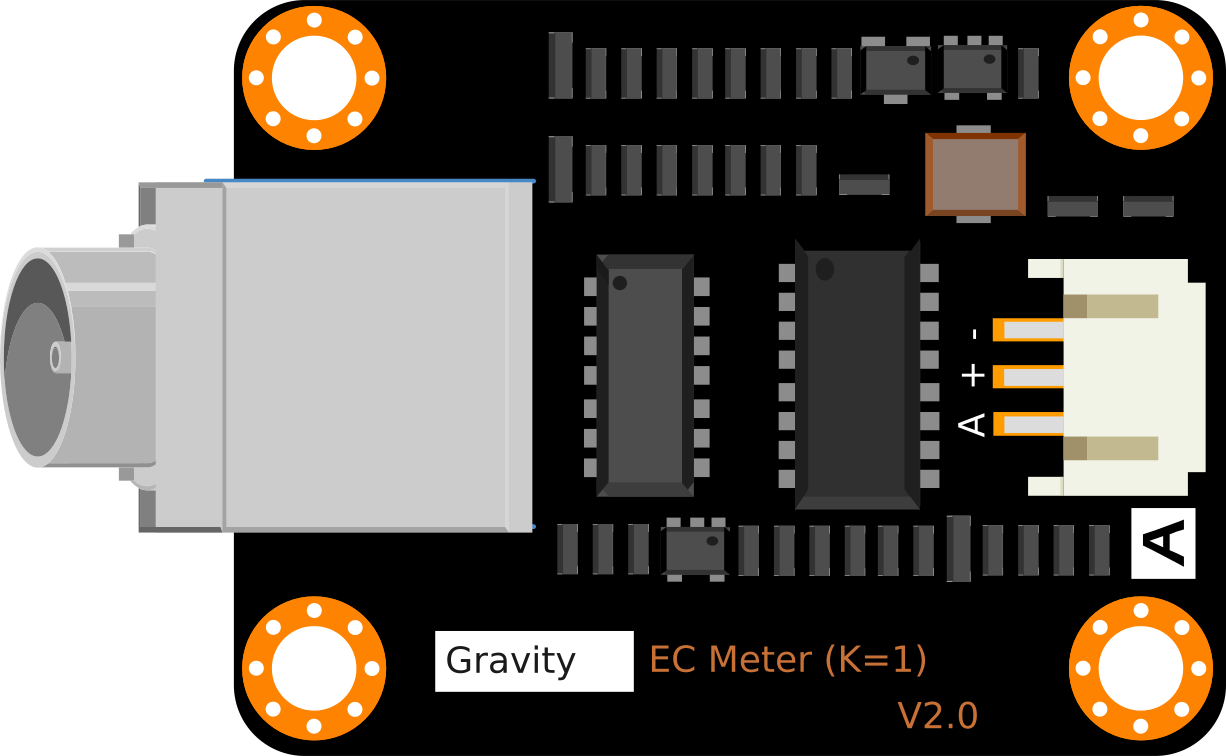

How to Use DFRobot EC Sensor: Examples, Pinouts, and Specs

Design with DFRobot EC Sensor in Cirkit Designer

Design with DFRobot EC Sensor in Cirkit DesignerIntroduction

The DFRobot EC Sensor is a specialized device designed to measure the electrical conductivity (EC) of a solution. Electrical conductivity is a key parameter in determining the concentration of dissolved salts or nutrients in a liquid. This sensor is widely used in applications such as hydroponics, aquaculture, and environmental monitoring, where maintaining optimal nutrient levels is critical for plant growth or aquatic life.

By providing accurate and reliable EC measurements, the DFRobot EC Sensor helps users monitor and control the quality of their solutions, ensuring optimal conditions for their specific applications.

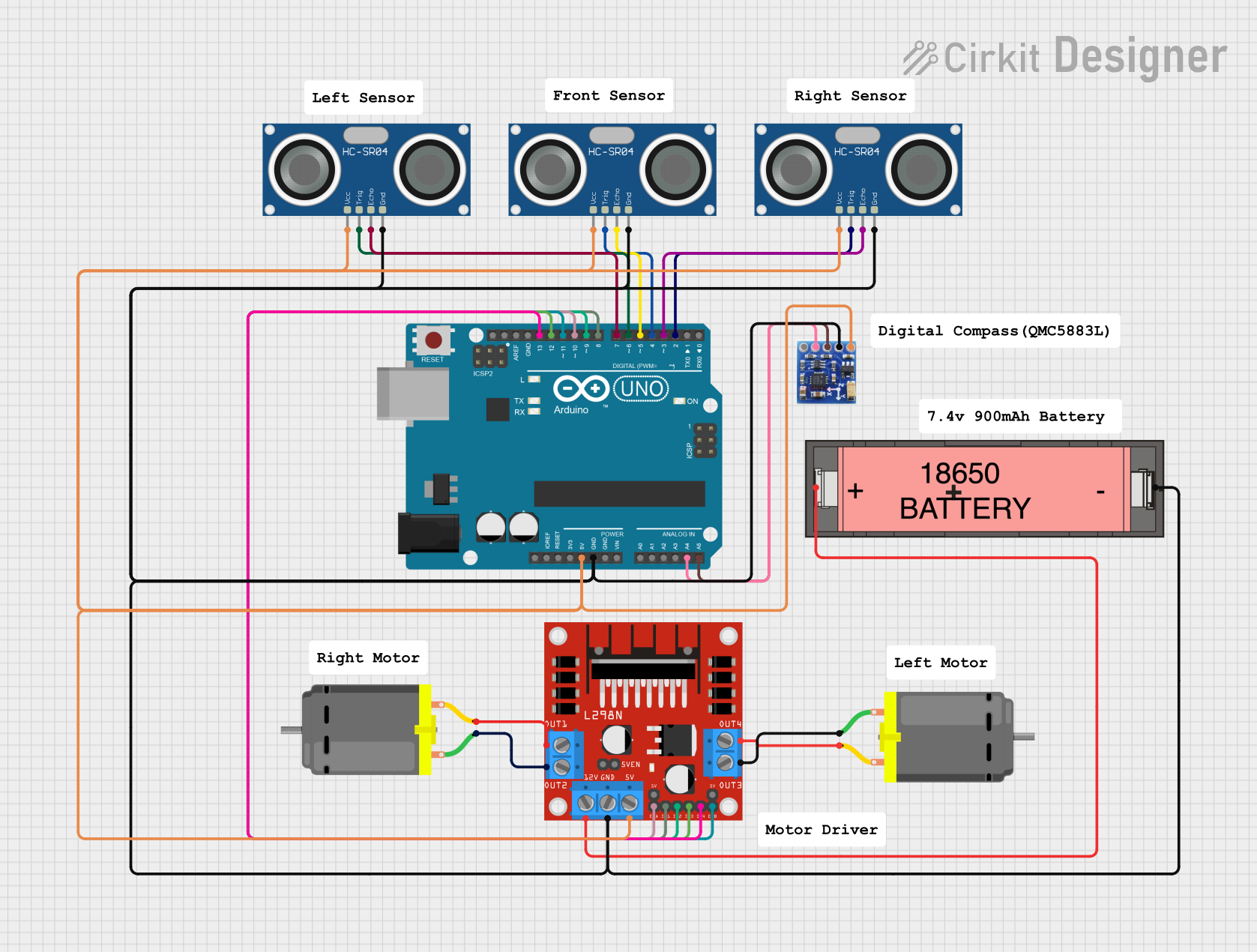

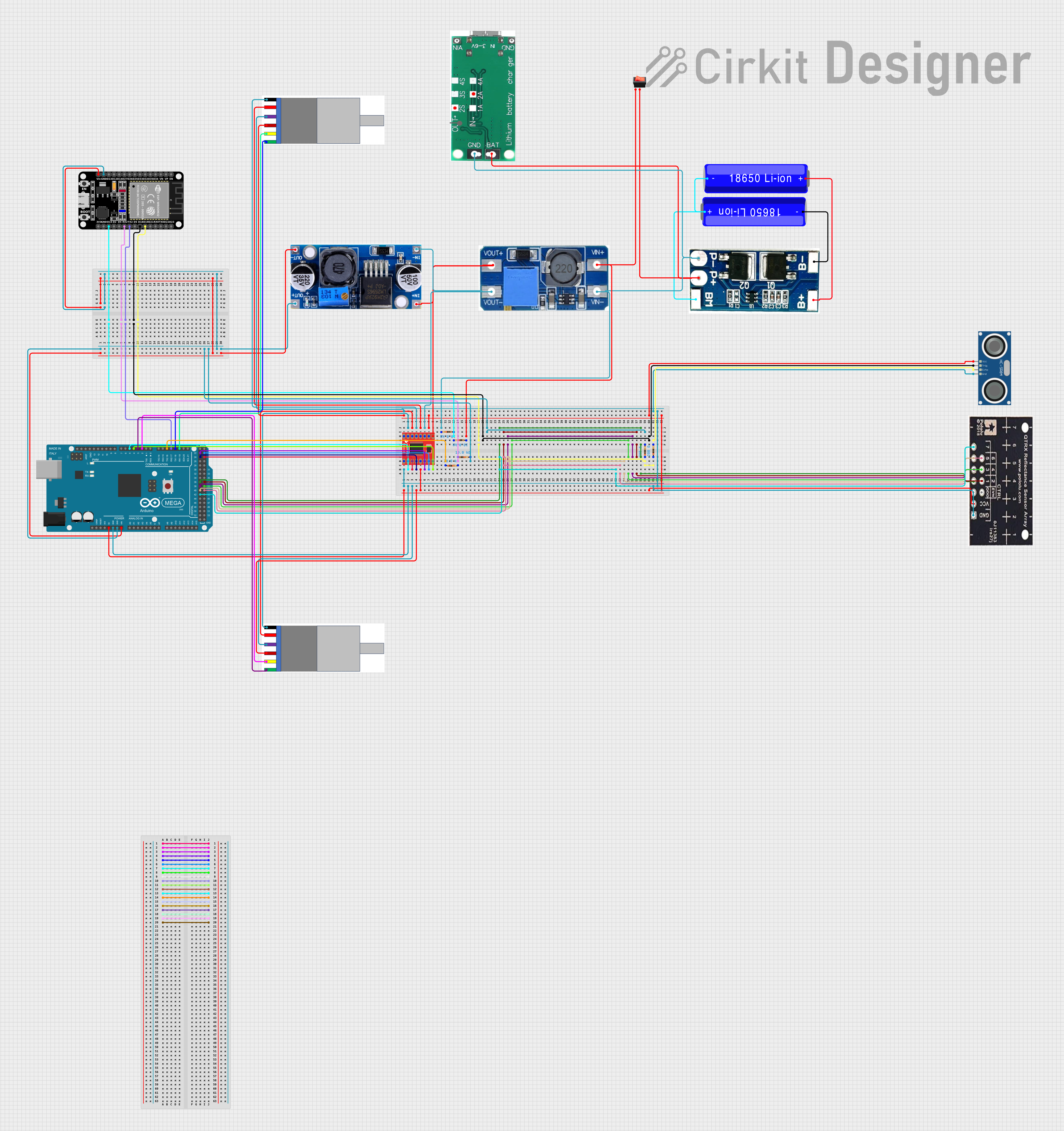

Explore Projects Built with DFRobot EC Sensor

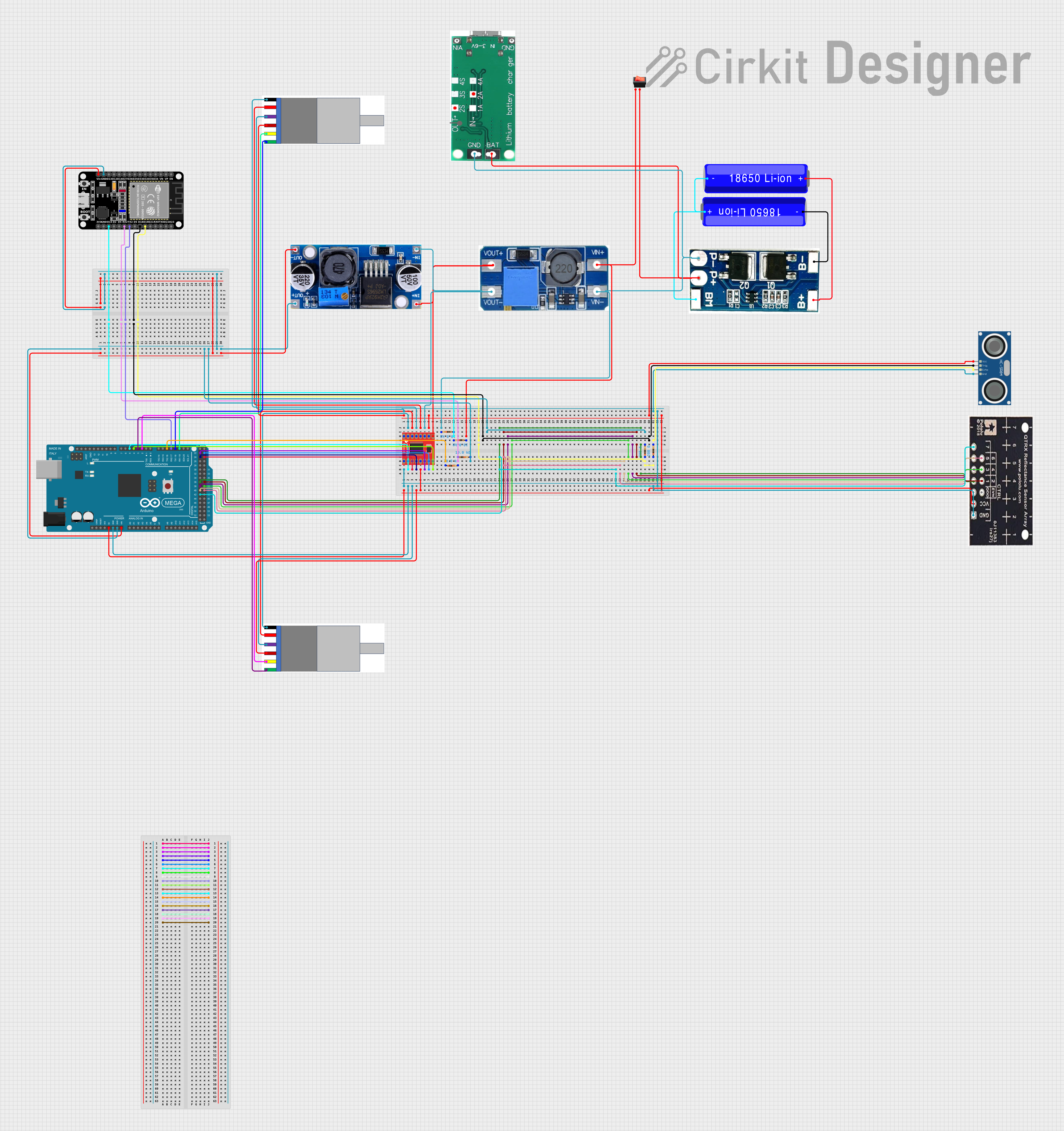

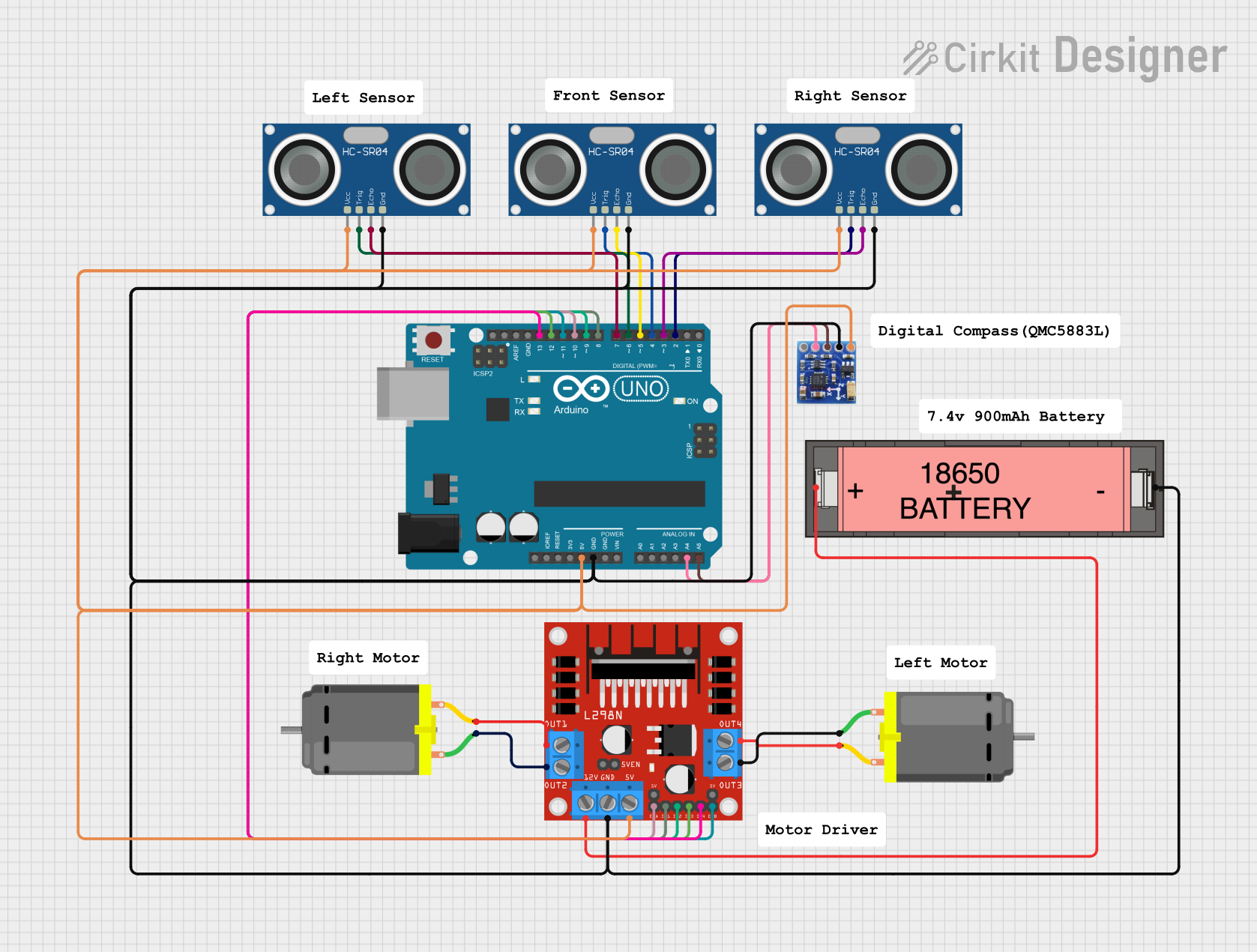

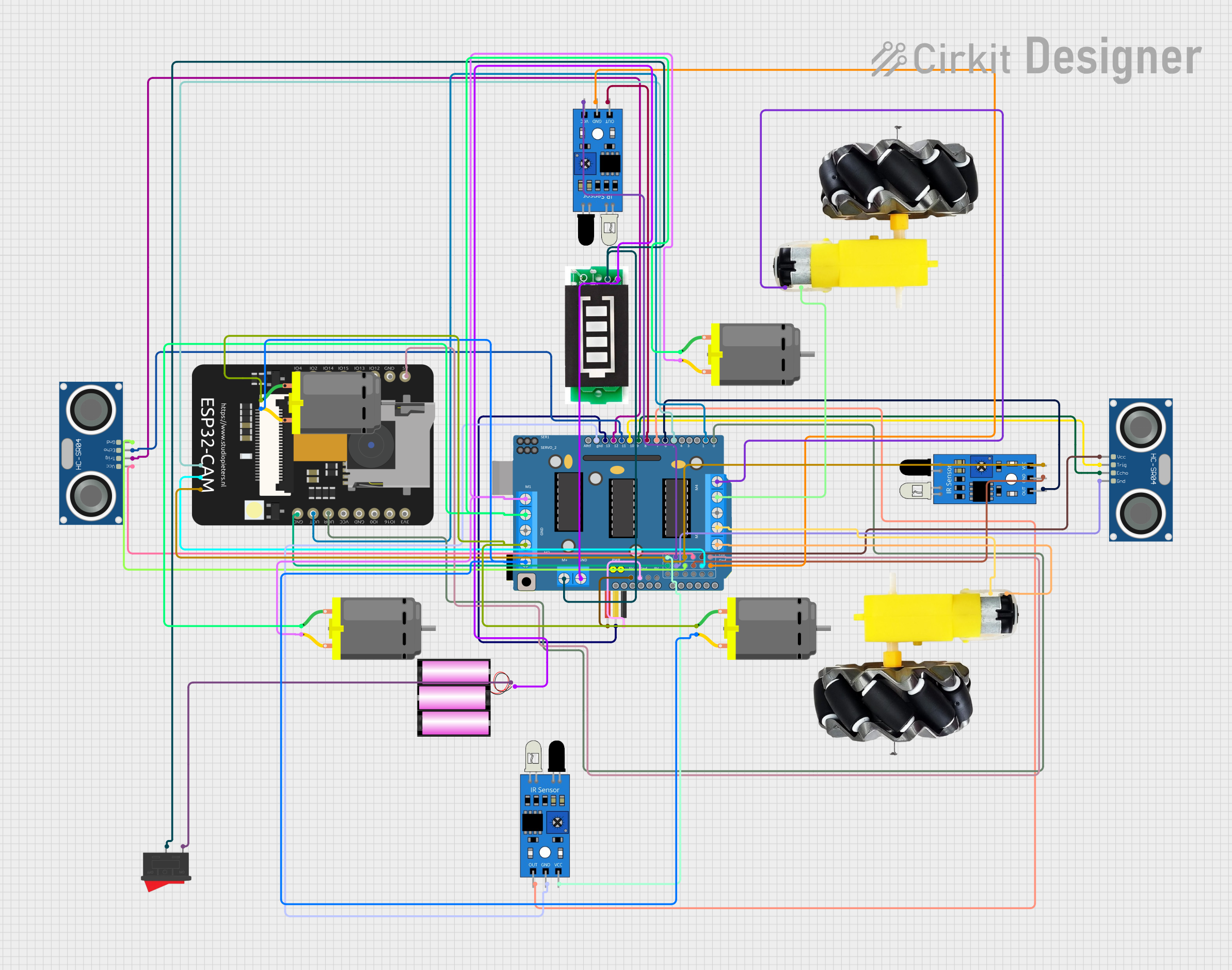

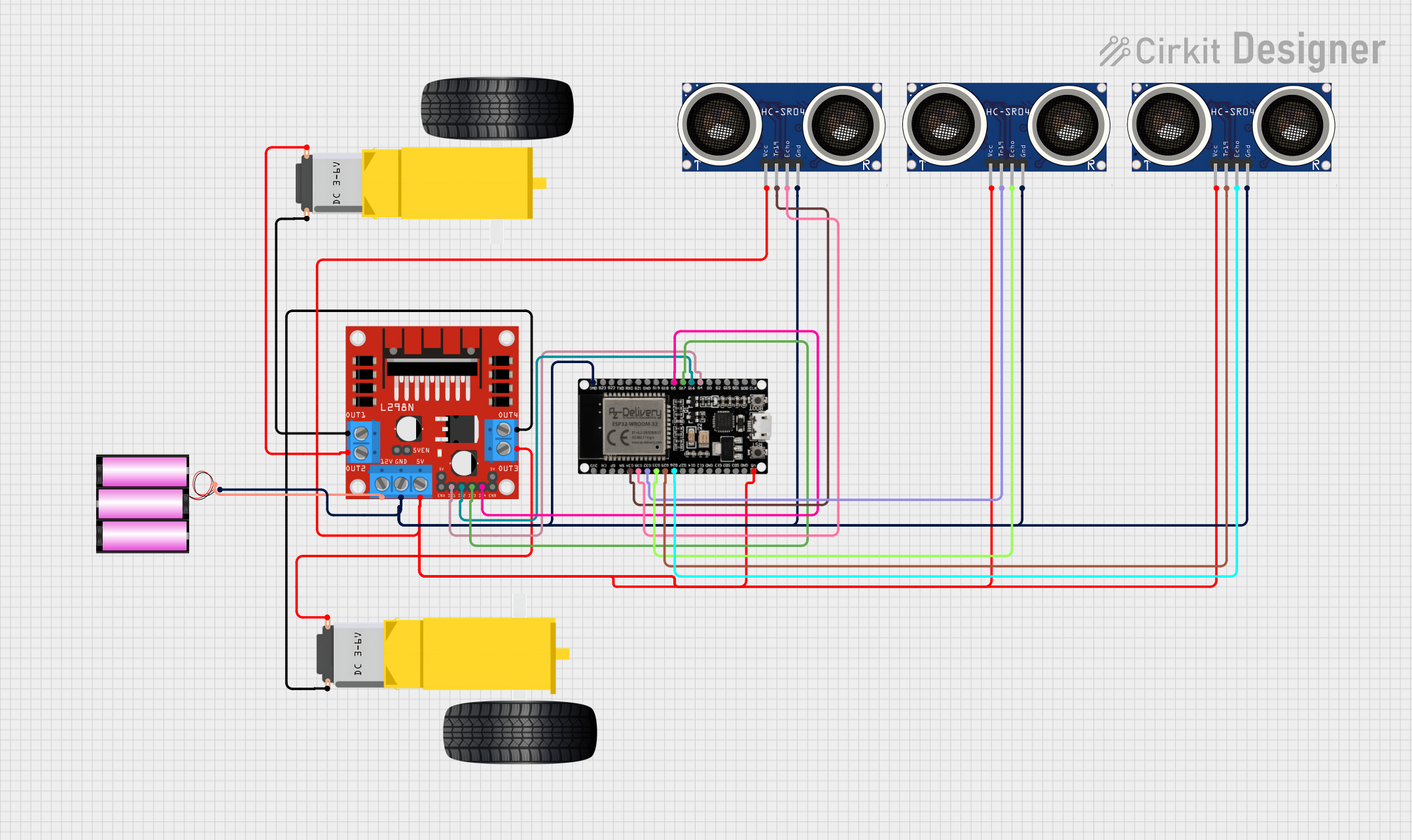

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

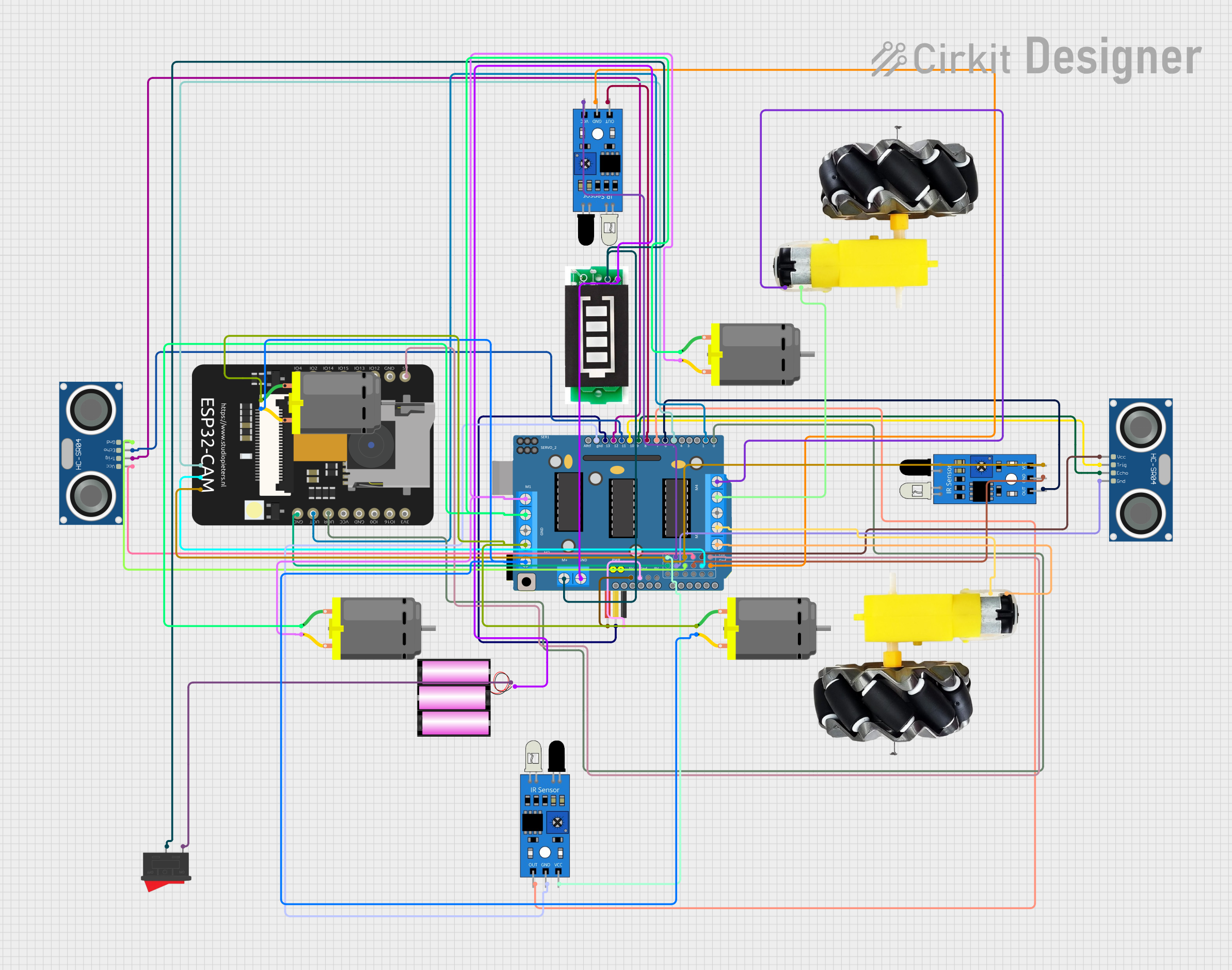

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with DFRobot EC Sensor

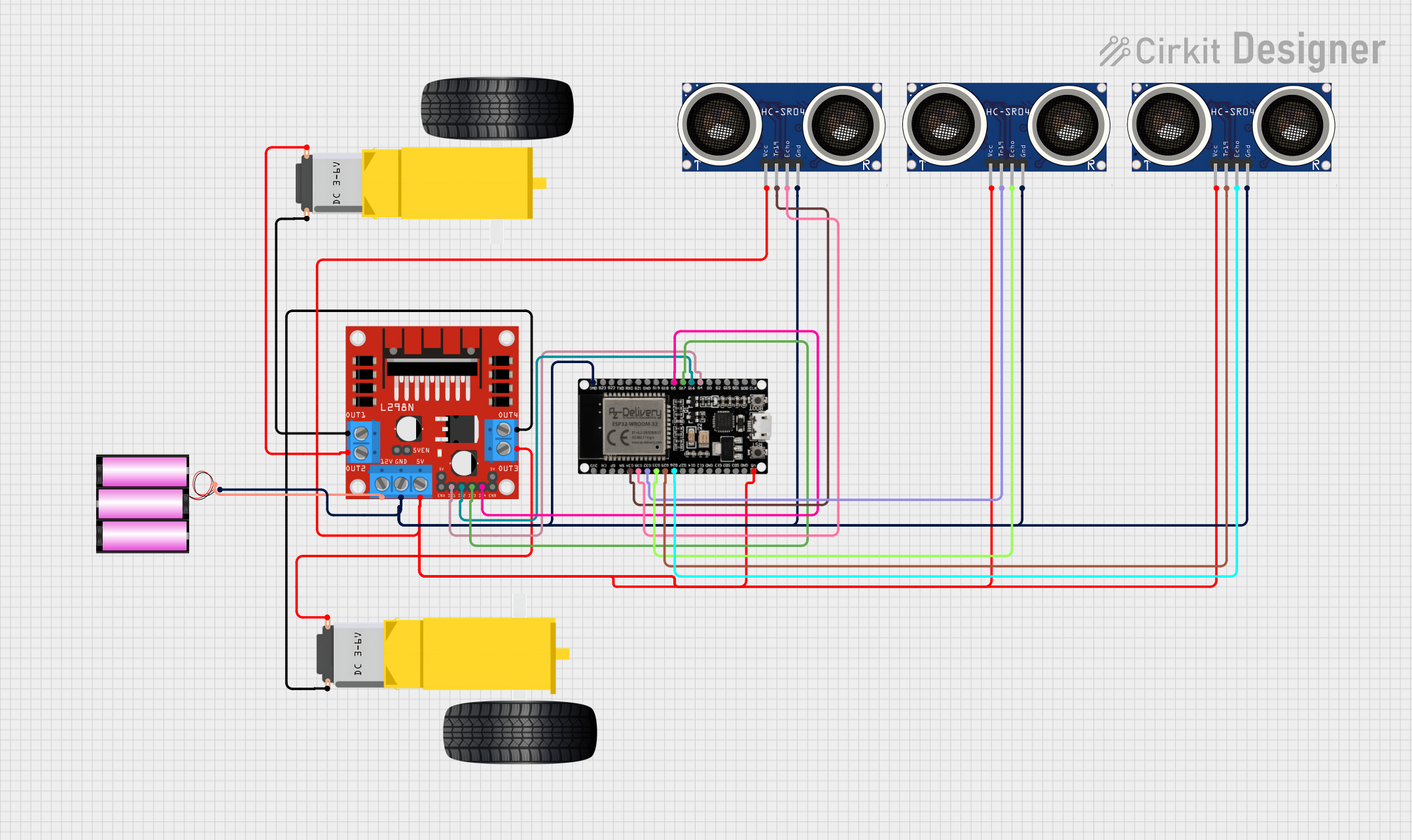

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

- Model: DFRobot EC Sensor

- Measurement Range: 0–20 mS/cm

- Accuracy: ±5% F.S. (Full Scale)

- Operating Voltage: 3.3V–5.5V

- Output Signal: Analog voltage

- Temperature Compensation: Supported (requires an external temperature sensor)

- Operating Temperature: 0°C–60°C

- Connector Type: BNC

- Dimensions: 42mm x 32mm (PCB)

Pin Configuration and Descriptions

The DFRobot EC Sensor module has a 3-pin interface for connecting to a microcontroller. The pinout is as follows:

| Pin | Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (3.3V–5.5V) |

| 2 | GND | Ground connection |

| 3 | AOUT | Analog output signal (proportional to EC) |

Usage Instructions

Connecting the Sensor

- Power Supply: Connect the VCC pin to a 3.3V or 5V power source and the GND pin to the ground of your microcontroller.

- Signal Output: Connect the AOUT pin to an analog input pin on your microcontroller (e.g., Arduino UNO's A0 pin).

- Probe Connection: Attach the EC probe to the BNC connector on the module.

- Temperature Compensation: For accurate readings, connect a temperature sensor (e.g., DFRobot DS18B20) to the microcontroller and implement temperature compensation in your code.

Sample Arduino Code

Below is an example of how to use the DFRobot EC Sensor with an Arduino UNO. This code reads the analog signal from the sensor and converts it into an EC value.

// Include necessary libraries

#include <Wire.h>

// Define the analog pin connected to the EC sensor

const int ecPin = A0;

// Calibration constants (adjust based on your calibration process)

const float voltageToEC = 5.0 / 1023.0; // Convert ADC value to voltage

const float calibrationFactor = 1.0; // Adjust based on calibration

void setup() {

Serial.begin(9600); // Initialize serial communication

pinMode(ecPin, INPUT); // Set EC pin as input

}

void loop() {

// Read the analog value from the EC sensor

int rawValue = analogRead(ecPin);

// Convert the raw ADC value to voltage

float voltage = rawValue * voltageToEC;

// Calculate the EC value (mS/cm) using the calibration factor

float ecValue = voltage * calibrationFactor;

// Print the EC value to the Serial Monitor

Serial.print("EC Value: ");

Serial.print(ecValue);

Serial.println(" mS/cm");

delay(1000); // Wait 1 second before the next reading

}

Best Practices

- Calibration: Calibrate the sensor using standard EC solutions to ensure accurate readings.

- Temperature Compensation: Use a temperature sensor to account for temperature variations, as EC readings are temperature-dependent.

- Cleaning: Regularly clean the EC probe with distilled water to prevent residue buildup, which can affect accuracy.

- Avoid Air Bubbles: Ensure the probe is fully submerged in the solution without air bubbles around the sensing area.

Troubleshooting and FAQs

Common Issues and Solutions

Inaccurate Readings

- Cause: The sensor is not calibrated.

- Solution: Calibrate the sensor using a standard EC solution.

Fluctuating Readings

- Cause: Air bubbles around the probe or unstable power supply.

- Solution: Ensure the probe is fully submerged without air bubbles and use a stable power source.

No Output Signal

- Cause: Incorrect wiring or damaged probe.

- Solution: Verify the wiring and check the probe for physical damage.

Temperature Compensation Not Working

- Cause: Temperature sensor not connected or incorrect compensation formula.

- Solution: Connect a compatible temperature sensor and implement the correct compensation formula in your code.

FAQs

Q: Can I use the DFRobot EC Sensor with a 3.3V microcontroller?

A: Yes, the sensor supports an operating voltage range of 3.3V–5.5V, making it compatible with 3.3V microcontrollers like the ESP32.

Q: How often should I calibrate the sensor?

A: It is recommended to calibrate the sensor every 2–4 weeks or whenever you notice a drift in readings.

Q: Can the sensor be used in seawater?

A: Yes, the sensor can measure EC in seawater, but ensure the EC value is within the sensor's measurement range (0–20 mS/cm).

Q: What is the lifespan of the EC probe?

A: The probe typically lasts 1–2 years, depending on usage and maintenance. Regular cleaning can extend its lifespan.

By following this documentation, you can effectively integrate and use the DFRobot EC Sensor in your projects.