How to Use Gear Motor with integrated Encoder: Examples, Pinouts, and Specs

Design with Gear Motor with integrated Encoder in Cirkit Designer

Design with Gear Motor with integrated Encoder in Cirkit DesignerIntroduction

The Gear Motor with Integrated Encoder by Naroote is a versatile and efficient component that combines a motor, a gearbox, and an encoder into a single unit. This design allows for precise control of speed, torque, and position, making it ideal for applications requiring high accuracy and feedback. The integrated encoder provides real-time feedback on the motor's rotation, enabling closed-loop control systems for enhanced performance.

Explore Projects Built with Gear Motor with integrated Encoder

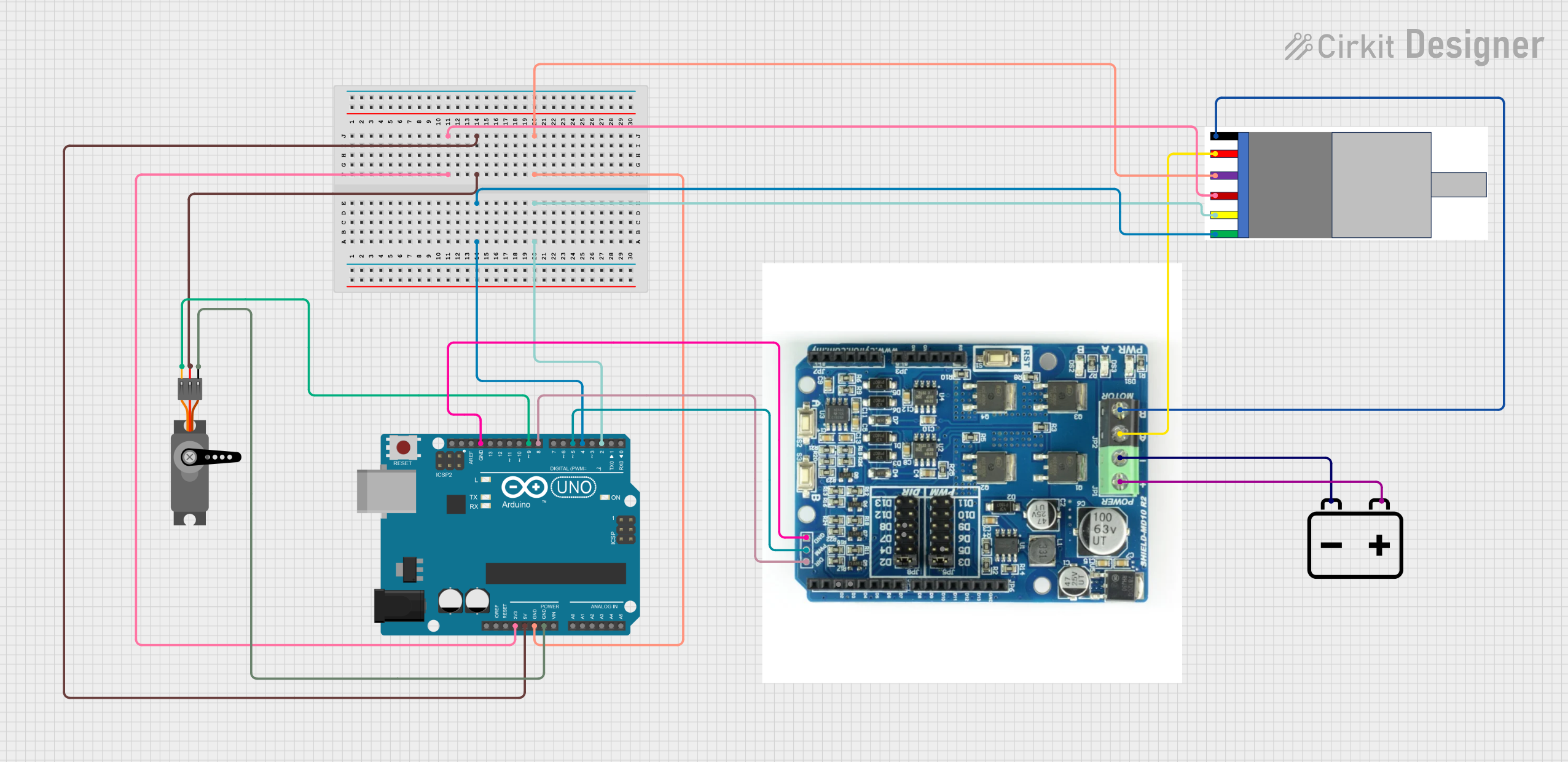

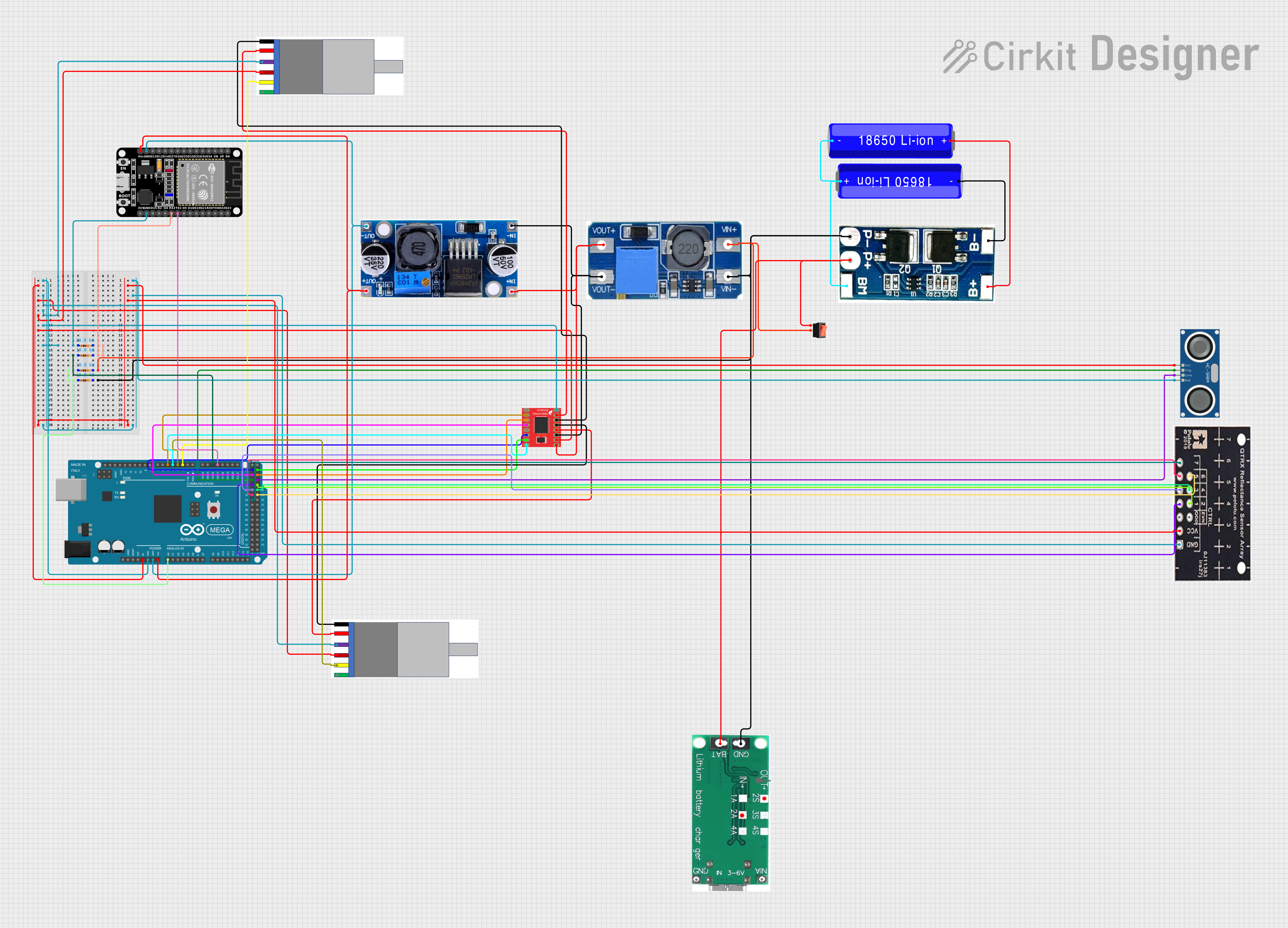

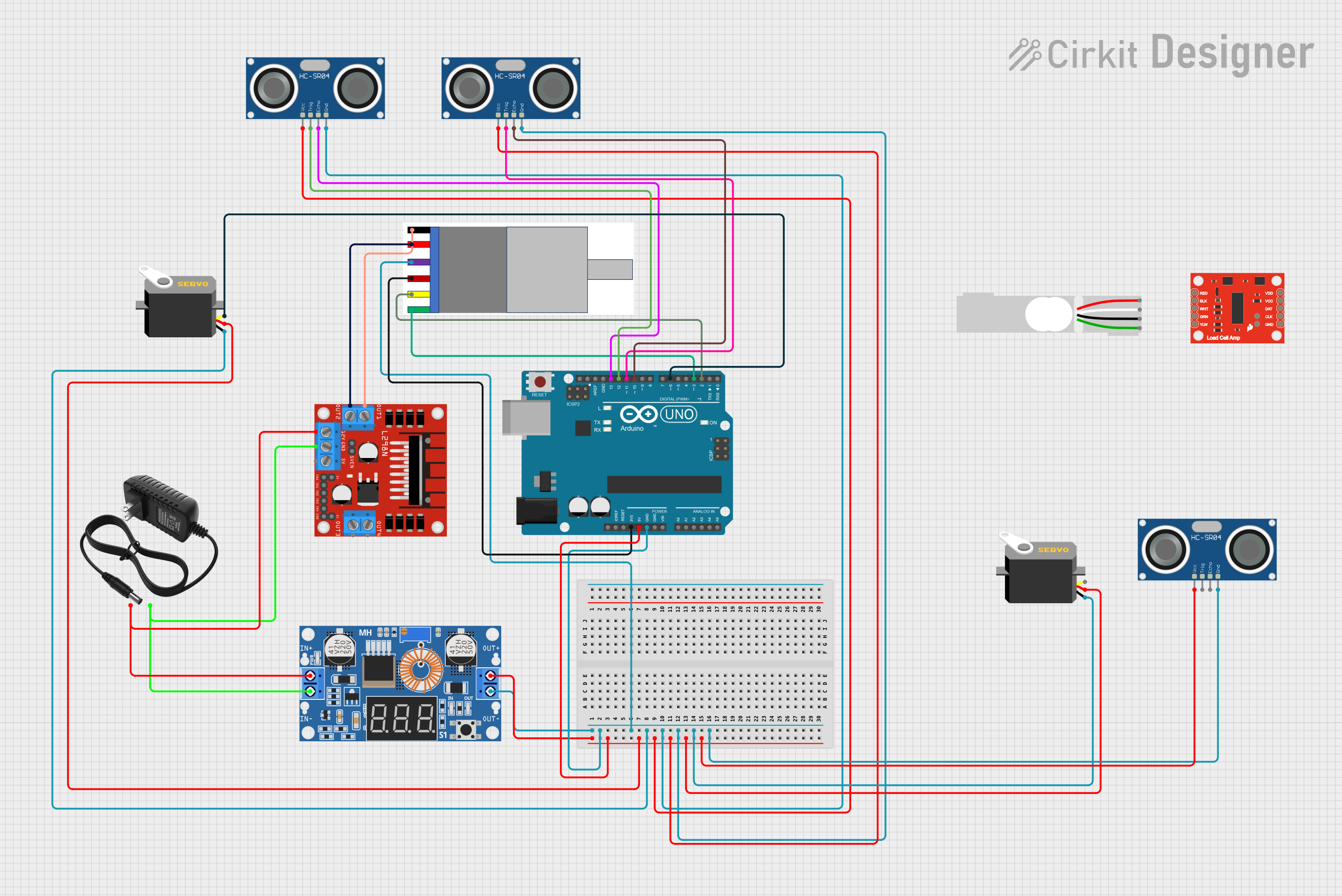

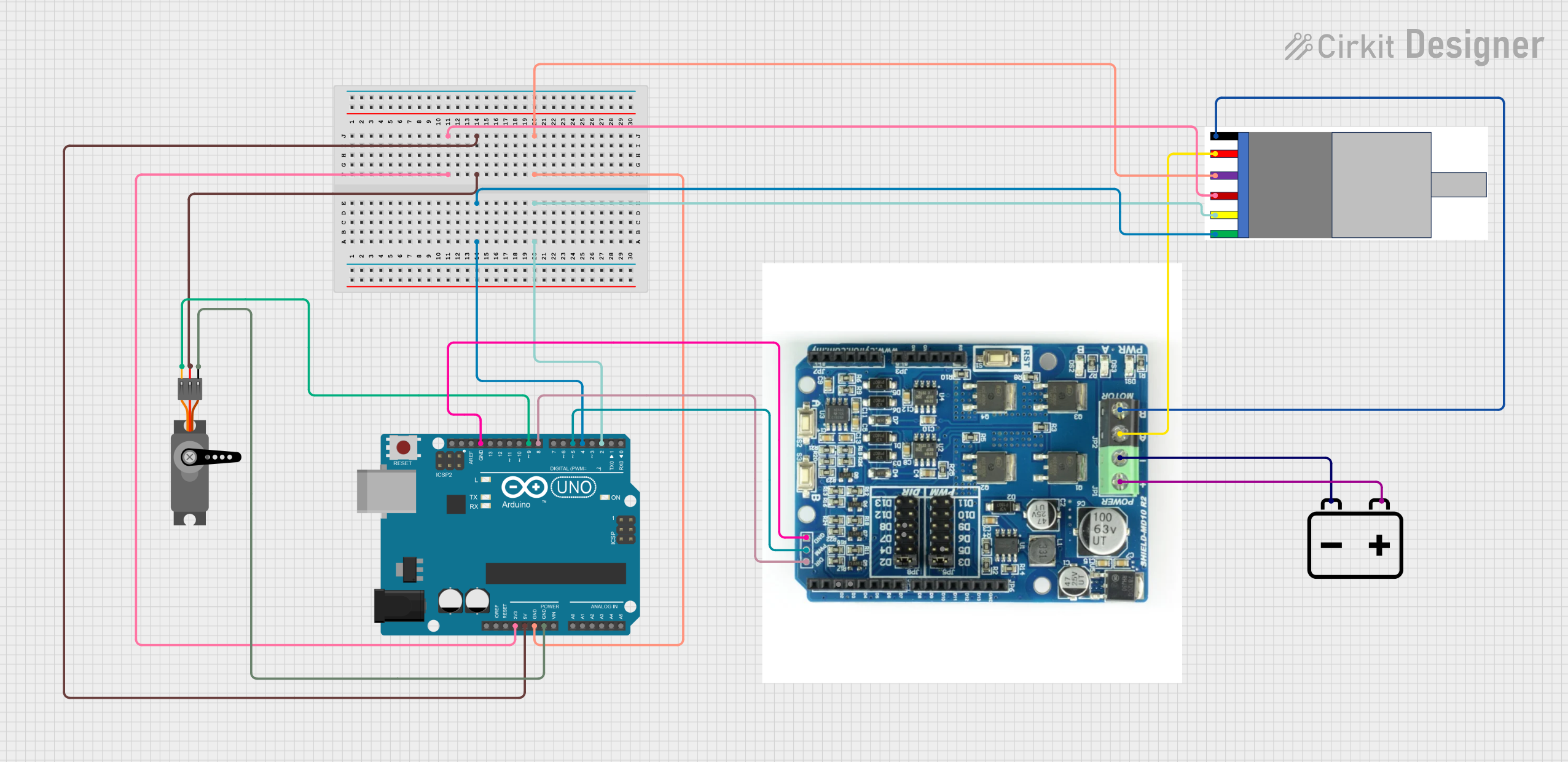

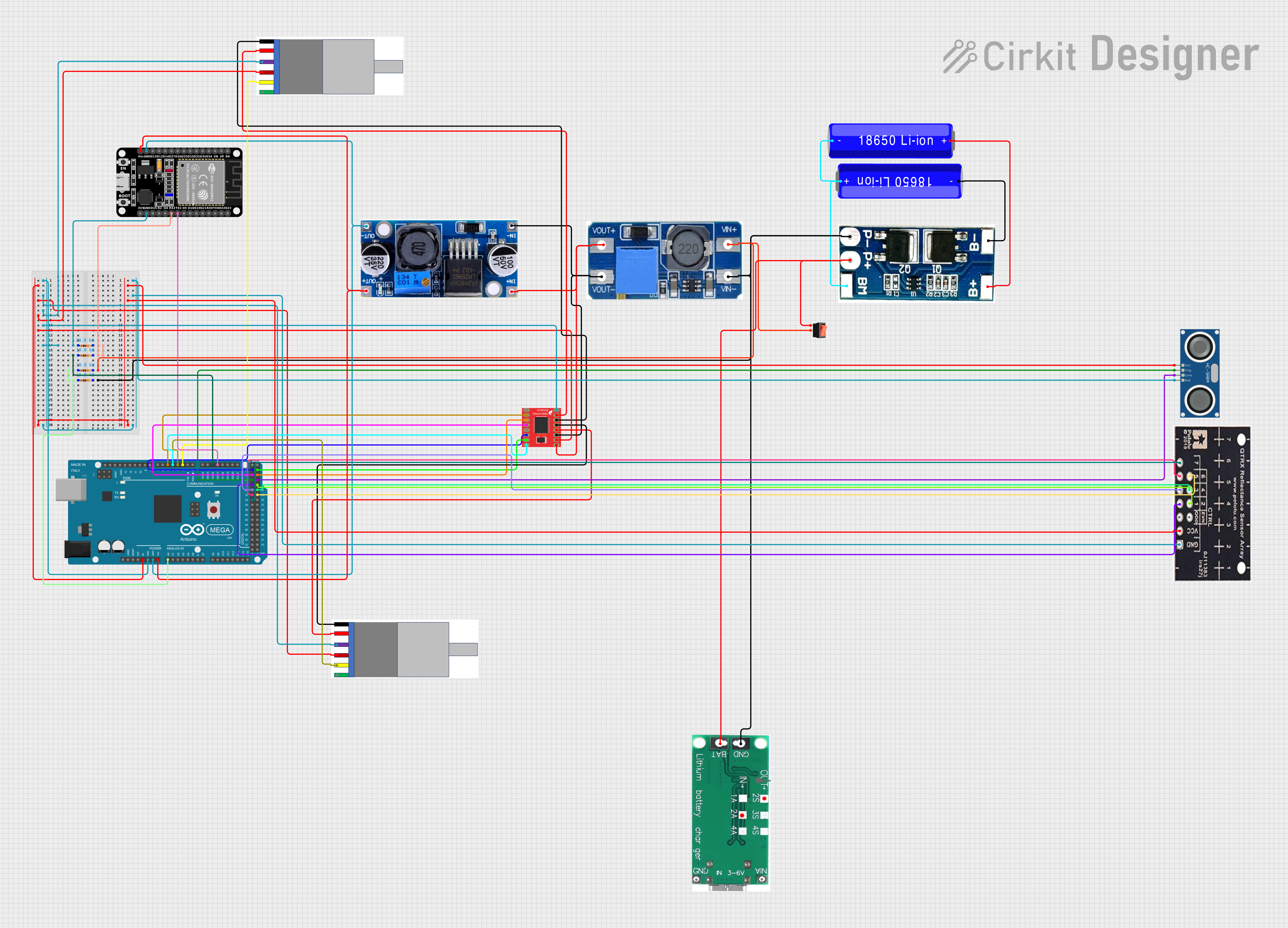

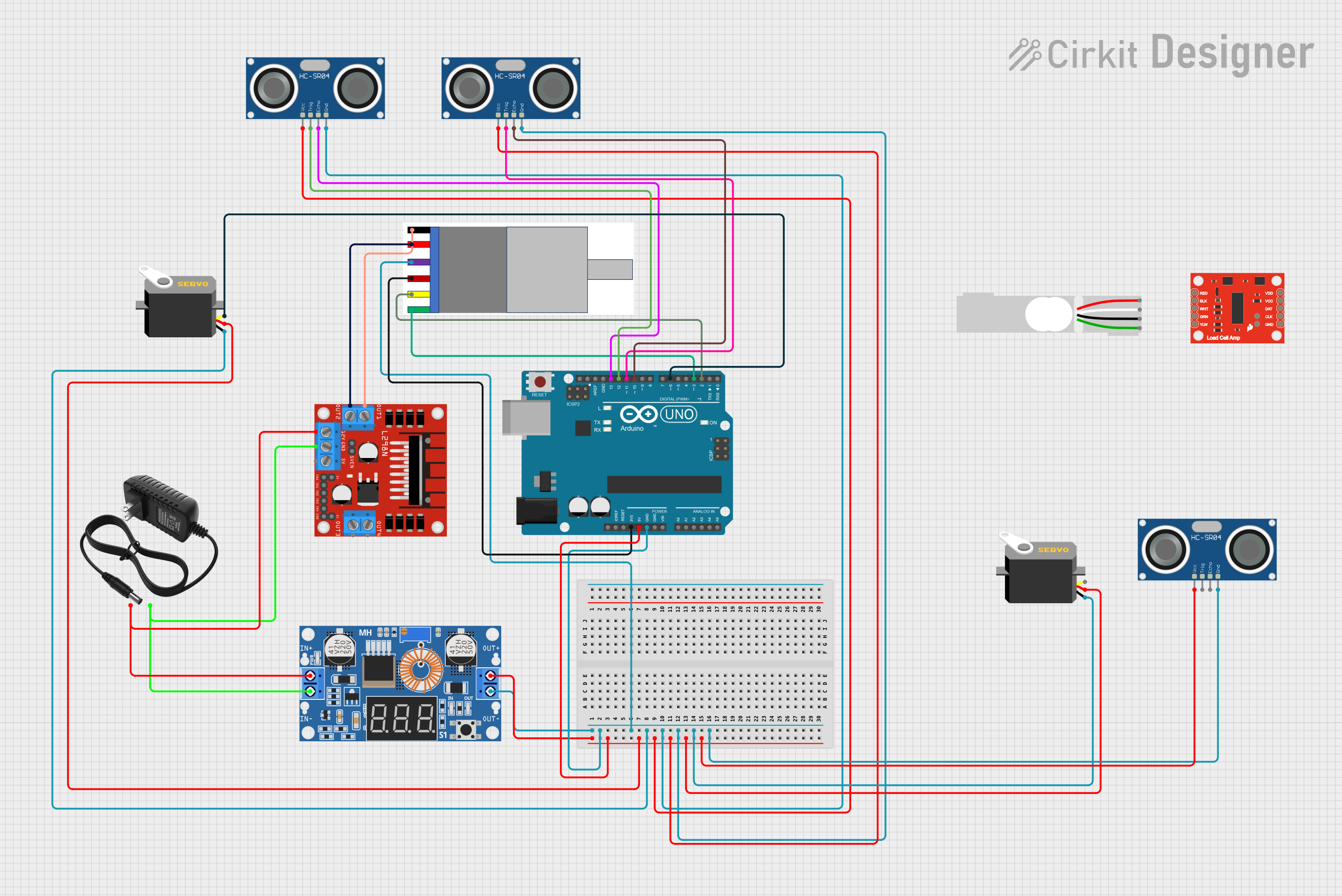

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Gear Motor with integrated Encoder

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: For precise movement and positioning of robotic arms or wheels.

- CNC Machines: Ensures accurate control of cutting tools or workpieces.

- Automated Systems: Used in conveyor belts, actuators, and other industrial automation.

- DIY Projects: Ideal for hobbyists building motorized systems with feedback control.

- Electric Vehicles: For controlling wheel speed and torque.

Technical Specifications

Key Technical Details

| Parameter | Specification |

|---|---|

| Operating Voltage | 6V to 12V |

| Rated Current | 0.5A to 1.2A (depending on load) |

| Gear Ratio | 1:30 |

| Encoder Resolution | 11 pulses per revolution (PPR) |

| Maximum Torque | 2.5 kg·cm |

| No-Load Speed | 200 RPM (at 12V) |

| Shaft Diameter | 6 mm |

| Operating Temperature | -10°C to 50°C |

| Dimensions | 70 mm x 30 mm x 25 mm |

| Weight | 120 g |

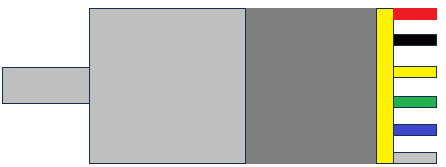

Pin Configuration and Descriptions

The gear motor with an integrated encoder typically has 6 wires for connection. Below is the pin configuration:

| Pin/Wire Color | Function | Description |

|---|---|---|

| Red | Motor Power (+) | Connect to the positive terminal of the power supply. |

| Black | Motor Power (-) | Connect to the negative terminal of the power supply. |

| Green | Encoder A Output | Outputs the first channel of encoder pulses. |

| Yellow | Encoder B Output | Outputs the second channel of encoder pulses. |

| Blue | Encoder Power (+) | Connect to the positive terminal of the encoder power supply (5V). |

| White | Encoder Power (-) | Connect to the ground of the encoder power supply. |

Usage Instructions

How to Use the Component in a Circuit

Powering the Motor:

- Connect the red wire to the positive terminal of your power supply (6V to 12V).

- Connect the black wire to the negative terminal of your power supply.

- Ensure the power supply can handle the motor's current requirements.

Connecting the Encoder:

- Connect the blue wire to a 5V power source for the encoder.

- Connect the white wire to the ground of the encoder power source.

- Connect the green and yellow wires to the microcontroller's digital input pins to read the encoder signals.

Reading Encoder Signals:

- The encoder outputs two square wave signals (A and B) that are 90° out of phase. These signals can be used to determine the direction and speed of the motor.

Controlling the Motor:

- Use an H-bridge motor driver to control the motor's speed and direction.

- Pulse Width Modulation (PWM) can be applied to the motor power pins for speed control.

Important Considerations and Best Practices

- Power Supply: Ensure the power supply voltage matches the motor's operating range (6V to 12V). Using a voltage outside this range may damage the motor.

- Current Handling: Use a power supply and motor driver capable of handling the motor's peak current.

- Encoder Signal Noise: Use pull-up resistors or software debouncing to filter noise from the encoder signals.

- Mounting: Secure the motor properly to avoid vibrations that could affect performance.

- Heat Management: Avoid prolonged operation at high loads to prevent overheating.

Example: Connecting to an Arduino UNO

Below is an example of how to connect and use the gear motor with an integrated encoder with an Arduino UNO:

Circuit Connections

- Motor Power: Connect the red and black wires to an H-bridge motor driver (e.g., L298N).

- Encoder:

- Connect the blue wire to the Arduino's 5V pin.

- Connect the white wire to the Arduino's GND pin.

- Connect the green wire to digital pin 2.

- Connect the yellow wire to digital pin 3.

Arduino Code

// Define encoder pins

const int encoderPinA = 2; // Green wire

const int encoderPinB = 3; // Yellow wire

volatile int encoderCount = 0; // Variable to store encoder count

void setup() {

pinMode(encoderPinA, INPUT); // Set encoder pin A as input

pinMode(encoderPinB, INPUT); // Set encoder pin B as input

// Attach interrupt to encoder pin A

attachInterrupt(digitalPinToInterrupt(encoderPinA), encoderISR, CHANGE);

Serial.begin(9600); // Initialize serial communication

}

void loop() {

// Print the encoder count to the Serial Monitor

Serial.print("Encoder Count: ");

Serial.println(encoderCount);

delay(500); // Delay for readability

}

// Interrupt Service Routine (ISR) for encoder

void encoderISR() {

// Read the state of encoder pin B

int stateB = digitalRead(encoderPinB);

// Determine direction based on state of pin B

if (stateB == HIGH) {

encoderCount++; // Clockwise rotation

} else {

encoderCount--; // Counterclockwise rotation

}

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Spinning:

- Cause: Insufficient power supply or incorrect wiring.

- Solution: Verify the power supply voltage and current. Check the red and black wire connections.

Encoder Signals Not Detected:

- Cause: Incorrect wiring or insufficient pull-up resistors.

- Solution: Ensure the encoder wires are connected correctly. Add pull-up resistors if necessary.

Inconsistent Encoder Readings:

- Cause: Electrical noise or loose connections.

- Solution: Use shielded cables for encoder wires and secure all connections.

Motor Overheating:

- Cause: Prolonged operation at high loads.

- Solution: Reduce the load or provide adequate cooling.

FAQs

Q: Can I use a 3.3V microcontroller with this encoder?

A: Yes, but ensure the encoder's output signals are compatible with the microcontroller's input voltage levels.Q: What is the purpose of the encoder?

A: The encoder provides feedback on the motor's rotation, enabling precise control of speed and position.Q: Can I reverse the motor's direction?

A: Yes, by reversing the polarity of the motor power wires or using an H-bridge motor driver.Q: How do I calculate the motor's speed using the encoder?

A: Count the encoder pulses over a fixed time interval and multiply by the encoder resolution.

This concludes the documentation for the Gear Motor with Integrated Encoder by Naroote.