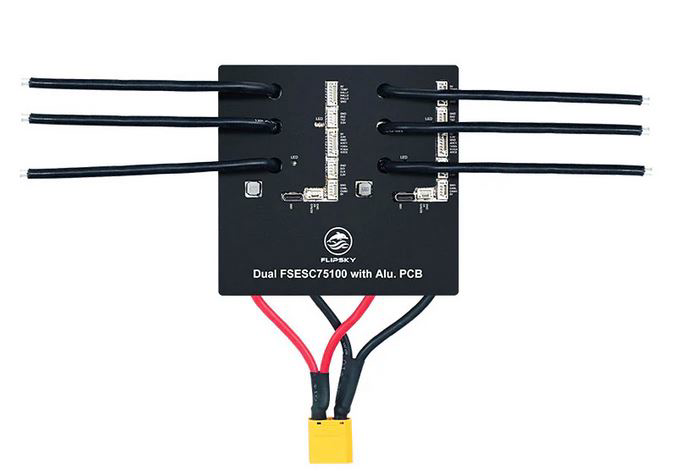

How to Use Flipsky Dual 75100 With Aluminum PCB: Examples, Pinouts, and Specs

Design with Flipsky Dual 75100 With Aluminum PCB in Cirkit Designer

Design with Flipsky Dual 75100 With Aluminum PCB in Cirkit DesignerIntroduction

The Flipsky Dual 75100 is a high-performance dual motor controller specifically designed for electric skateboards, scooters, and other electric vehicles. It features an aluminum PCB, which enhances heat dissipation and ensures durability under high-power operation. This motor controller is capable of driving two brushless DC (BLDC) motors simultaneously, making it an ideal choice for applications requiring precise motor control and high efficiency.

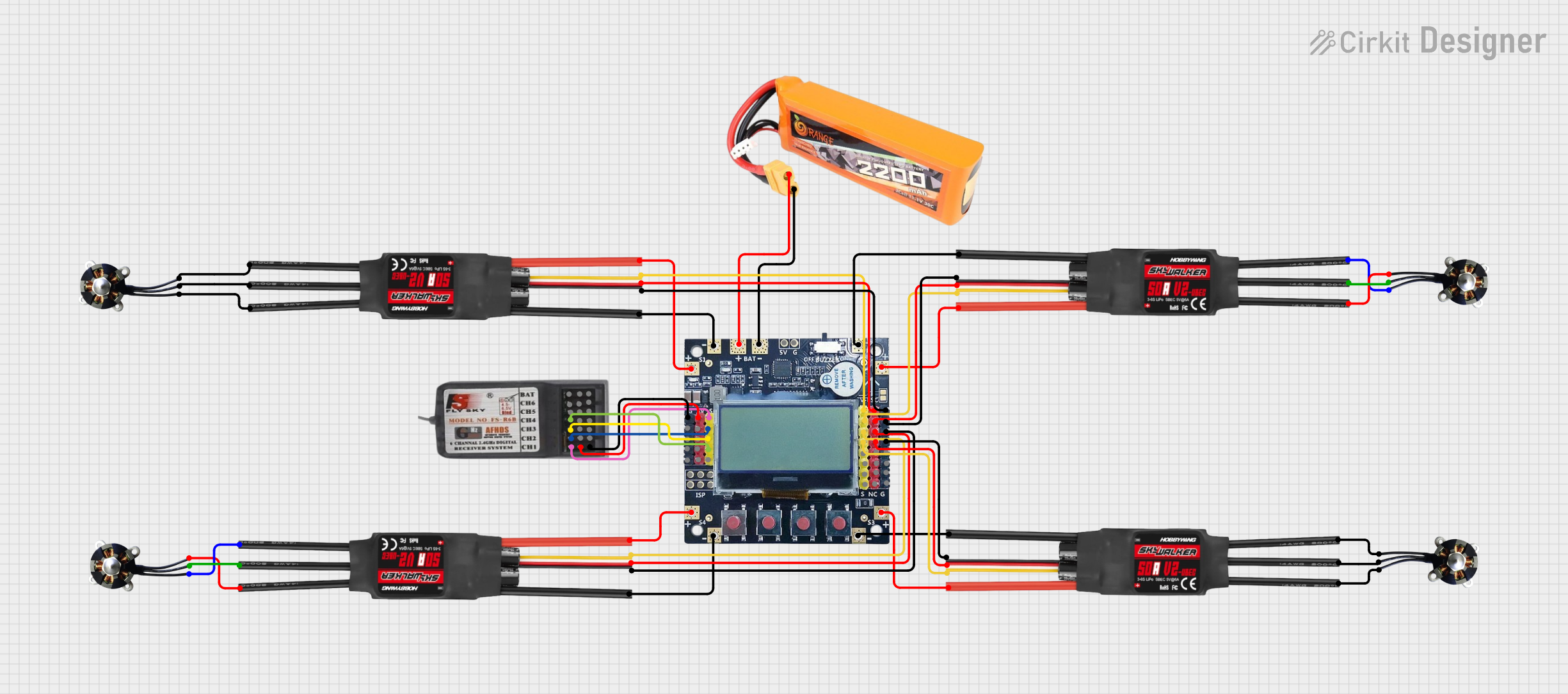

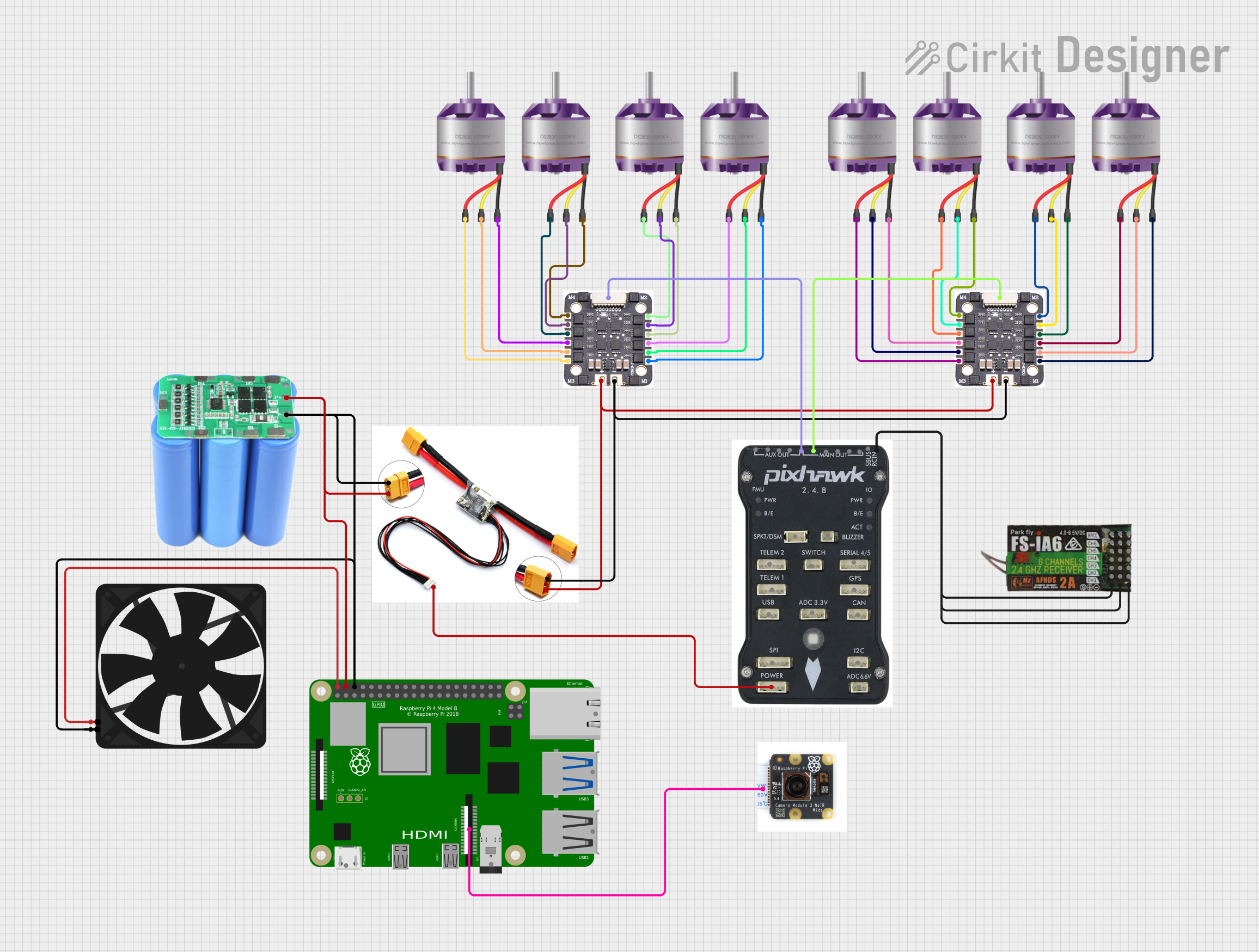

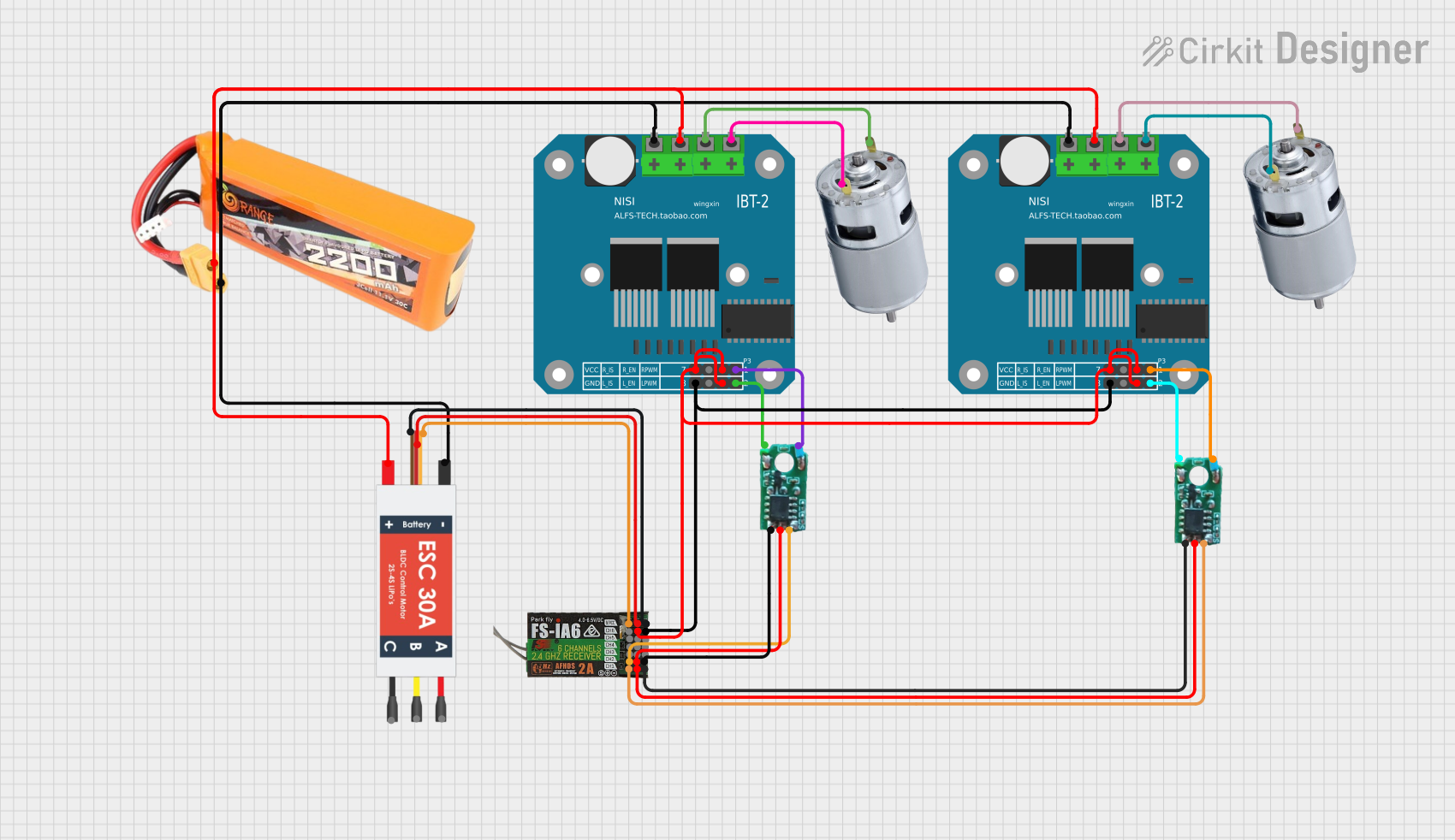

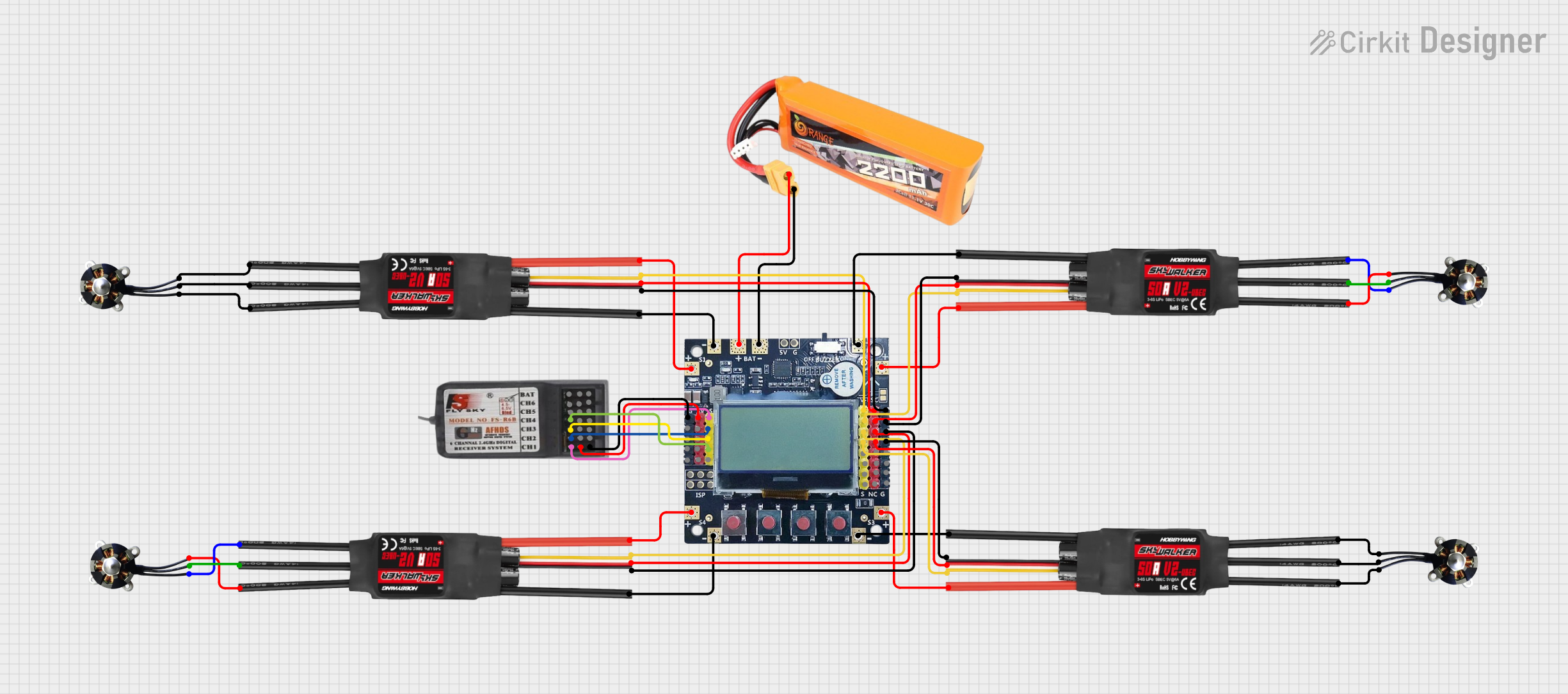

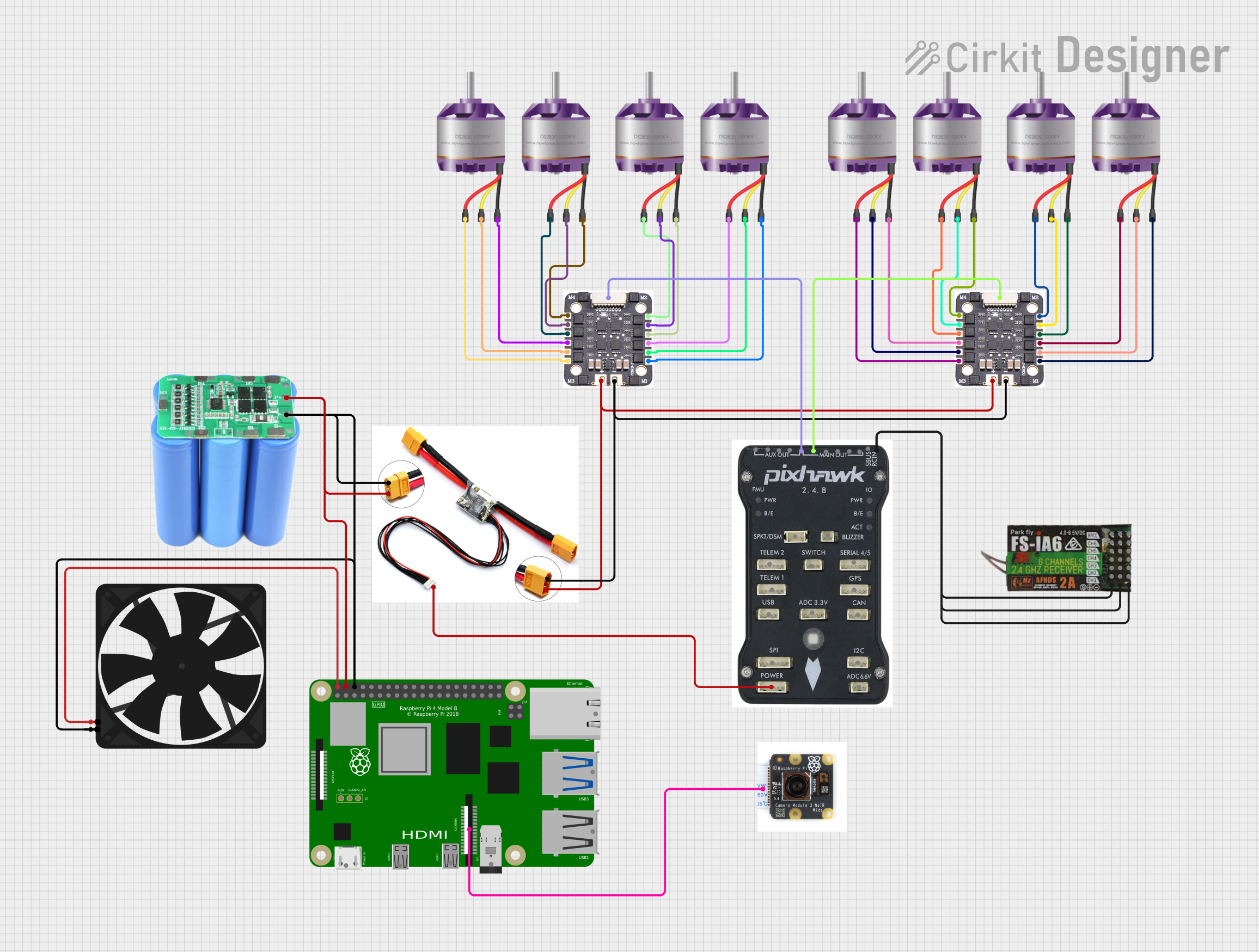

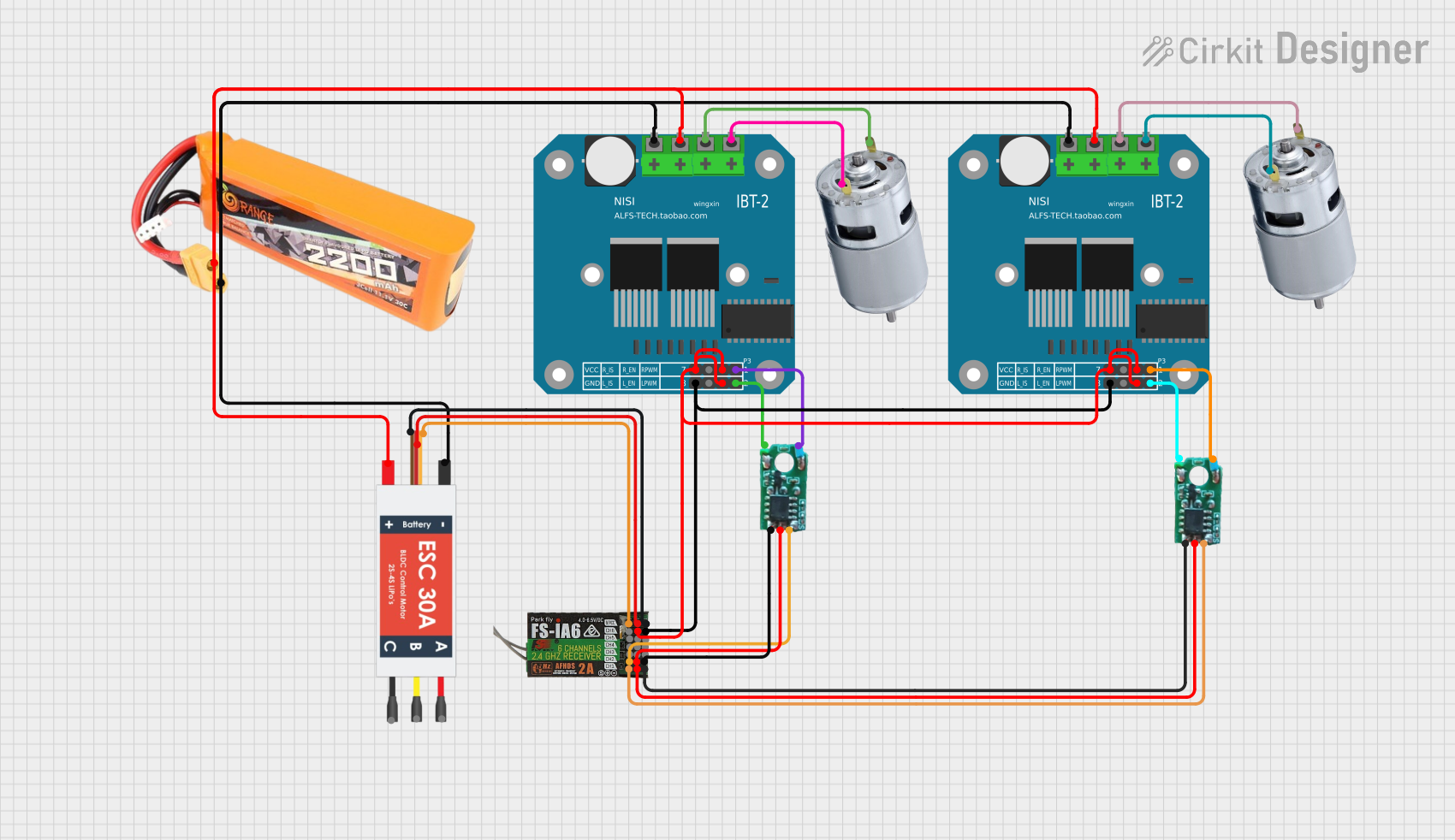

Explore Projects Built with Flipsky Dual 75100 With Aluminum PCB

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Flipsky Dual 75100 With Aluminum PCB

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Electric skateboards and longboards

- Electric scooters and bikes

- Robotics and automation systems

- DIY electric vehicle projects

- High-performance RC vehicles

Technical Specifications

The Flipsky Dual 75100 is engineered to deliver robust performance and reliability. Below are its key technical specifications:

| Parameter | Value |

|---|---|

| Continuous Current (Per Side) | 75A |

| Peak Current (Per Side) | 100A |

| Voltage Range | 14V - 84V (4S - 20S LiPo) |

| Supported Motor Types | Brushless DC (BLDC), FOC |

| Communication Protocols | UART, CAN, PWM |

| PCB Material | Aluminum for enhanced heat dissipation |

| Dimensions | 100mm x 74mm x 20mm |

| Weight | 300g |

Pin Configuration and Descriptions

The Flipsky Dual 75100 features multiple connectors for power, motor, and communication. Below is the pin configuration:

Power and Motor Connections

| Pin Name | Description |

|---|---|

| VBAT+ | Positive terminal for battery input |

| VBAT- | Negative terminal for battery input |

| M1A, M1B, M1C | Phase connections for Motor 1 |

| M2A, M2B, M2C | Phase connections for Motor 2 |

Communication and Control

| Pin Name | Description |

|---|---|

| UART_RX | UART receive pin for communication |

| UART_TX | UART transmit pin for communication |

| CAN_H | CAN bus high line |

| CAN_L | CAN bus low line |

| PWM1 | PWM input for Motor 1 |

| PWM2 | PWM input for Motor 2 |

| GND | Ground for communication signals |

Usage Instructions

How to Use the Component in a Circuit

- Power Connection: Connect the VBAT+ and VBAT- terminals to a compatible battery pack (14V-84V). Ensure the battery can supply sufficient current for your application.

- Motor Connection: Connect the three-phase wires of each motor to the corresponding M1A, M1B, M1C (for Motor 1) and M2A, M2B, M2C (for Motor 2) terminals.

- Control Signals: Use the UART, CAN, or PWM pins to send control signals to the motor controller. For Arduino-based projects, UART is commonly used.

- Cooling: Ensure proper ventilation or additional cooling, as the controller may generate heat during operation despite the aluminum PCB.

Important Considerations and Best Practices

- Voltage Compatibility: Ensure the battery voltage is within the supported range (14V-84V). Exceeding this range may damage the controller.

- Current Limits: Configure the current limits in the firmware to match your motor and battery specifications.

- Firmware Configuration: Use the VESC Tool software to configure the controller for your specific motors and application.

- Wiring: Double-check all connections before powering on the system to avoid short circuits or damage.

- Heat Management: While the aluminum PCB improves heat dissipation, consider adding a heatsink or active cooling for high-power applications.

Example: Using with Arduino UNO

Below is an example of controlling the Flipsky Dual 75100 using UART communication with an Arduino UNO:

#include <SoftwareSerial.h>

// Define RX and TX pins for UART communication

#define RX_PIN 10 // Arduino pin connected to UART_TX of the controller

#define TX_PIN 11 // Arduino pin connected to UART_RX of the controller

// Initialize SoftwareSerial for UART communication

SoftwareSerial motorController(RX_PIN, TX_PIN);

void setup() {

// Start serial communication with the motor controller

motorController.begin(115200); // Default baud rate for the controller

Serial.begin(9600); // For debugging via Serial Monitor

// Send an example command to the motor controller

// Replace with actual commands based on your application

motorController.write("start_motor_1");

Serial.println("Motor 1 start command sent.");

}

void loop() {

// Example: Read data from the motor controller

if (motorController.available()) {

String response = motorController.readString();

Serial.println("Controller Response: " + response);

}

// Add your motor control logic here

}

Note: Replace

"start_motor_1"with the actual command format supported by the Flipsky Dual 75100. Refer to the VESC Tool documentation for command details.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Spinning

- Cause: Incorrect wiring or configuration.

- Solution: Verify motor phase connections and ensure the controller is configured correctly using the VESC Tool.

Overheating

- Cause: Insufficient cooling or excessive current draw.

- Solution: Add a heatsink or active cooling. Reduce the current limits in the firmware.

No Communication with Controller

- Cause: Incorrect UART, CAN, or PWM connections.

- Solution: Check the wiring and ensure the correct baud rate or protocol is used.

Controller Not Powering On

- Cause: Insufficient battery voltage or loose connections.

- Solution: Ensure the battery voltage is within the supported range and check all power connections.

FAQs

Q: Can I use the Flipsky Dual 75100 with a single motor?

A: Yes, you can use the controller with a single motor by connecting it to either Motor 1 or Motor 2 terminals. Ensure the unused motor terminals are left unconnected.

Q: What software is required to configure the controller?

A: The Flipsky Dual 75100 is compatible with the VESC Tool software, which allows you to configure motor parameters, current limits, and control modes.

Q: Is the controller waterproof?

A: No, the controller is not waterproof. It is recommended to protect it from water and moisture during use.

Q: Can I use this controller for hub motors?

A: Yes, the Flipsky Dual 75100 supports hub motors as long as they are brushless DC (BLDC) motors and within the voltage and current limits of the controller.