How to Use Motor Driver: Examples, Pinouts, and Specs

Design with Motor Driver in Cirkit Designer

Design with Motor Driver in Cirkit DesignerIntroduction

A motor driver is an electronic circuit designed to control the operation of a motor by regulating its speed, direction, and sometimes torque. It acts as an interface between a microcontroller (or other control systems) and the motor, enabling precise control over the motor's performance. Motor drivers are essential in applications where motors are used, as they provide the necessary current and voltage to drive the motor while protecting the control circuitry.

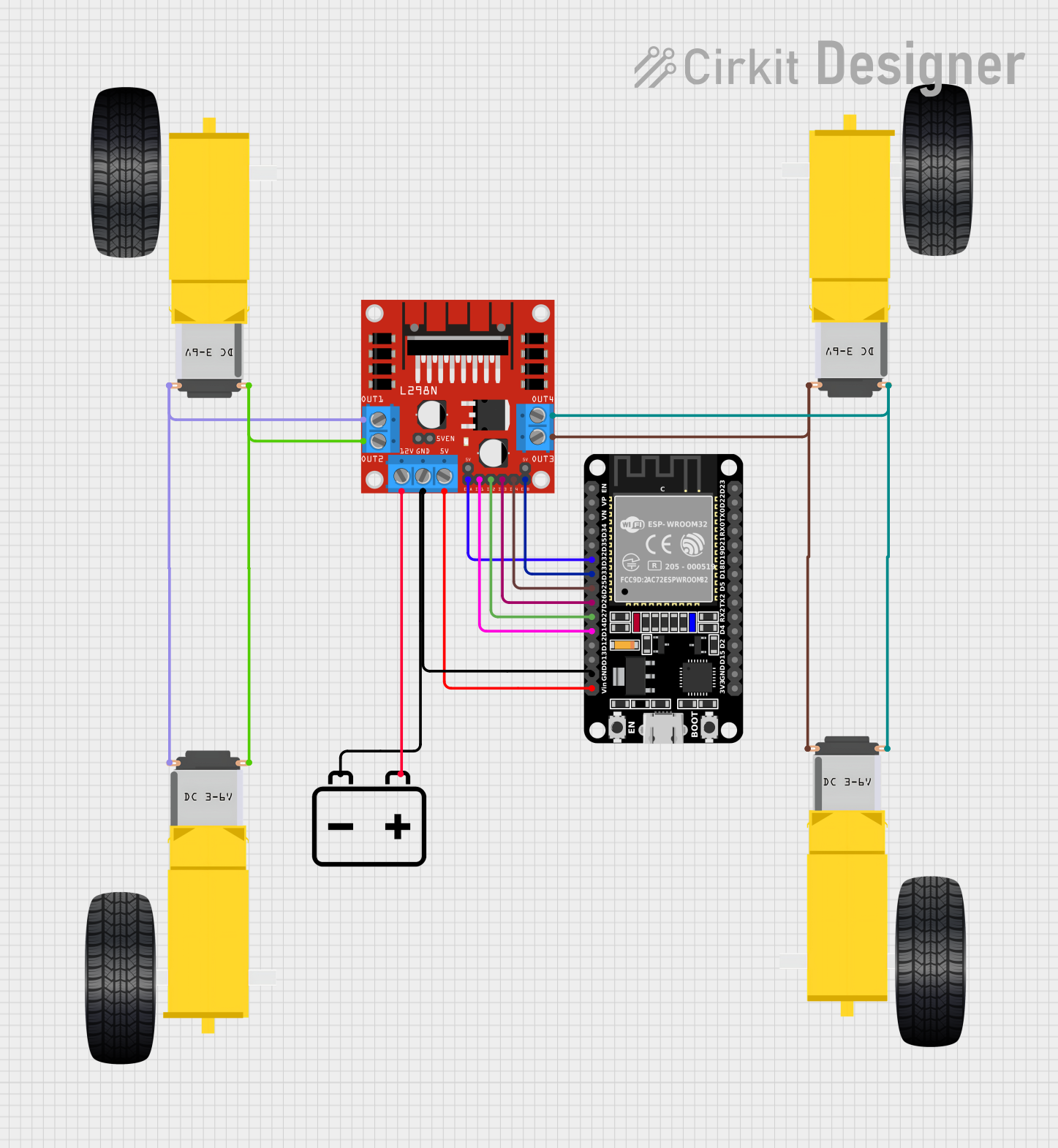

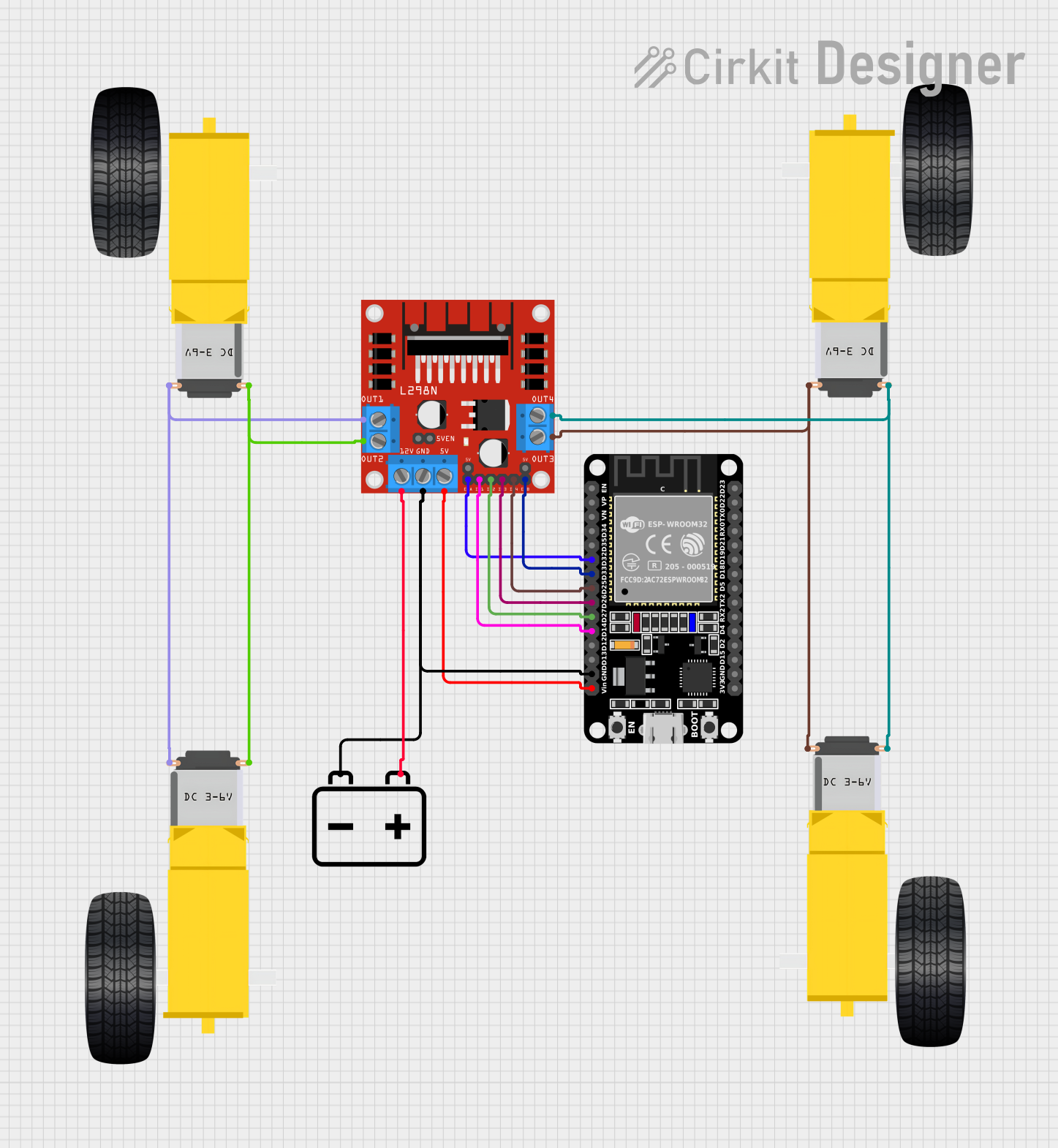

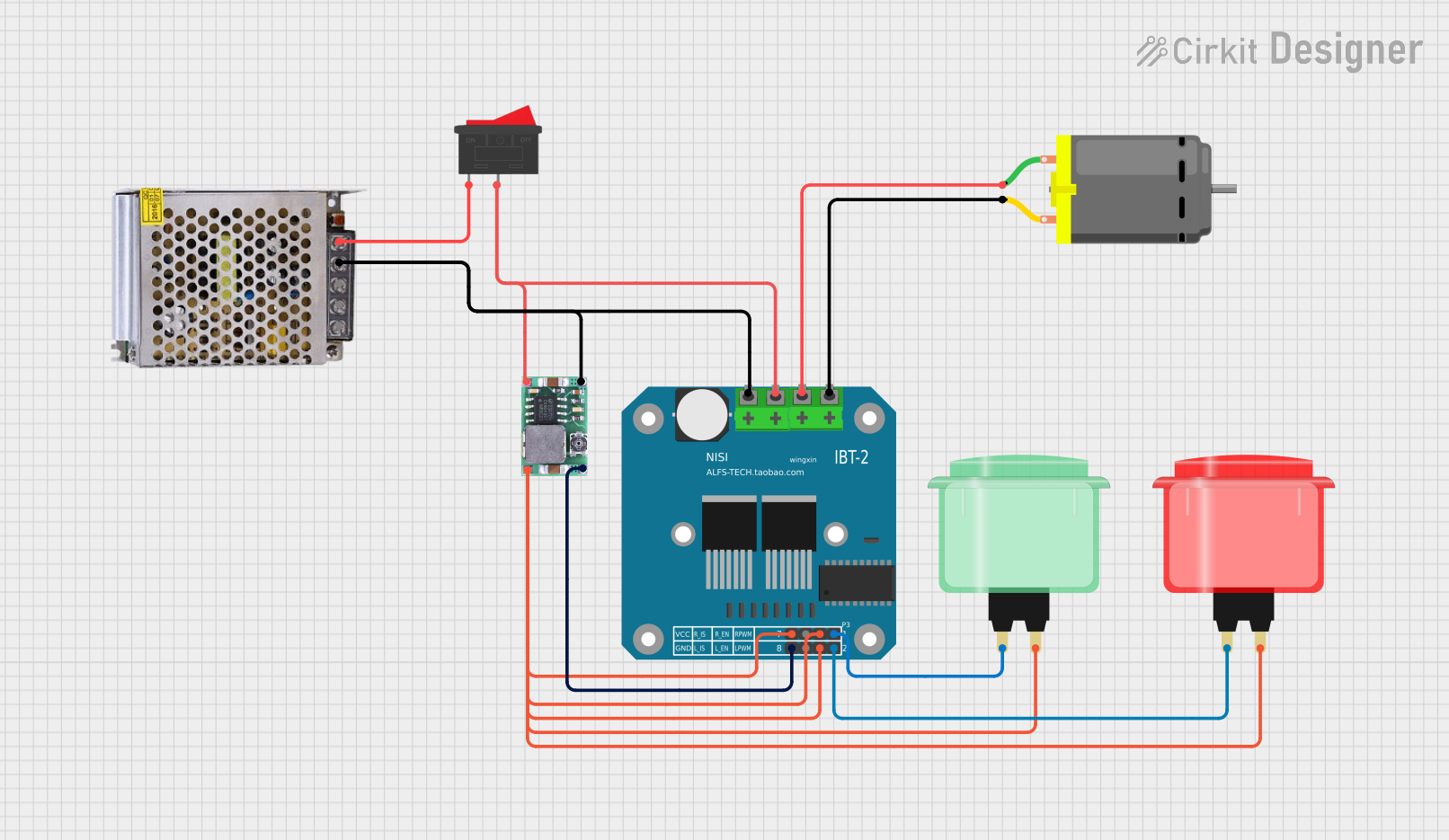

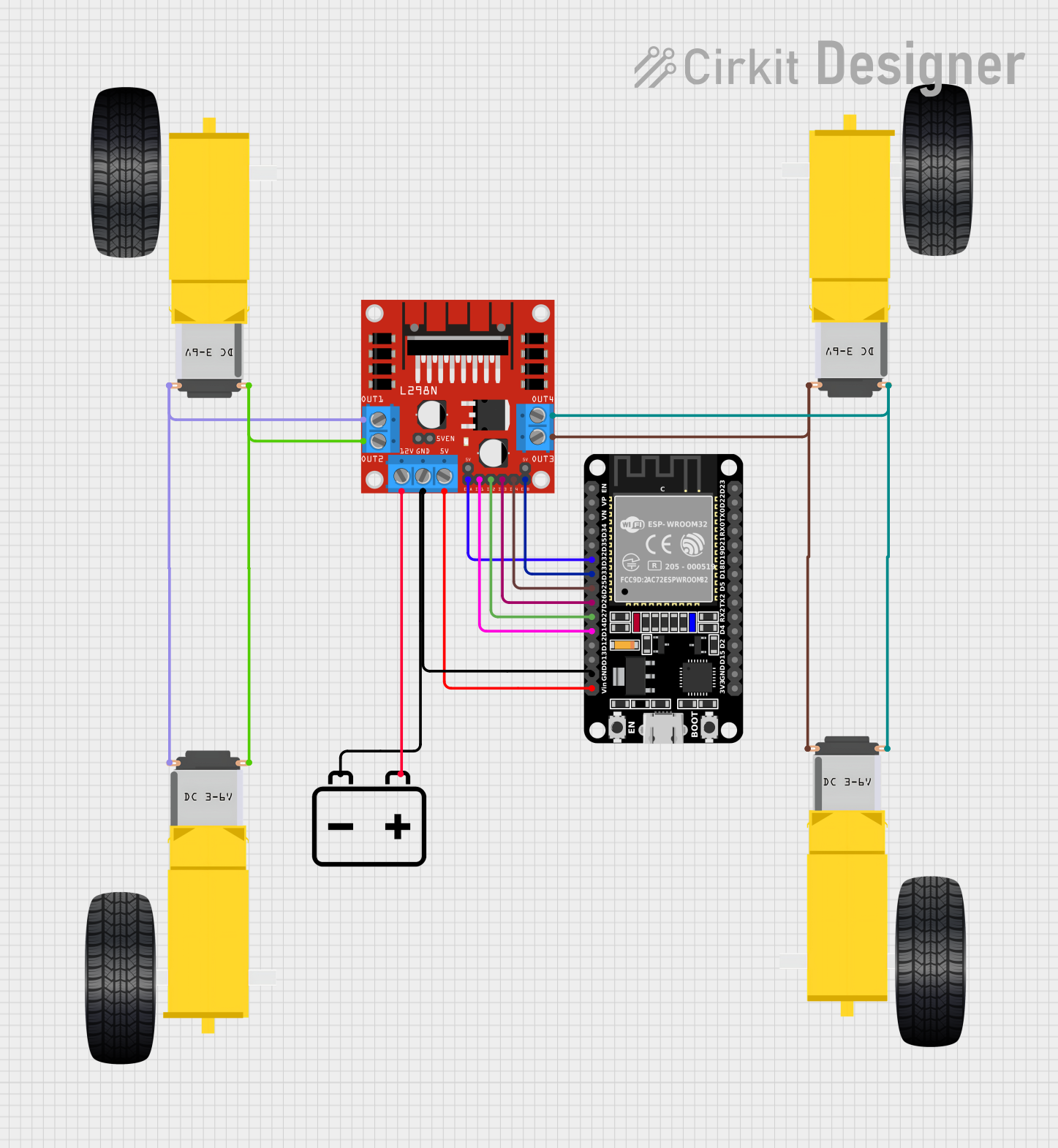

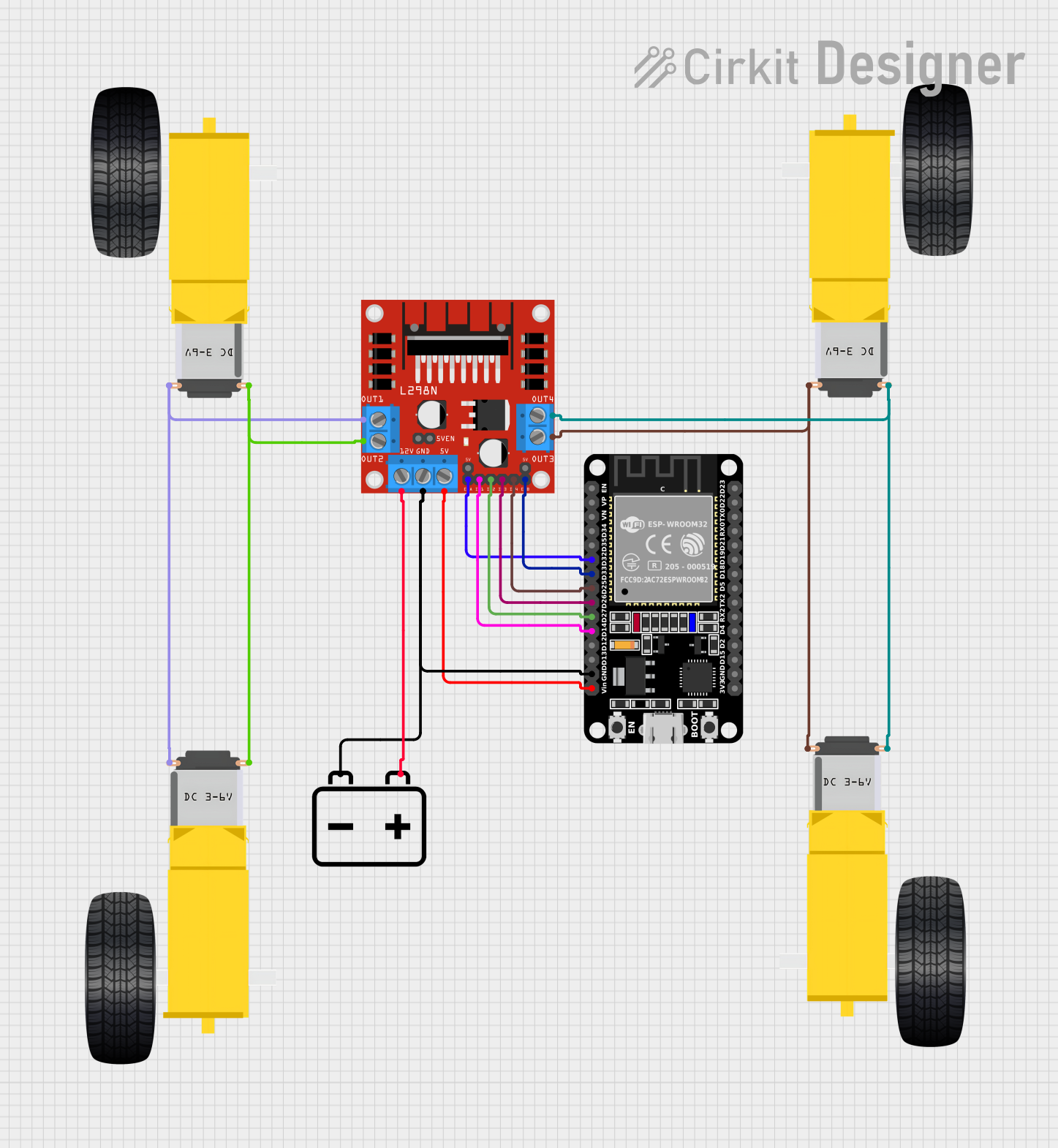

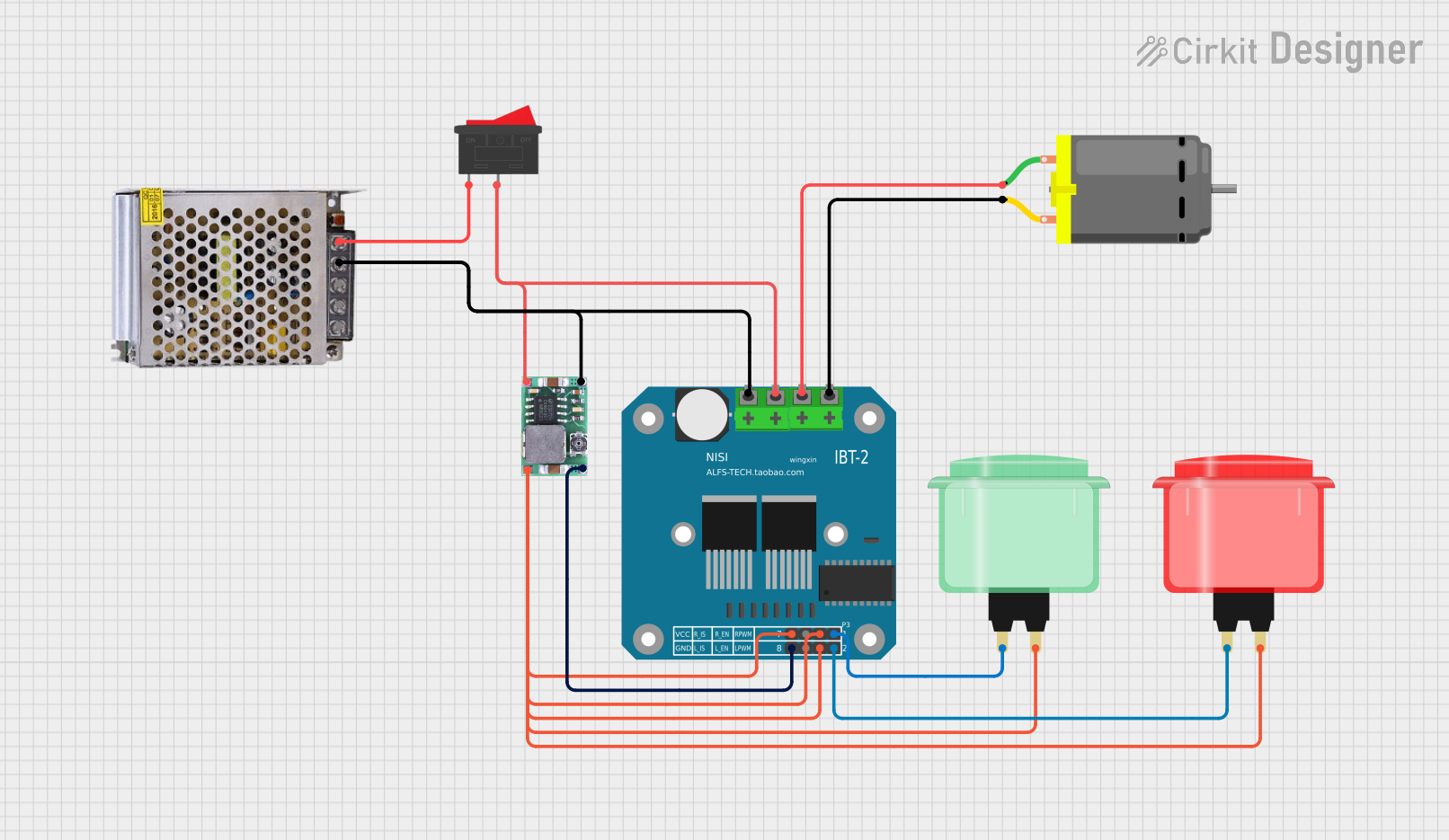

Explore Projects Built with Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Controlling DC motors, stepper motors, or servo motors in robotic systems.

- Industrial Automation: Driving motors in conveyor belts, robotic arms, and machinery.

- Consumer Electronics: Used in devices like electric fans, toys, and drones.

- Automotive: Powering motors in electric vehicles, power windows, and wipers.

Technical Specifications

Below are the general technical specifications for a typical motor driver (e.g., L298N Dual H-Bridge Motor Driver):

Key Technical Details

- Operating Voltage: 5V to 46V

- Output Current: Up to 2A per channel (continuous), 3A peak

- Logic Voltage: 5V (compatible with most microcontrollers)

- Control Inputs: PWM (Pulse Width Modulation) for speed control

- Number of Channels: Dual (can control two motors independently)

- Built-in Protection: Thermal shutdown and overcurrent protection

Pin Configuration and Descriptions

The following table describes the pinout for a typical motor driver module:

| Pin Name | Description |

|---|---|

| VCC | Power supply for the motor (e.g., 12V or 24V, depending on the motor). |

| GND | Ground connection. |

| 5V | Logic voltage input (from the microcontroller, typically 5V). |

| IN1, IN2 | Control inputs for Motor A (used to set direction and enable PWM control). |

| IN3, IN4 | Control inputs for Motor B (used to set direction and enable PWM control). |

| ENA | Enable pin for Motor A (connect to PWM pin for speed control). |

| ENB | Enable pin for Motor B (connect to PWM pin for speed control). |

| OUT1, OUT2 | Output terminals for Motor A. |

| OUT3, OUT4 | Output terminals for Motor B. |

Usage Instructions

How to Use the Component in a Circuit

Power Connections:

- Connect the motor power supply to the

VCCpin and ground to theGNDpin. - Ensure the power supply voltage matches the motor's requirements.

- Connect the motor power supply to the

Logic Connections:

- Connect the

5Vpin to the 5V output of your microcontroller. - Use the

IN1,IN2,IN3, andIN4pins to control the direction of the motors. - Connect the

ENAandENBpins to PWM-capable pins on the microcontroller for speed control.

- Connect the

Motor Connections:

- Connect the motor terminals to the

OUT1andOUT2pins (for Motor A) orOUT3andOUT4pins (for Motor B).

- Connect the motor terminals to the

Control Logic:

- Use the control inputs (

IN1,IN2, etc.) to set the motor's direction:IN1 = HIGH,IN2 = LOW: Motor A rotates forward.IN1 = LOW,IN2 = HIGH: Motor A rotates backward.IN1 = LOW,IN2 = LOW: Motor A stops.

- Use PWM signals on the

ENAandENBpins to control the motor speed.

- Use the control inputs (

Important Considerations and Best Practices

- Power Supply: Ensure the motor driver and motor are powered by a supply that can provide sufficient current.

- Heat Dissipation: Use a heat sink or cooling fan if the motor driver gets too hot during operation.

- Protection: Avoid short circuits and ensure proper wiring to prevent damage to the motor driver.

- Decoupling Capacitors: Add capacitors near the power supply pins to reduce noise and voltage spikes.

Example Code for Arduino UNO

Below is an example code snippet to control a DC motor using an L298N motor driver and an Arduino UNO:

// Define motor control pins

const int IN1 = 9; // Motor A direction control pin 1

const int IN2 = 8; // Motor A direction control pin 2

const int ENA = 10; // Motor A speed control (PWM) pin

void setup() {

// Set motor control pins as outputs

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

pinMode(ENA, OUTPUT);

}

void loop() {

// Rotate motor forward at 50% speed

digitalWrite(IN1, HIGH); // Set IN1 HIGH

digitalWrite(IN2, LOW); // Set IN2 LOW

analogWrite(ENA, 128); // Set ENA to 50% duty cycle (128/255)

delay(2000); // Run motor for 2 seconds

// Rotate motor backward at 75% speed

digitalWrite(IN1, LOW); // Set IN1 LOW

digitalWrite(IN2, HIGH); // Set IN2 HIGH

analogWrite(ENA, 192); // Set ENA to 75% duty cycle (192/255)

delay(2000); // Run motor for 2 seconds

// Stop the motor

digitalWrite(IN1, LOW); // Set IN1 LOW

digitalWrite(IN2, LOW); // Set IN2 LOW

analogWrite(ENA, 0); // Set ENA to 0% duty cycle (motor off)

delay(2000); // Wait for 2 seconds before repeating

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Running:

- Cause: Incorrect wiring or insufficient power supply.

- Solution: Double-check all connections and ensure the power supply meets the motor's requirements.

Motor Running in the Wrong Direction:

- Cause: Control pins (

IN1,IN2, etc.) are not set correctly. - Solution: Verify the logic levels on the control pins and adjust as needed.

- Cause: Control pins (

Motor Driver Overheating:

- Cause: Excessive current draw or poor heat dissipation.

- Solution: Use a heat sink or cooling fan, and ensure the motor's current is within the driver's limits.

PWM Speed Control Not Working:

- Cause: PWM signal not properly configured.

- Solution: Check the PWM pin configuration in the code and ensure the microcontroller supports PWM on the selected pins.

FAQs

Can I use the motor driver with a 3.3V microcontroller?

- Yes, but ensure the logic voltage of the motor driver is compatible with 3.3V signals.

What types of motors can I control with this driver?

- The motor driver can control DC motors and stepper motors (with appropriate wiring and control logic).

How do I connect multiple motor drivers to one microcontroller?

- Use separate control pins for each motor driver, or use a multiplexer if pin availability is limited.