How to Use 16-Channel PWM Servo Driver: Examples, Pinouts, and Specs

Design with 16-Channel PWM Servo Driver in Cirkit Designer

Design with 16-Channel PWM Servo Driver in Cirkit DesignerIntroduction

The 16-Channel PWM Servo Driver is a versatile device designed to control up to 16 servos or PWM outputs simultaneously. It uses pulse-width modulation (PWM) signals to provide precise control over the position and speed of each servo, making it an essential component in robotics, automation, and other applications requiring multi-servo control. This driver is typically controlled via I2C communication, making it compatible with microcontrollers like Arduino, Raspberry Pi, and others.

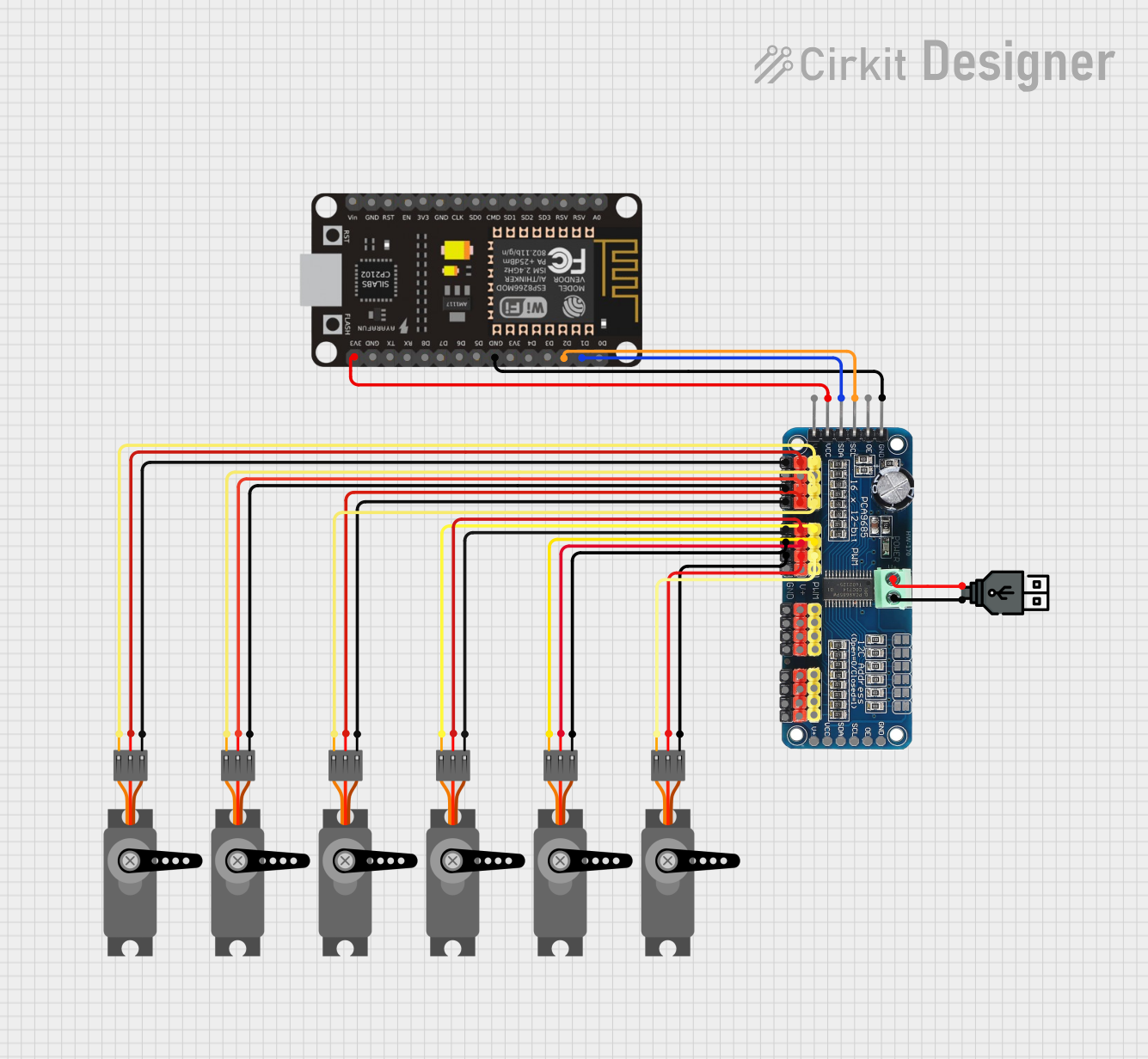

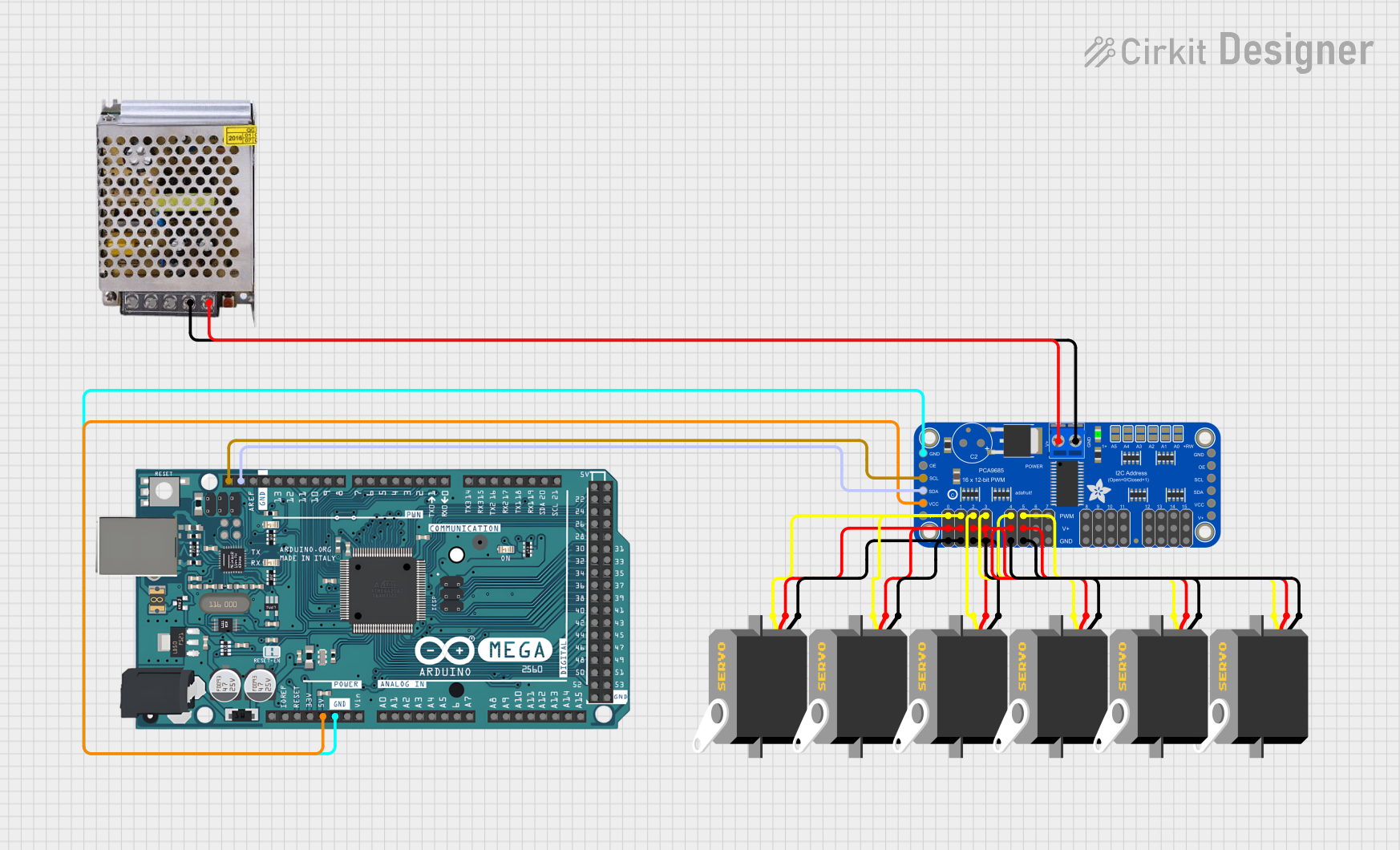

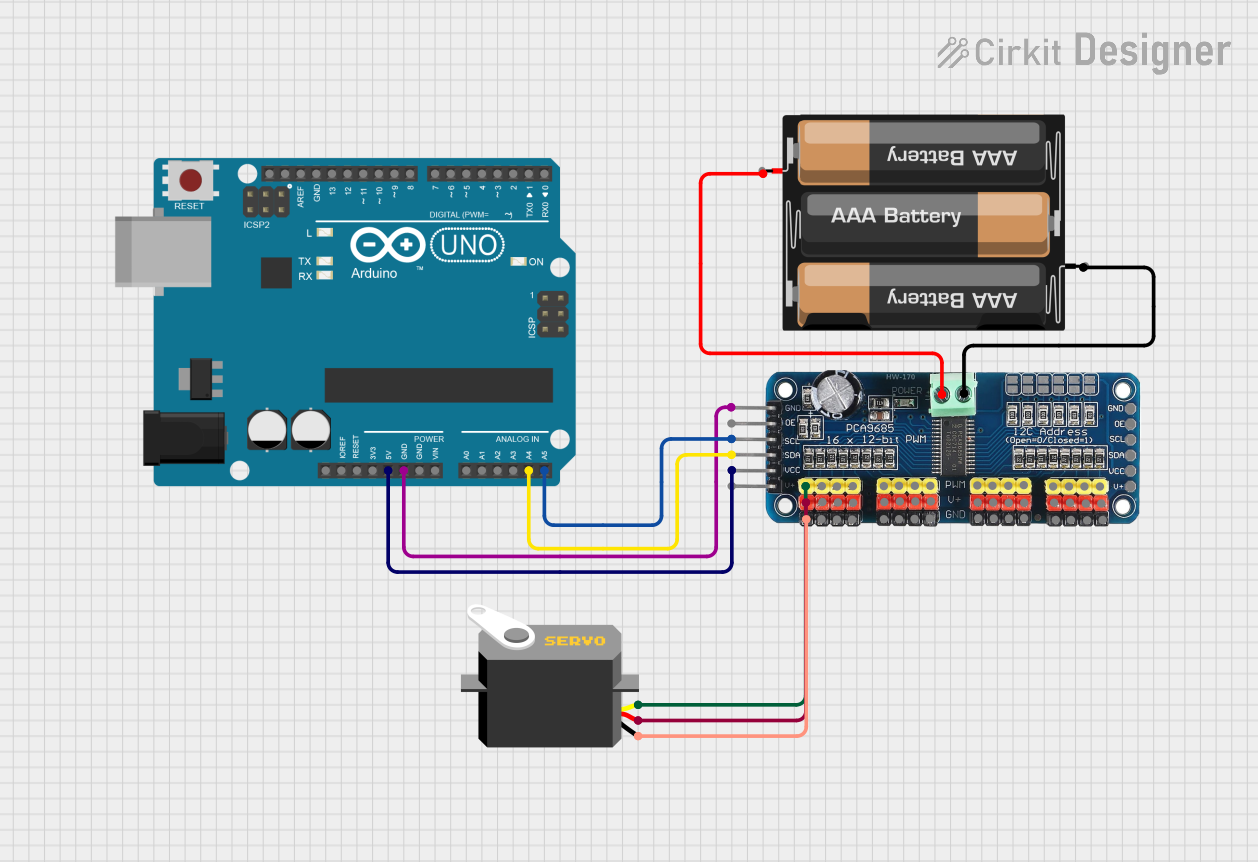

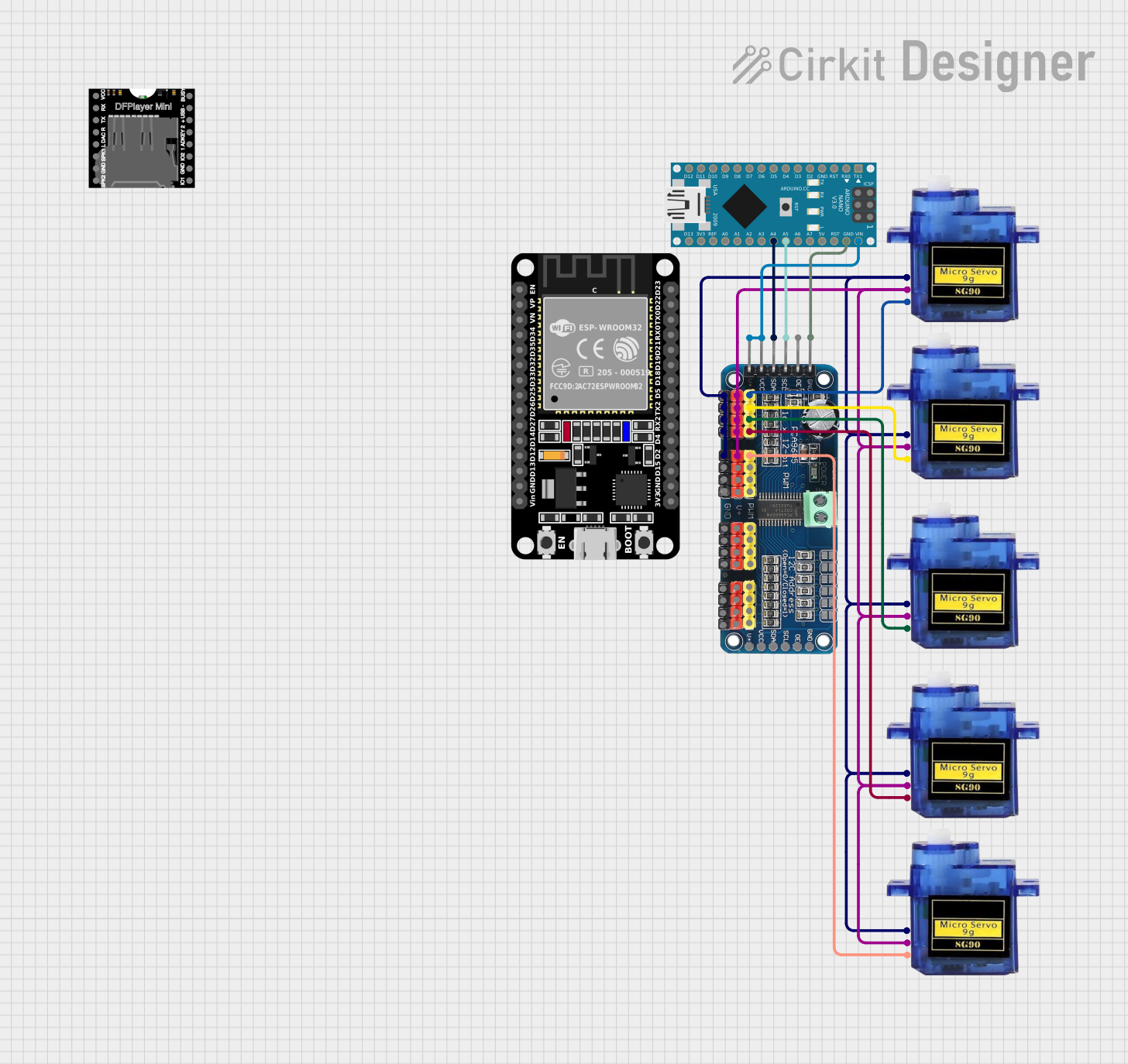

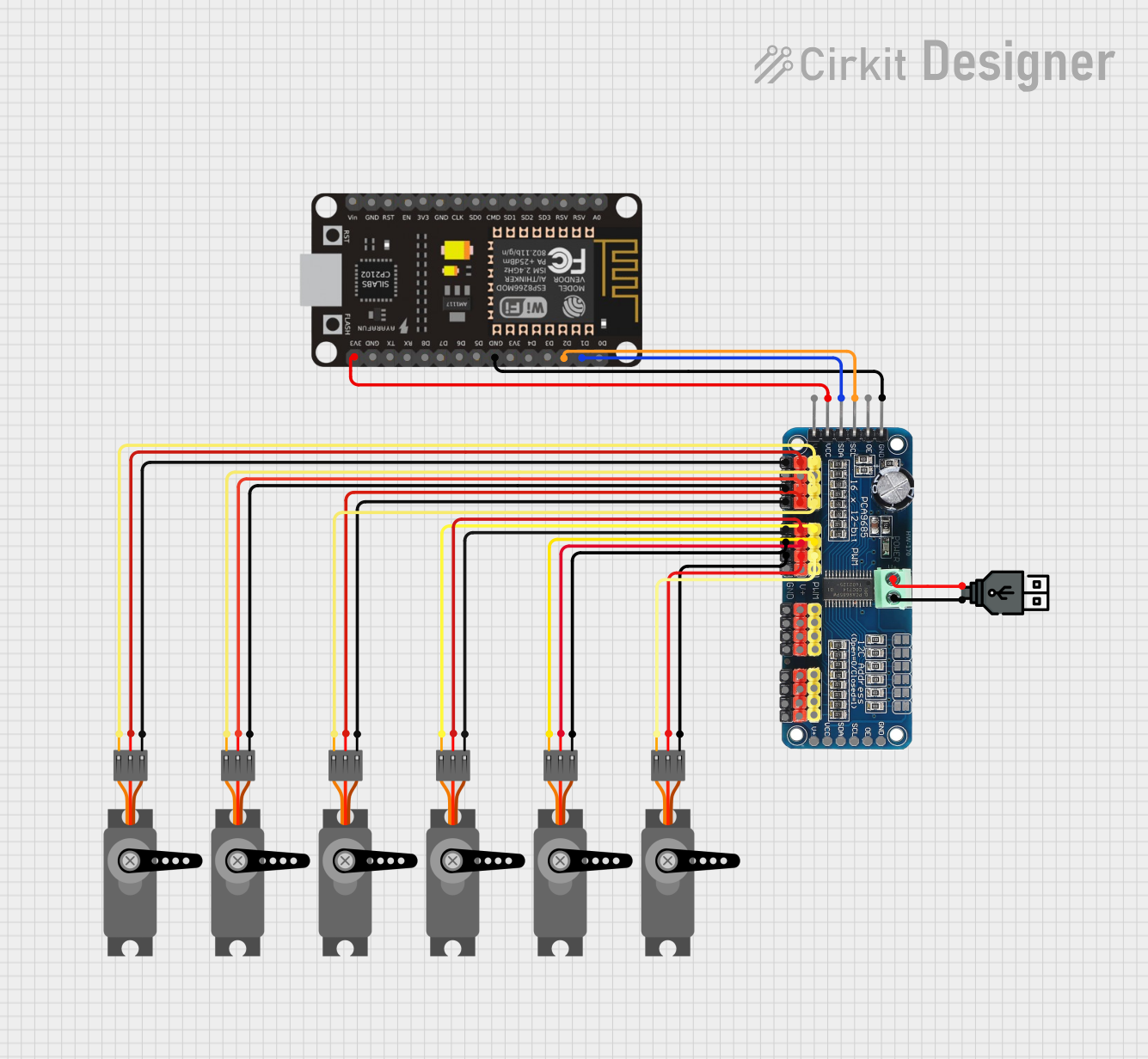

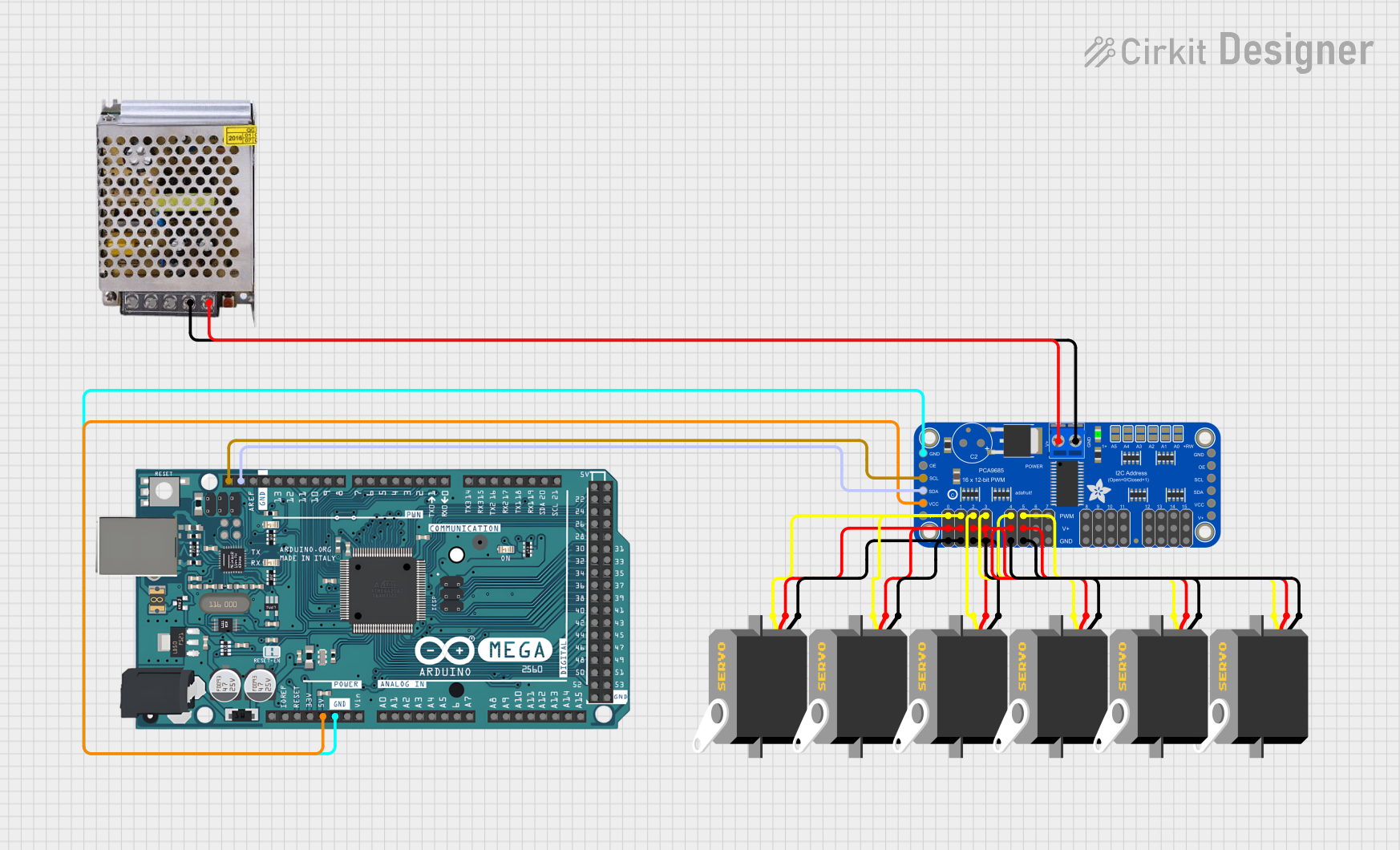

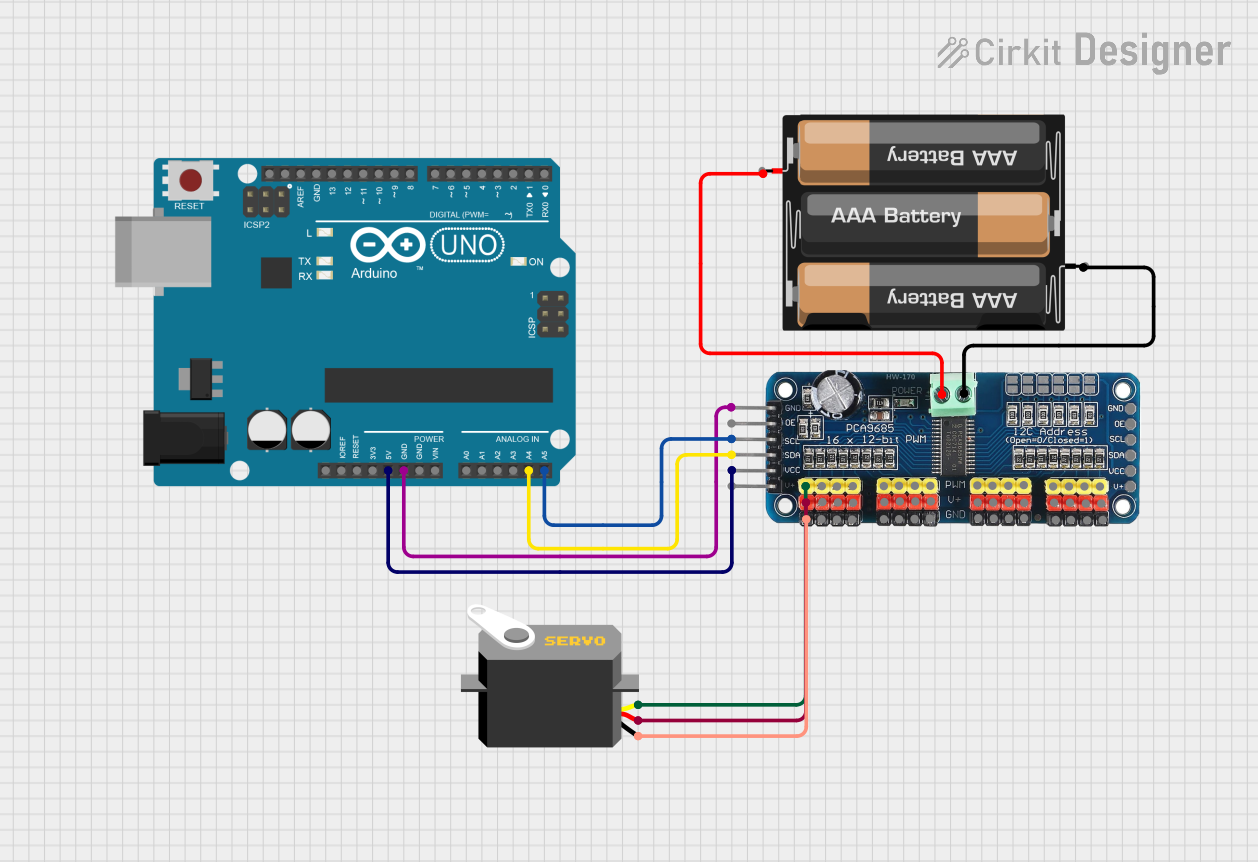

Explore Projects Built with 16-Channel PWM Servo Driver

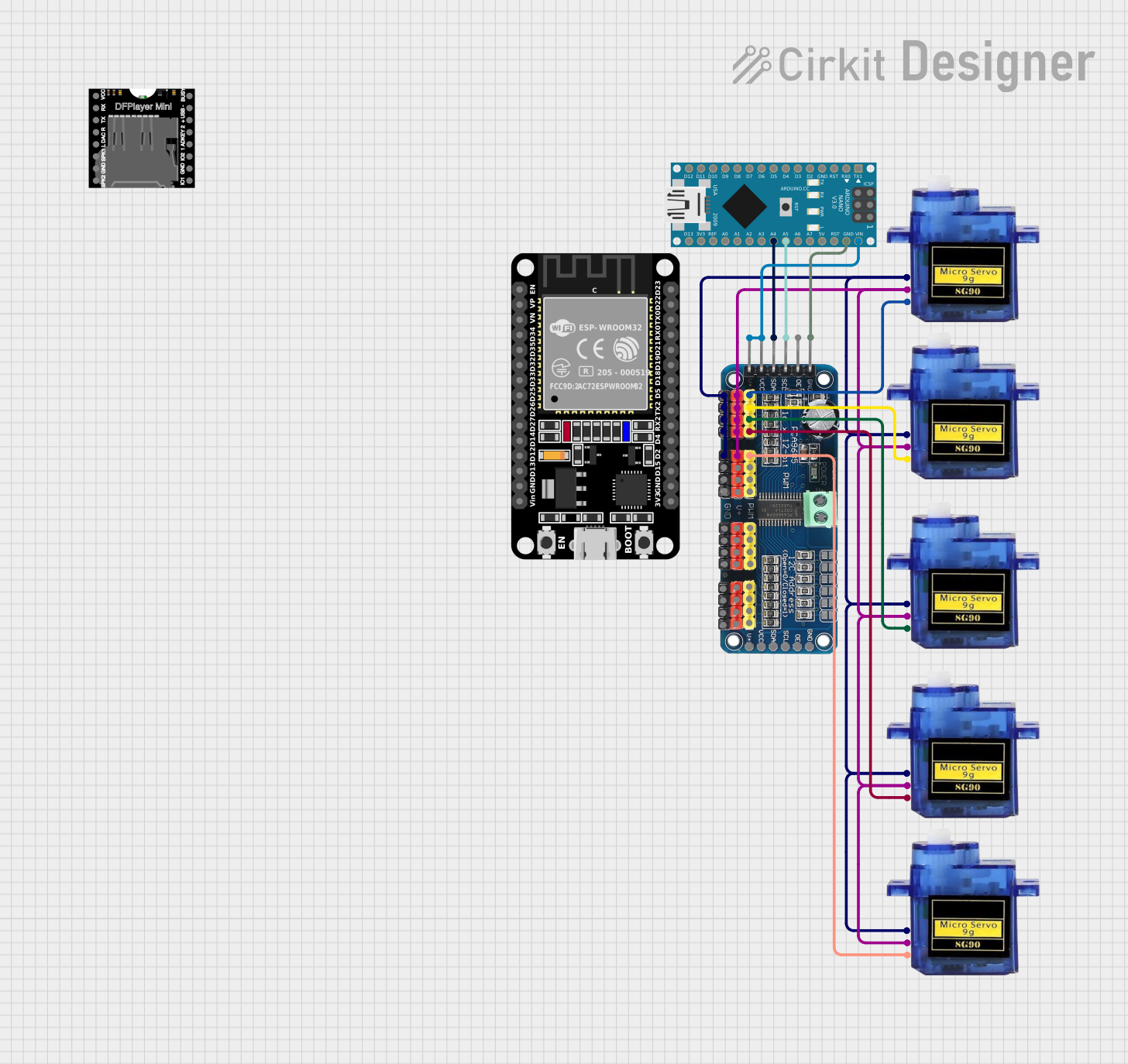

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 16-Channel PWM Servo Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Controlling robotic arms, legs, or grippers.

- Automation: Managing actuators in industrial systems.

- Animatronics: Driving multiple servos for lifelike motion.

- Model building: Controlling servos in RC cars, planes, or boats.

- LED control: Driving PWM-based LEDs for dimming or effects.

Technical Specifications

- Operating Voltage: 3.3V to 5.5V

- PWM Frequency: Adjustable from 40Hz to 1000Hz

- Resolution: 12-bit (4096 steps per PWM cycle)

- Communication Protocol: I2C (7-bit address, configurable)

- Output Channels: 16 independent PWM outputs

- Output Current: Up to 25mA per channel

- I2C Address Range: 0x40 to 0x7F (configurable via address pins)

- Dimensions: Typically 60mm x 25mm (varies by manufacturer)

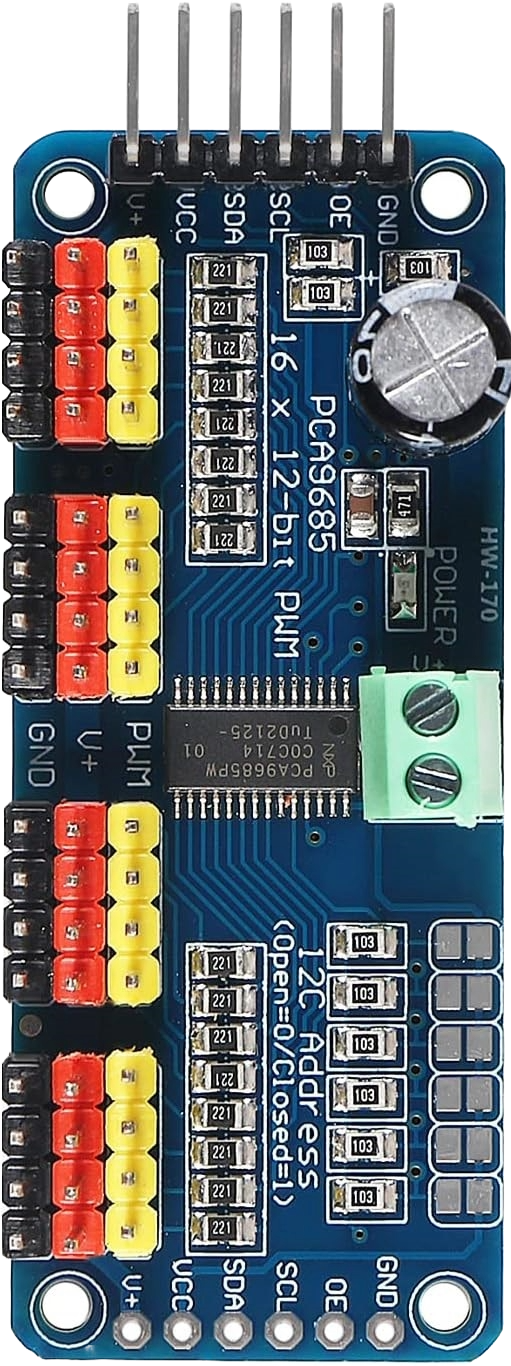

Pin Configuration and Descriptions

| Pin Name | Description |

|---|---|

| VCC | Power input for the logic circuit (3.3V to 5.5V). |

| GND | Ground connection. |

| SDA | I2C data line for communication with the microcontroller. |

| SCL | I2C clock line for communication with the microcontroller. |

| OE | Output enable pin (active low). Disables all outputs when pulled high. |

| PWM 0-15 | 16 PWM output pins for connecting servos or other PWM-controlled devices. |

| A0-A5 | Address selection pins for configuring the I2C address of the device. |

Usage Instructions

How to Use the Component in a Circuit

- Power the Driver: Connect the VCC pin to a 3.3V or 5V power source and the GND pin to ground.

- Connect the I2C Lines: Connect the SDA and SCL pins to the corresponding I2C pins on your microcontroller.

- Set the I2C Address: Use the A0-A5 pins to configure the I2C address if multiple drivers are used.

- Connect Servos: Attach the servo signal wires to the PWM output pins (PWM 0-15). Ensure the servos are powered by an external power source capable of handling their current requirements.

- Enable Outputs: Ensure the OE pin is pulled low to enable the PWM outputs.

Important Considerations and Best Practices

- Power Supply: Use a separate power supply for the servos to avoid overloading the microcontroller's power regulator.

- Bypass Capacitors: Add a capacitor (e.g., 1000µF) across the servo power supply to stabilize voltage during operation.

- I2C Pull-Up Resistors: Ensure proper pull-up resistors (typically 4.7kΩ) are present on the SDA and SCL lines.

- PWM Frequency: Set the PWM frequency to match the requirements of your servos (typically 50Hz for standard servos).

- Avoid Overloading: Do not exceed the current rating of the driver or the power supply.

Example Code for Arduino UNO

Below is an example of how to control a servo using the 16-Channel PWM Servo Driver with an Arduino UNO:

#include <Wire.h>

#include <Adafruit_PWMServoDriver.h>

// Create an instance of the PWM driver

Adafruit_PWMServoDriver pwm = Adafruit_PWMServoDriver();

#define SERVOMIN 150 // Minimum pulse length count (adjust for your servo)

#define SERVOMAX 600 // Maximum pulse length count (adjust for your servo)

void setup() {

Serial.begin(9600);

Serial.println("16-Channel PWM Servo Driver Test");

pwm.begin(); // Initialize the PWM driver

pwm.setPWMFreq(50); // Set PWM frequency to 50Hz for standard servos

}

void loop() {

// Sweep servo on channel 0 from minimum to maximum position

for (int pulse = SERVOMIN; pulse <= SERVOMAX; pulse++) {

pwm.setPWM(0, 0, pulse); // Set PWM signal on channel 0

delay(10); // Small delay for smooth motion

}

// Sweep servo back from maximum to minimum position

for (int pulse = SERVOMAX; pulse >= SERVOMIN; pulse--) {

pwm.setPWM(0, 0, pulse); // Set PWM signal on channel 0

delay(10); // Small delay for smooth motion

}

}

Troubleshooting and FAQs

Common Issues and Solutions

Servos Not Moving:

- Ensure the servos are powered by an adequate external power supply.

- Verify the I2C connections (SDA and SCL) and ensure pull-up resistors are present.

- Check the I2C address of the driver and ensure it matches the address in your code.

Erratic Servo Movement:

- Confirm that the PWM frequency is set correctly (e.g., 50Hz for standard servos).

- Add a bypass capacitor across the servo power supply to reduce noise.

Driver Not Responding:

- Check the wiring of the VCC and GND pins.

- Verify that the OE pin is pulled low to enable outputs.

- Use an I2C scanner sketch to confirm the driver is detected on the I2C bus.

Overheating:

- Ensure the current draw of the connected servos does not exceed the driver's or power supply's limits.

- Use a heat sink or active cooling if necessary.

FAQs

Can I use this driver with a Raspberry Pi? Yes, the driver is compatible with Raspberry Pi via the I2C interface. Use libraries like

Adafruit_Python_PCA9685for easy integration.What is the maximum number of drivers I can use simultaneously? Up to 62 drivers can be chained together by configuring unique I2C addresses using the A0-A5 pins.

Can I control LEDs with this driver? Yes, the driver can control PWM-based LEDs for dimming or effects. Adjust the PWM frequency as needed for LED applications.

What happens if I exceed the current rating? Exceeding the current rating may damage the driver or cause erratic behavior. Always ensure the total current draw is within safe limits.