How to Use L298N Motor Driver: Examples, Pinouts, and Specs

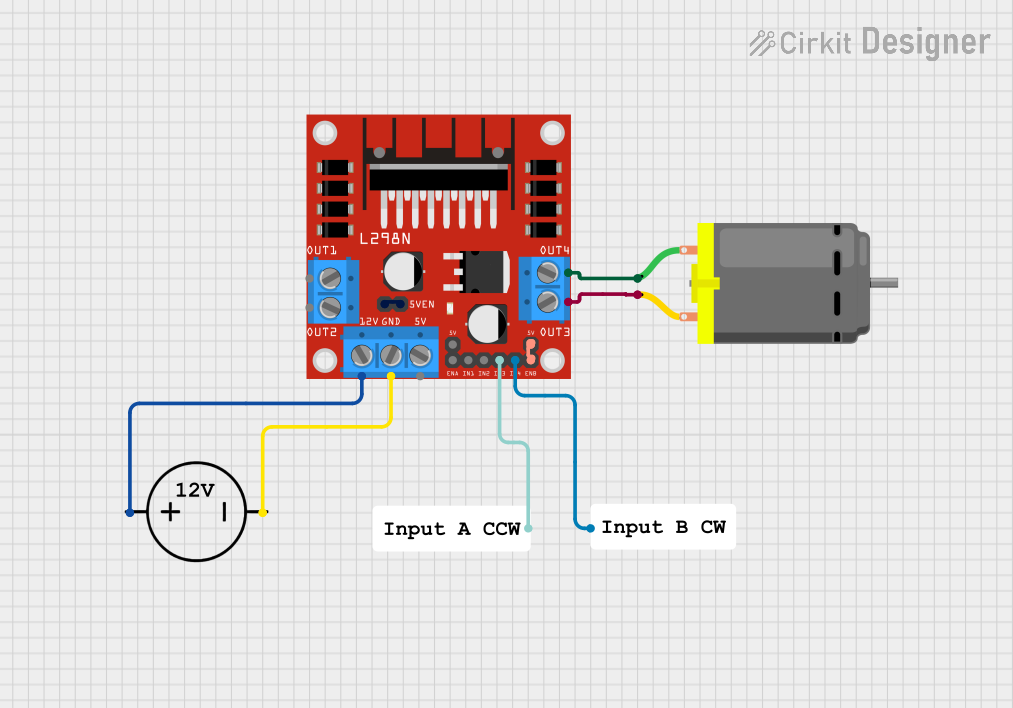

Design with L298N Motor Driver in Cirkit Designer

Design with L298N Motor Driver in Cirkit DesignerIntroduction

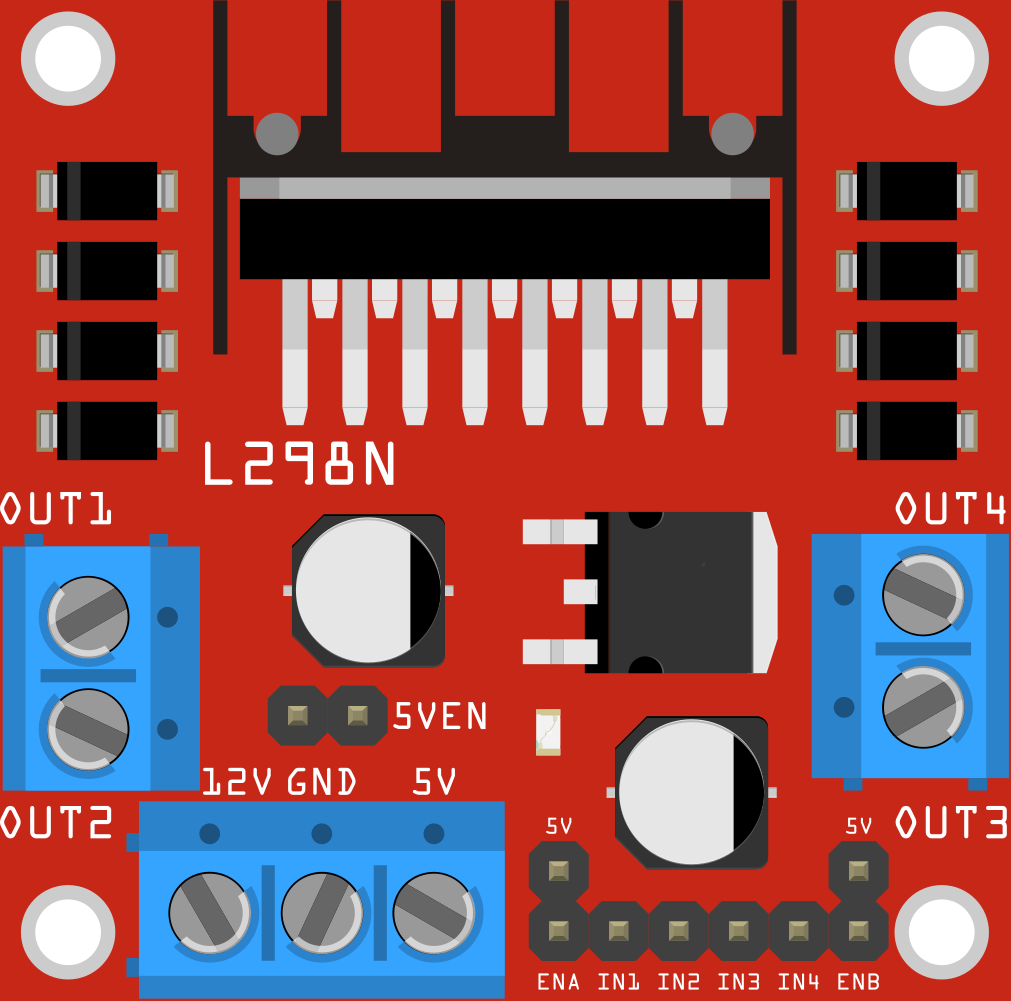

The L298N Motor Driver, manufactured by QWER (Part ID: L298N), is an integrated circuit designed to control two DC motors or a single stepper motor. It supports bidirectional control and speed regulation using PWM (Pulse Width Modulation). With a current handling capacity of up to 2A per channel and an operating voltage range of 5V to 35V, the L298N is a versatile and reliable choice for robotics, automation, and motor control applications.

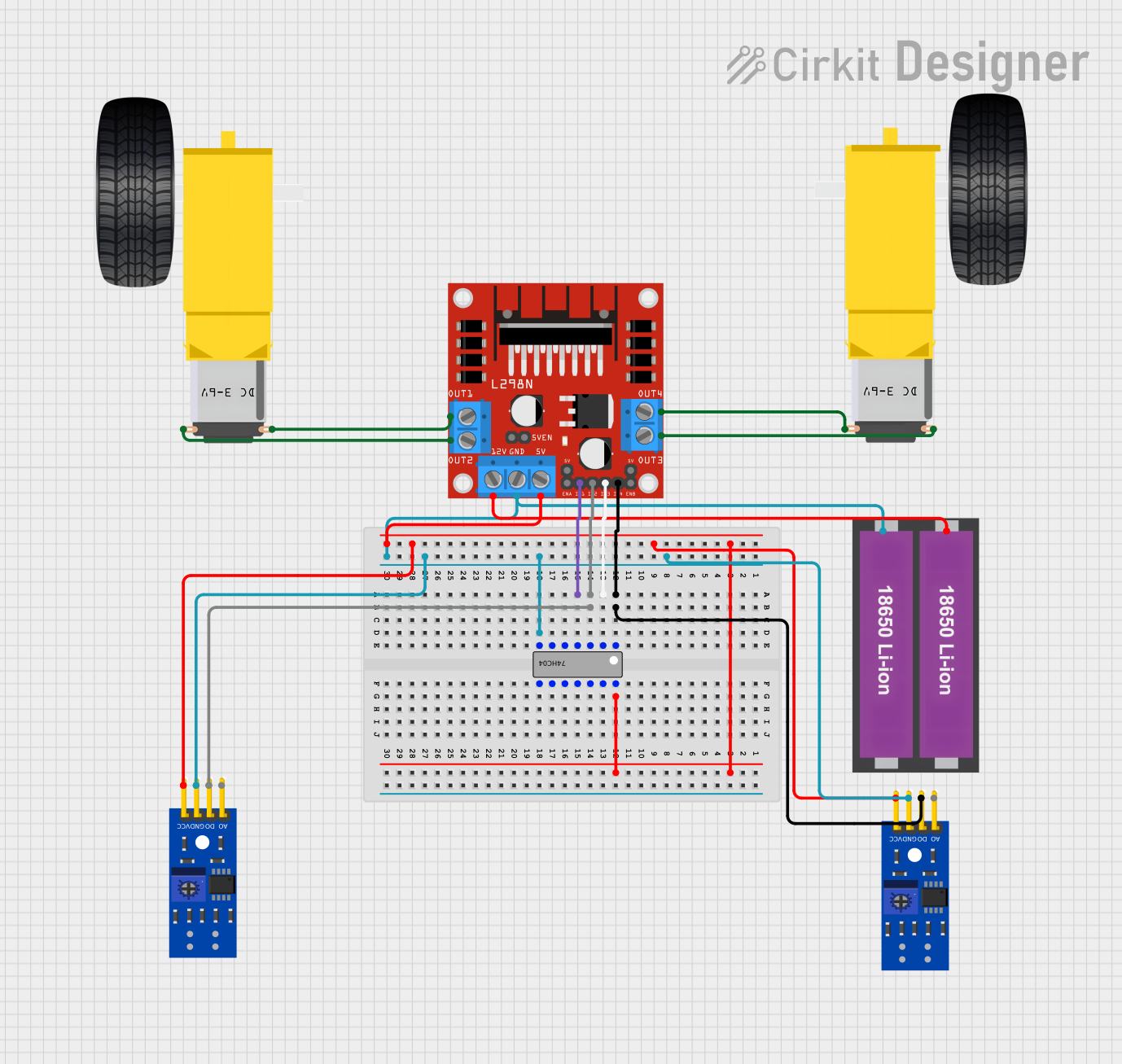

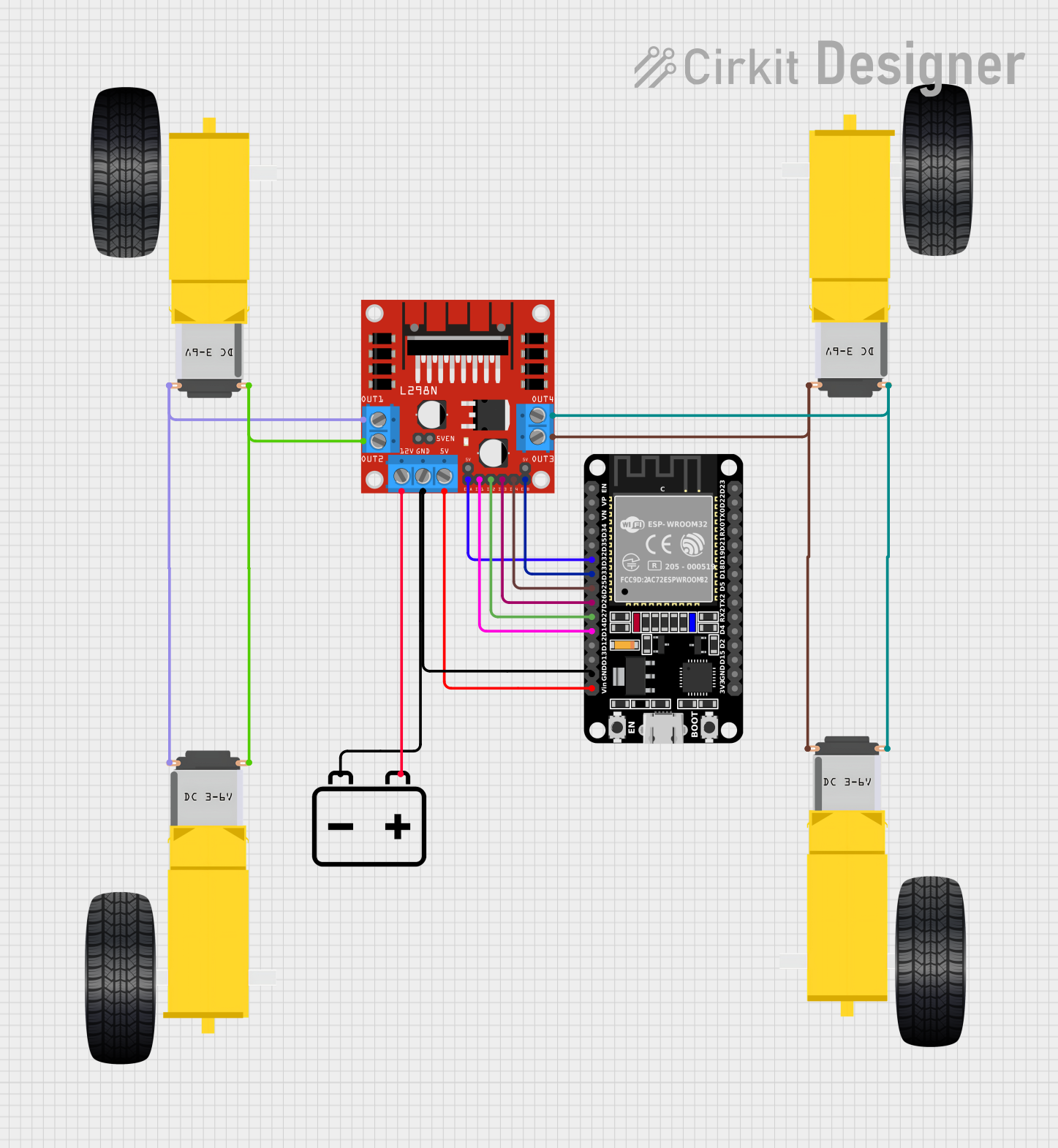

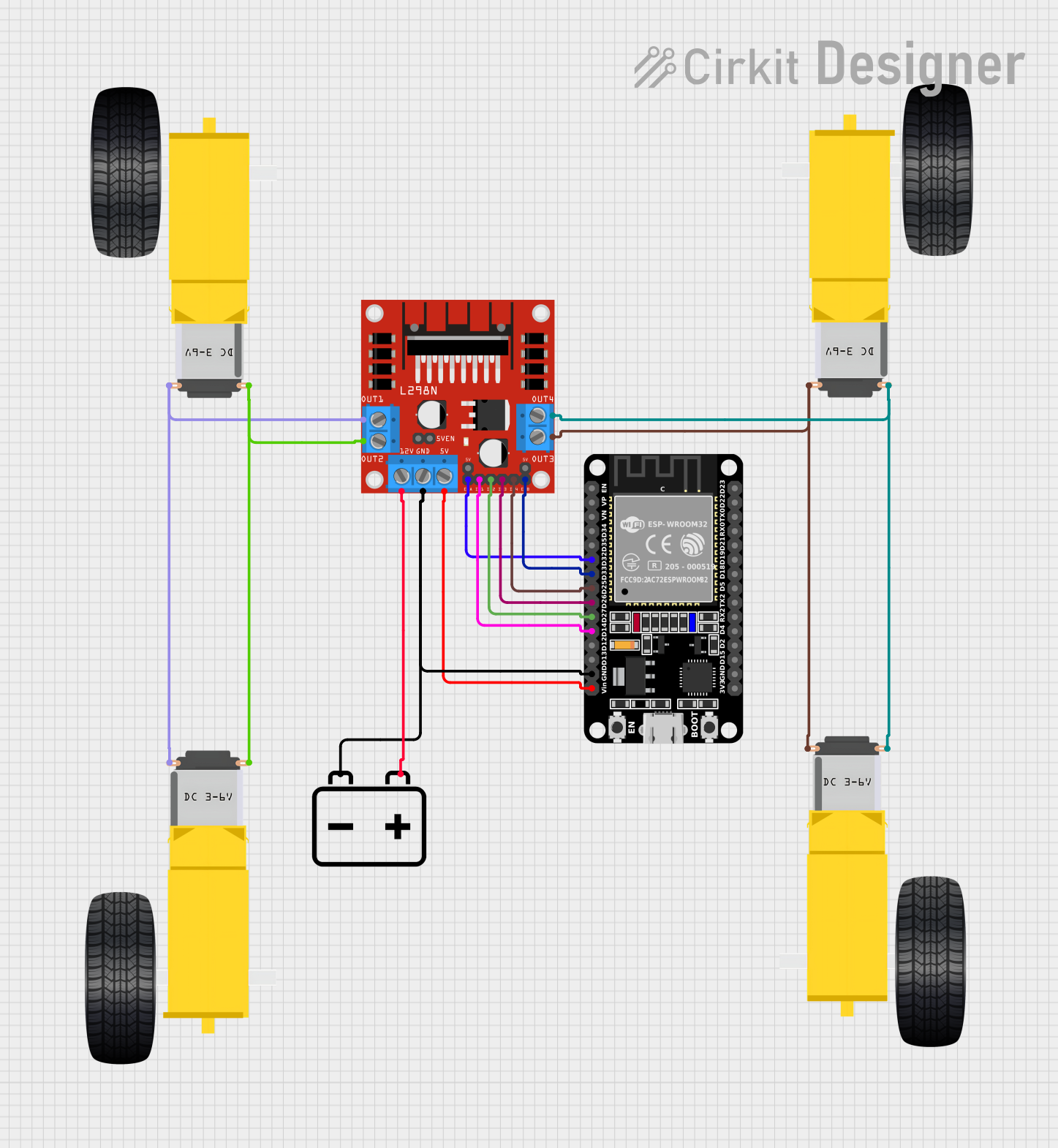

Explore Projects Built with L298N Motor Driver

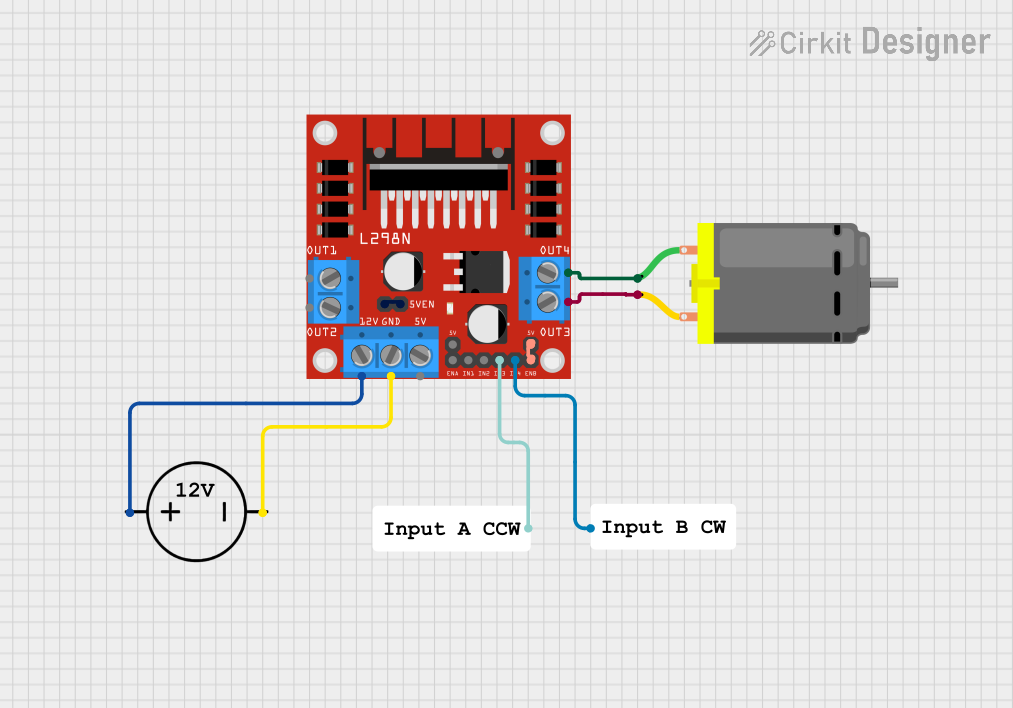

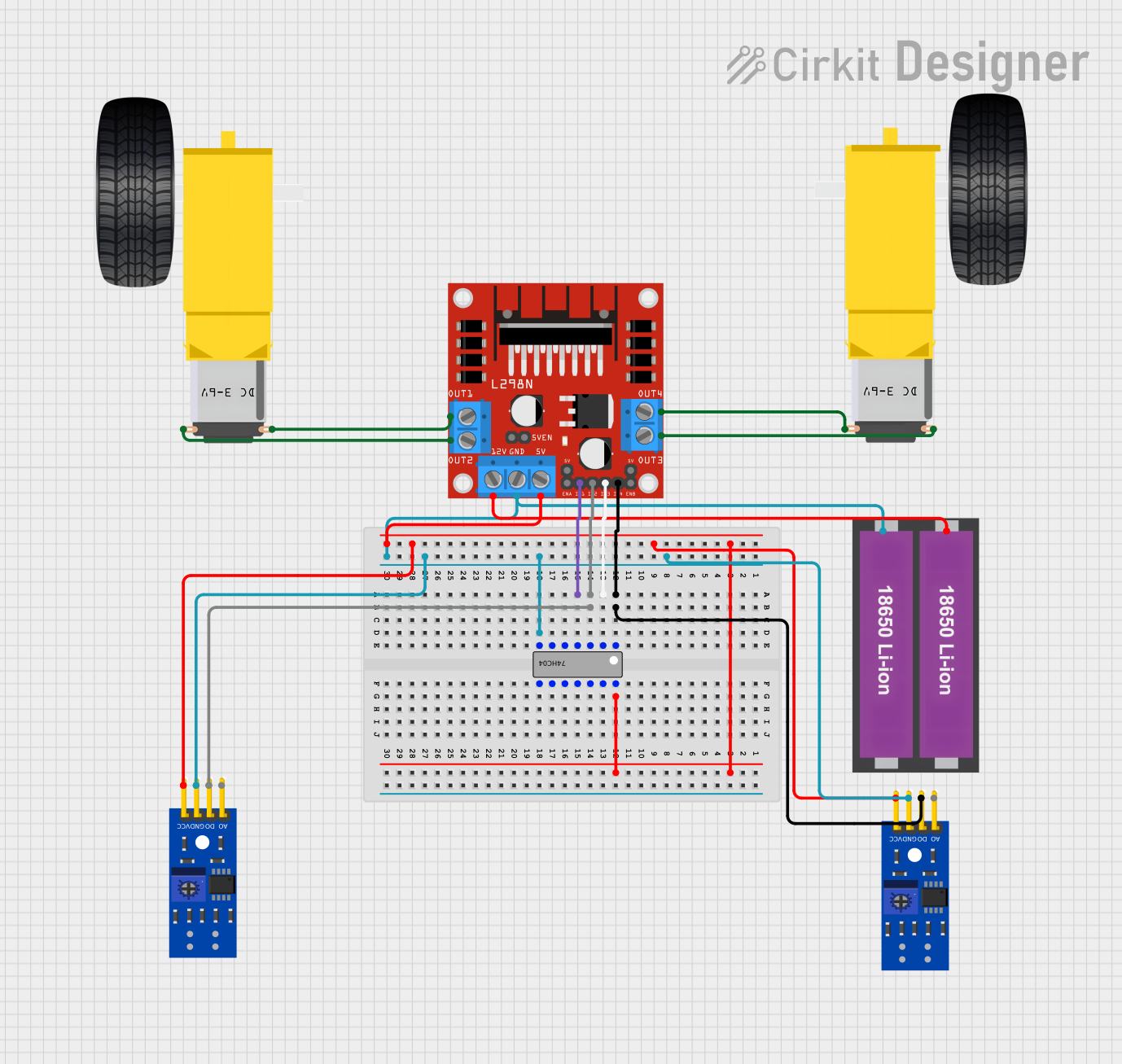

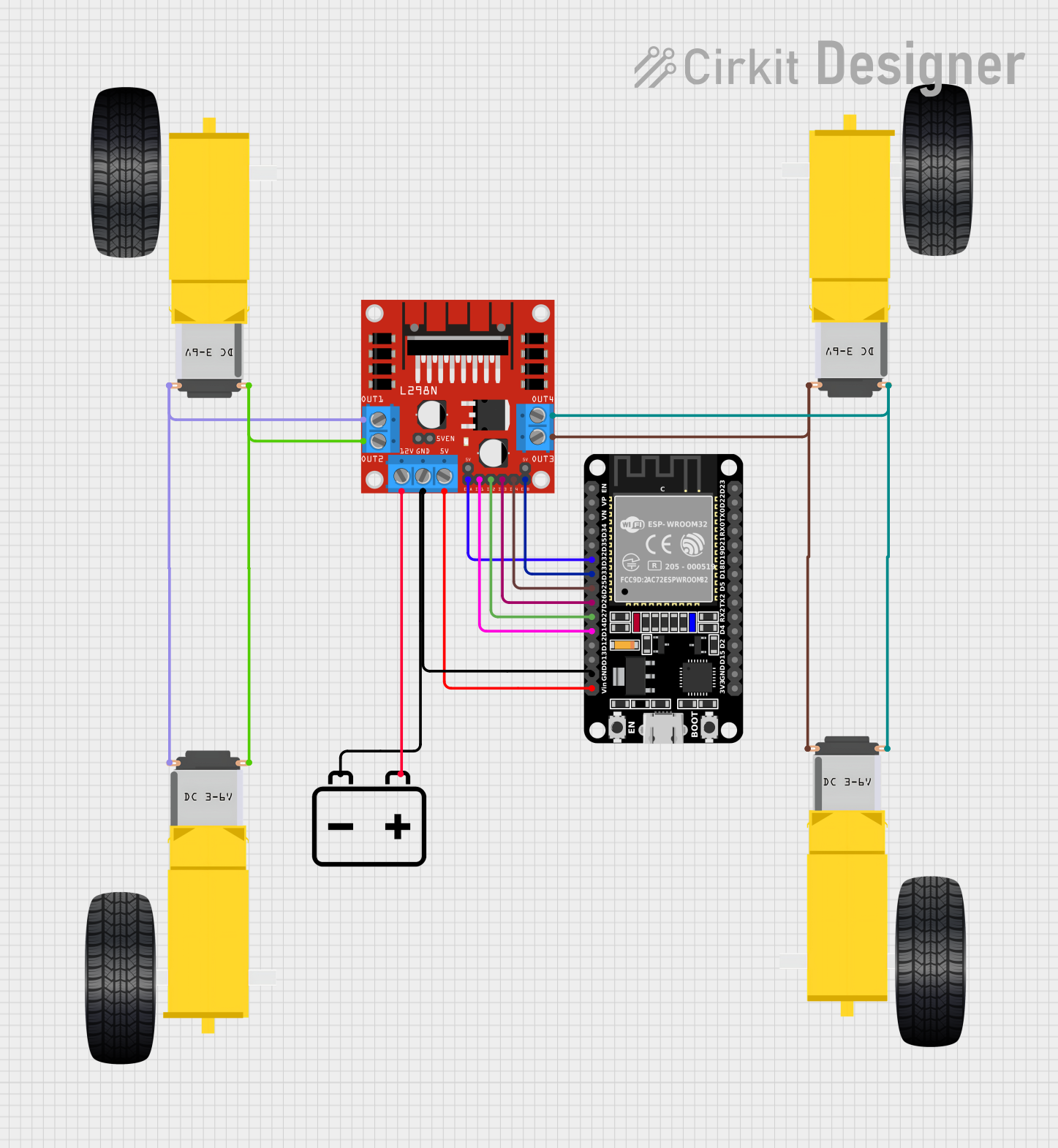

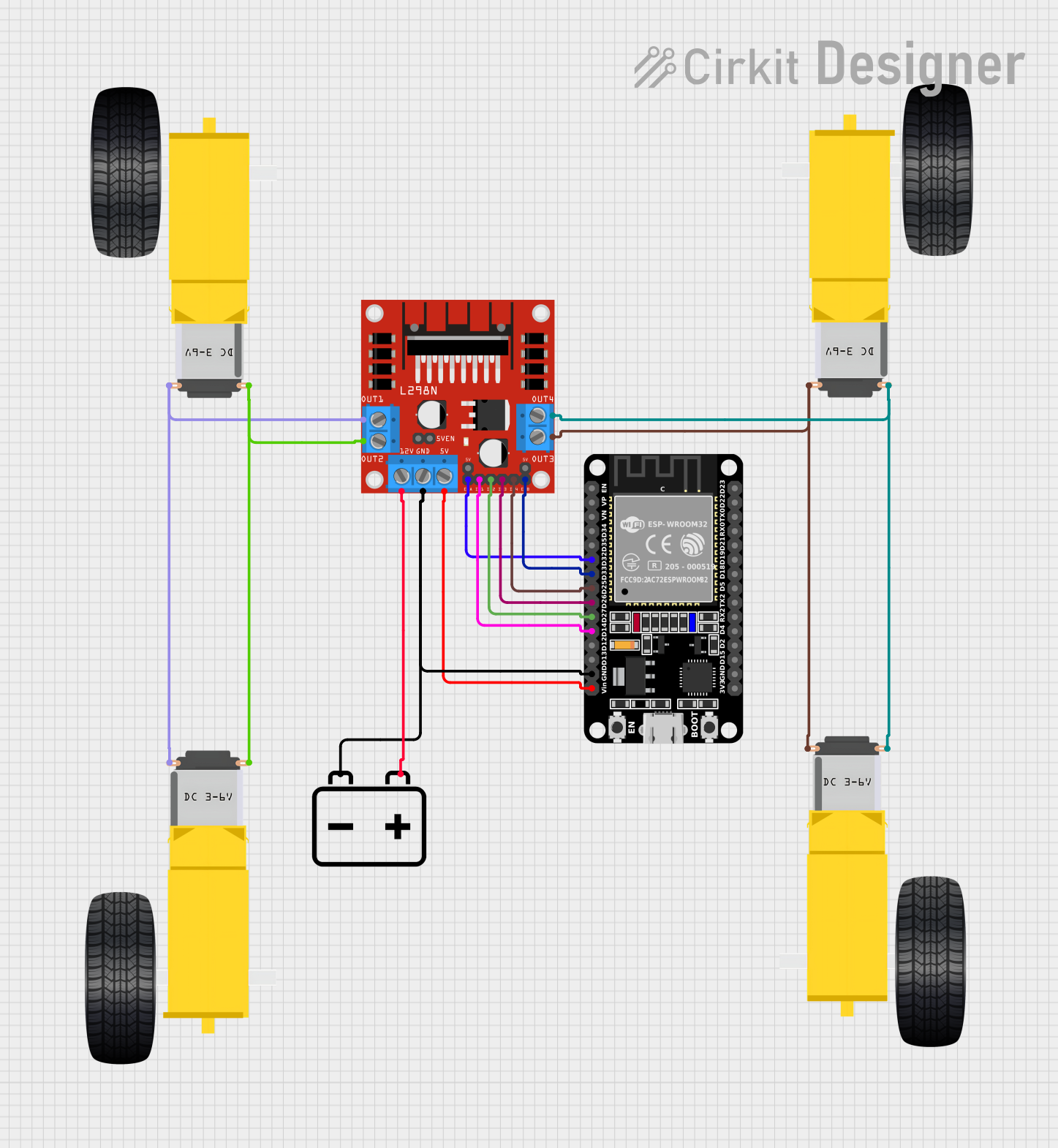

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with L298N Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotics: Driving wheels or robotic arms

- Automation systems: Conveyor belts, actuators

- DIY projects: RC cars, drones, and other motorized devices

- Stepper motor control for CNC machines or 3D printers

Technical Specifications

Below are the key technical details of the L298N Motor Driver:

| Parameter | Value |

|---|---|

| Manufacturer | QWER |

| Part ID | L298N |

| Operating Voltage | 5V to 35V |

| Maximum Current | 2A per channel |

| Logic Voltage | 5V |

| PWM Frequency | Up to 20 kHz |

| Number of Channels | 2 (H-Bridge configuration) |

| Motor Types Supported | DC motors, stepper motors |

| Operating Temperature | -25°C to +130°C |

Pin Configuration and Descriptions

The L298N Motor Driver has the following pin configuration:

| Pin Name | Pin Type | Description |

|---|---|---|

| IN1 | Input | Control input for Motor A (logic HIGH or LOW) |

| IN2 | Input | Control input for Motor A (logic HIGH or LOW) |

| IN3 | Input | Control input for Motor B (logic HIGH or LOW) |

| IN4 | Input | Control input for Motor B (logic HIGH or LOW) |

| ENA | Input (PWM) | Enable pin for Motor A (connect to PWM for speed control) |

| ENB | Input (PWM) | Enable pin for Motor B (connect to PWM for speed control) |

| OUT1 | Output | Output to Motor A terminal 1 |

| OUT2 | Output | Output to Motor A terminal 2 |

| OUT3 | Output | Output to Motor B terminal 1 |

| OUT4 | Output | Output to Motor B terminal 2 |

| VCC | Power Input | Motor power supply (5V to 35V) |

| GND | Ground | Common ground |

| 5V | Power Output | 5V output (used to power logic circuits if needed) |

Usage Instructions

How to Use the L298N in a Circuit

Power Connections:

- Connect the motor power supply to the

VCCpin (5V to 35V). - Connect the ground of the power supply to the

GNDpin. - If the motor power supply is above 7V, you can use the onboard 5V regulator to power the logic circuit by connecting the

5Vpin to your microcontroller.

- Connect the motor power supply to the

Motor Connections:

- For Motor A, connect its terminals to

OUT1andOUT2. - For Motor B, connect its terminals to

OUT3andOUT4.

- For Motor A, connect its terminals to

Control Connections:

- Connect the

IN1andIN2pins to your microcontroller to control Motor A's direction. - Connect the

IN3andIN4pins to your microcontroller to control Motor B's direction. - Use the

ENAandENBpins for speed control by providing a PWM signal.

- Connect the

Logic Power:

- If using an external 5V logic power source, connect it to the

5Vpin. Ensure the ground of the logic power source is connected to theGNDpin.

- If using an external 5V logic power source, connect it to the

Important Considerations

- Heat Dissipation: The L298N can get hot during operation. Use a heatsink or active cooling for high-current applications.

- Current Limitation: Ensure the motor's current does not exceed 2A per channel to avoid damage.

- Flyback Diodes: The L298N has built-in flyback diodes to protect against voltage spikes caused by motor inductance.

Example: Connecting to an Arduino UNO

Below is an example of how to control a DC motor using the L298N and an Arduino UNO:

Circuit Connections

- Connect

ENAto Arduino pin 9 (PWM output). - Connect

IN1to Arduino pin 8. - Connect

IN2to Arduino pin 7. - Connect the motor terminals to

OUT1andOUT2. - Connect the motor power supply to

VCCandGND.

Arduino Code

// L298N Motor Driver Example with Arduino UNO

// Controls a single DC motor connected to Motor A

#define ENA 9 // PWM pin for speed control

#define IN1 8 // Direction control pin 1

#define IN2 7 // Direction control pin 2

void setup() {

// Set motor control pins as outputs

pinMode(ENA, OUTPUT);

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

}

void loop() {

// Rotate motor forward

digitalWrite(IN1, HIGH); // Set IN1 HIGH

digitalWrite(IN2, LOW); // Set IN2 LOW

analogWrite(ENA, 150); // Set speed (0-255)

delay(2000); // Run for 2 seconds

// Rotate motor backward

digitalWrite(IN1, LOW); // Set IN1 LOW

digitalWrite(IN2, HIGH); // Set IN2 HIGH

analogWrite(ENA, 150); // Set speed (0-255)

delay(2000); // Run for 2 seconds

// Stop motor

digitalWrite(IN1, LOW); // Set IN1 LOW

digitalWrite(IN2, LOW); // Set IN2 LOW

analogWrite(ENA, 0); // Set speed to 0

delay(2000); // Wait for 2 seconds

}

Troubleshooting and FAQs

Common Issues

Motor Not Spinning:

- Check the power supply voltage and ensure it matches the motor's requirements.

- Verify the connections to the

INandOUTpins. - Ensure the

ENAorENBpin is receiving a PWM signal or is set HIGH.

Overheating:

- Ensure the current drawn by the motor does not exceed 2A per channel.

- Use a heatsink or active cooling for high-current applications.

Noisy Motor Operation:

- Check for loose connections.

- Use capacitors across the motor terminals to reduce electrical noise.

FAQs

Q: Can the L298N control stepper motors?

A: Yes, the L298N can control a bipolar stepper motor by using both channels (Motor A and Motor B).

Q: Can I use the onboard 5V regulator to power my Arduino?

A: Yes, if the motor power supply is above 7V, the onboard 5V regulator can provide power to the Arduino. However, ensure the current draw does not exceed the regulator's capacity.

Q: What is the maximum PWM frequency supported?

A: The L298N supports PWM frequencies up to 20 kHz.

Q: Can I control more than two motors with one L298N?

A: No, the L298N can control only two DC motors or one stepper motor. For additional motors, use multiple L298N modules.