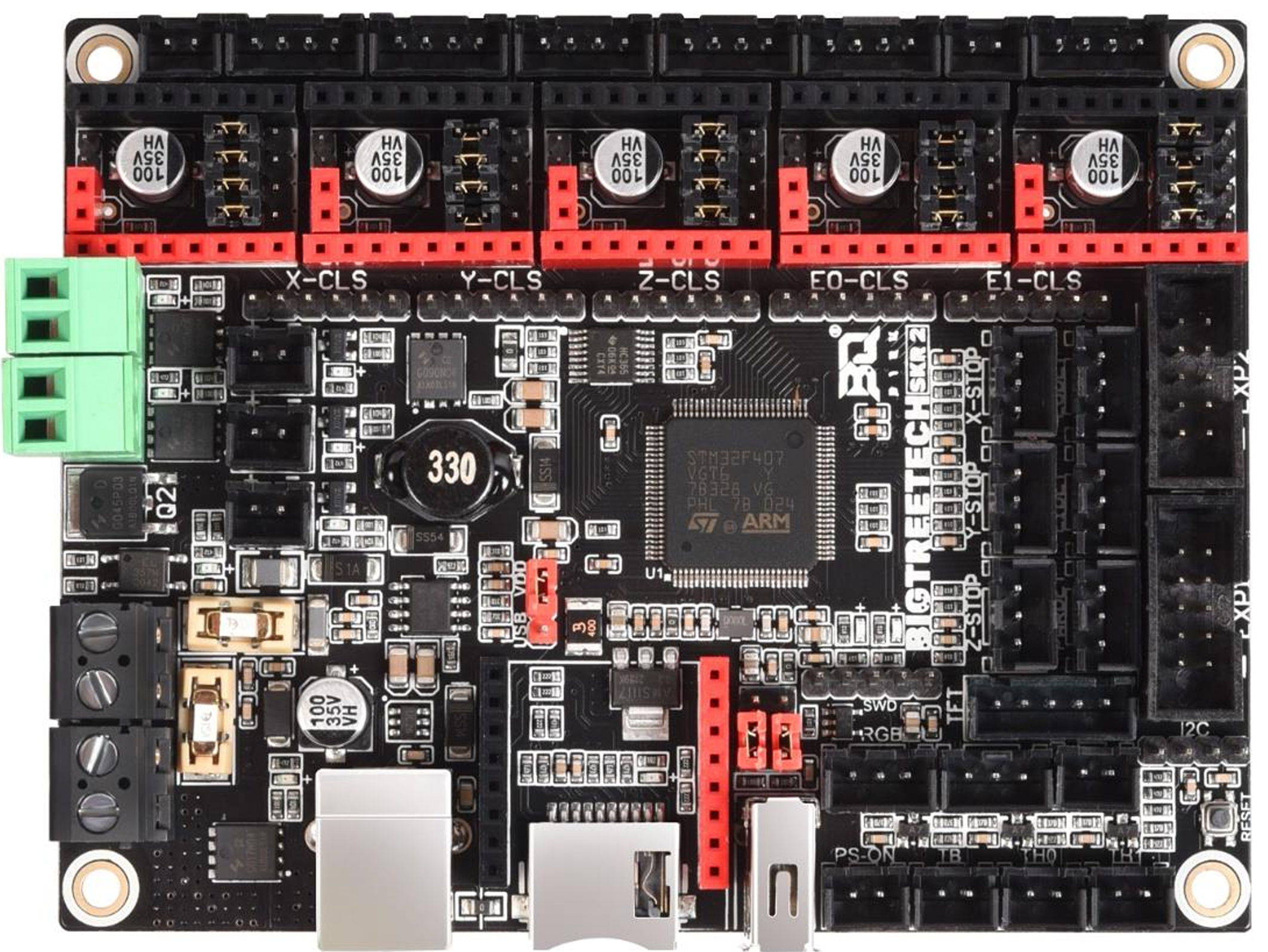

How to Use SKR 2: Examples, Pinouts, and Specs

Design with SKR 2 in Cirkit Designer

Design with SKR 2 in Cirkit DesignerIntroduction

The SKR 2 by BIGTREETECH is a high-performance 32-bit control board designed for 3D printers. Powered by an ARM Cortex-M3 processor, the SKR 2 offers advanced features and capabilities for smooth and precise control of 3D printing operations. It supports a wide range of stepper motor drivers, making it a versatile choice for both hobbyists and professionals.

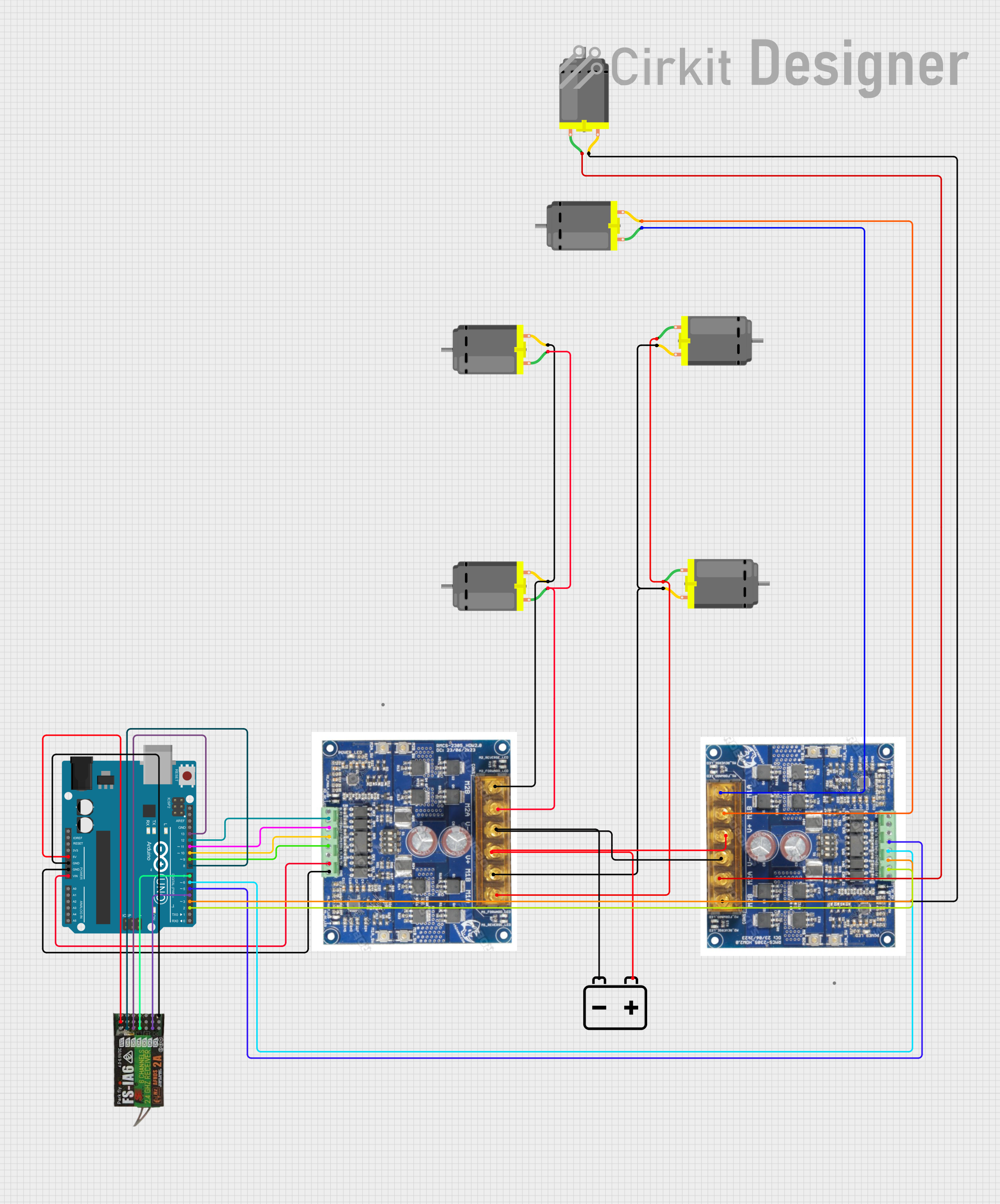

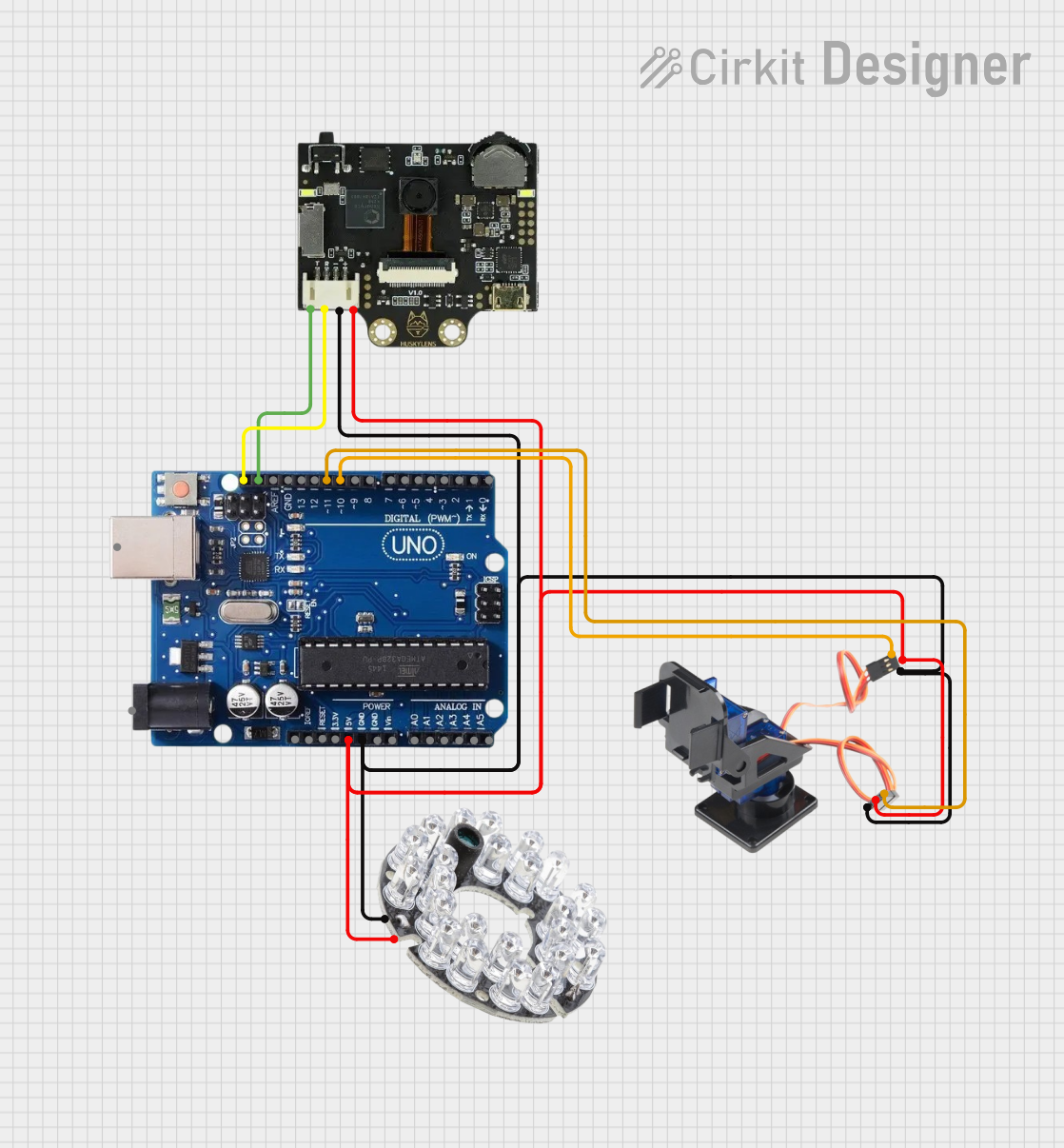

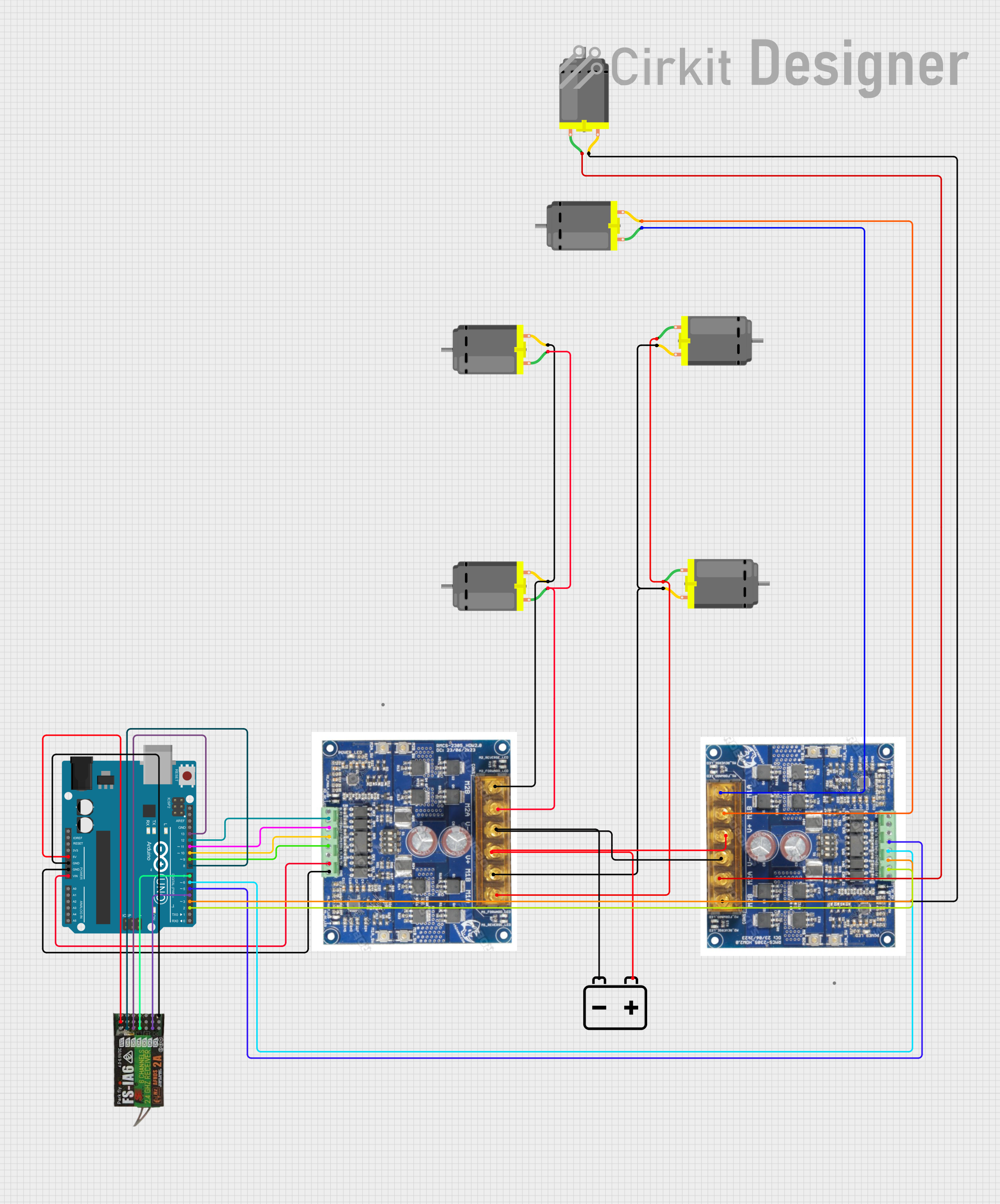

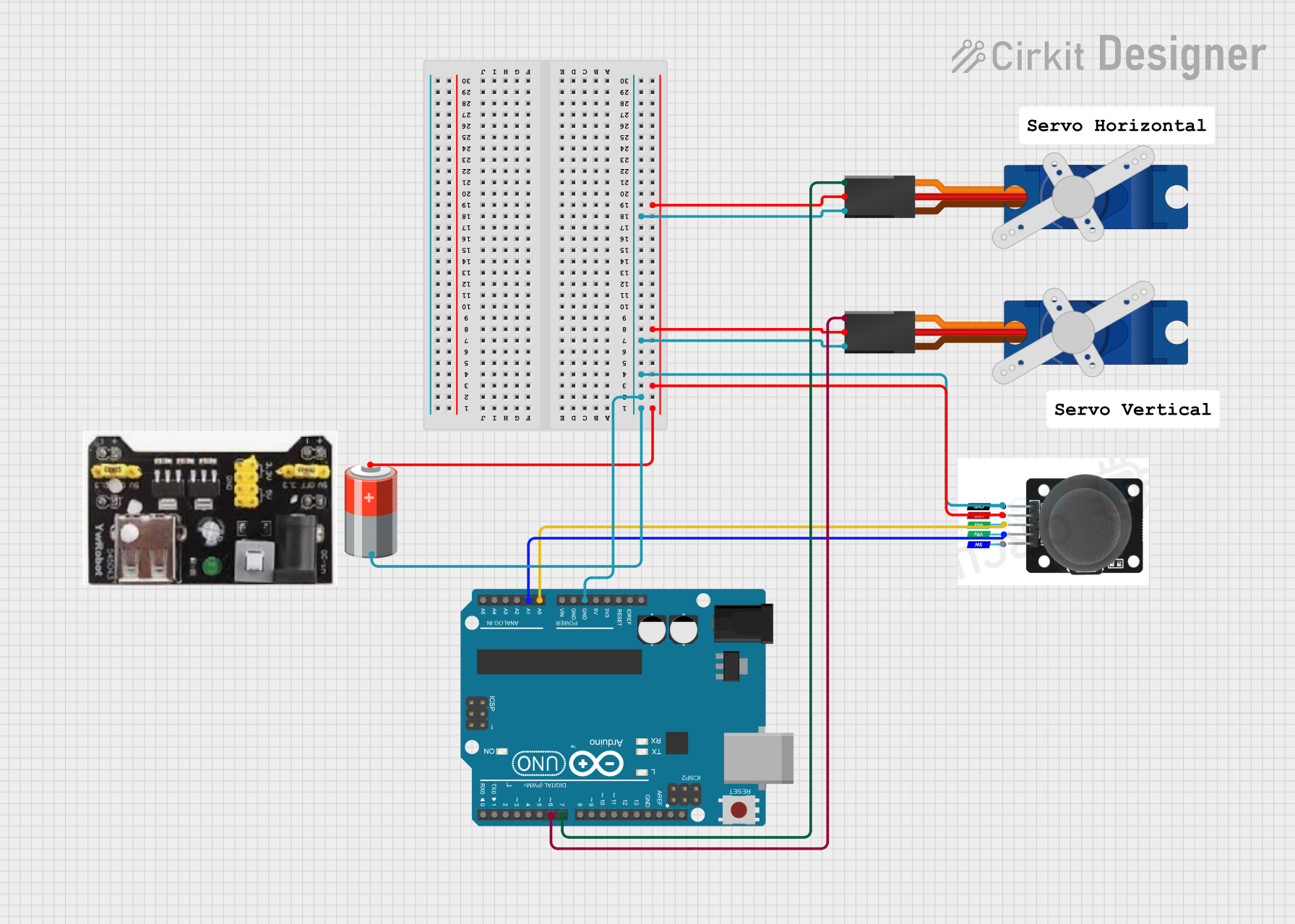

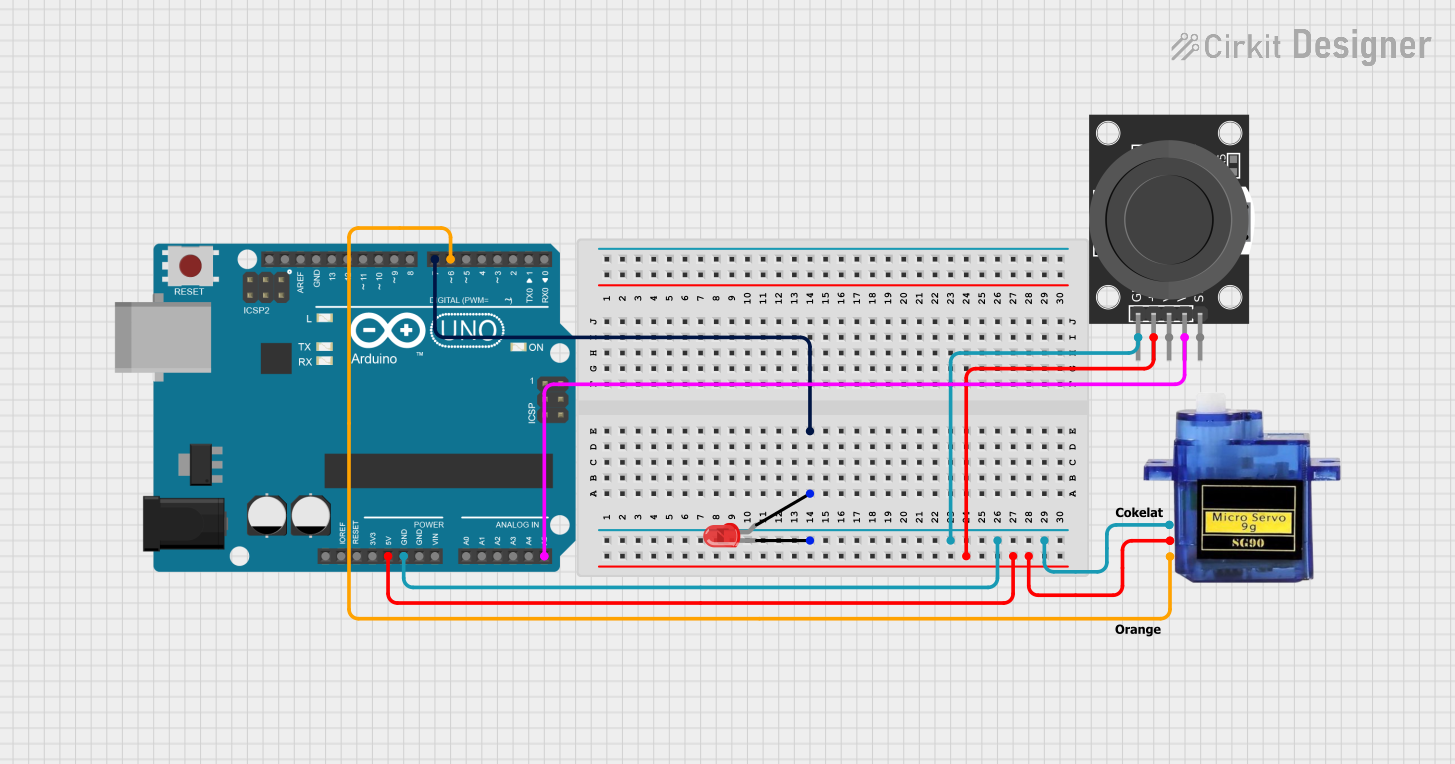

Explore Projects Built with SKR 2

Open Project in Cirkit Designer

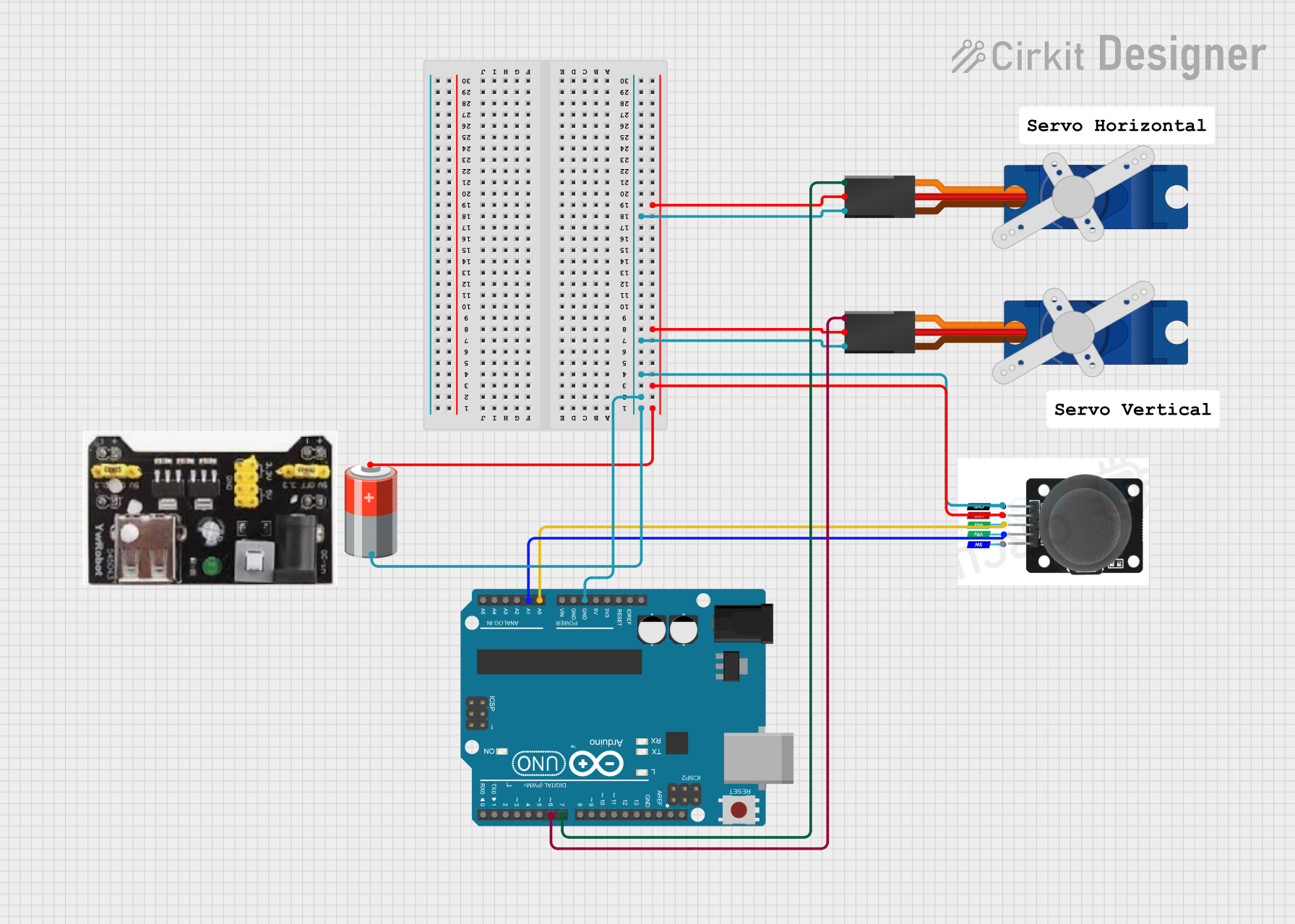

Open Project in Cirkit Designer

Open Project in Cirkit Designer

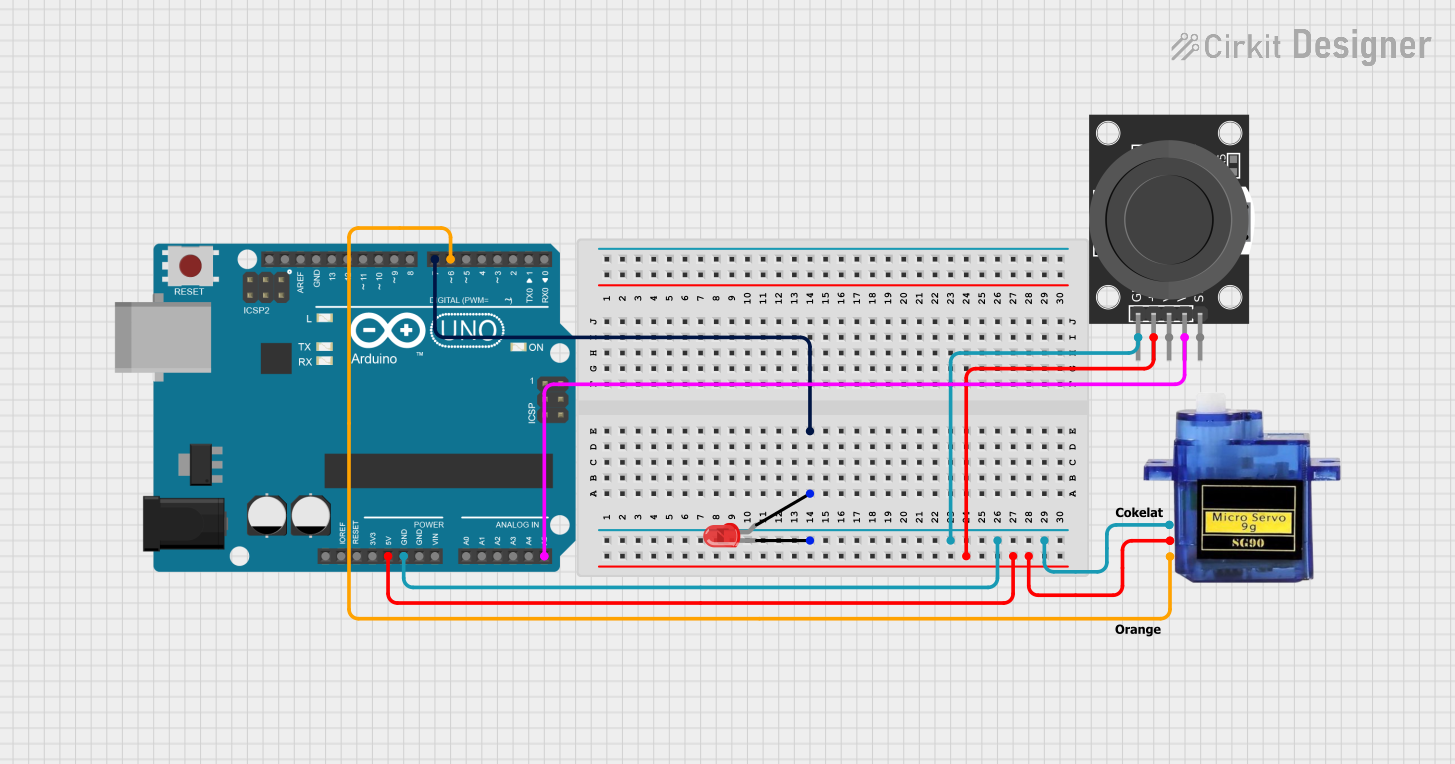

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with SKR 2

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- 3D printers (FDM, SLA, and other types)

- CNC machines

- Robotics projects requiring precise motor control

- Custom automation systems

The SKR 2 is particularly popular for upgrading older 3D printers to take advantage of modern features like silent stepper drivers, advanced firmware, and improved processing power.

Technical Specifications

Key Technical Details

- Processor: ARM Cortex-M3 (STM32F407 or LPC1769, depending on the version)

- Input Voltage: 12V–24V DC

- Stepper Driver Support: Compatible with TMC, A4988, DRV8825, and other drivers

- Number of Stepper Driver Slots: 5

- Heated Bed Output: Supports high-power heated beds

- Firmware: Compatible with Marlin 2.x and other open-source firmware

- Connectivity: USB, SD card slot, and UART for communication

- Expansion Ports: Multiple ports for BLTouch, filament runout sensors, and other peripherals

- Dimensions: 110mm x 85mm

Pin Configuration and Descriptions

The SKR 2 features multiple connectors and pins for various functions. Below is a summary of the key pin configurations:

Stepper Motor Driver Slots

| Slot Name | Description |

|---|---|

| X | Controls the X-axis stepper motor |

| Y | Controls the Y-axis stepper motor |

| Z | Controls the Z-axis stepper motor |

| E0 | Controls the primary extruder motor |

| E1 | Controls the secondary extruder motor |

Peripheral Connectors

| Connector Name | Description |

|---|---|

| BLTouch | For automatic bed leveling sensors |

| FAN0, FAN1 | For connecting cooling fans |

| HE0, HE1 | For extruder heater cartridges |

| BED | For heated bed power output |

| TFT | For connecting a touchscreen display |

| USB | For USB communication with a computer |

| SD Card Slot | For loading firmware and G-code files |

Power Input

| Pin Name | Description |

|---|---|

| VIN | Main power input (12V–24V DC) |

| GND | Ground connection |

Usage Instructions

How to Use the SKR 2 in a Circuit

- Power Connection: Connect a 12V–24V DC power supply to the VIN and GND terminals. Ensure the power supply can handle the current requirements of your 3D printer.

- Stepper Drivers: Insert compatible stepper drivers (e.g., TMC2209, A4988) into the designated slots. Ensure the orientation matches the board's markings.

- Motor Connections: Connect stepper motors to the X, Y, Z, E0, and E1 motor outputs as needed.

- Heated Bed and Extruder: Connect the heated bed to the BED output and the extruder heater cartridge(s) to HE0 and/or HE1.

- Firmware: Install Marlin 2.x firmware on the board. Use the SD card slot or USB connection to upload the firmware.

- Peripherals: Connect additional peripherals like BLTouch, fans, and filament runout sensors to their respective ports.

Important Considerations and Best Practices

- Stepper Driver Configuration: Configure the stepper driver current and microstepping settings according to your printer's requirements.

- Cooling: Ensure adequate cooling for the board and stepper drivers, especially when running at high currents.

- Firmware Setup: Customize the firmware to match your printer's hardware (e.g., stepper motor steps/mm, bed size, and endstop configuration).

- Wiring: Double-check all connections to avoid short circuits or damage to the board.

Example: Connecting SKR 2 to an Arduino UNO

While the SKR 2 is typically used as a standalone controller, it can communicate with an Arduino UNO via UART for advanced applications. Below is an example Arduino sketch for sending commands to the SKR 2:

#include <SoftwareSerial.h>

// Define RX and TX pins for communication with SKR 2

SoftwareSerial SKRSerial(10, 11); // RX = pin 10, TX = pin 11

void setup() {

// Initialize serial communication

Serial.begin(9600); // For debugging with the PC

SKRSerial.begin(115200); // Communication with SKR 2

Serial.println("Arduino-SKR 2 Communication Initialized");

}

void loop() {

// Send a G-code command to the SKR 2

SKRSerial.println("G28"); // Home all axes

delay(5000); // Wait 5 seconds before sending the next command

// Check for responses from the SKR 2

if (SKRSerial.available()) {

String response = SKRSerial.readString();

Serial.println("Response from SKR 2: " + response);

}

}

Troubleshooting and FAQs

Common Issues and Solutions

Board Not Powering On

- Cause: Incorrect power supply connection or insufficient voltage.

- Solution: Verify the power supply voltage (12V–24V) and ensure proper polarity.

Stepper Motors Not Moving

- Cause: Incorrect stepper driver installation or configuration.

- Solution: Check the orientation of the stepper drivers and ensure the firmware is configured correctly.

Firmware Not Loading

- Cause: Incorrect firmware file or SD card formatting.

- Solution: Ensure the firmware file is named

firmware.binand the SD card is formatted as FAT32.

Overheating Components

- Cause: Insufficient cooling for the board or stepper drivers.

- Solution: Add cooling fans or heatsinks to prevent overheating.

FAQs

Q: Can I use the SKR 2 with TMC2209 drivers?

- A: Yes, the SKR 2 is fully compatible with TMC2209 drivers. Ensure UART mode is configured correctly.

Q: What firmware is recommended for the SKR 2?

- A: Marlin 2.x is the most commonly used firmware for the SKR 2. Other firmware options like Klipper are also supported.

Q: How do I update the firmware?

- A: Copy the firmware file (

firmware.bin) to an SD card, insert it into the SKR 2, and power on the board. The firmware will automatically update.

- A: Copy the firmware file (

Q: Can I connect a touchscreen to the SKR 2?

- A: Yes, the SKR 2 has a dedicated TFT port for connecting BIGTREETECH touchscreens.

This concludes the documentation for the SKR 2. For further assistance, refer to the official BIGTREETECH resources or community forums.