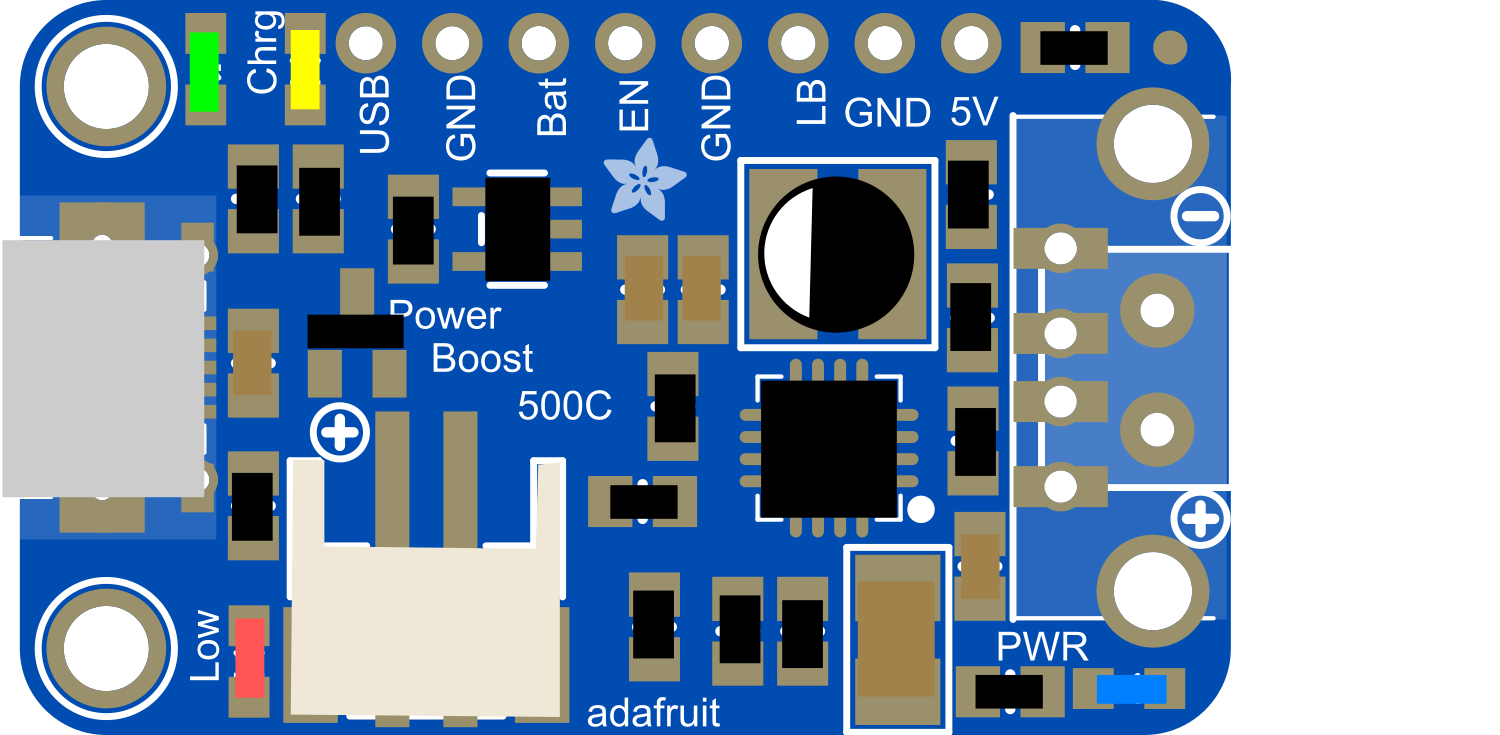

How to Use PowerBoost 500 Charger Pad: Examples, Pinouts, and Specs

Design with PowerBoost 500 Charger Pad in Cirkit Designer

Design with PowerBoost 500 Charger Pad in Cirkit DesignerIntroduction

The PowerBoost 500 Charger Pad is a versatile and compact electronic component designed to provide a 5V power supply with a maximum output current of 500mA. This component integrates a power boost converter with a USB charging circuit, making it ideal for portable electronics, wearable devices, and DIY projects that require a stable power source from a lower voltage battery, such as a single-cell LiPo (Lithium Polymer) battery. The pad version is particularly suitable for embedding into custom PCB designs, offering a streamlined solution for power management.

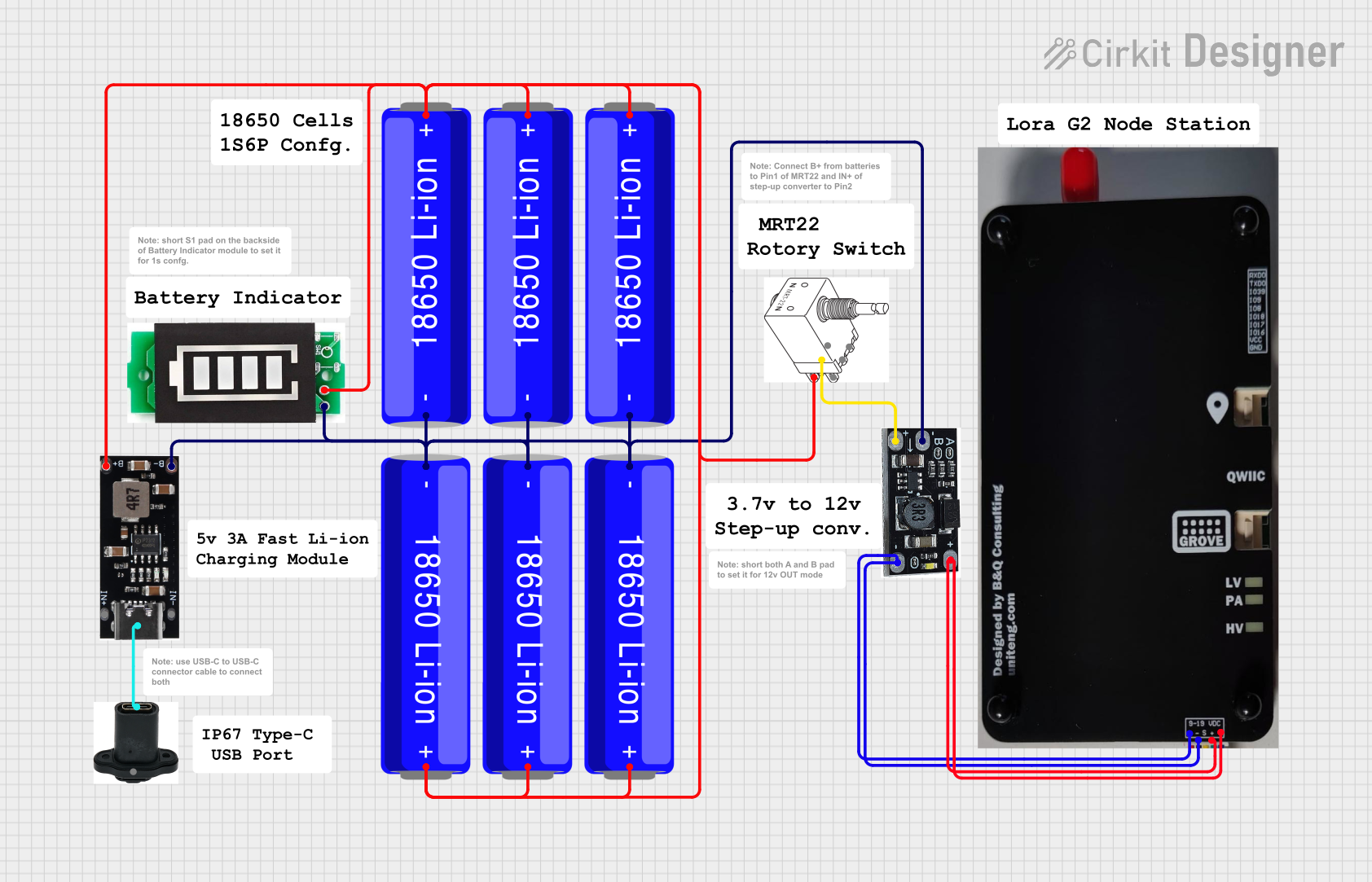

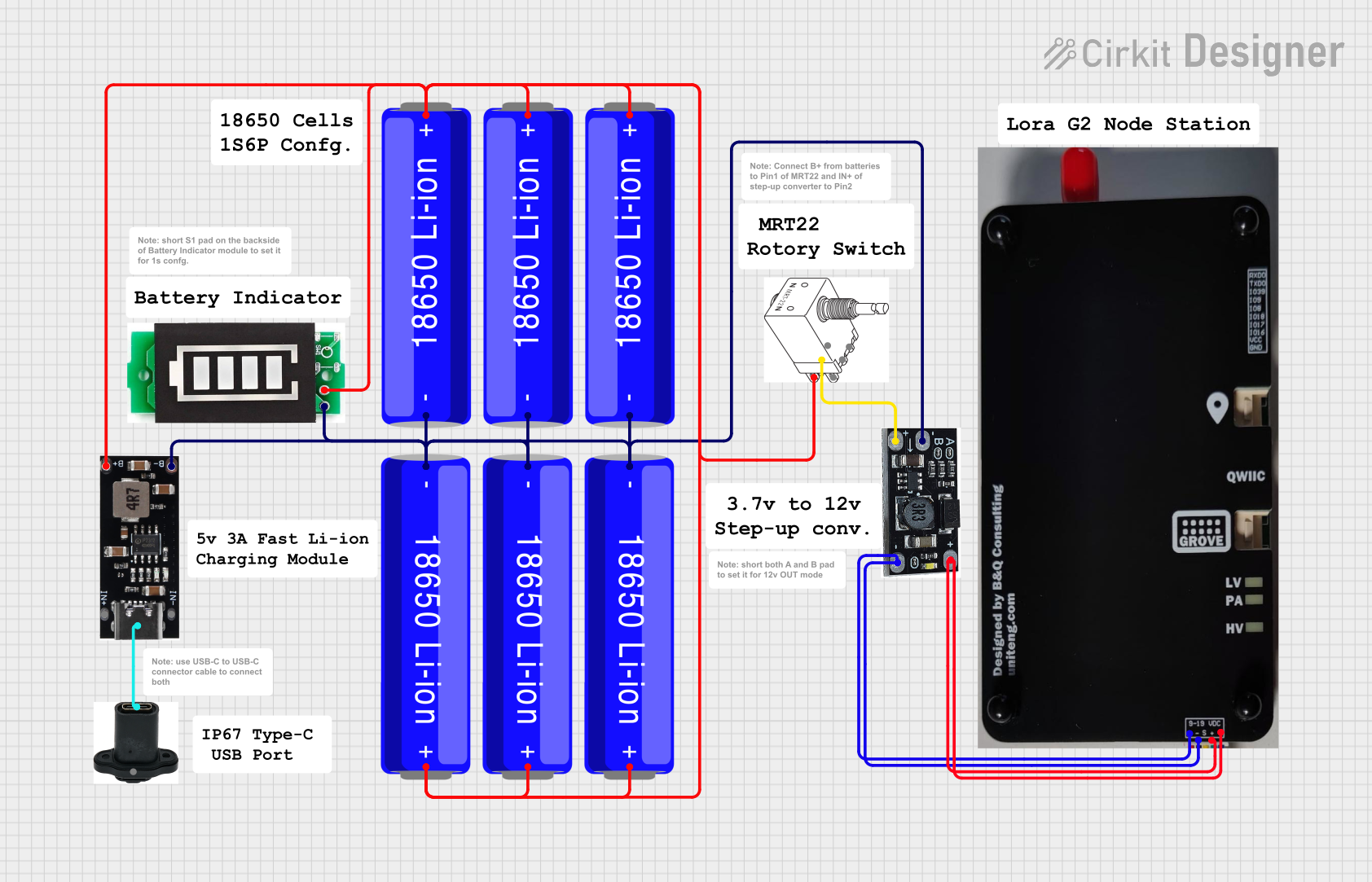

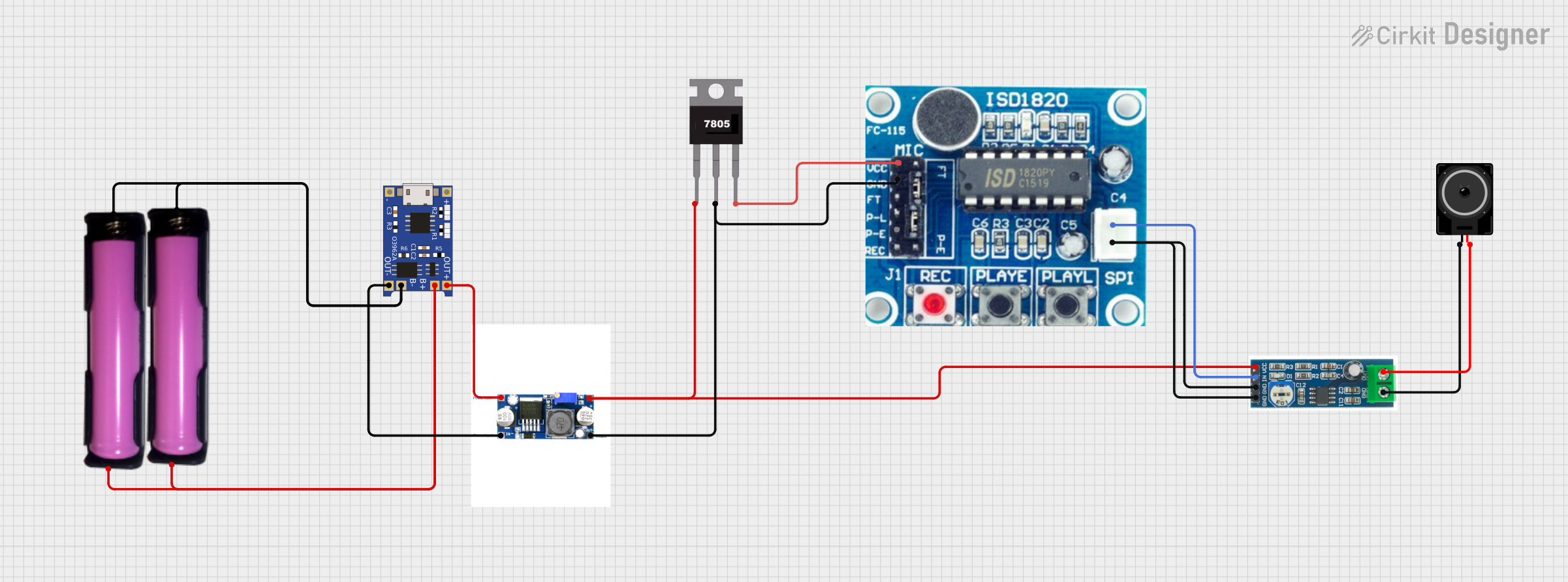

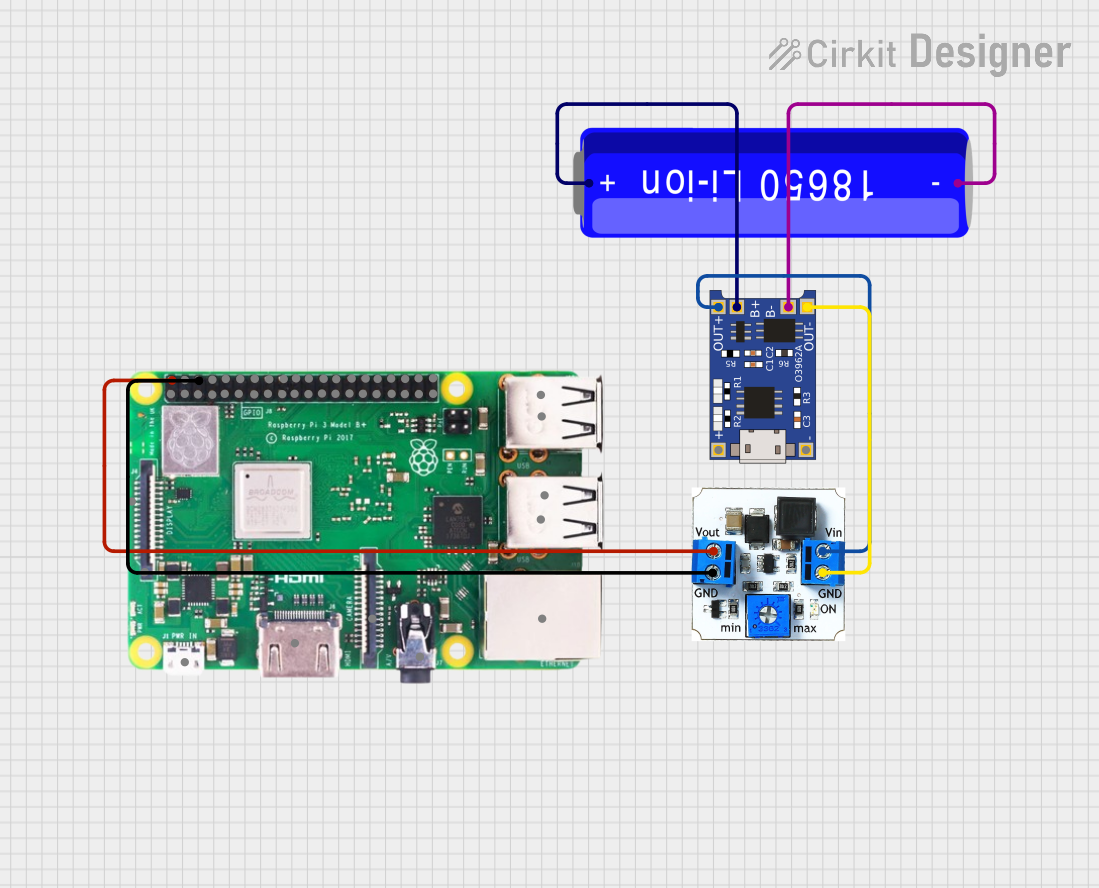

Explore Projects Built with PowerBoost 500 Charger Pad

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

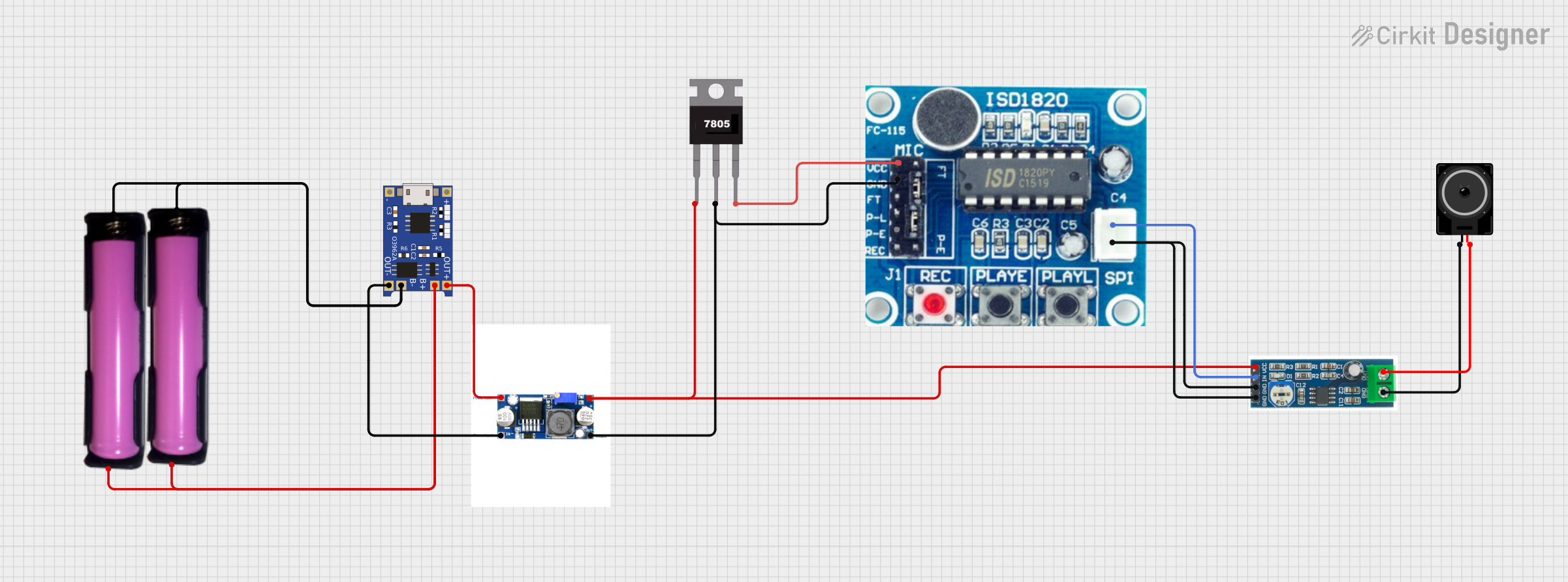

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with PowerBoost 500 Charger Pad

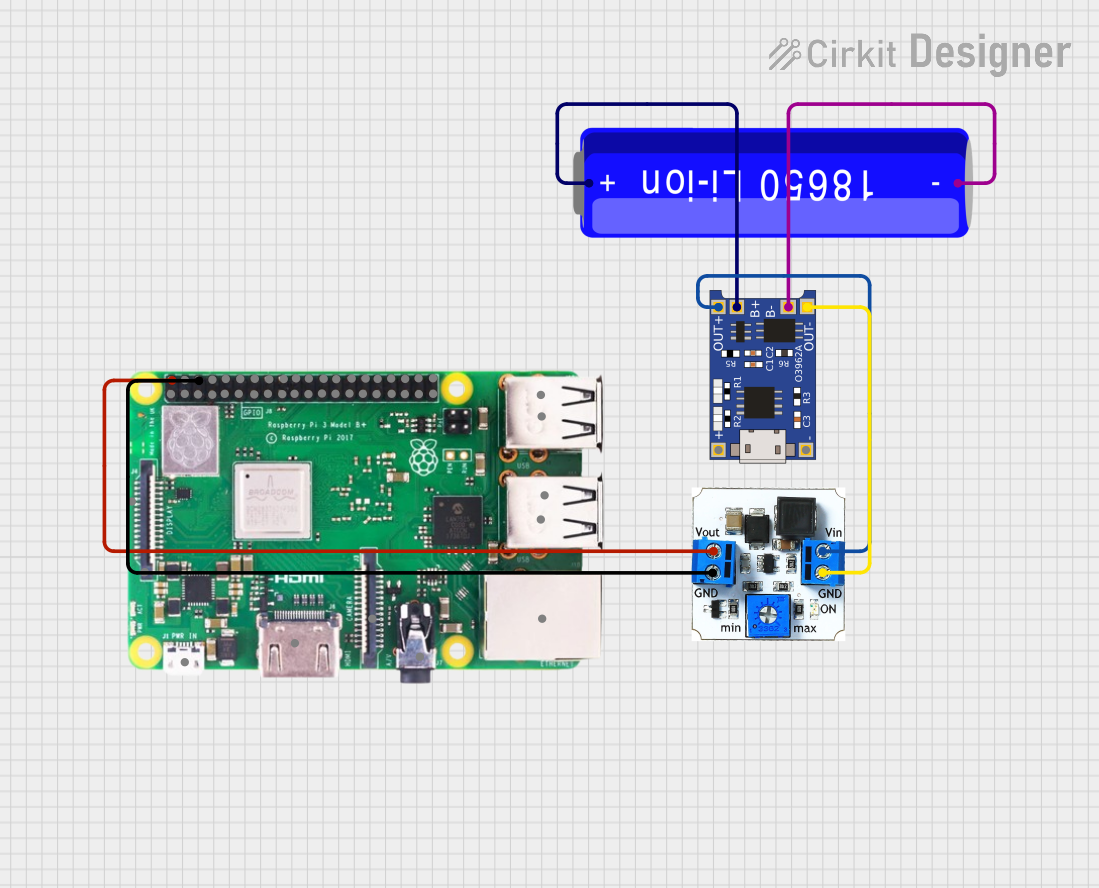

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Portable USB chargers

- Battery-powered projects requiring a 5V supply

- Wearable electronics

- DIY electronics projects with space constraints

- Integration into custom PCB designs for compact and efficient power supply

Technical Specifications

Key Technical Details

- Input Voltage: 3.7V nominal (suitable for LiPo batteries)

- Output Voltage: 5V fixed

- Maximum Output Current: 500mA

- Efficiency: Up to 90% (varies based on input and output conditions)

- Integrated charging circuit for USB devices

- Low battery indicator output

Pin Configuration and Descriptions

| Pin Number | Name | Description |

|---|---|---|

| 1 | GND | Ground connection for both input and output. |

| 2 | BAT | Battery input, connect to the positive terminal of the battery. |

| 3 | 5V | Regulated 5V output, can supply up to 500mA. |

| 4 | EN | Enable pin, drive high to enable the boost converter. |

| 5 | LBO | Low Battery Output, goes low when the battery voltage is below a threshold. |

Usage Instructions

How to Use the Component in a Circuit

- Connect the positive terminal of a charged LiPo battery to the

BATpin. - Connect the ground of the battery to the

GNDpin. - The

5Vpin will now output a regulated 5V when theENpin is driven high. - To enable the power boost converter, connect the

ENpin to a high logic level (e.g., 3.3V or 5V). To disable the converter, connect it to ground. - The

LBOpin can be connected to an LED or a microcontroller input pin to monitor the battery status.

Important Considerations and Best Practices

- Ensure that the battery used is capable of supplying the required current for your application.

- Avoid placing high-power components too close to the PowerBoost 500 Charger Pad to prevent heat buildup.

- When integrating into a PCB, provide adequate copper area for heat dissipation.

- Do not exceed the maximum input and output ratings to prevent damage to the component.

Troubleshooting and FAQs

Common Issues Users Might Face

- No Output Voltage: Ensure the

ENpin is driven high and the battery is properly charged and connected. - Insufficient Output Current: Check if the battery is capable of supplying the required current. Replace the battery if necessary.

- Overheating: Make sure there is enough space around the component for heat dissipation.

Solutions and Tips for Troubleshooting

- If the

LBOpin is active, recharge the battery to ensure proper operation. - Double-check all connections, especially the polarity of the battery.

- If the device is not functioning, disconnect the power and inspect the board for any signs of damage or soldering issues.

FAQs

Q: Can I use the PowerBoost 500 Charger Pad with batteries other than LiPo? A: The PowerBoost 500 Charger Pad is optimized for 3.7V LiPo batteries. Using other types of batteries is not recommended and may not provide the desired performance.

Q: What should I do if the PowerBoost 500 Charger Pad is not boosting the voltage to 5V?

A: Verify that the EN pin is high and that the battery is properly charged. If the issue persists, inspect the component and connections for any faults.

Q: Is it possible to charge the battery through the PowerBoost 500 Charger Pad? A: Yes, the PowerBoost 500 Charger Pad includes a charging circuit for recharging the connected LiPo battery via a USB connection.

Q: How can I integrate the PowerBoost 500 Charger Pad into my custom PCB design? A: The pad version of the PowerBoost 500 Charger Pad is designed for easy integration. Refer to the manufacturer's footprint and layout guidelines when designing your PCB.

Q: Can I connect multiple devices to the 5V output? A: Yes, as long as the total current draw does not exceed 500mA.

Example Code for Arduino UNO

The following example demonstrates how to monitor the battery status using an Arduino UNO:

// Define the pin connected to the Low Battery Output (LBO)

const int lowBatteryPin = 2;

void setup() {

// Set the lowBatteryPin as an input

pinMode(lowBatteryPin, INPUT);

// Begin serial communication at 9600 baud rate

Serial.begin(9600);

}

void loop() {

// Read the state of the low battery indicator

int batteryStatus = digitalRead(lowBatteryPin);

// If the LBO pin is LOW, the battery is below the threshold voltage

if (batteryStatus == LOW) {

Serial.println("Low battery warning!");

} else {

Serial.println("Battery level is OK.");

}

// Wait for 1 second before checking again

delay(1000);

}

Remember to keep code comments concise and within the 80 character line length limit.