How to Use BDC PWM DC MOTOR CONTROLLER 10A 6-90V: Examples, Pinouts, and Specs

Design with BDC PWM DC MOTOR CONTROLLER 10A 6-90V in Cirkit Designer

Design with BDC PWM DC MOTOR CONTROLLER 10A 6-90V in Cirkit DesignerIntroduction

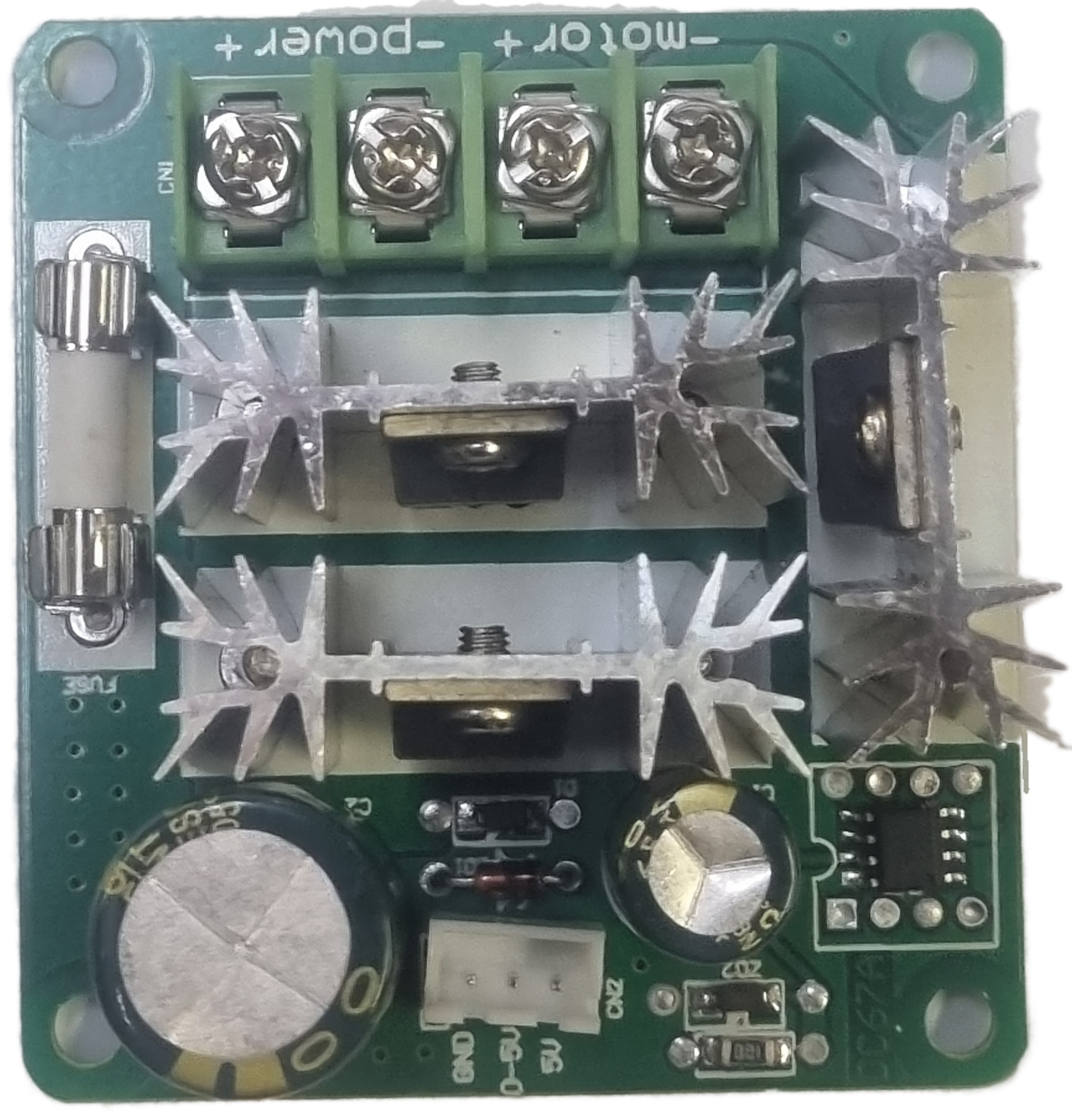

The BDD PWM DC Motor Controller 10A 6-90V is an electronic device designed to control the speed of a DC motor using Pulse Width Modulation (PWM). It is capable of handling currents up to 10A and can be used with a supply voltage ranging from 6V to 90V. This controller is commonly used in applications such as robotics, automotive, industrial control systems, and DIY projects where precise motor speed control is required.

Explore Projects Built with BDC PWM DC MOTOR CONTROLLER 10A 6-90V

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with BDC PWM DC MOTOR CONTROLLER 10A 6-90V

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

- Supply Voltage (Vcc): 6V to 90V DC

- Output Current (Continuous): Up to 10A

- PWM Frequency: Adjustable, typically around 15kHz

- Duty Cycle Range: 0% to 100%

- Control Method: PWM

- Operating Temperature: -20°C to 40°C

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | V+ | Positive supply voltage input (6V to 90V DC) |

| 2 | GND | Ground connection |

| 3 | OUT+ | Positive motor output |

| 4 | OUT- | Negative motor output |

| 5 | VR | Speed control potentiometer (if applicable) |

| 6 | SW | On/Off switch (if applicable) |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply Connection: Connect the positive terminal of your DC power supply to the V+ pin and the negative terminal to the GND pin.

- Motor Connection: Connect the positive terminal of the DC motor to the OUT+ pin and the negative terminal to the OUT- pin.

- Speed Control: If your controller has a built-in potentiometer (VR), you can adjust the motor speed by turning the knob. For controllers without a potentiometer, an external PWM signal can be used to control the speed.

- Switching On/Off: If your controller has a built-in switch (SW), use it to turn the motor on or off. Otherwise, you can use an external switch or relay.

Important Considerations and Best Practices

- Ensure that the power supply voltage and motor specifications do not exceed the controller's ratings.

- Always start with a low speed setting and gradually increase to prevent damage to the motor.

- Use appropriate heat sinks if operating near the maximum current rating to prevent overheating.

- Keep the controller away from moisture and dust.

- When using with an Arduino or similar microcontroller, ensure that the PWM signal levels are compatible.

Example Code for Arduino UNO

// Example code to control a BDD PWM DC Motor Controller with an Arduino UNO

const int pwmPin = 3; // Connect to the PWM input of the motor controller

void setup() {

pinMode(pwmPin, OUTPUT);

}

void loop() {

// Set motor speed to 50% duty cycle

analogWrite(pwmPin, 127); // 127 is approximately 50% of 255

delay(2000); // Run at this speed for 2 seconds

// Stop the motor

analogWrite(pwmPin, 0);

delay(1000); // Motor is stopped for 1 second

// Increase speed to 75% duty cycle

analogWrite(pwmPin, 191); // 191 is approximately 75% of 255

delay(2000); // Run at this speed for 2 seconds

// Stop the motor

analogWrite(pwmPin, 0);

delay(1000); // Motor is stopped for 1 second

}

Troubleshooting and FAQs

Common Issues

- Motor not responding: Check connections and ensure the power supply is within the specified range.

- Motor overheating: Reduce the load or duty cycle, and ensure proper ventilation.

- Inconsistent motor speed: Verify that the PWM signal is stable and within the correct frequency range.

Solutions and Tips for Troubleshooting

- Double-check wiring and connections for any loose contacts.

- Measure the supply voltage to ensure it falls within the specified range.

- If using an external PWM signal, use an oscilloscope to verify the signal's integrity.

- Ensure that the motor's current draw does not exceed 10A.

FAQs

Q: Can I control the motor speed using a microcontroller? A: Yes, you can use a microcontroller like an Arduino to generate a PWM signal and control the motor speed.

Q: What is the maximum frequency for the PWM input? A: The maximum frequency typically is around 15kHz, but it's best to consult the specific controller's datasheet for precise values.

Q: Can this controller be used for motors requiring more than 10A? A: No, this controller is rated for a maximum continuous current of 10A. Using it with motors that require more current can damage the controller.