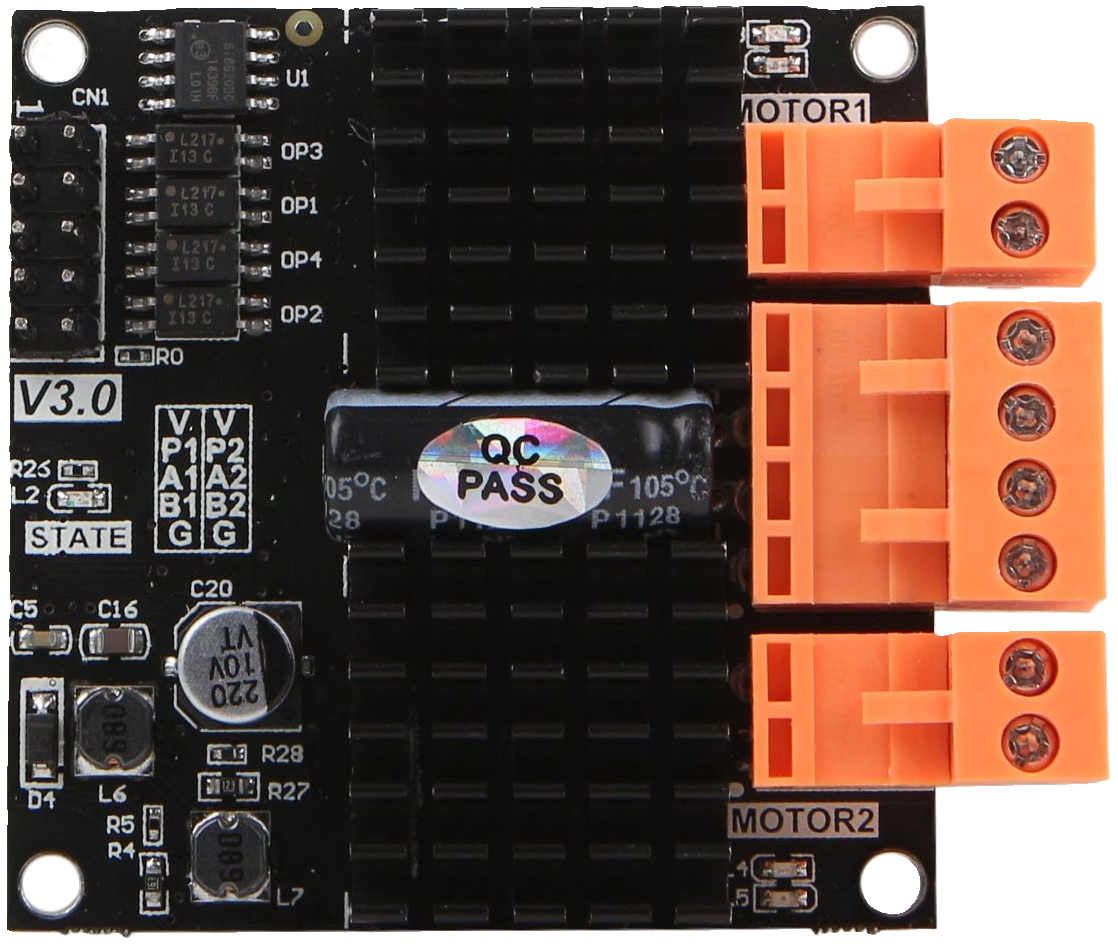

How to Use Dual-Channel DC Motor Driver-12A: Examples, Pinouts, and Specs

Design with Dual-Channel DC Motor Driver-12A in Cirkit Designer

Design with Dual-Channel DC Motor Driver-12A in Cirkit DesignerIntroduction

The Dual-Channel DC Motor Driver-12A (Manufacturer Part ID: DFR0601) by DFRobot is a robust motor driver designed to control two DC motors simultaneously. It supports bidirectional control and speed regulation using PWM (Pulse Width Modulation) signals. With a maximum current capacity of 12A per channel, this motor driver is ideal for high-power motor applications.

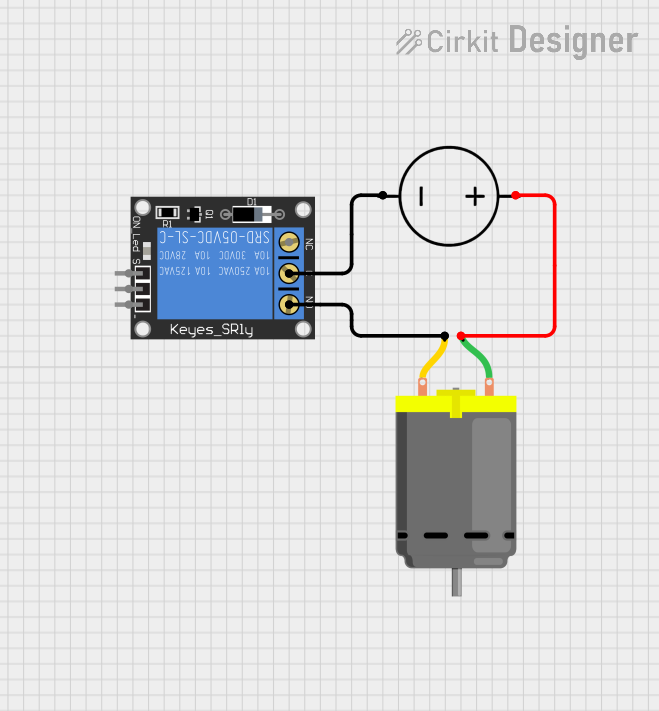

Explore Projects Built with Dual-Channel DC Motor Driver-12A

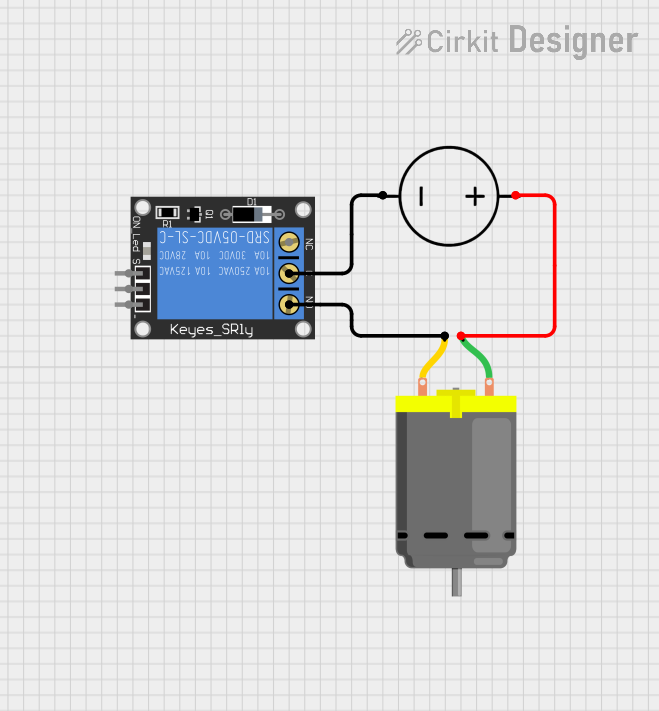

Open Project in Cirkit Designer

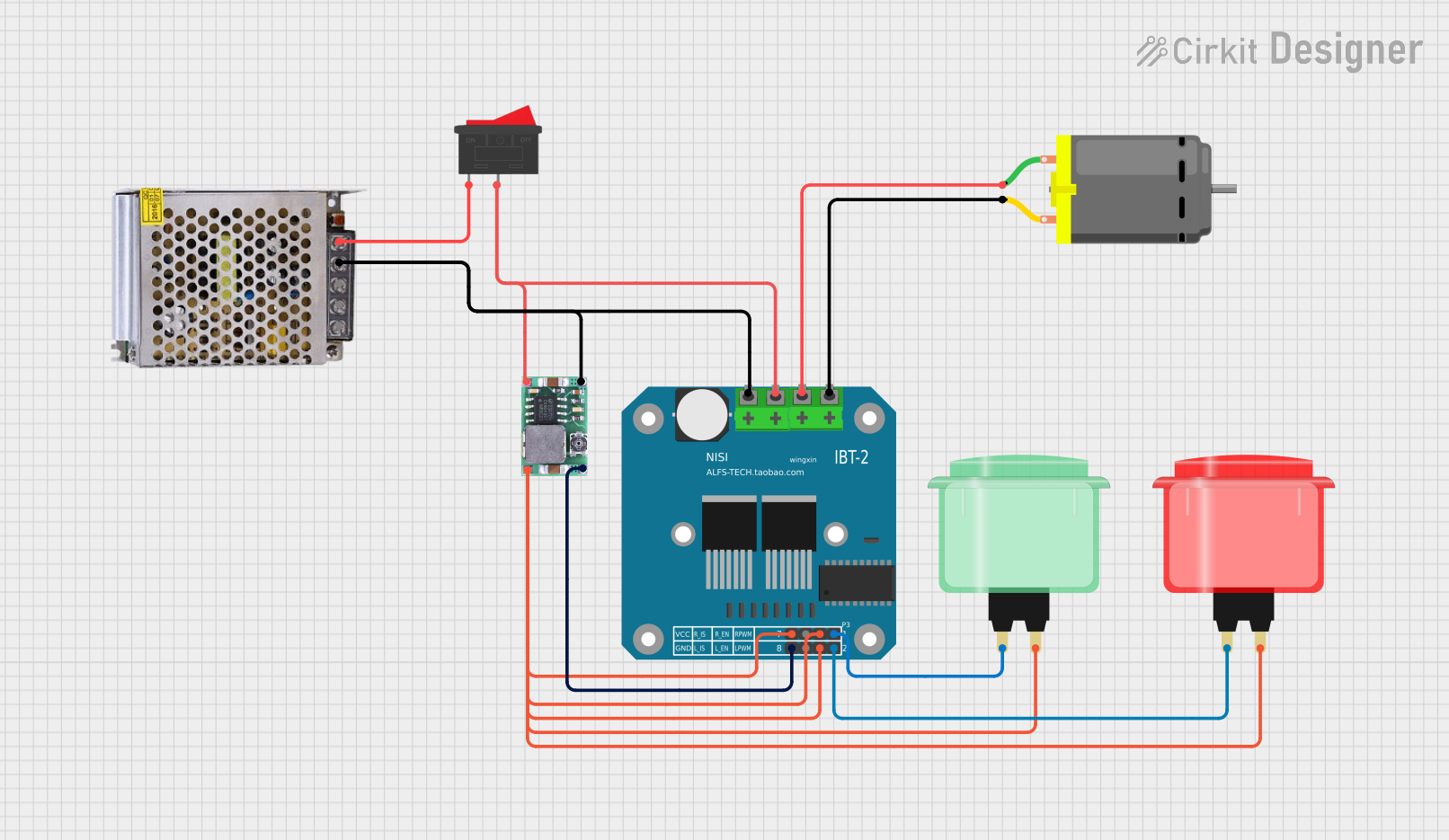

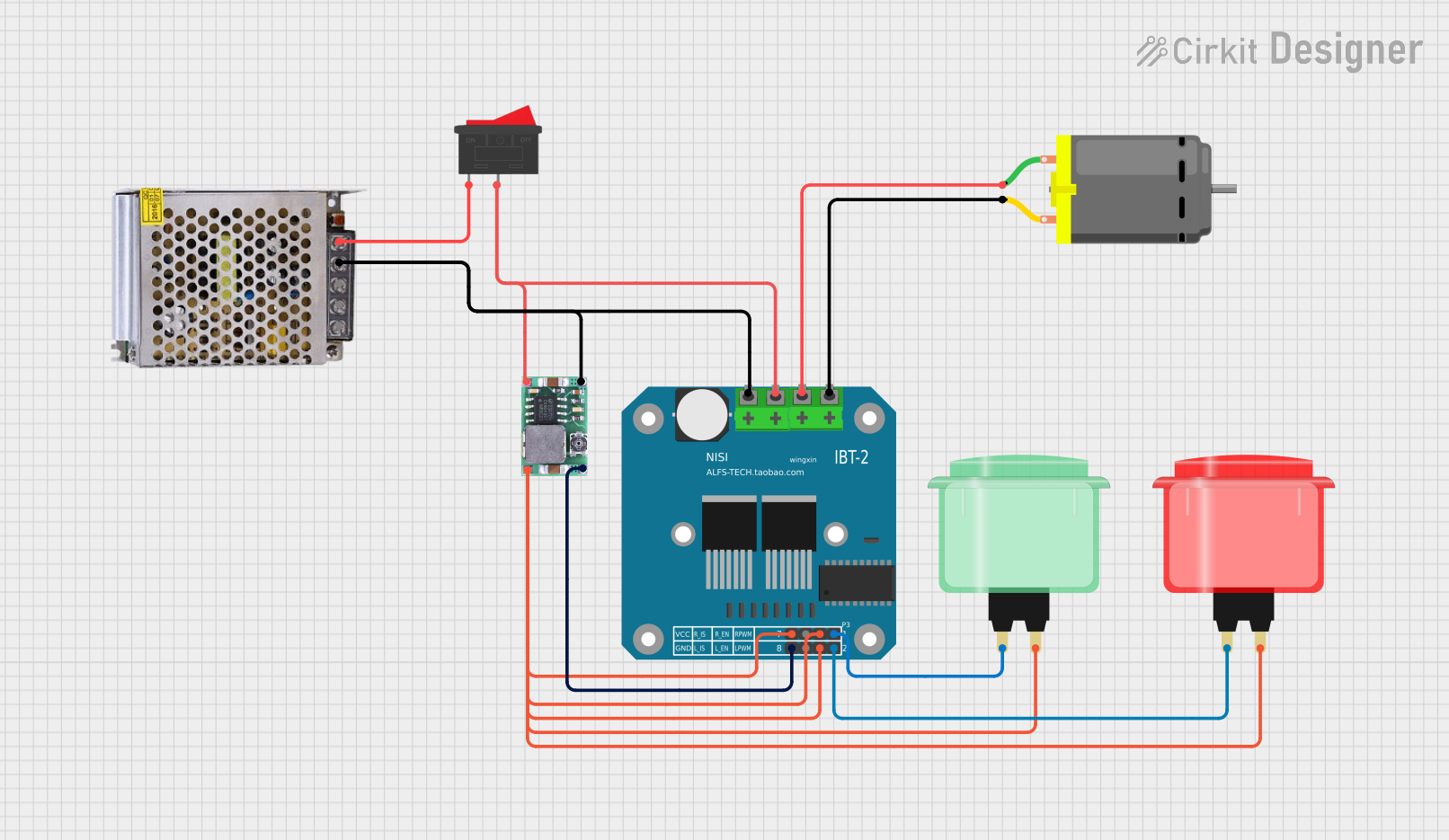

Open Project in Cirkit Designer

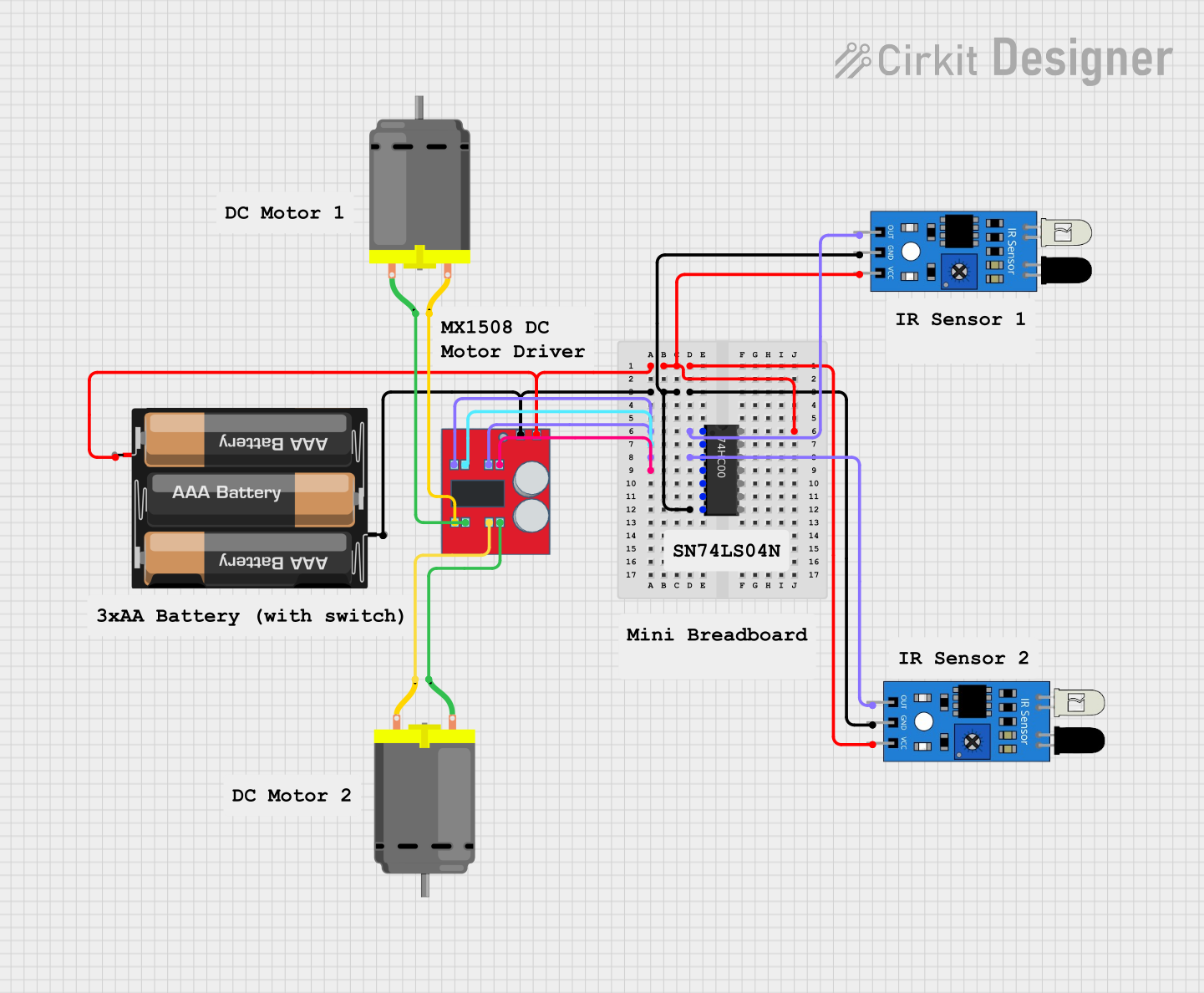

Open Project in Cirkit Designer

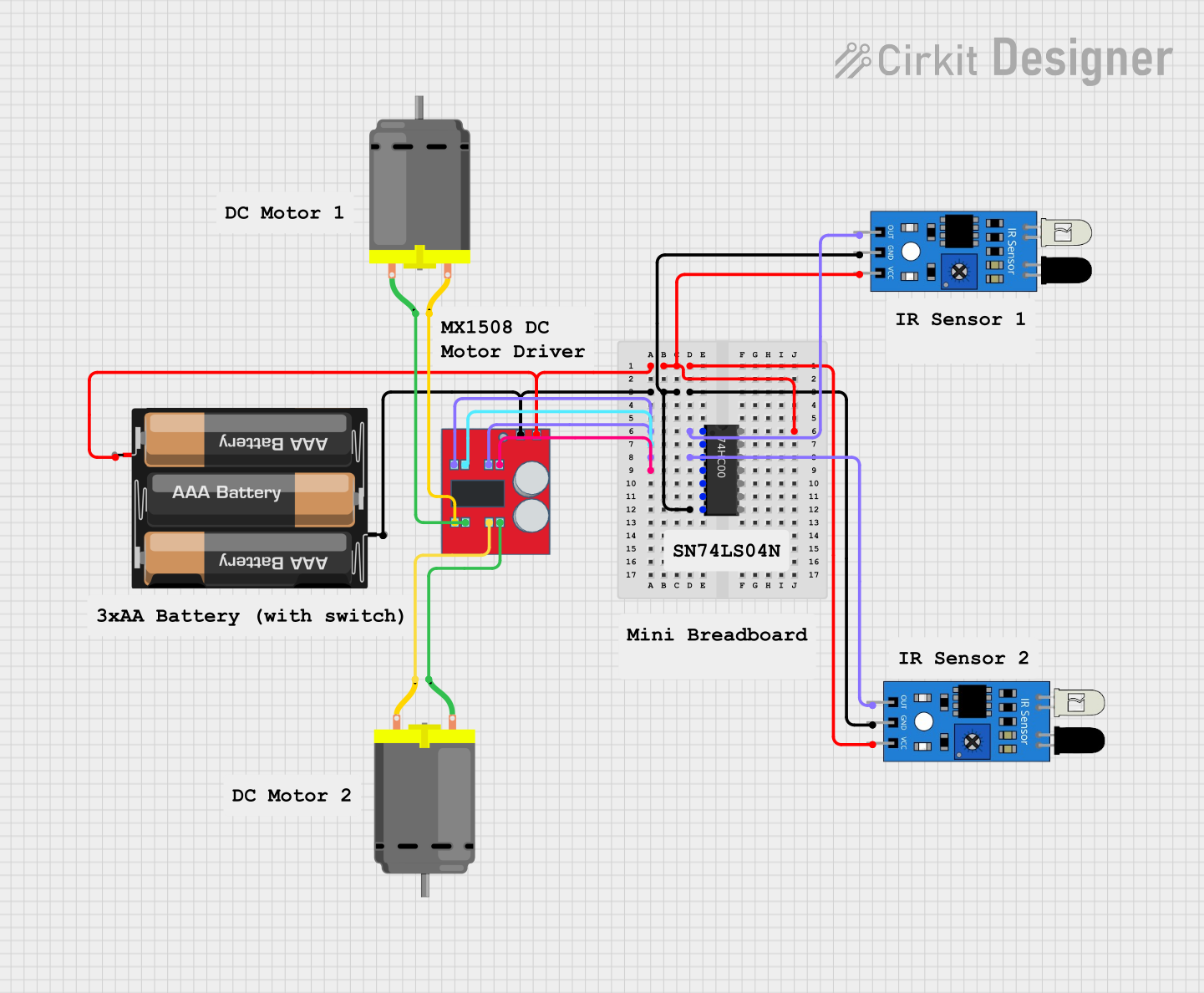

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Dual-Channel DC Motor Driver-12A

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotics and automation systems

- Electric vehicles and carts

- Conveyor belts and industrial machinery

- Remote-controlled cars and boats

- DIY projects requiring precise motor control

Technical Specifications

The following table outlines the key technical details of the DFR0601 motor driver:

| Parameter | Specification |

|---|---|

| Operating Voltage | 6.5V to 30V |

| Maximum Current (per channel) | 12A |

| Control Signal | PWM (Pulse Width Modulation) |

| Logic Voltage | 3.3V to 5V |

| PWM Frequency Range | 0Hz to 20kHz |

| Motor Channels | 2 |

| Dimensions | 60mm x 54mm x 15mm |

| Weight | 30g |

Pin Configuration and Descriptions

The DFR0601 motor driver has the following pin layout:

| Pin Name | Type | Description |

|---|---|---|

| VIN | Power Input | Connect to the motor power supply (6.5V to 30V). |

| GND | Ground | Common ground for the motor driver and control circuit. |

| VCC | Logic Voltage | Connect to the control system's logic voltage (3.3V or 5V). |

| INA1 | Control Input | Input signal to control the direction of Motor A. |

| INB1 | Control Input | Input signal to control the direction of Motor A. |

| PWM1 | Control Input | PWM signal to control the speed of Motor A. |

| INA2 | Control Input | Input signal to control the direction of Motor B. |

| INB2 | Control Input | Input signal to control the direction of Motor B. |

| PWM2 | Control Input | PWM signal to control the speed of Motor B. |

| OUTA+ | Motor Output | Positive terminal for Motor A. |

| OUTA- | Motor Output | Negative terminal for Motor A. |

| OUTB+ | Motor Output | Positive terminal for Motor B. |

| OUTB- | Motor Output | Negative terminal for Motor B. |

Usage Instructions

Connecting the Motor Driver

- Power Supply: Connect the motor power supply to the

VINpin and ground to theGNDpin. Ensure the voltage is within the range of 6.5V to 30V. - Logic Voltage: Connect the

VCCpin to the logic voltage of your control system (3.3V or 5V). - Motor Connections:

- Connect the terminals of Motor A to

OUTA+andOUTA-. - Connect the terminals of Motor B to

OUTB+andOUTB-.

- Connect the terminals of Motor A to

- Control Signals:

- Use the

INA1,INB1, andPWM1pins to control Motor A. - Use the

INA2,INB2, andPWM2pins to control Motor B.

- Use the

Controlling the Motors with an Arduino UNO

Below is an example Arduino sketch to control two DC motors using the DFR0601 motor driver:

// Define motor control pins

#define INA1 7 // Direction control for Motor A

#define INB1 8 // Direction control for Motor A

#define PWM1 9 // Speed control (PWM) for Motor A

#define INA2 4 // Direction control for Motor B

#define INB2 5 // Direction control for Motor B

#define PWM2 6 // Speed control (PWM) for Motor B

void setup() {

// Set motor control pins as outputs

pinMode(INA1, OUTPUT);

pinMode(INB1, OUTPUT);

pinMode(PWM1, OUTPUT);

pinMode(INA2, OUTPUT);

pinMode(INB2, OUTPUT);

pinMode(PWM2, OUTPUT);

}

void loop() {

// Example: Run Motor A forward at 50% speed

digitalWrite(INA1, HIGH); // Set direction forward

digitalWrite(INB1, LOW);

analogWrite(PWM1, 128); // Set speed (0-255, 128 = 50%)

// Example: Run Motor B backward at 75% speed

digitalWrite(INA2, LOW); // Set direction backward

digitalWrite(INB2, HIGH);

analogWrite(PWM2, 192); // Set speed (0-255, 192 = 75%)

delay(5000); // Run for 5 seconds

// Stop both motors

analogWrite(PWM1, 0); // Stop Motor A

analogWrite(PWM2, 0); // Stop Motor B

delay(2000); // Wait for 2 seconds

}

Important Considerations

- Ensure the motor power supply voltage matches the motor's operating voltage.

- Do not exceed the maximum current rating of 12A per channel.

- Use appropriate heat dissipation methods (e.g., heat sinks) for prolonged high-current operation.

- Always connect the ground (

GND) of the motor driver to the ground of the control system.

Troubleshooting and FAQs

Common Issues

Motors not running:

- Verify that the power supply is connected and within the specified voltage range.

- Check the control signals (INA, INB, and PWM) for proper logic levels.

- Ensure the ground (

GND) is shared between the motor driver and the control system.

Motor running in the wrong direction:

- Swap the

INAandINBsignals for the affected motor. - Verify the wiring of the motor terminals.

- Swap the

Overheating:

- Ensure the current draw of the motors does not exceed 12A per channel.

- Use a heat sink or active cooling if operating at high currents for extended periods.

PWM signal not working:

- Confirm that the PWM frequency is within the supported range (0Hz to 20kHz).

- Check the Arduino code for correct

analogWritevalues (0-255).

FAQs

Q: Can I use this motor driver with a 24V motor?

A: Yes, the motor driver supports operating voltages up to 30V, so it is compatible with 24V motors.

Q: Can I control the motor driver with a Raspberry Pi?

A: Yes, the motor driver accepts 3.3V logic signals, making it compatible with Raspberry Pi GPIO pins.

Q: What happens if the current exceeds 12A?

A: Exceeding the current limit may damage the motor driver. Use a fuse or current-limiting circuit to protect the driver.

Q: Can I control only one motor with this driver?

A: Yes, you can use only one channel (Motor A or Motor B) if your application requires it. Leave the unused channel unconnected.