How to Use L9110: Examples, Pinouts, and Specs

Design with L9110 in Cirkit Designer

Design with L9110 in Cirkit DesignerIntroduction

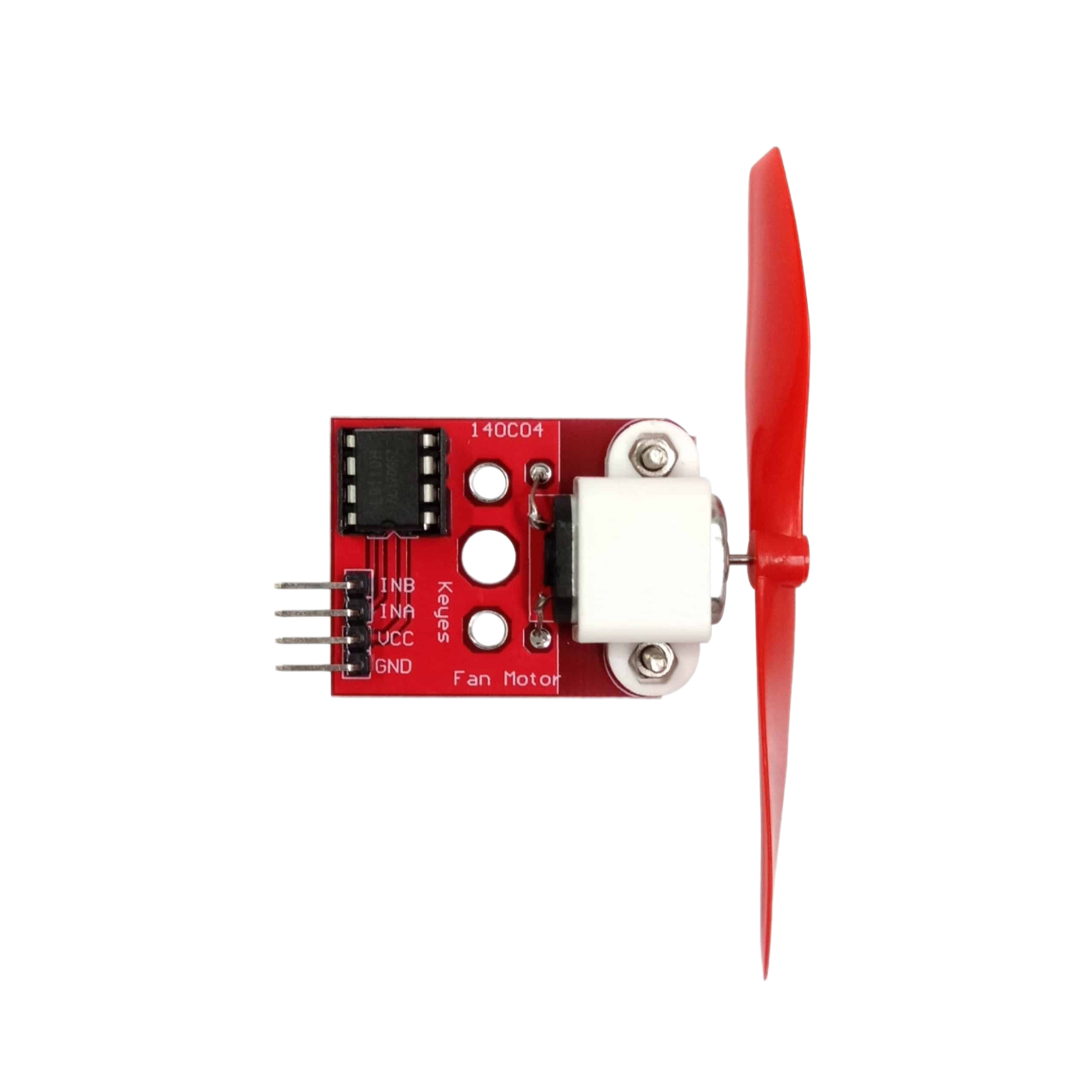

The L9110 is a dual H-bridge motor driver IC manufactured by LC. It is designed to control two DC motors or one stepper motor, enabling bidirectional movement. The L9110 is compact, efficient, and widely used in robotics, automation, and other motor control applications. Its ability to drive motors in both forward and reverse directions makes it a versatile choice for hobbyists and professionals alike.

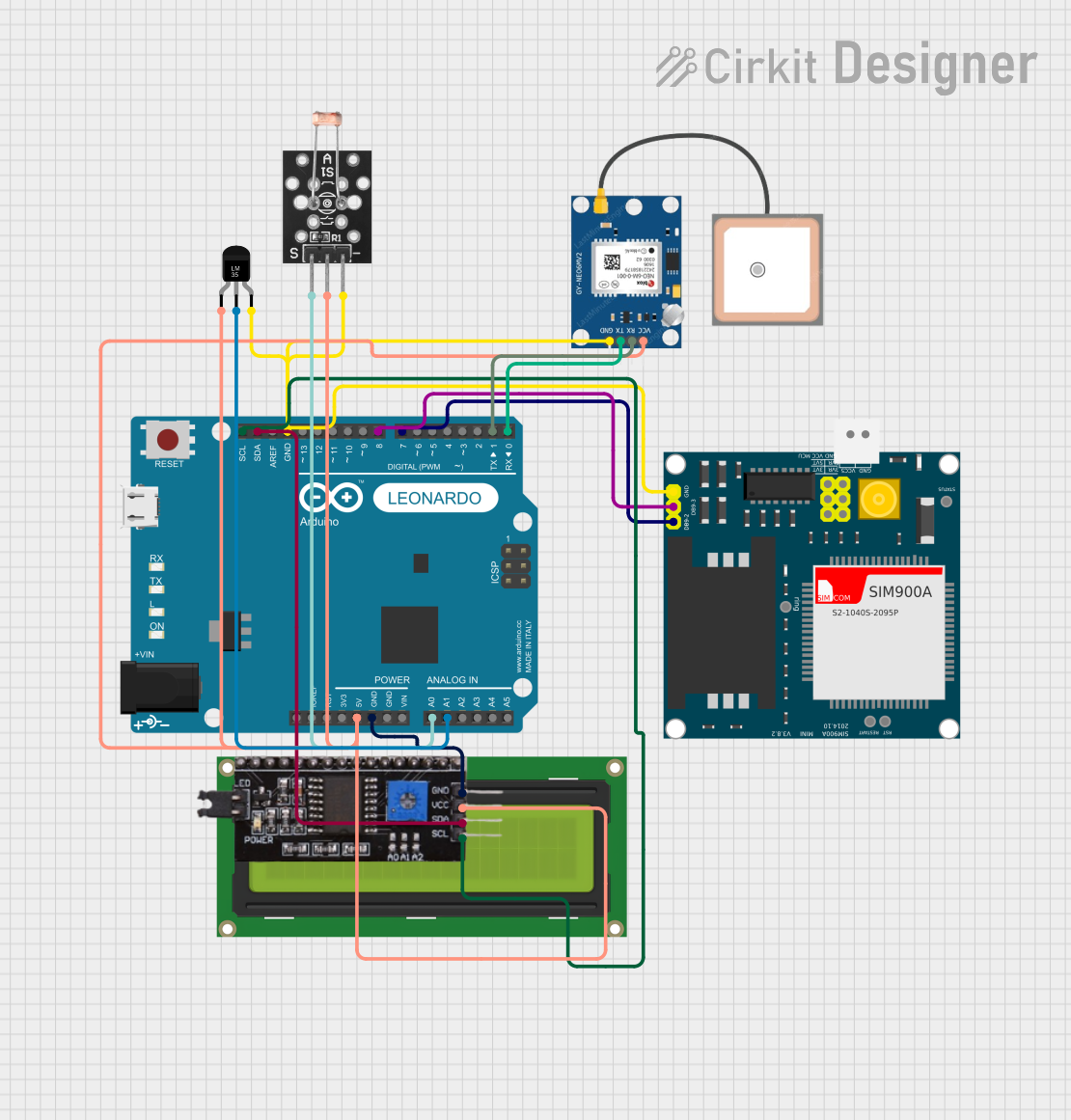

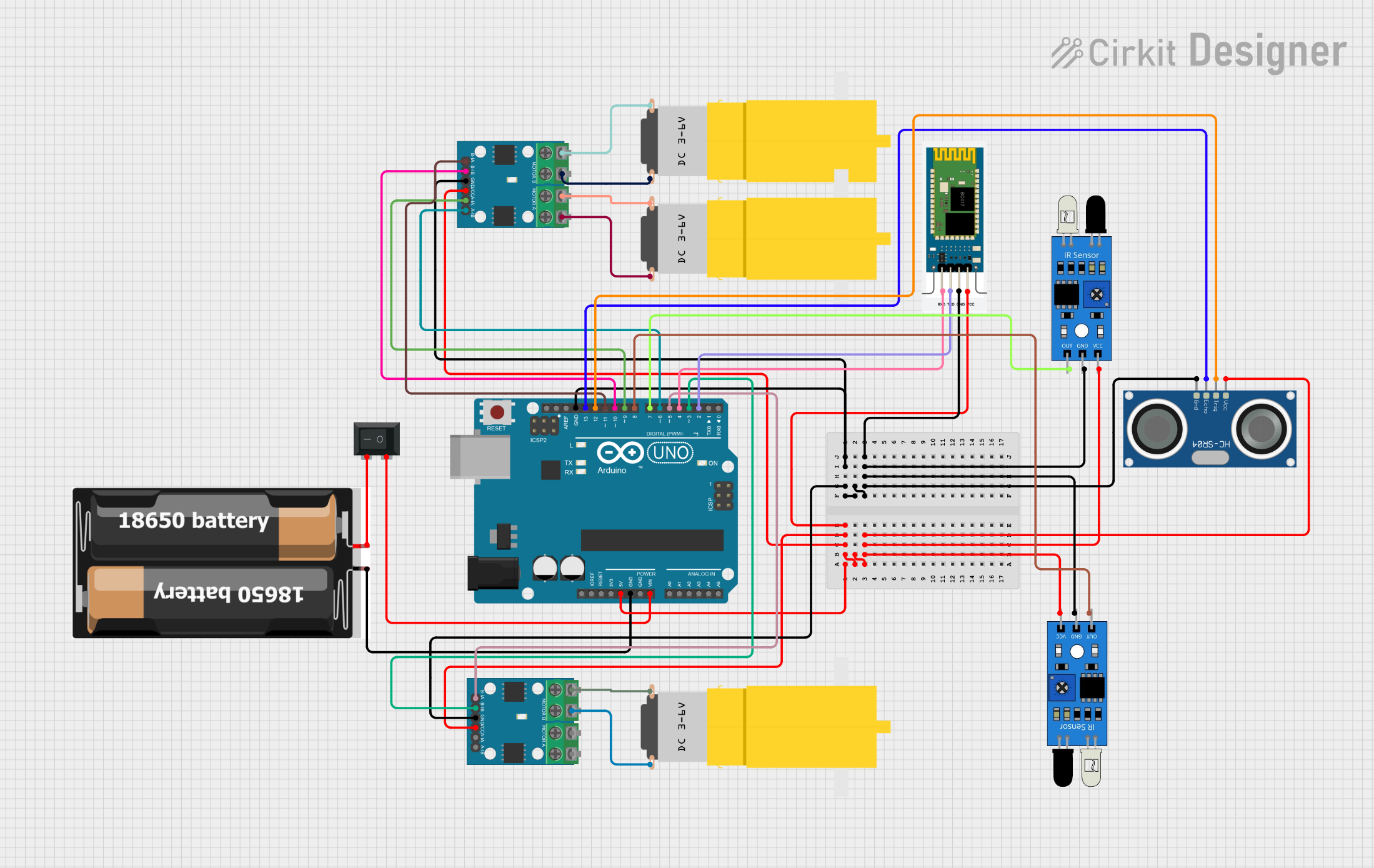

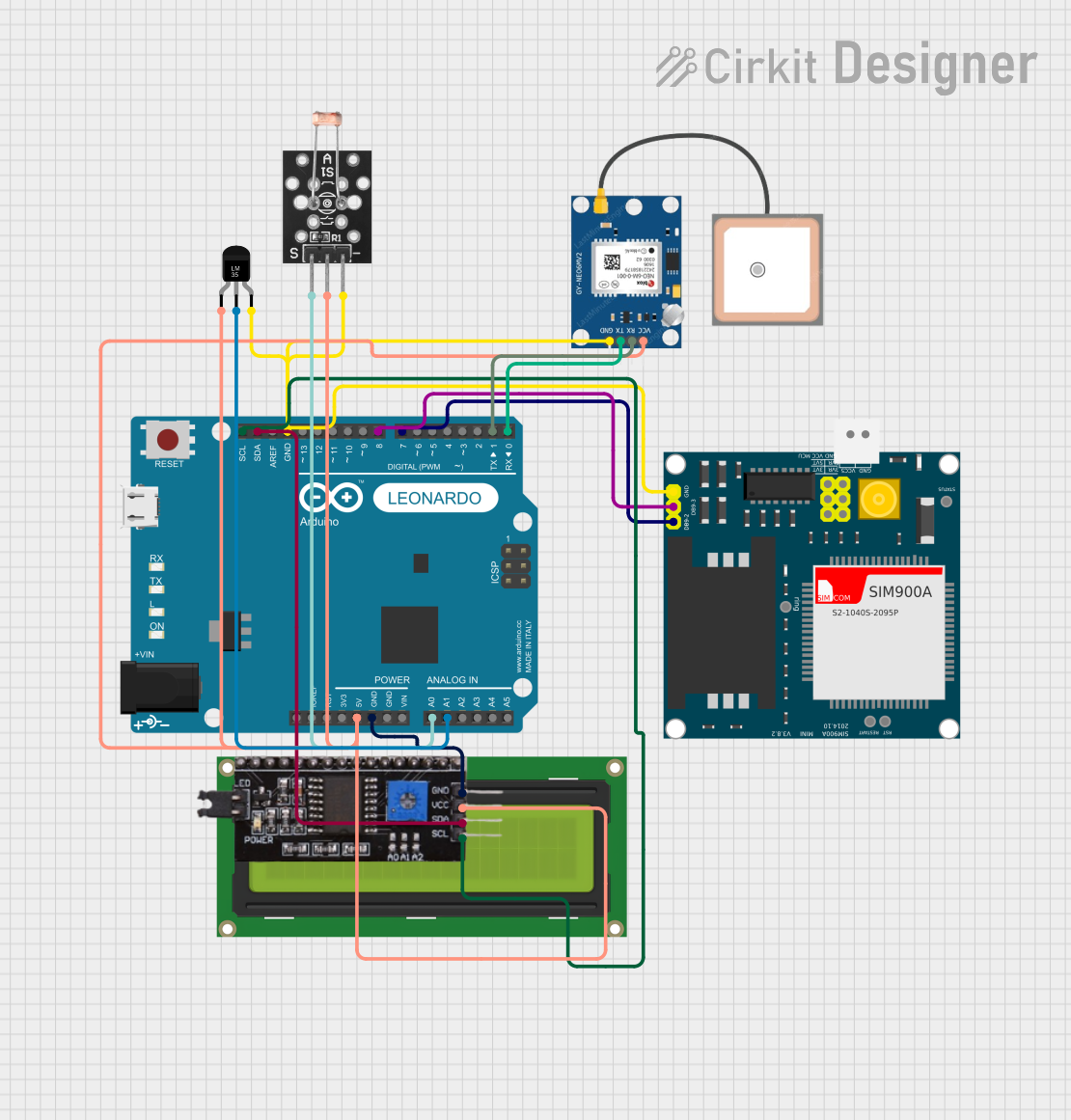

Explore Projects Built with L9110

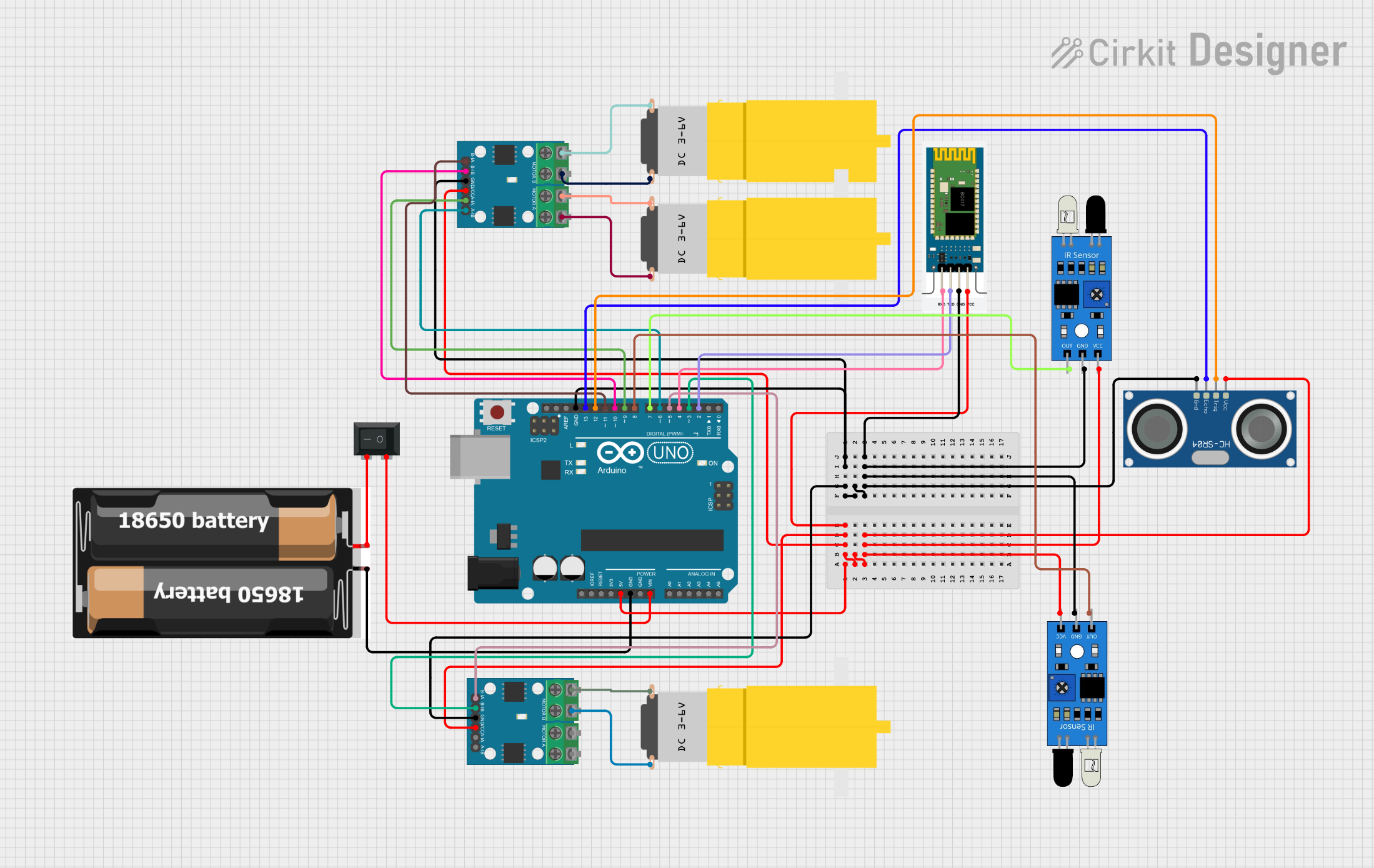

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with L9110

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotics and automation systems

- Remote-controlled vehicles

- Conveyor belts and motorized platforms

- Stepper motor control for CNC machines or 3D printers

- DIY electronics projects involving motorized components

Technical Specifications

The L9110 motor driver IC is designed to operate efficiently in low-power motor control applications. Below are its key technical specifications:

| Parameter | Value |

|---|---|

| Operating Voltage | 2.5V to 12V |

| Output Current (per channel) | 800mA (continuous) |

| Peak Output Current | 1.5A |

| Logic Input Voltage | 0V to 5V |

| Control Logic | TTL/CMOS compatible |

| Operating Temperature | -40°C to +85°C |

| Number of Channels | 2 (dual H-bridge) |

| Motor Types Supported | DC motors, stepper motors |

Pin Configuration and Descriptions

The L9110 IC typically comes in an 8-pin DIP or SOP package. Below is the pinout and description:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | A-1A | Input signal for Motor A (controls direction) |

| 2 | A-1B | Input signal for Motor A (controls direction) |

| 3 | VCC | Power supply for the motor driver (2.5V to 12V) |

| 4 | GND | Ground connection |

| 5 | B-1A | Input signal for Motor B (controls direction) |

| 6 | B-1B | Input signal for Motor B (controls direction) |

| 7 | Motor B+ | Output terminal for Motor B |

| 8 | Motor A+ | Output terminal for Motor A |

Usage Instructions

The L9110 is straightforward to use in motor control circuits. Below are the steps and considerations for using the IC effectively:

Connecting the L9110

- Power Supply: Connect the VCC pin to a power source (2.5V to 12V) suitable for your motor. Ensure the GND pin is connected to the ground of your circuit.

- Motor Connections: Connect the motor terminals to the Motor A+ and Motor B+ pins.

- Control Signals: Use the A-1A, A-1B, B-1A, and B-1B pins to control the direction and speed of the motors. These pins are connected to a microcontroller or other control logic.

Example Circuit with Arduino UNO

Below is an example of how to connect and control the L9110 with an Arduino UNO to drive a single DC motor:

Circuit Connections

- Connect the VCC pin of the L9110 to the 5V pin of the Arduino.

- Connect the GND pin of the L9110 to the GND pin of the Arduino.

- Connect A-1A to Arduino digital pin 9.

- Connect A-1B to Arduino digital pin 10.

- Connect the motor terminals to Motor A+ and Motor A-.

Arduino Code Example

// L9110 Motor Driver Example with Arduino UNO

// Controls a single DC motor connected to Motor A terminals

// Define control pins for Motor A

const int motorA1A = 9; // Pin connected to A-1A

const int motorA1B = 10; // Pin connected to A-1B

void setup() {

// Set motor control pins as outputs

pinMode(motorA1A, OUTPUT);

pinMode(motorA1B, OUTPUT);

}

void loop() {

// Rotate motor forward

digitalWrite(motorA1A, HIGH); // Set A-1A HIGH

digitalWrite(motorA1B, LOW); // Set A-1B LOW

delay(2000); // Run motor for 2 seconds

// Stop motor

digitalWrite(motorA1A, LOW); // Set A-1A LOW

digitalWrite(motorA1B, LOW); // Set A-1B LOW

delay(1000); // Wait for 1 second

// Rotate motor backward

digitalWrite(motorA1A, LOW); // Set A-1A LOW

digitalWrite(motorA1B, HIGH); // Set A-1B HIGH

delay(2000); // Run motor for 2 seconds

// Stop motor

digitalWrite(motorA1A, LOW); // Set A-1A LOW

digitalWrite(motorA1B, LOW); // Set A-1B LOW

delay(1000); // Wait for 1 second

}

Important Considerations

- Power Supply: Ensure the power supply voltage matches the motor's requirements and does not exceed the L9110's maximum voltage rating.

- Heat Dissipation: The IC may heat up during operation. Use proper ventilation or a heat sink if necessary.

- Current Limits: Do not exceed the maximum continuous current rating of 800mA per channel to avoid damaging the IC.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Spinning

- Cause: Incorrect wiring or insufficient power supply.

- Solution: Double-check all connections and ensure the power supply voltage is within the specified range.

Motor Spins in One Direction Only

- Cause: One of the control pins (A-1A, A-1B, B-1A, B-1B) is not receiving the correct signal.

- Solution: Verify the control signals from the microcontroller and ensure they are toggling correctly.

IC Overheating

- Cause: Excessive current draw or poor ventilation.

- Solution: Reduce the motor load, ensure proper ventilation, or add a heat sink.

No Output Voltage

- Cause: Faulty IC or incorrect power supply connection.

- Solution: Test the IC with a multimeter and verify the power supply connections.

FAQs

Q: Can the L9110 drive stepper motors?

A: Yes, the L9110 can drive stepper motors by controlling the two H-bridge channels in sequence. However, additional logic or a library may be required for precise stepper motor control.

Q: What is the maximum motor voltage the L9110 can handle?

A: The L9110 can handle motor voltages up to 12V. Ensure the motor's voltage rating matches the power supply.

Q: Can I use the L9110 with a 3.3V microcontroller?

A: Yes, the L9110's control logic is compatible with 3.3V and 5V logic levels.

Q: Is the L9110 suitable for high-power motors?

A: No, the L9110 is designed for low-power motors with a maximum continuous current of 800mA per channel. For high-power motors, consider using a more robust motor driver.