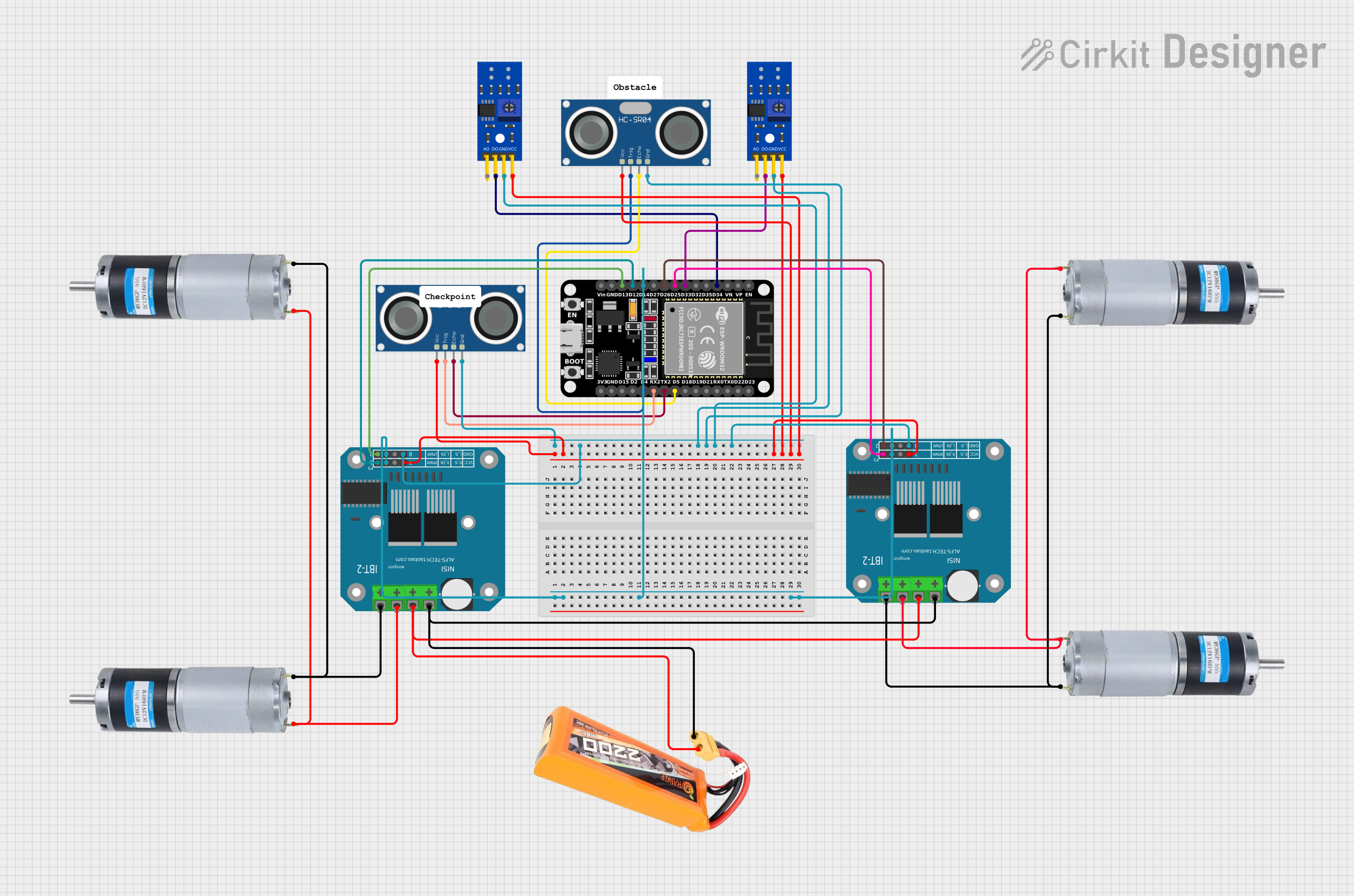

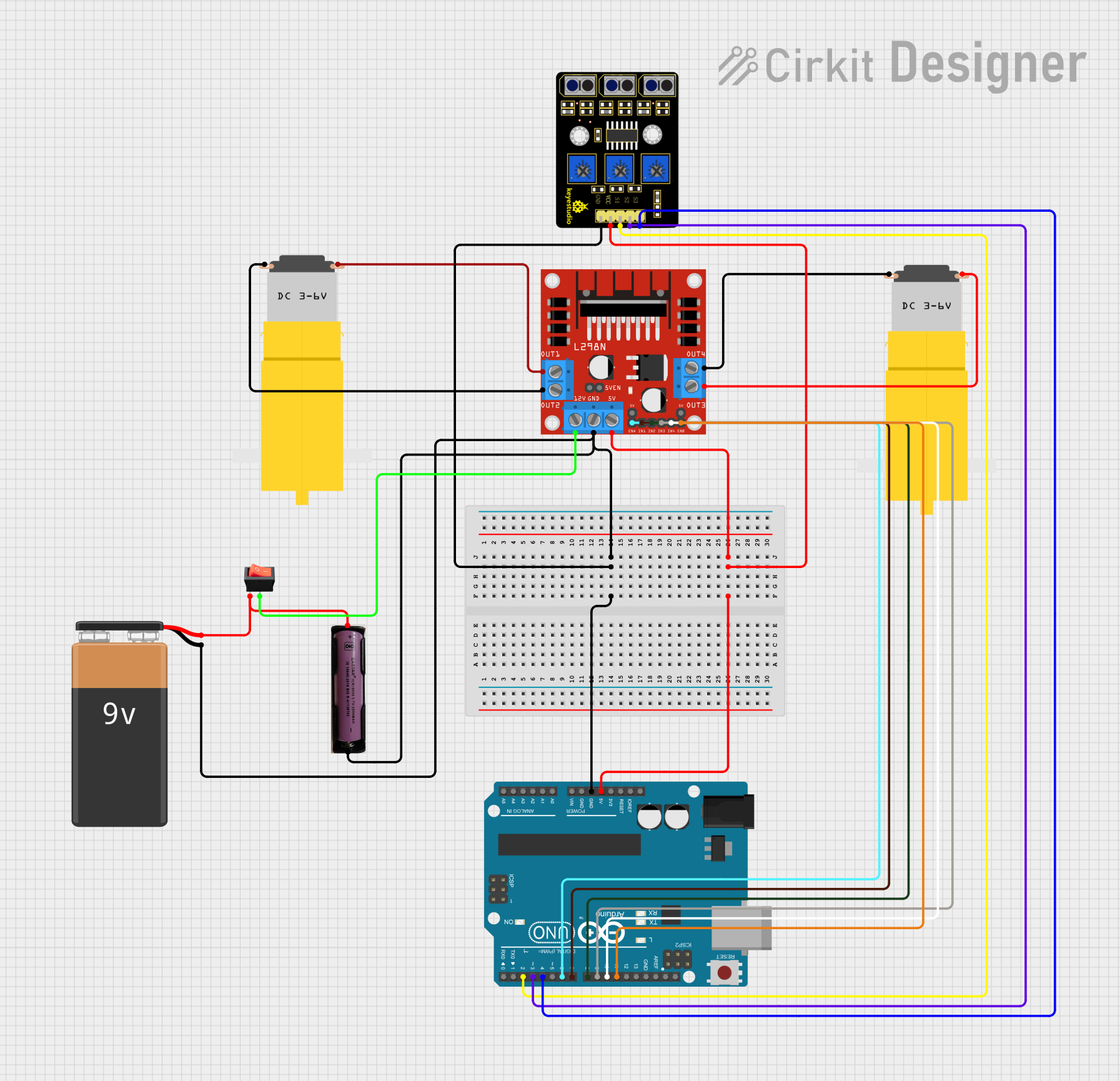

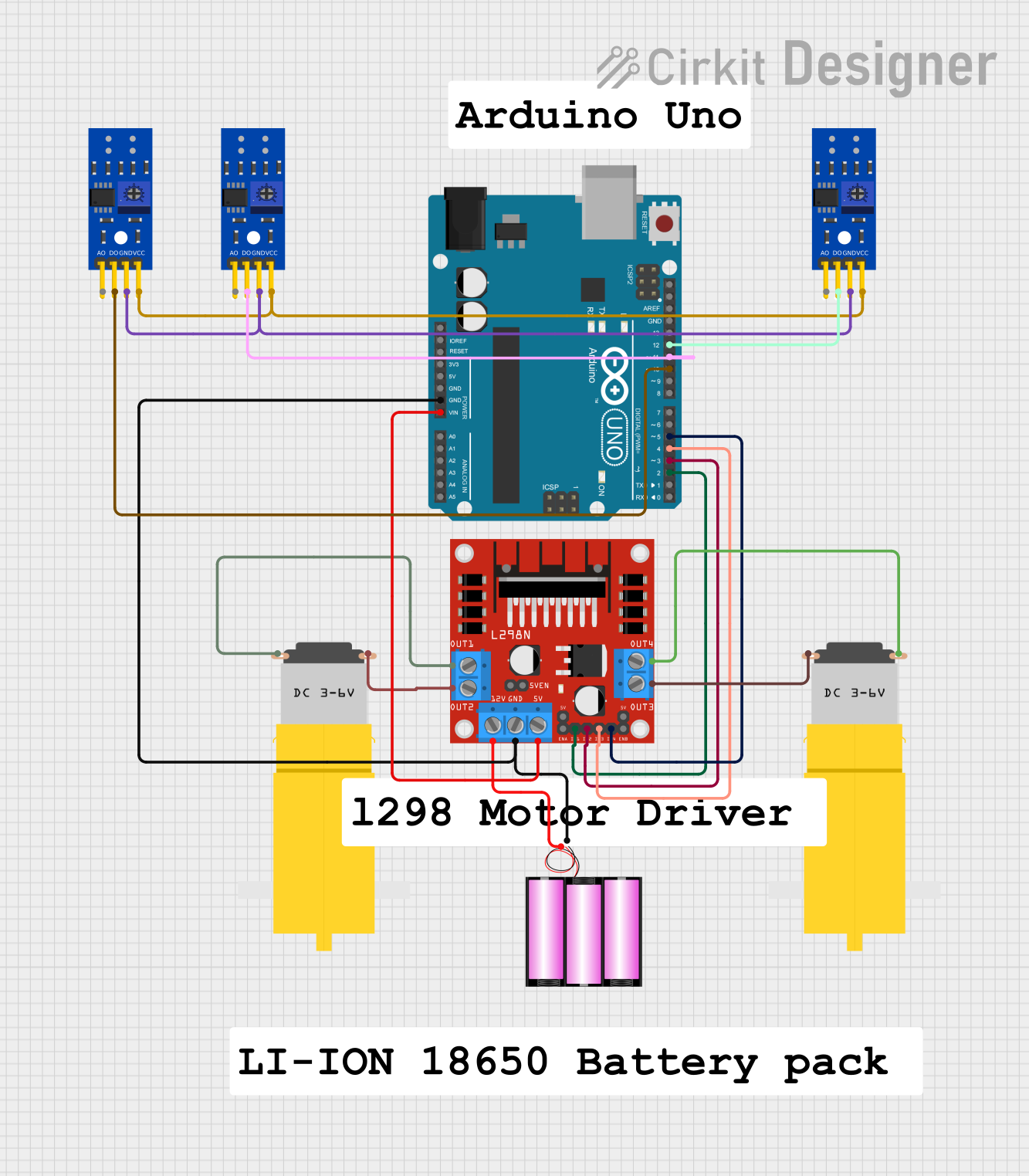

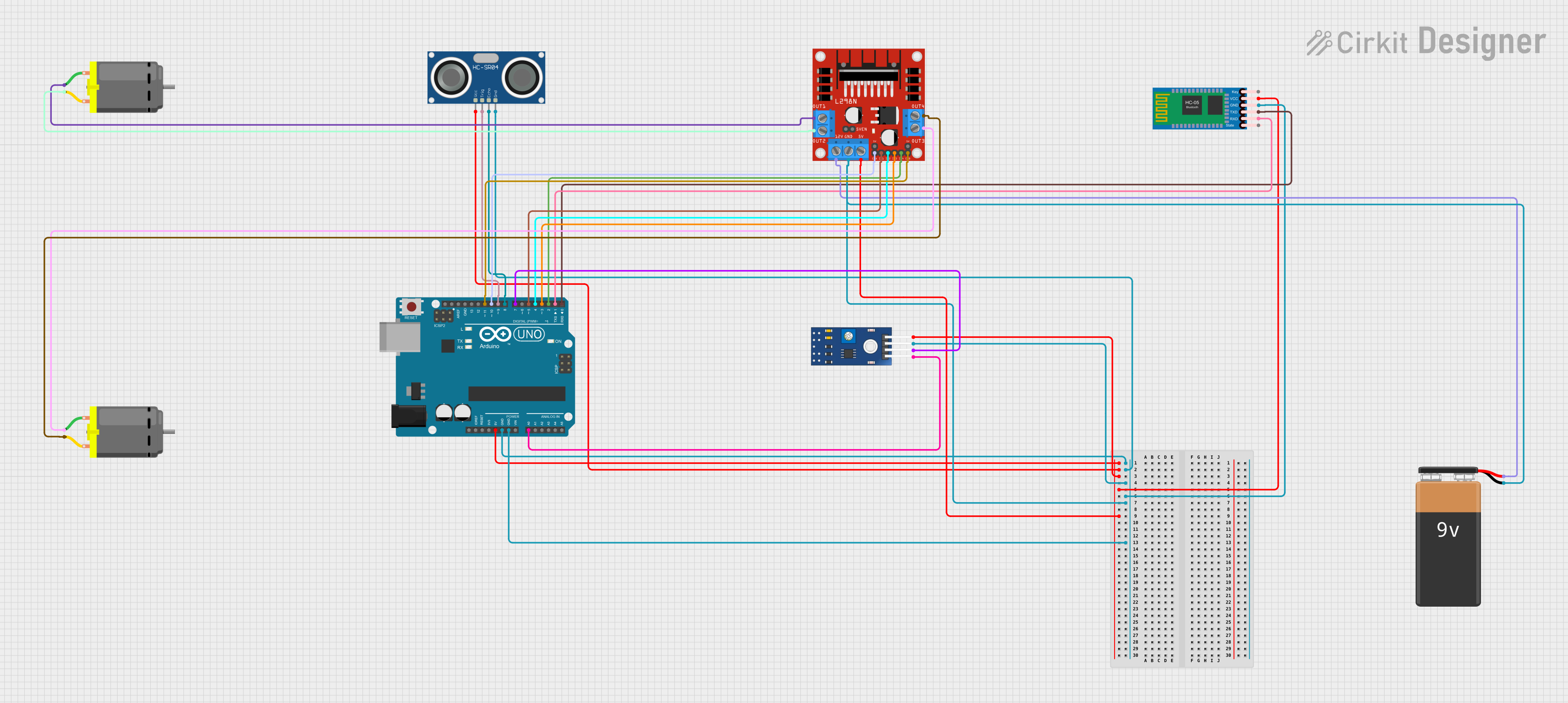

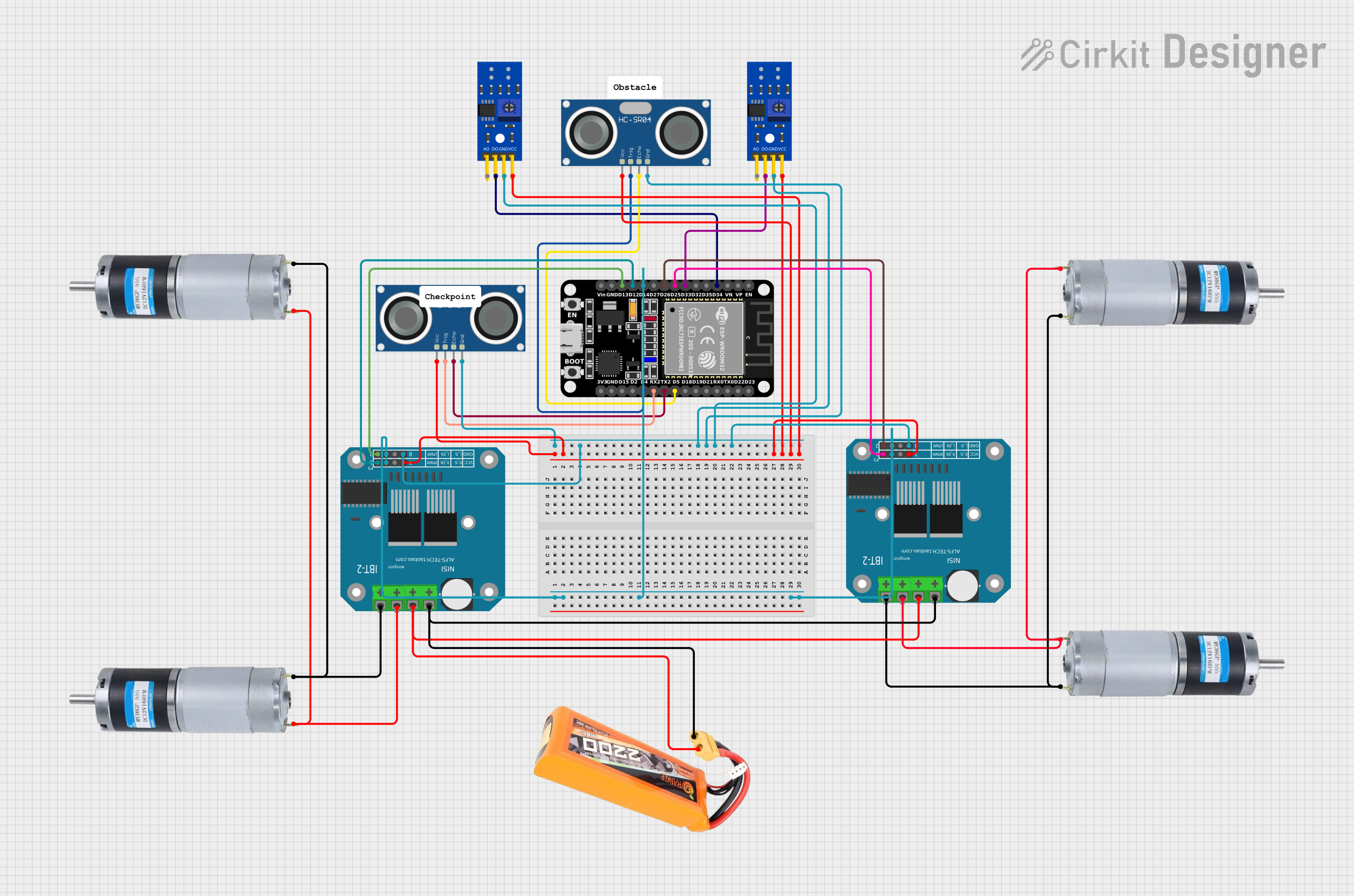

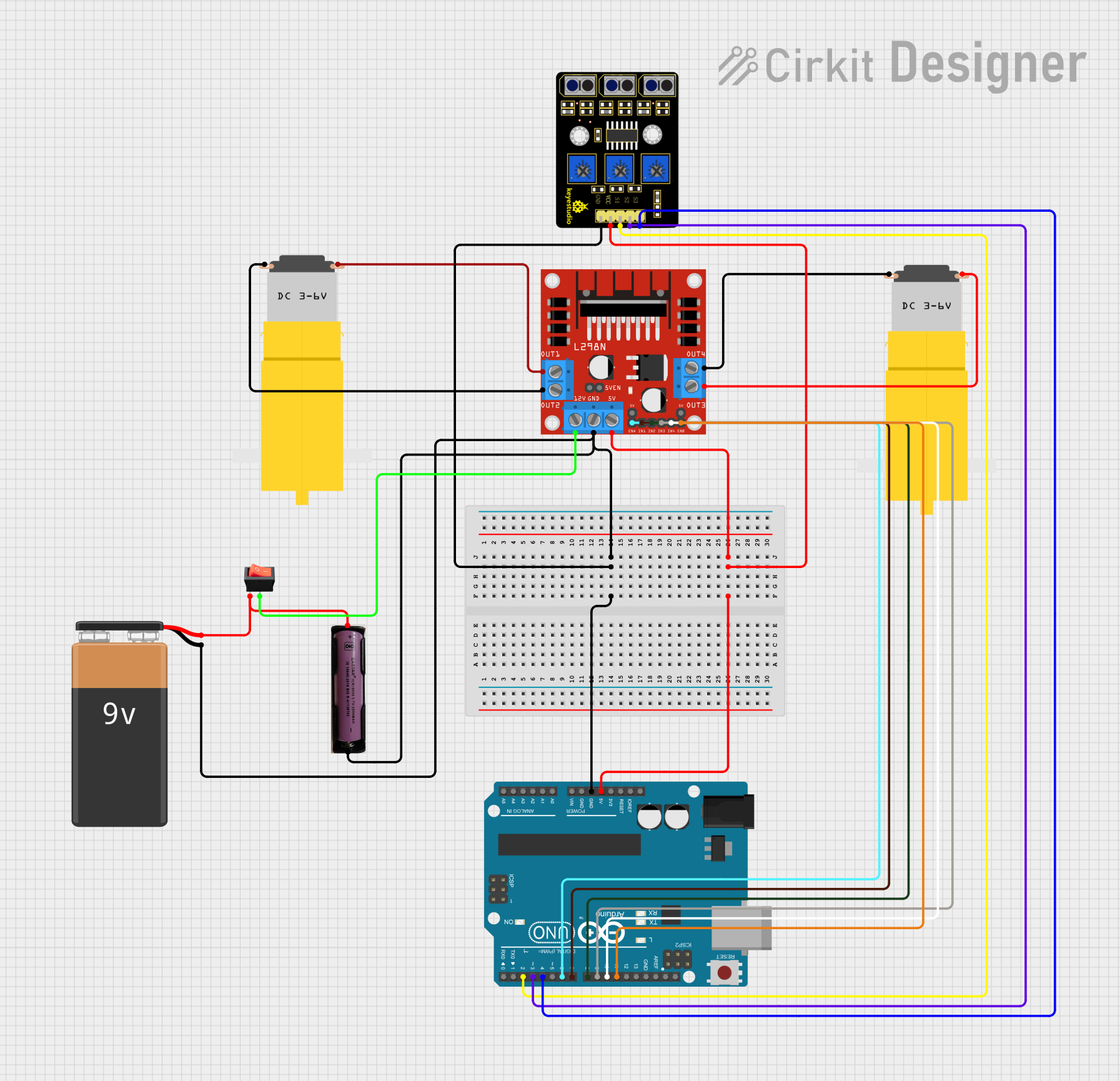

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with line tracking

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Line-following robots for educational and competitive robotics

- Automated guided vehicles (AGVs) in warehouses

- Path-following systems in industrial automation

- Obstacle avoidance and navigation in robotics

Technical Specifications

The following table outlines the key technical details of the Line Tracking Sensor:

| Parameter | Value |

|---|---|

| Operating Voltage | 3.3V to 5V |

| Operating Current | ≤ 20mA |

| Detection Range | 1mm to 12mm |

| Output Type | Digital (High/Low) |

| Sensor Type | Infrared (IR) Reflective Sensor |

| Dimensions | 32mm x 14mm x 7mm |

| Weight | 3g |

Pin Configuration and Descriptions

The Line Tracking Sensor has a 3-pin interface. The pinout is as follows:

| Pin | Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (3.3V to 5V) |

| 2 | GND | Ground connection |

| 3 | OUT | Digital output signal (High when no line is detected, Low when a line is detected) |

Usage Instructions

How to Use the Component in a Circuit

- Power the Sensor: Connect the

VCCpin to a 3.3V or 5V power source and theGNDpin to the ground of your circuit. - Connect the Output: Connect the

OUTpin to a digital input pin on your microcontroller (e.g., Arduino UNO). - Position the Sensor: Place the sensor approximately 2-10mm above the surface to ensure accurate line detection.

- Calibrate the Sensor: Adjust the sensor's position or sensitivity (if adjustable) to optimize detection for your specific line and surface.

Important Considerations and Best Practices

- Surface Contrast: Ensure the line has a high contrast with the surrounding surface (e.g., black line on a white surface).

- Ambient Light: Minimize ambient light interference by using the sensor in controlled lighting conditions.

- Sensor Placement: Mount the sensor securely to avoid vibrations or misalignment during operation.

- Multiple Sensors: For complex line-following tasks, use multiple sensors to improve accuracy and responsiveness.

Example Code for Arduino UNO

Below is an example code snippet to interface the Line Tracking Sensor with an Arduino UNO:

// Line Tracking Sensor Example Code

// Manufacturer: Arduinno, Part ID: UNO

// This code reads the sensor's output and prints the status to the Serial Monitor.

const int sensorPin = 2; // Connect the OUT pin of the sensor to digital pin 2

void setup() {

pinMode(sensorPin, INPUT); // Set the sensor pin as input

Serial.begin(9600); // Initialize serial communication at 9600 baud

}

void loop() {

int sensorValue = digitalRead(sensorPin); // Read the sensor's output

if (sensorValue == LOW) {

// Line detected

Serial.println("Line detected!");

} else {

// No line detected

Serial.println("No line detected.");

}

delay(100); // Small delay for stability

}

Troubleshooting and FAQs

Common Issues and Solutions

Sensor Not Detecting the Line

- Cause: The sensor is too far from the surface or the line contrast is insufficient.

- Solution: Adjust the sensor's height to 2-10mm and ensure the line has a high contrast with the surface.

False Positives or Erratic Behavior

- Cause: Ambient light interference or reflective surfaces.

- Solution: Use the sensor in a controlled lighting environment and avoid reflective surfaces.

No Output Signal

- Cause: Incorrect wiring or insufficient power supply.

- Solution: Verify the connections and ensure the power supply voltage is within the specified range (3.3V to 5V).

FAQs

Q: Can this sensor detect colored lines?

A: The sensor primarily detects contrast, so it works best with black lines on light surfaces or vice versa. It may not reliably detect colored lines with low contrast.

Q: How many sensors should I use for a line-following robot?

A: For basic line-following, one sensor may suffice. However, for better accuracy and complex paths, using two or more sensors is recommended.

Q: Can this sensor be used outdoors?

A: The sensor is sensitive to ambient light, so it is best used indoors or in controlled lighting conditions. For outdoor use, additional shielding may be required.

Q: Is the sensor compatible with other microcontrollers?

A: Yes, the sensor provides a standard digital output, making it compatible with most microcontrollers, including Arduino, Raspberry Pi, and others.