How to Use Buck converter: Examples, Pinouts, and Specs

Design with Buck converter in Cirkit Designer

Design with Buck converter in Cirkit DesignerIntroduction

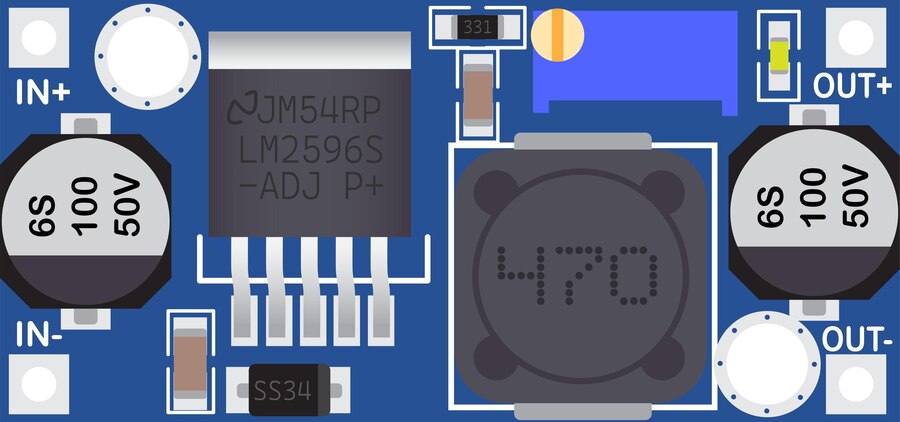

A Buck converter, also known as a step-down converter, is an essential electronic component used to convert a higher direct current (DC) input voltage to a lower DC output voltage with high efficiency. This type of power supply module is widely used in battery-operated devices, power supplies for various electronic applications, and as a voltage regulator in many circuits.

Common applications include:

- Portable devices (e.g., smartphones, laptops)

- Power management in embedded systems

- Automotive electronics

- LED drivers

- Renewable energy systems, such as solar power converters

Explore Projects Built with Buck converter

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Buck converter

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

- Input Voltage Range: Typically ranges from a couple of volts above the desired output to tens of volts.

- Output Voltage Range: Adjustable based on the design, often from 1V to several tens of volts.

- Efficiency: Up to 95%, depending on the design and load conditions.

- Switching Frequency: Varies with design, commonly from 100 kHz to several MHz.

- Load Current: Depending on the model, can range from a few milliamps to tens of amps.

Pin Configuration and Descriptions

| Pin Number | Name | Description |

|---|---|---|

| 1 | VIN | Input voltage supply pin. Connect to the source of the DC voltage to be stepped down. |

| 2 | GND | Ground pin. Connect to the system ground. |

| 3 | VOUT | Output voltage pin. This is where the buck converter provides the stepped-down voltage. |

| 4 | EN | Enable pin. A logic high signal here enables the buck converter, while a logic low signal disables it. |

| 5 | FB | Feedback pin. Used for voltage feedback to regulate the output voltage. Often connected to a voltage divider. |

Usage Instructions

How to Use the Buck Converter in a Circuit

- Connection: Connect the input voltage source to the VIN and GND pins. Ensure that the input voltage does not exceed the maximum rating of the buck converter.

- Output Voltage Setting: If the buck converter has an adjustable output, set the desired voltage using the feedback pin (FB) and an appropriate voltage divider or potentiometer.

- Enable the Converter: Apply a logic high signal to the EN pin to turn on the buck converter.

- Load Connection: Connect the load to the VOUT and GND pins.

Important Considerations and Best Practices

- Input Capacitor: Place a capacitor close to the VIN and GND pins to stabilize the input supply and reduce voltage spikes.

- Output Capacitor: Use an output capacitor to smooth out the voltage ripple and provide a stable output.

- Thermal Management: Ensure adequate cooling for the buck converter, especially at high load currents, to prevent overheating.

- Inductor Selection: Choose an inductor with a current rating above the maximum load current and low series resistance to maintain efficiency.

- Switching Noise: Be aware of potential electromagnetic interference (EMI) generated by the switching action. Proper layout and filtering can mitigate this.

Troubleshooting and FAQs

Common Issues

- Output Voltage Too Low or High: Check the feedback network and ensure the correct setting if the output is adjustable.

- Converter Not Starting: Verify the input voltage is within range and the EN pin is receiving a high signal.

- Overheating: Reduce the load current, improve cooling, or check for short circuits.

Solutions and Tips for Troubleshooting

- No Output: Ensure that the buck converter is enabled and that all connections are secure.

- Inconsistent Output: Check for proper capacitor and inductor values, and replace if necessary.

- Noise Issues: Add filtering capacitors or inductors, and keep the switching paths as short as possible.

FAQs

Q: Can I use a buck converter to charge batteries? A: Yes, but ensure that the output voltage is appropriate for the battery and that proper charging circuitry is in place.

Q: How do I choose the right inductor for my application? A: Consider the maximum load current, desired ripple current, and switching frequency. The inductor should have a saturation current above the peak load current.

Q: What is the purpose of the feedback pin? A: The feedback pin allows the buck converter to regulate the output voltage by comparing it to a reference voltage.

Example Code for Arduino UNO

Below is an example code snippet for controlling an Arduino-compatible buck converter module with an enable pin.

// Define the enable pin for the buck converter

const int buckConverterEnablePin = 7;

void setup() {

// Set the enable pin as an output

pinMode(buckConverterEnablePin, OUTPUT);

}

void loop() {

// Enable the buck converter

digitalWrite(buckConverterEnablePin, HIGH);

delay(5000); // Keep the converter on for 5 seconds

// Disable the buck converter

digitalWrite(buckConverterEnablePin, LOW);

delay(5000); // Keep the converter off for 5 seconds

}

This code will toggle the buck converter on and off every 5 seconds. Ensure that the enable pin on the buck converter is connected to pin 7 on the Arduino UNO.