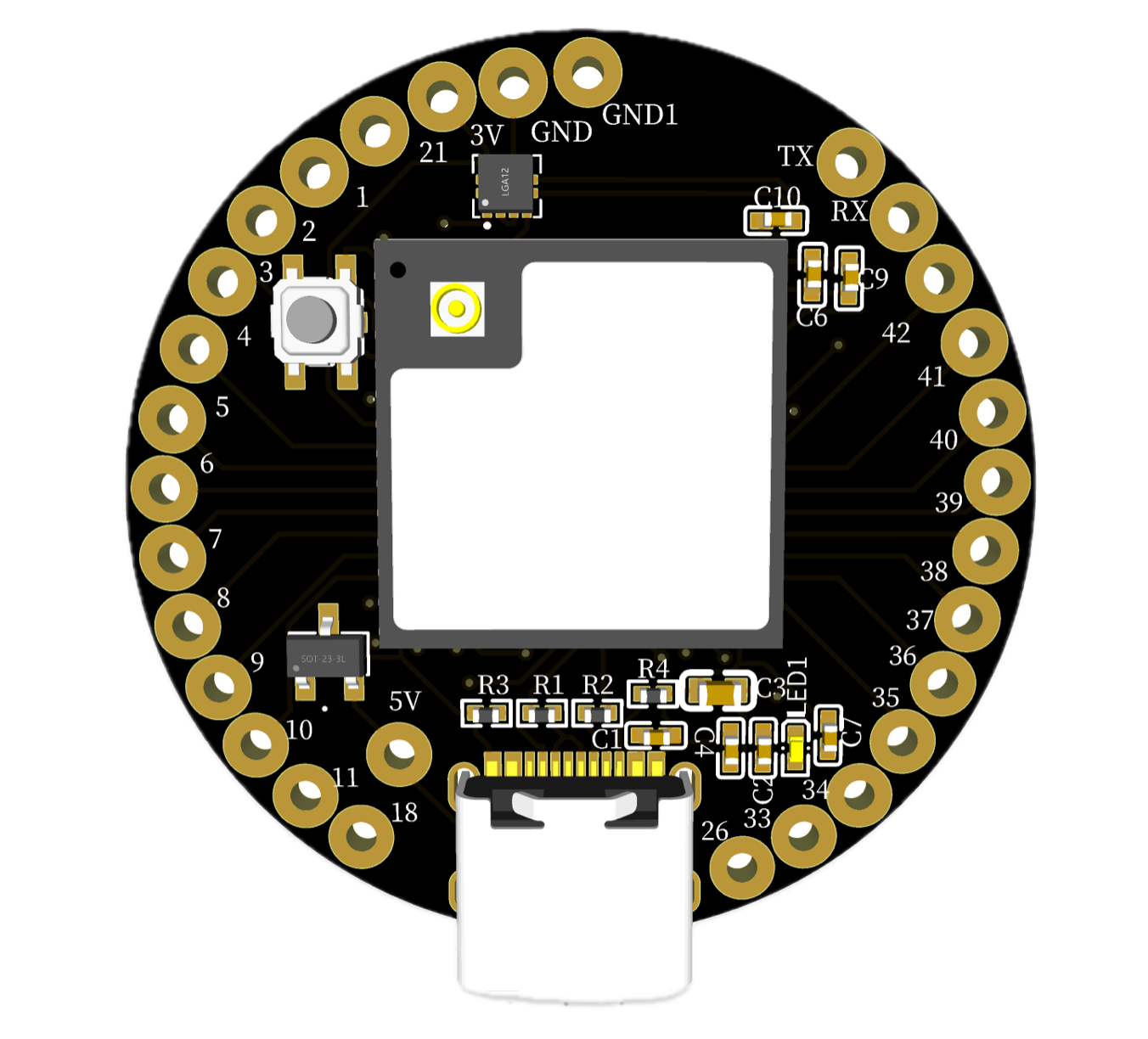

How to Use IndusBoard: Examples, Pinouts, and Specs

Design with IndusBoard in Cirkit Designer

Design with IndusBoard in Cirkit DesignerIntroduction

The IndusBoard Coin V2 is a versatile development board designed for industrial applications. It features multiple I/O options, robust power management, and compatibility with various communication protocols. This board is ideal for developing and prototyping industrial automation systems, IoT devices, and other embedded applications.

Common Applications:

- Industrial automation

- IoT (Internet of Things) devices

- Embedded systems development

- Prototyping and testing of industrial equipment

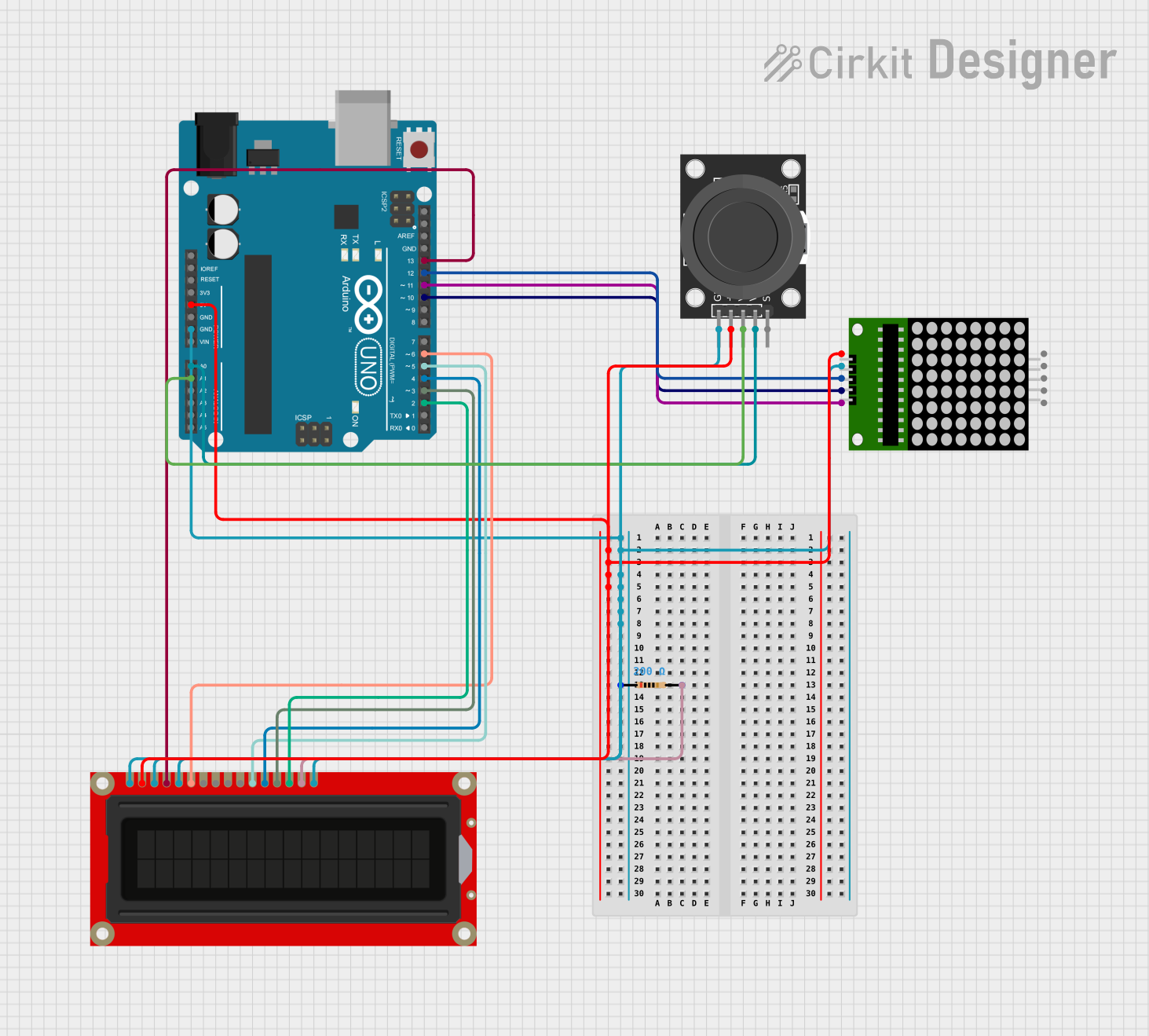

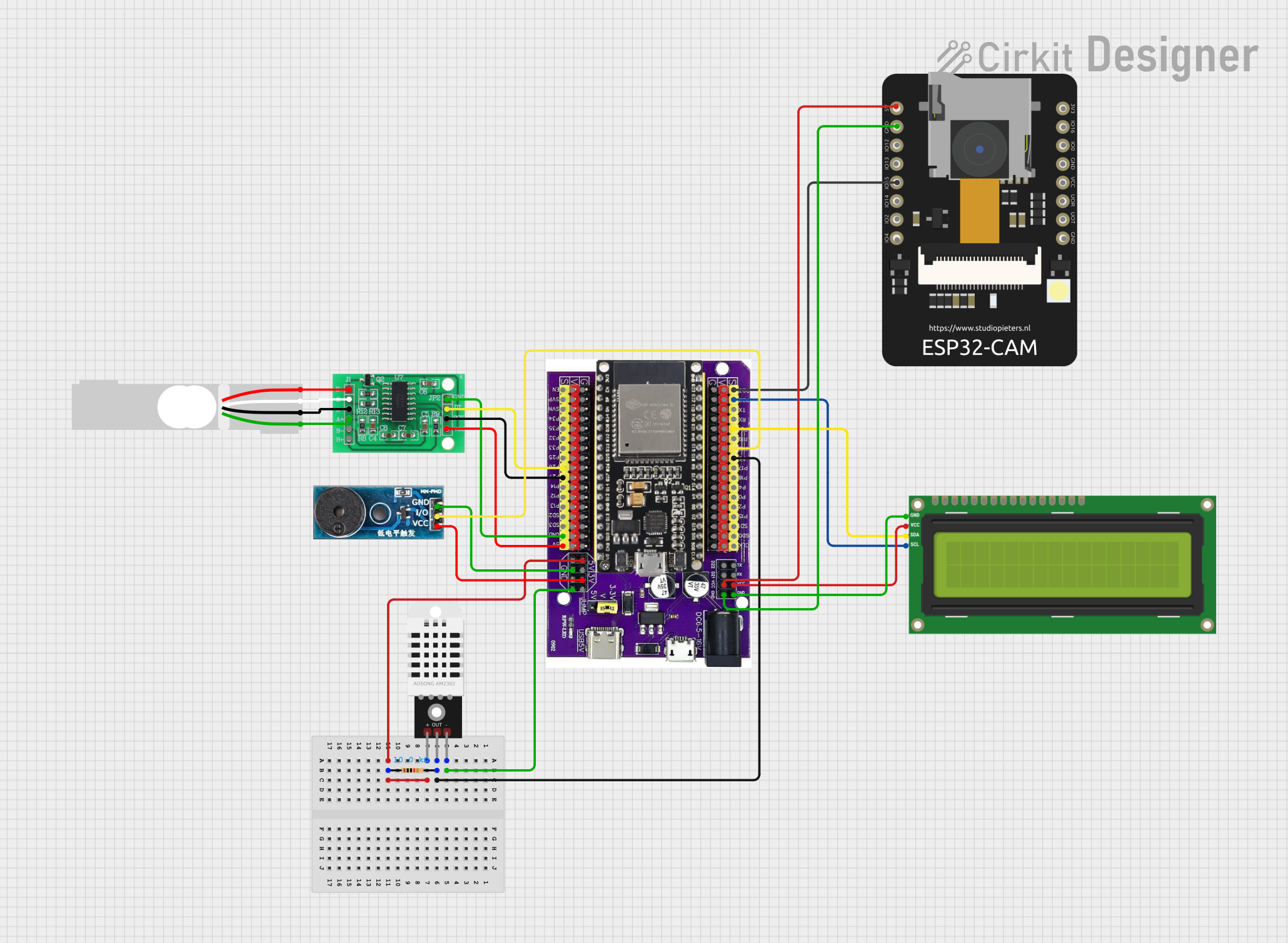

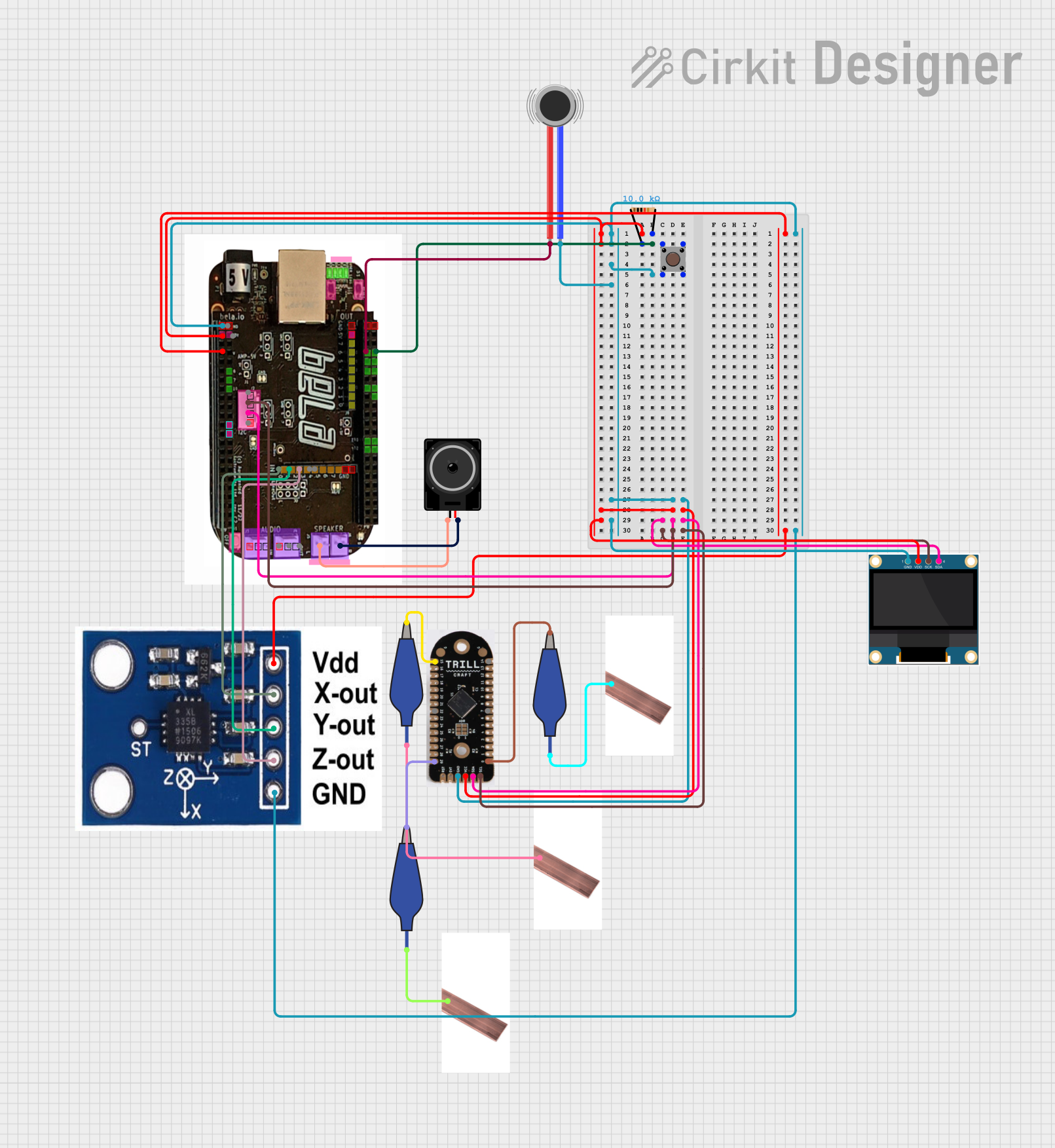

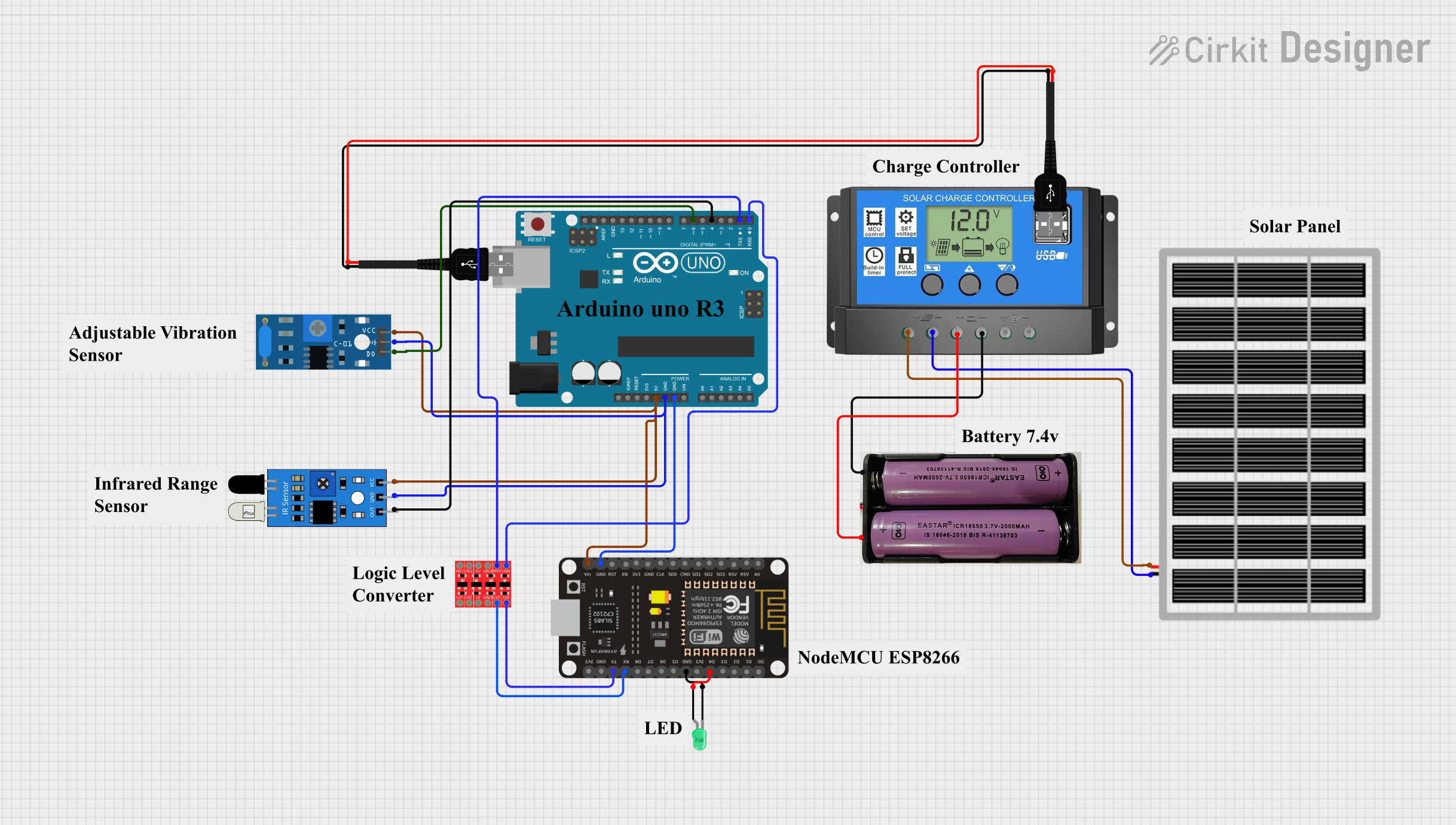

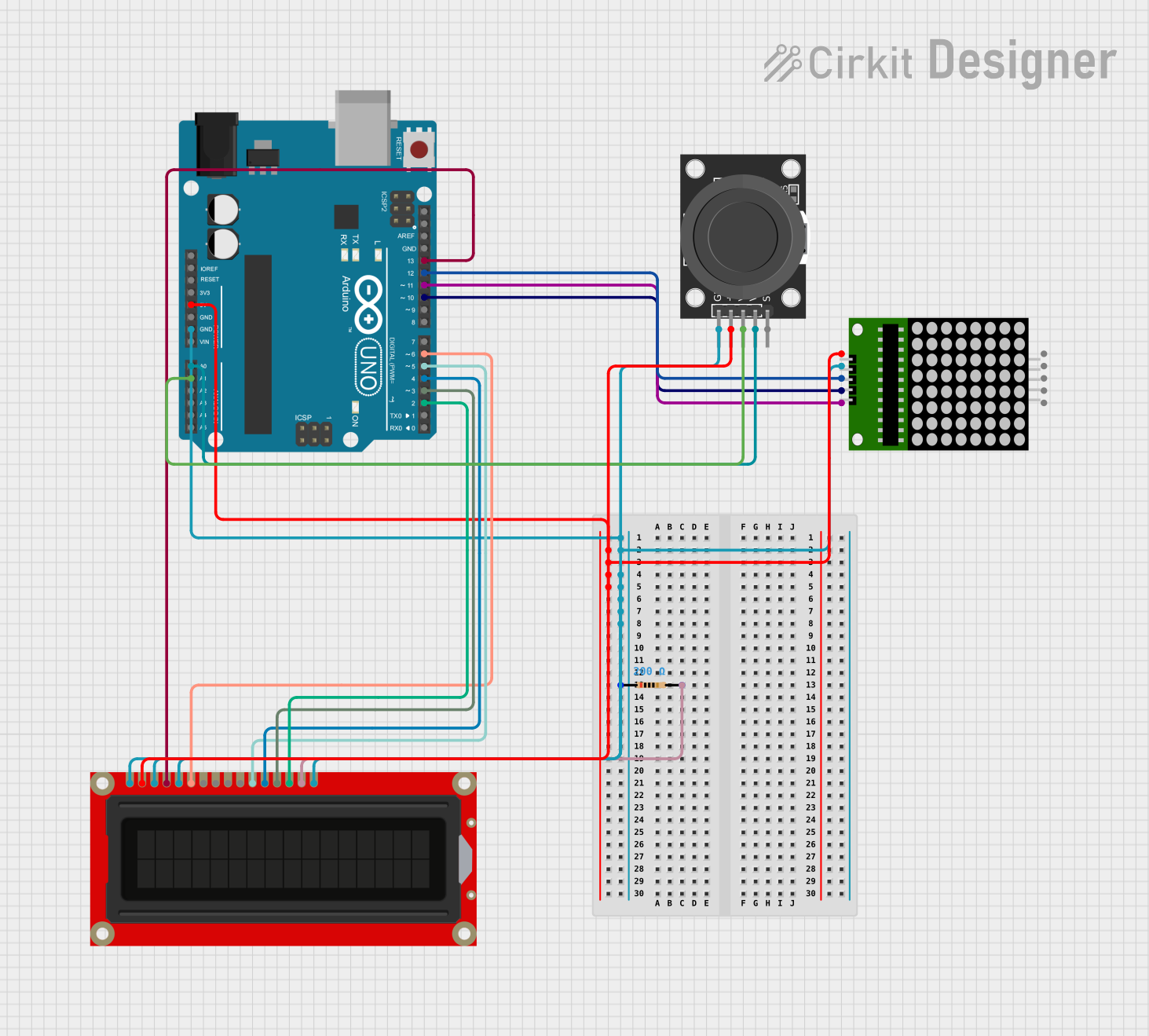

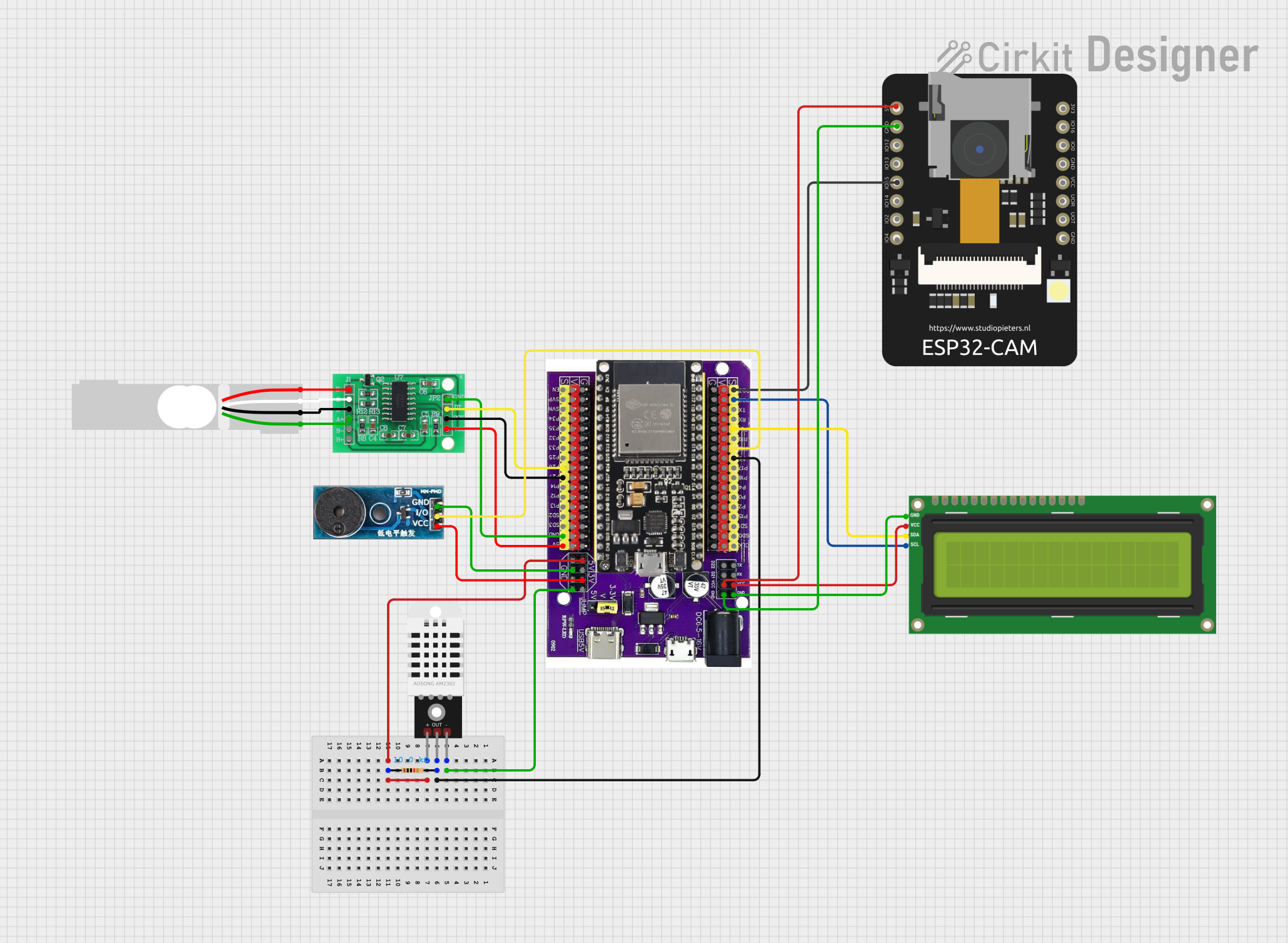

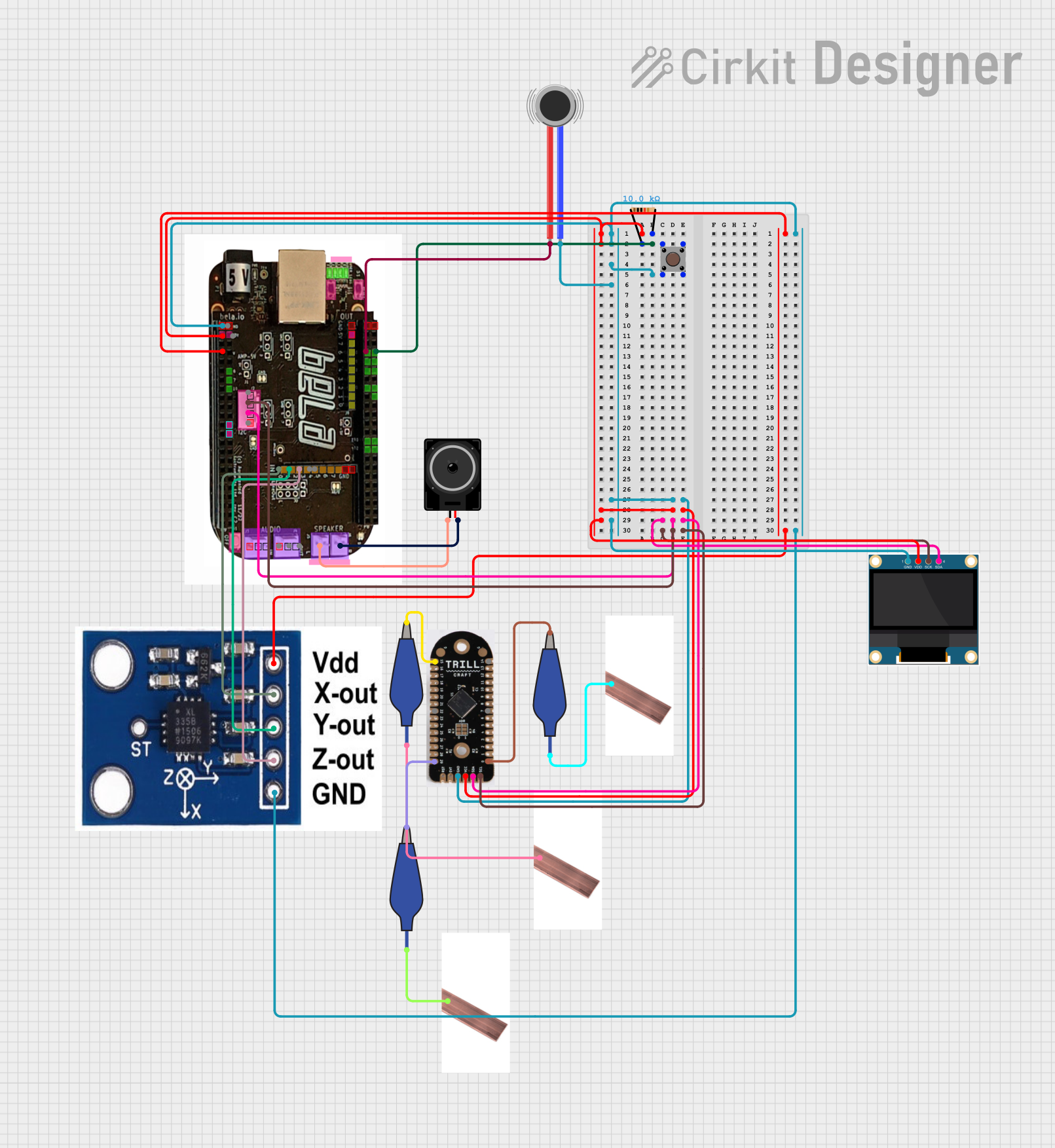

Explore Projects Built with IndusBoard

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with IndusBoard

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Operating Voltage | 3.3V / 5V |

| Input Voltage (recommended) | 7-12V |

| Input Voltage (limit) | 6-20V |

| Digital I/O Pins | 14 (of which 6 provide PWM output) |

| Analog Input Pins | 6 |

| DC Current per I/O Pin | 20 mA |

| Flash Memory | 32 KB (ATmega328P) |

| SRAM | 2 KB (ATmega328P) |

| EEPROM | 1 KB (ATmega328P) |

| Clock Speed | 16 MHz |

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | D0/RX | Digital I/O, UART Receive |

| 2 | D1/TX | Digital I/O, UART Transmit |

| 3 | D2 | Digital I/O |

| 4 | D3 | Digital I/O, PWM |

| 5 | D4 | Digital I/O |

| 6 | D5 | Digital I/O, PWM |

| 7 | D6 | Digital I/O, PWM |

| 8 | D7 | Digital I/O |

| 9 | D8 | Digital I/O |

| 10 | D9 | Digital I/O, PWM |

| 11 | D10 | Digital I/O, PWM |

| 12 | D11 | Digital I/O, PWM |

| 13 | D12 | Digital I/O |

| 14 | D13 | Digital I/O, LED |

| 15 | A0 | Analog Input |

| 16 | A1 | Analog Input |

| 17 | A2 | Analog Input |

| 18 | A3 | Analog Input |

| 19 | A4 | Analog Input, I2C SDA |

| 20 | A5 | Analog Input, I2C SCL |

| 21 | GND | Ground |

| 22 | 5V | 5V Power Output |

| 23 | 3.3V | 3.3V Power Output |

| 24 | VIN | Input Voltage |

| 25 | RESET | Reset |

Usage Instructions

How to Use the Component in a Circuit

Powering the Board:

- Connect the VIN pin to a power source (7-12V recommended).

- Alternatively, you can power the board via the USB port.

Connecting I/O Devices:

- Digital I/O: Connect your digital sensors or actuators to the digital pins (D0-D13).

- Analog Input: Connect your analog sensors to the analog input pins (A0-A5).

Communication:

- UART: Use pins D0 (RX) and D1 (TX) for serial communication.

- I2C: Use pins A4 (SDA) and A5 (SCL) for I2C communication.

Important Considerations and Best Practices

- Ensure that the input voltage does not exceed the recommended limits to avoid damaging the board.

- Use appropriate pull-up or pull-down resistors for digital inputs to ensure stable readings.

- When using PWM outputs, be mindful of the current limits to prevent overheating.

- For reliable communication, use proper shielding and grounding techniques, especially in industrial environments.

Troubleshooting and FAQs

Common Issues and Solutions

Board Not Powering On:

- Solution: Check the power connections and ensure the input voltage is within the recommended range.

Digital I/O Not Responding:

- Solution: Verify the connections and ensure the correct pin numbers are used in the code. Check for proper pull-up or pull-down resistors.

Analog Readings Are Inaccurate:

- Solution: Ensure the analog sensors are properly connected and calibrated. Check for electrical noise and use proper shielding.

Communication Issues (UART/I2C):

- Solution: Verify the wiring and ensure the correct baud rate (for UART) or address (for I2C) is used. Check for proper grounding and shielding.

FAQs

Q1: Can I use the IndusBoard Coin V2 with an Arduino UNO? A1: Yes, the IndusBoard Coin V2 is compatible with the Arduino UNO. You can use the Arduino IDE to program the board.

Q2: What is the maximum current that can be drawn from the 5V and 3.3V pins? A2: The maximum current that can be drawn from the 5V pin is 500 mA, and from the 3.3V pin is 50 mA.

Q3: How do I reset the board? A3: You can reset the board by pressing the RESET button or by connecting the RESET pin to GND momentarily.

Example Code for Arduino UNO

// Example code to blink an LED connected to pin 13

void setup() {

// Initialize digital pin 13 as an output.

pinMode(13, OUTPUT);

}

void loop() {

// Turn the LED on (HIGH is the voltage level)

digitalWrite(13, HIGH);

// Wait for a second

delay(1000);

// Turn the LED off by making the voltage LOW

digitalWrite(13, LOW);

// Wait for a second

delay(1000);

}

For more information, visit the manufacturer's website.

This documentation provides a comprehensive overview of the IndusBoard Coin V2, including its technical specifications, usage instructions, and troubleshooting tips. Whether you are a beginner or an experienced user, this guide will help you make the most of this versatile development board.