How to Use Floatless Relay: Examples, Pinouts, and Specs

Design with Floatless Relay in Cirkit Designer

Design with Floatless Relay in Cirkit DesignerIntroduction

A floatless relay is an electronic device used to detect the level of liquid in a tank or container without the use of a mechanical float. It operates by sensing the conductivity of the liquid and is commonly used in applications such as water level control and automatic water supply systems. This component is highly reliable and maintenance-free, making it ideal for various industrial and domestic applications.

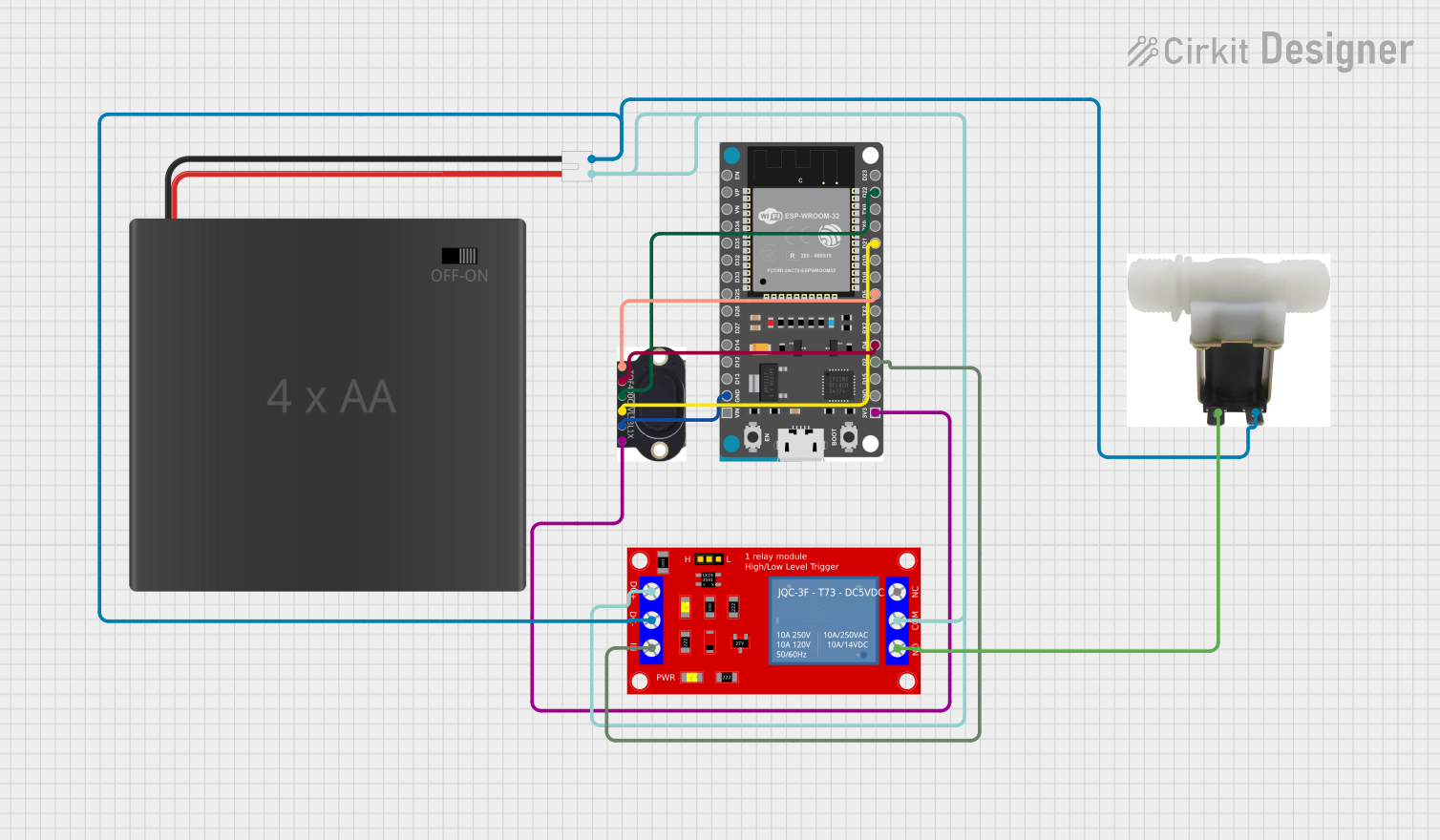

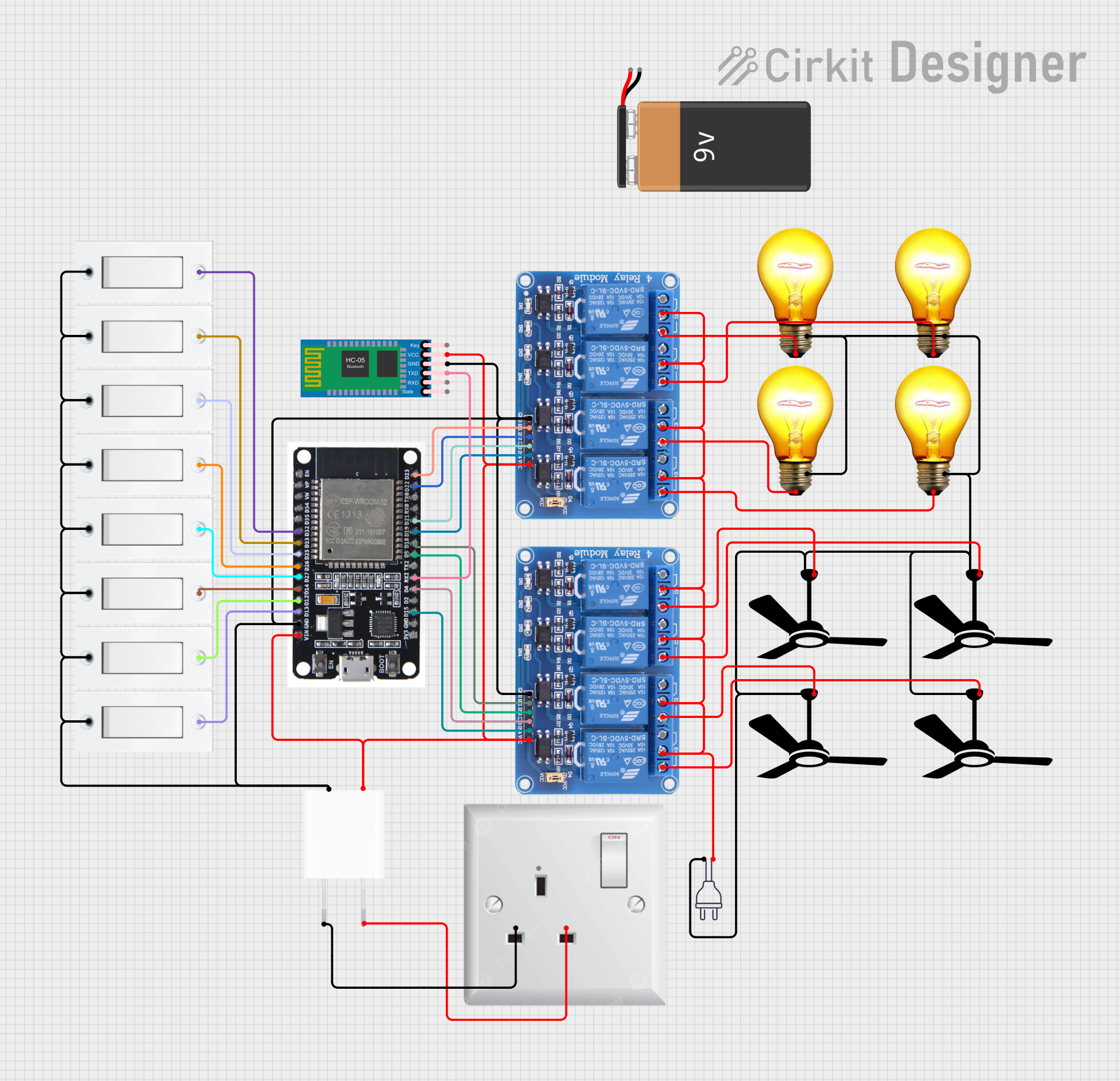

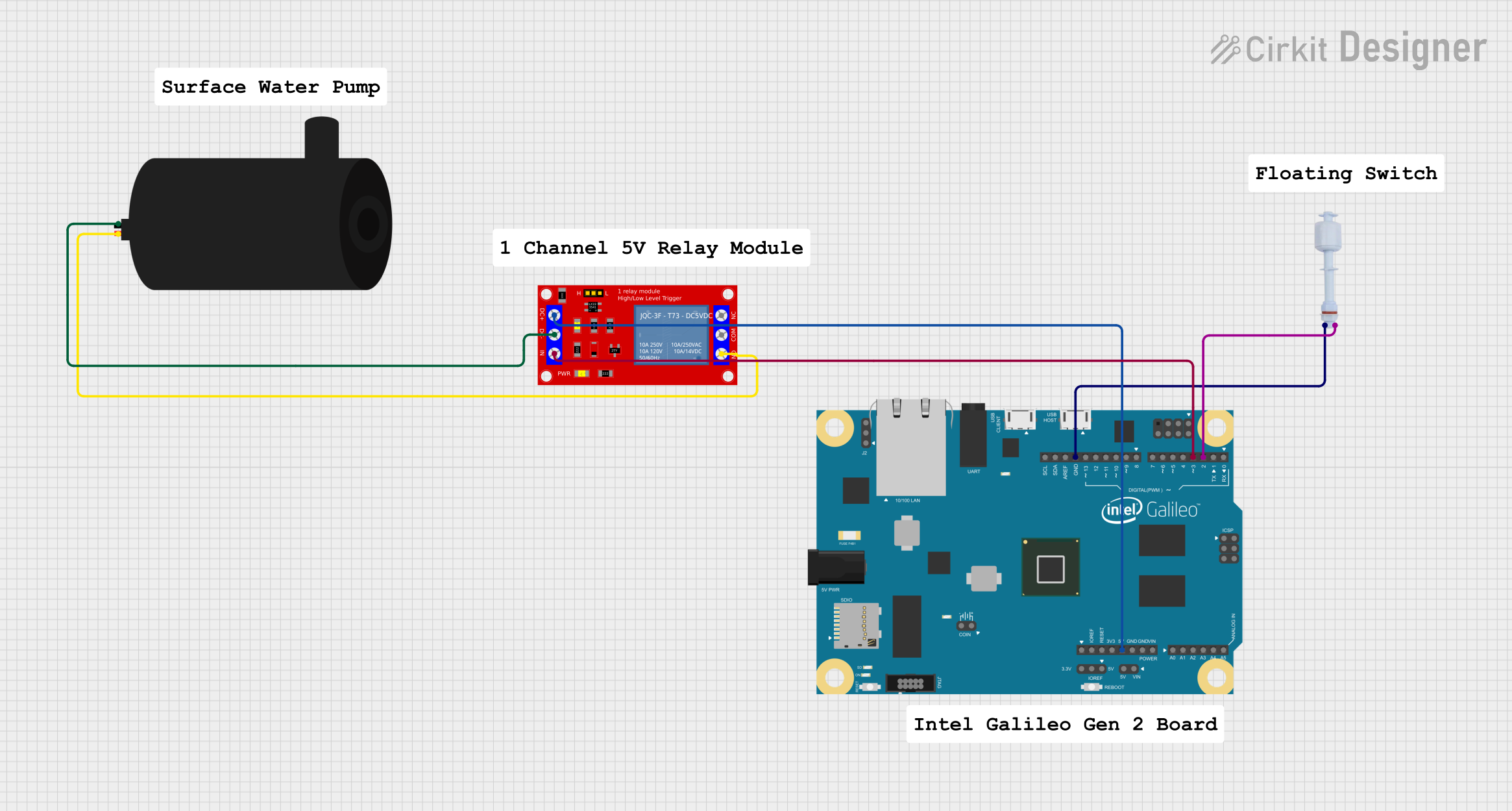

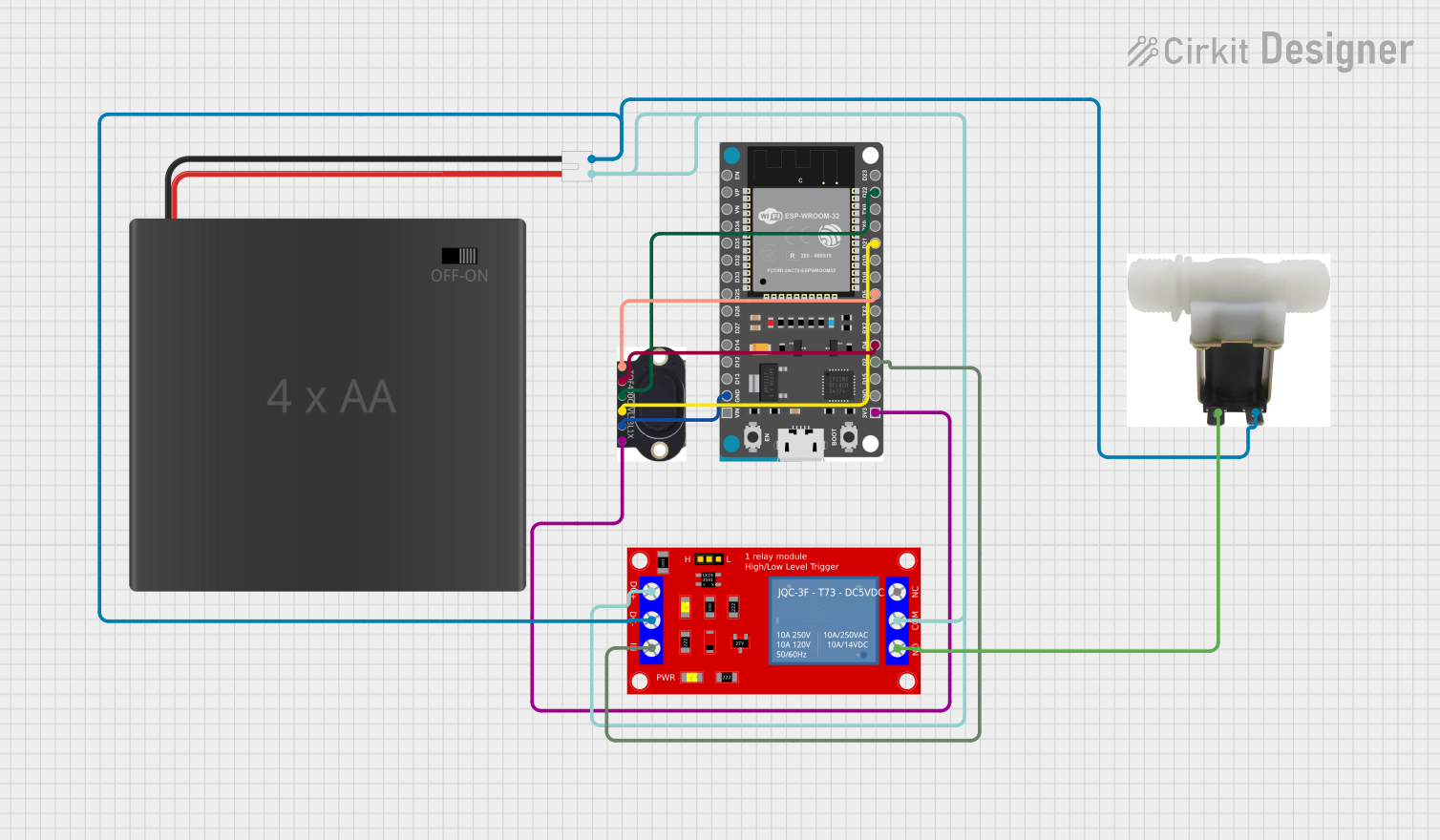

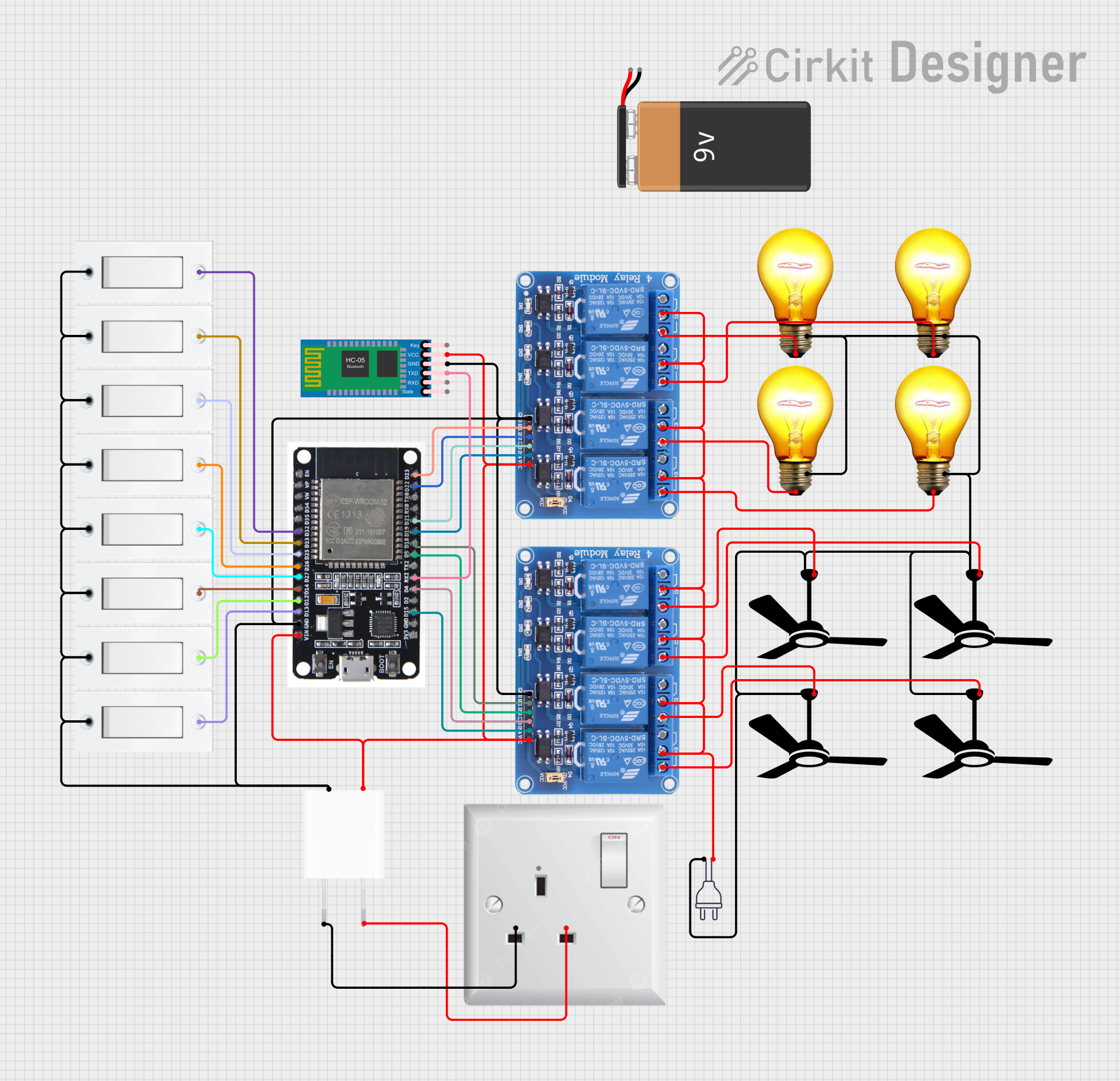

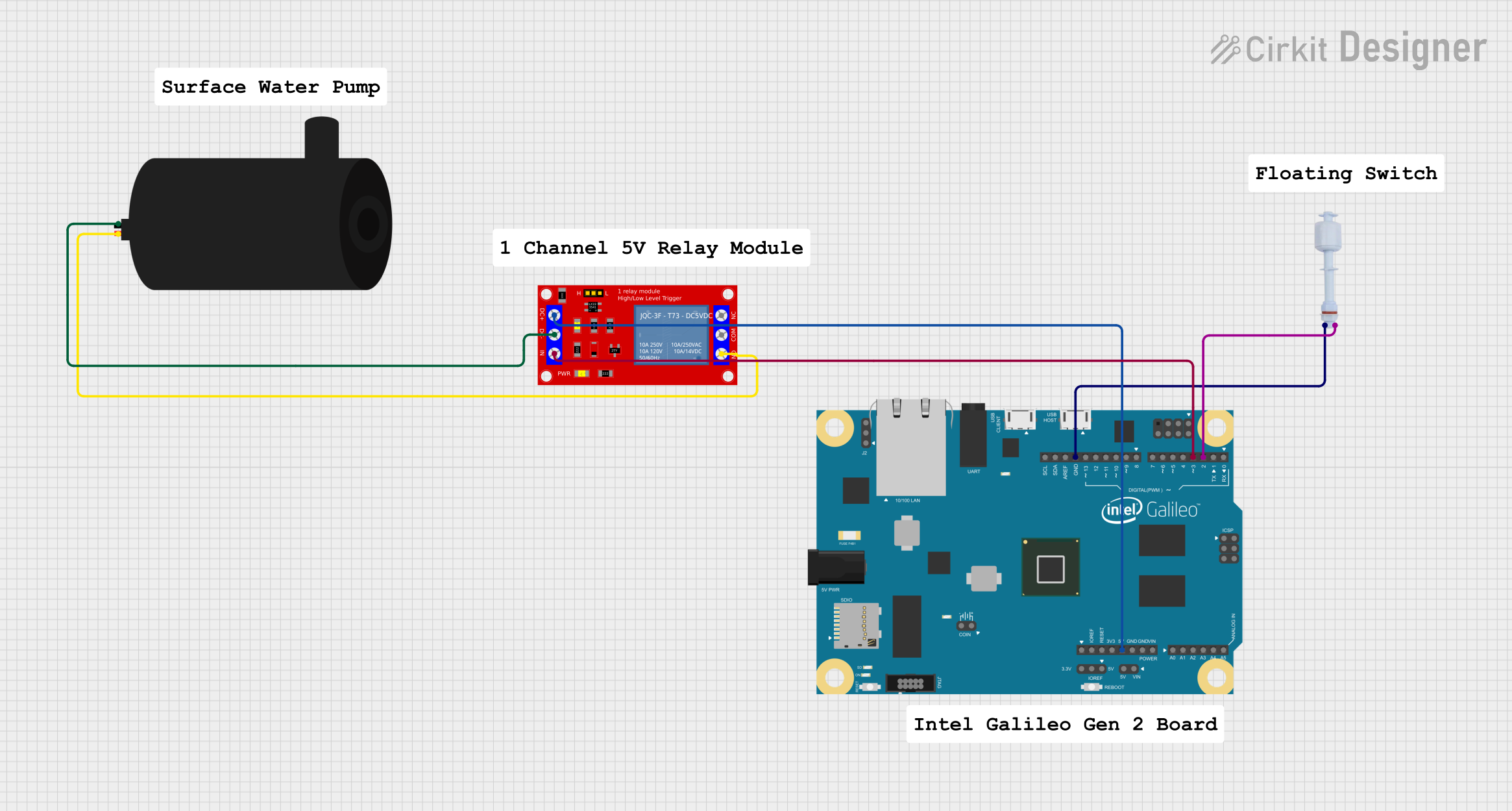

Explore Projects Built with Floatless Relay

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Floatless Relay

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Operating Voltage | 24V DC / 110V AC / 220V AC |

| Operating Current | 10mA - 100mA |

| Power Consumption | < 3W |

| Contact Capacity | 5A at 250V AC |

| Sensitivity Range | 0 - 100kΩ |

| Response Time | < 100ms |

| Operating Temperature | -10°C to 55°C |

| Storage Temperature | -25°C to 75°C |

Pin Configuration and Descriptions

| Pin No. | Pin Name | Description |

|---|---|---|

| 1 | COM | Common terminal for power supply |

| 2 | NC | Normally Closed contact |

| 3 | NO | Normally Open contact |

| 4 | E1 | Electrode 1 (connected to the liquid level sensor) |

| 5 | E2 | Electrode 2 (connected to the liquid level sensor) |

| 6 | GND | Ground terminal |

Usage Instructions

How to Use the Component in a Circuit

Power Supply Connection:

- Connect the power supply to the COM pin (Pin 1) and GND pin (Pin 6).

- Ensure the power supply voltage matches the operating voltage of the floatless relay.

Sensor Connection:

- Connect the liquid level sensor electrodes to E1 (Pin 4) and E2 (Pin 5).

- Ensure the electrodes are properly placed in the tank or container to detect the desired liquid level.

Output Connection:

- Connect the load (e.g., pump, alarm) to the NO (Pin 3) or NC (Pin 2) contact based on the desired operation.

- NO contact will close when the liquid level is detected, while NC contact will open.

Important Considerations and Best Practices

- Proper Grounding: Ensure the GND pin is properly connected to avoid false triggering.

- Electrode Placement: Place the electrodes at appropriate levels to accurately detect the liquid level.

- Power Supply: Use a stable power supply to avoid fluctuations that may affect the relay's operation.

- Regular Inspection: Periodically inspect the electrodes for any buildup or corrosion that may affect conductivity.

Troubleshooting and FAQs

Common Issues Users Might Face

False Triggering:

- Solution: Check the grounding and ensure the electrodes are clean and properly placed.

No Response from Relay:

- Solution: Verify the power supply voltage and connections. Ensure the electrodes are submerged in the liquid.

Intermittent Operation:

- Solution: Check for loose connections and ensure the power supply is stable.

FAQs

Q1: Can the floatless relay be used with any type of liquid?

- A1: The floatless relay is designed to work with conductive liquids. It may not work with non-conductive liquids like oil.

Q2: How do I adjust the sensitivity of the floatless relay?

- A2: Sensitivity can be adjusted using a potentiometer or a similar adjustment mechanism provided on the relay.

Q3: Can I use the floatless relay with an Arduino UNO?

- A3: Yes, the floatless relay can be interfaced with an Arduino UNO. Below is an example code for interfacing:

// Arduino UNO and Floatless Relay Interface

const int relayPin = 2; // Pin connected to the relay's NO contact

const int sensorPin = A0; // Pin connected to the sensor output

void setup() {

pinMode(relayPin, OUTPUT); // Set relay pin as output

pinMode(sensorPin, INPUT); // Set sensor pin as input

Serial.begin(9600); // Initialize serial communication

}

void loop() {

int sensorValue = analogRead(sensorPin); // Read sensor value

Serial.println(sensorValue); // Print sensor value to serial monitor

if (sensorValue > 500) { // Adjust threshold as needed

digitalWrite(relayPin, HIGH); // Activate relay

} else {

digitalWrite(relayPin, LOW); // Deactivate relay

}

delay(500); // Wait for 500 milliseconds

}

This code reads the sensor value and activates the relay when the liquid level is detected. Adjust the threshold value based on your specific requirements.

By following this documentation, users can effectively utilize the floatless relay in their applications, ensuring reliable and maintenance-free liquid level detection.