How to Use Coin Vibration Motor: Examples, Pinouts, and Specs

Design with Coin Vibration Motor in Cirkit Designer

Design with Coin Vibration Motor in Cirkit DesignerIntroduction

The Coin Vibration Motor is a compact, coin-shaped motor designed to produce vibrations when powered. It is widely used in applications requiring haptic feedback, such as mobile devices, gaming controllers, wearable devices, and medical equipment. Its small size and low power consumption make it ideal for portable and battery-powered devices.

Common applications include:

- Haptic feedback in smartphones and gaming controllers

- Wearable devices for notifications or alerts

- Medical devices for tactile feedback

- Toys and small gadgets requiring vibration effects

Explore Projects Built with Coin Vibration Motor

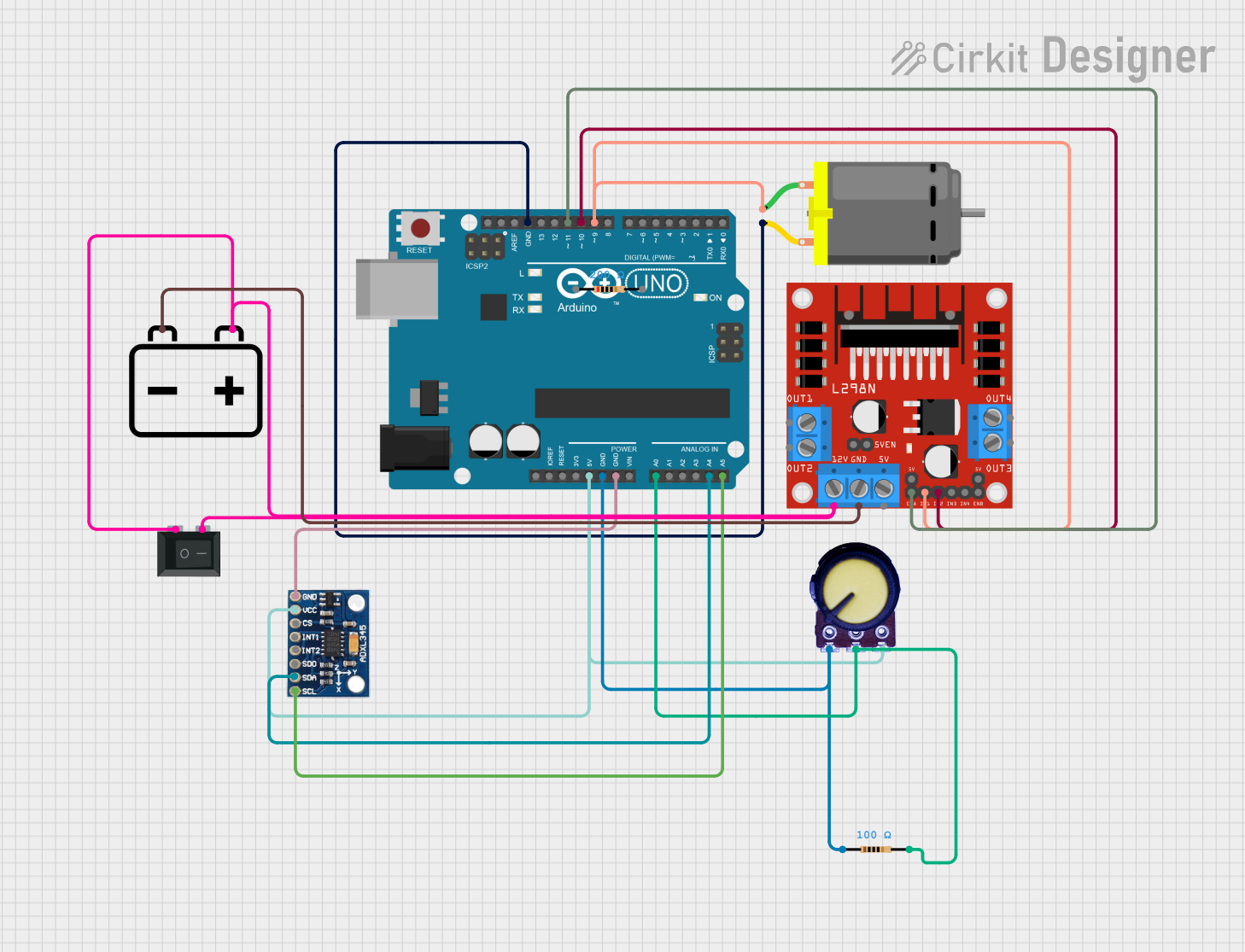

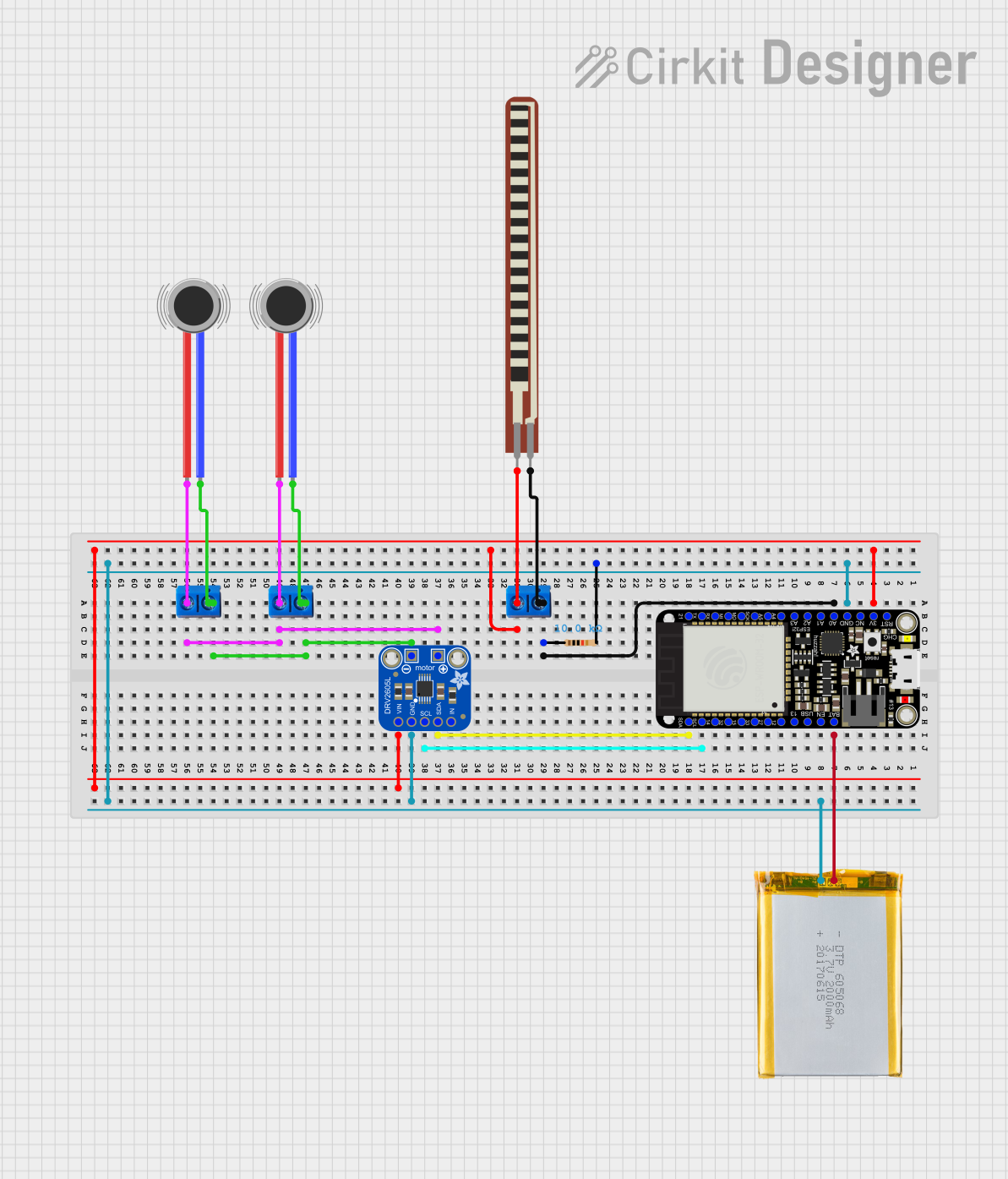

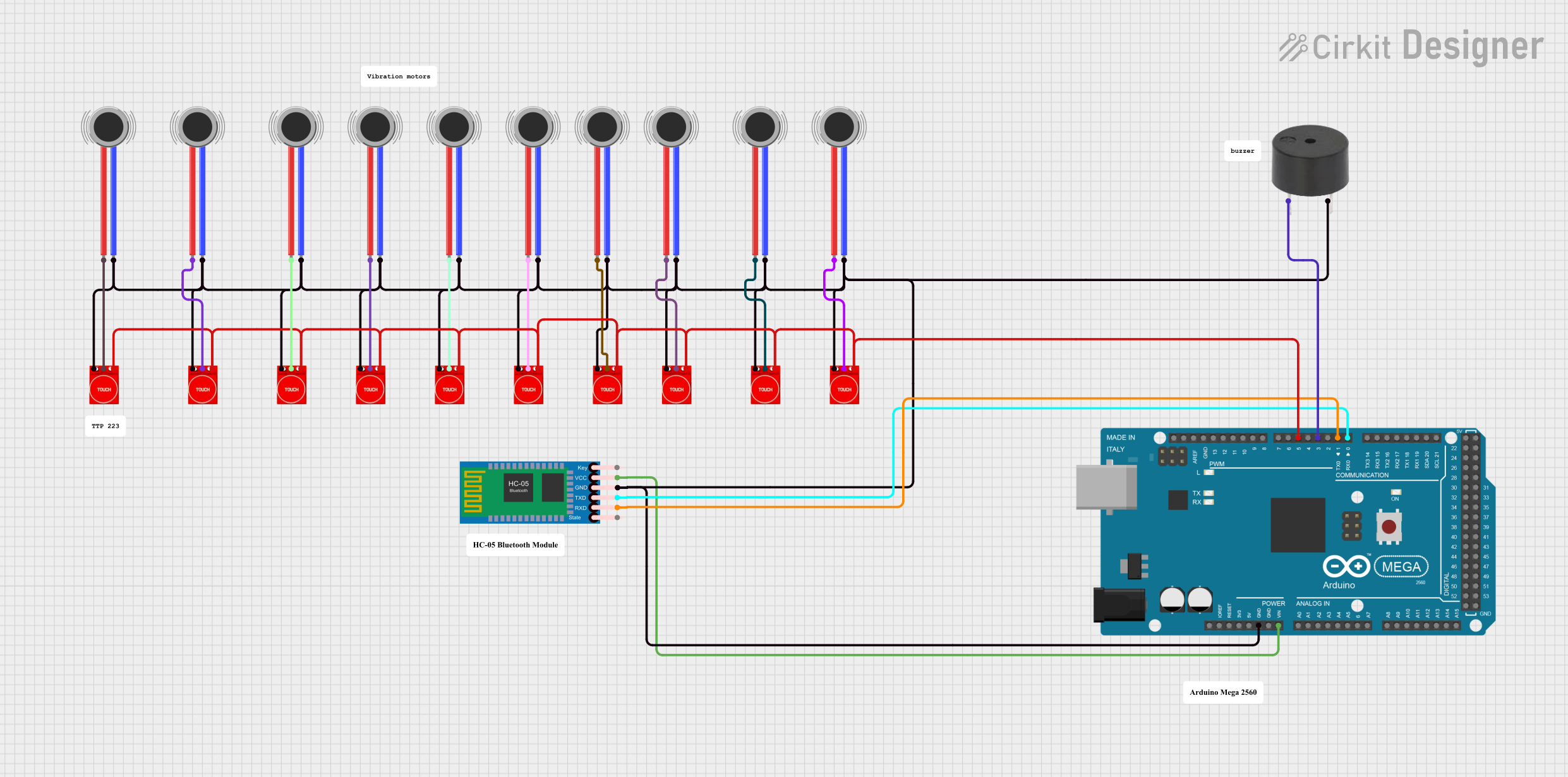

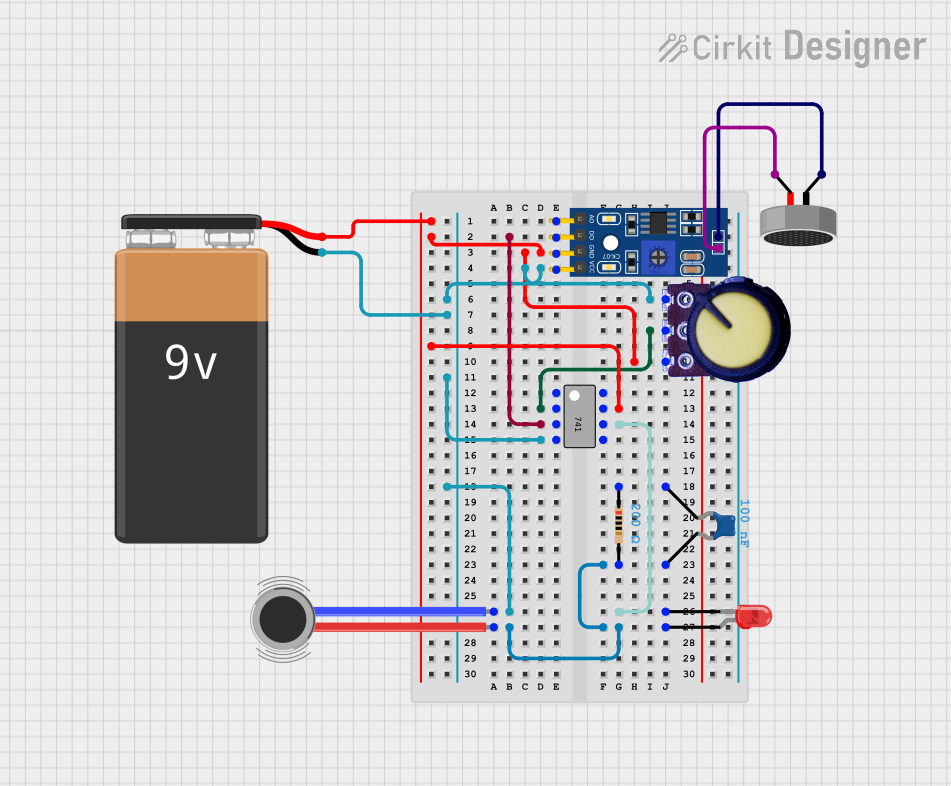

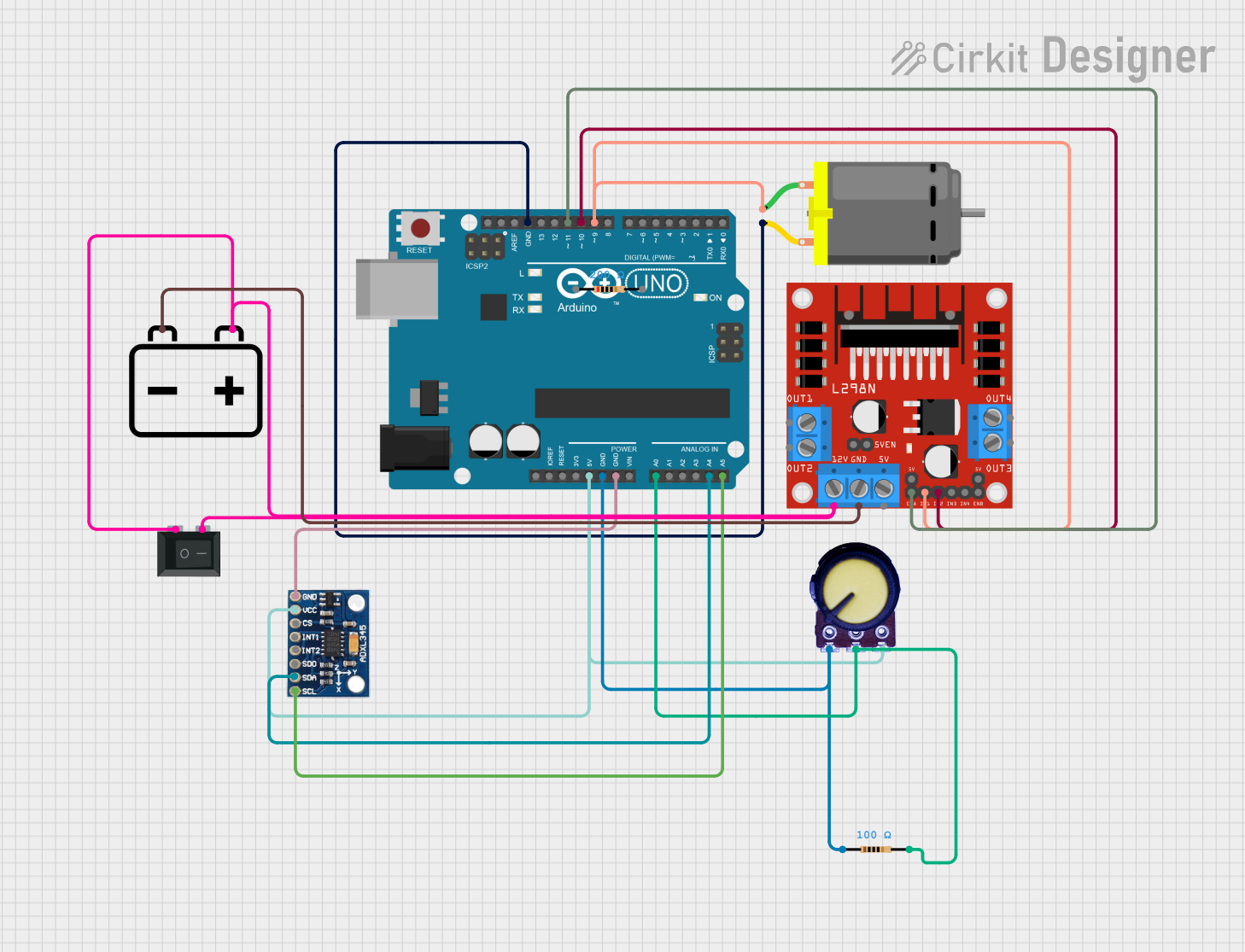

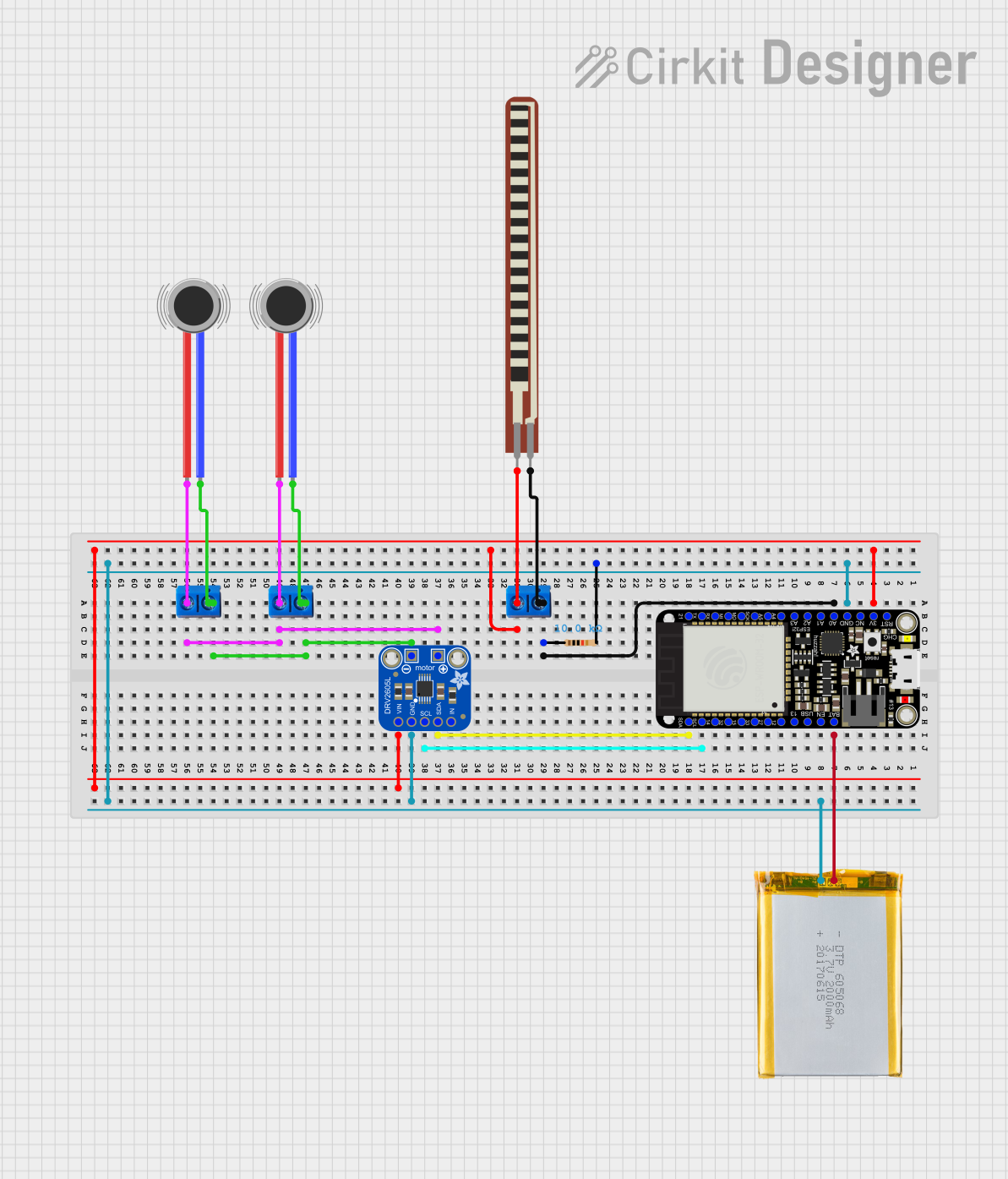

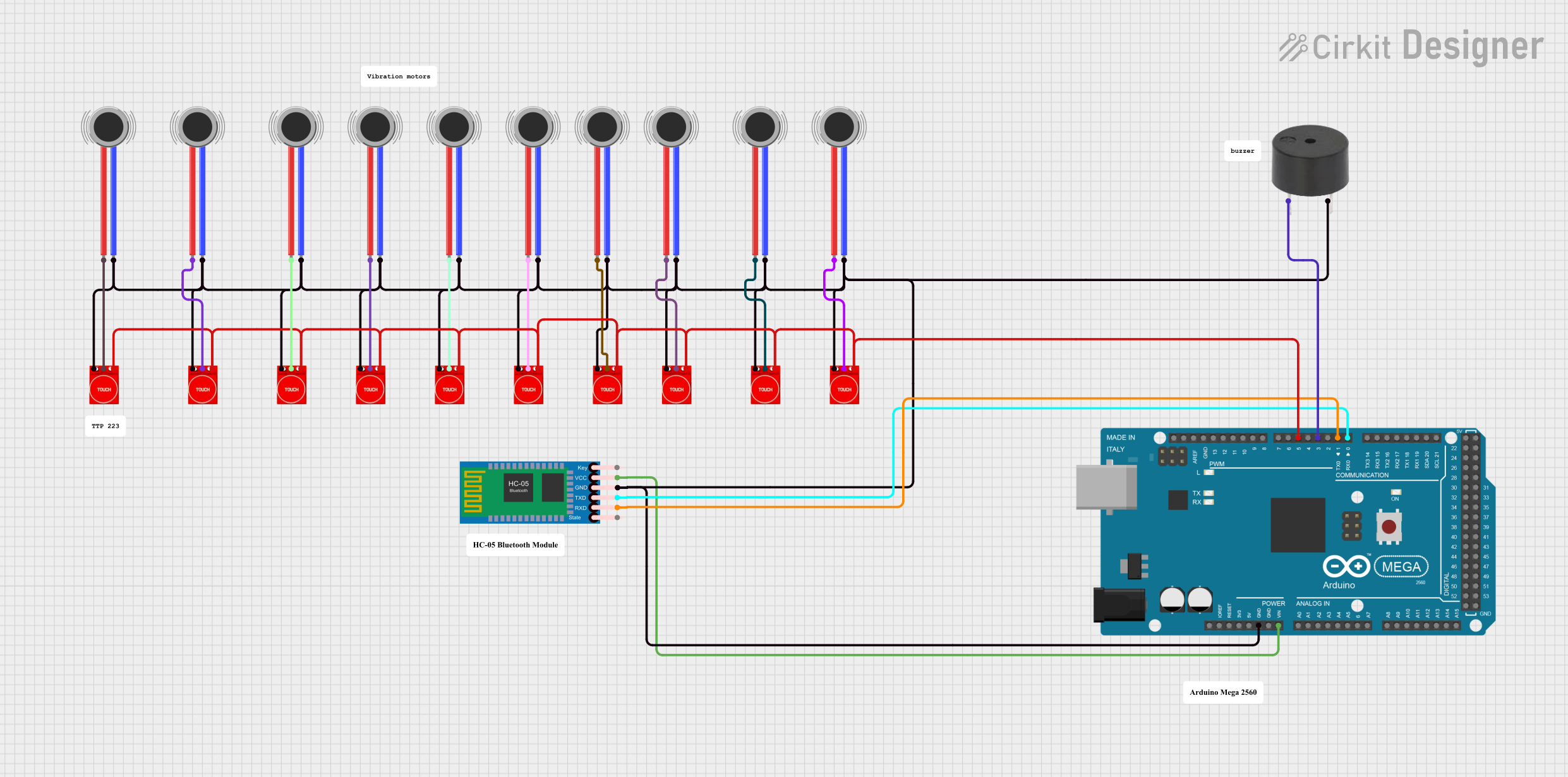

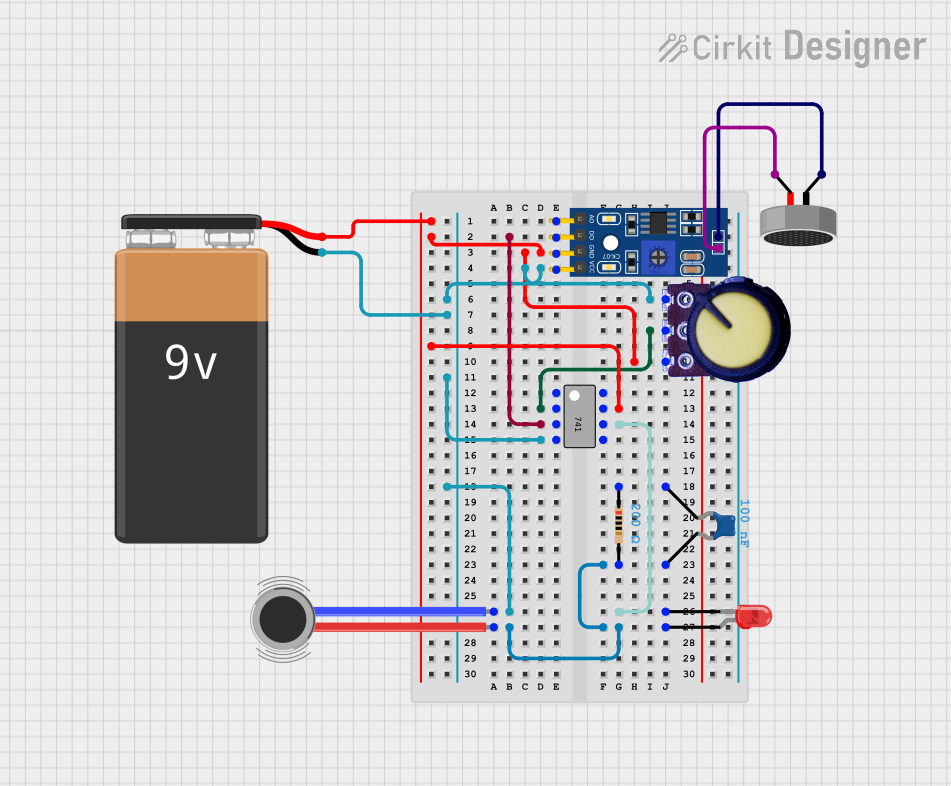

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Coin Vibration Motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Below are the key technical details of the Coin Vibration Motor:

| Parameter | Value |

|---|---|

| Operating Voltage | 2.5V to 3.7V |

| Rated Voltage | 3.0V |

| Operating Current | 80mA (typical at 3.0V) |

| Starting Voltage | 2.3V (minimum) |

| Vibration Frequency | 100-150 Hz |

| Dimensions | Diameter: 10mm, Thickness: 3mm |

| Weight | ~1.5g |

| Connection Type | Wire leads (red: positive, black: negative) |

Pin Configuration and Descriptions

The Coin Vibration Motor typically has two wire leads for connection:

| Wire Color | Description |

|---|---|

| Red | Positive terminal (+) |

| Black | Negative terminal (-) |

Usage Instructions

How to Use the Coin Vibration Motor in a Circuit

- Power Supply: Connect the red wire to the positive terminal of a power source (e.g., 3.0V) and the black wire to the negative terminal (ground). Ensure the voltage is within the operating range (2.5V to 3.7V).

- Control with a Microcontroller: To control the motor using a microcontroller like an Arduino, use a transistor or MOSFET as a switch. The motor cannot be directly connected to the microcontroller due to its current requirements.

- Add a Flyback Diode: Place a flyback diode across the motor terminals to protect the circuit from voltage spikes caused by the motor's inductive load.

Example Circuit with Arduino UNO

Below is an example of how to control the Coin Vibration Motor using an Arduino UNO and an NPN transistor (e.g., 2N2222):

Components Required:

- Coin Vibration Motor

- Arduino UNO

- NPN Transistor (e.g., 2N2222)

- 1kΩ Resistor

- Flyback Diode (e.g., 1N4007)

- External Power Supply (3V)

Circuit Diagram:

- Connect the red wire of the motor to the collector of the NPN transistor.

- Connect the black wire of the motor to the negative terminal of the external power supply.

- Connect the positive terminal of the external power supply to the motor's red wire.

- Place a flyback diode across the motor terminals (cathode to red wire, anode to black wire).

- Connect the emitter of the transistor to ground.

- Connect a 1kΩ resistor between the Arduino digital pin (e.g., pin 9) and the base of the transistor.

Arduino Code:

// Arduino code to control a Coin Vibration Motor

// The motor is connected to pin 9 via an NPN transistor

const int motorPin = 9; // Define the pin connected to the transistor base

void setup() {

pinMode(motorPin, OUTPUT); // Set motorPin as an output

}

void loop() {

digitalWrite(motorPin, HIGH); // Turn the motor ON

delay(1000); // Keep the motor ON for 1 second

digitalWrite(motorPin, LOW); // Turn the motor OFF

delay(1000); // Keep the motor OFF for 1 second

}

Important Considerations and Best Practices

- Voltage Limits: Do not exceed the rated voltage (3.7V) to avoid damaging the motor.

- Current Requirements: Ensure the power supply can provide sufficient current (80mA typical).

- Mounting: Secure the motor properly to prevent it from moving during operation, which could affect performance.

- Heat Dissipation: Avoid prolonged operation at maximum voltage to prevent overheating.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Vibrate:

- Check the power supply voltage and ensure it is within the operating range.

- Verify the connections (red to positive, black to ground).

- Ensure the transistor or MOSFET is functioning correctly if used in the circuit.

Motor Vibrates Weakly:

- Confirm the power supply can deliver sufficient current (80mA typical).

- Check for loose or poor connections.

Motor Overheats:

- Reduce the operating voltage to the rated value (3.0V).

- Limit the duration of continuous operation.

Arduino Cannot Control the Motor:

- Ensure a transistor or MOSFET is used to handle the motor's current.

- Verify the Arduino pin is configured as an output and is providing the correct signal.

FAQs

Q: Can I connect the motor directly to an Arduino pin?

A: No, the motor requires more current than an Arduino pin can supply. Use a transistor or MOSFET as a switch.

Q: Can I use a higher voltage power supply?

A: No, exceeding the maximum voltage (3.7V) can damage the motor. Use a voltage regulator if necessary.

Q: How do I reduce noise from the motor?

A: Add a small capacitor (e.g., 0.1µF) across the motor terminals to suppress electrical noise.

Q: Can I use PWM to control the motor speed?

A: Yes, you can use PWM (Pulse Width Modulation) to adjust the vibration intensity by varying the duty cycle of the signal sent to the transistor.

This concludes the documentation for the Coin Vibration Motor.