How to Use Solenoid Valve 12V: Examples, Pinouts, and Specs

Design with Solenoid Valve 12V in Cirkit Designer

Design with Solenoid Valve 12V in Cirkit DesignerIntroduction

A 12V solenoid valve is an electromechanical device designed to control the flow of liquid or gas in a system. It operates by using an electric current to generate a magnetic field, which in turn moves a plunger to open or close the valve. Solenoid valves are widely used in applications such as irrigation systems, automatic faucets, and pneumatic or hydraulic systems.

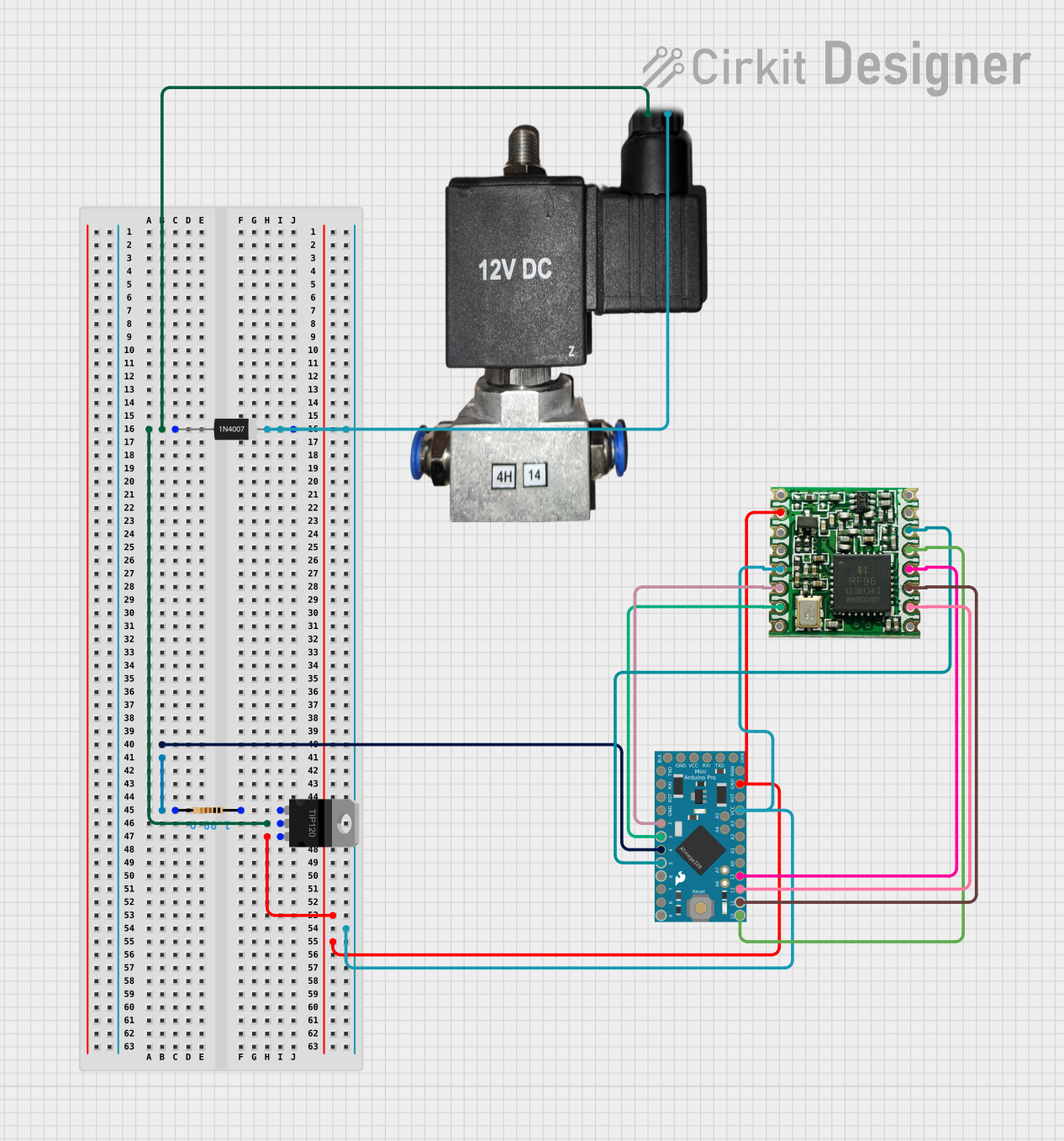

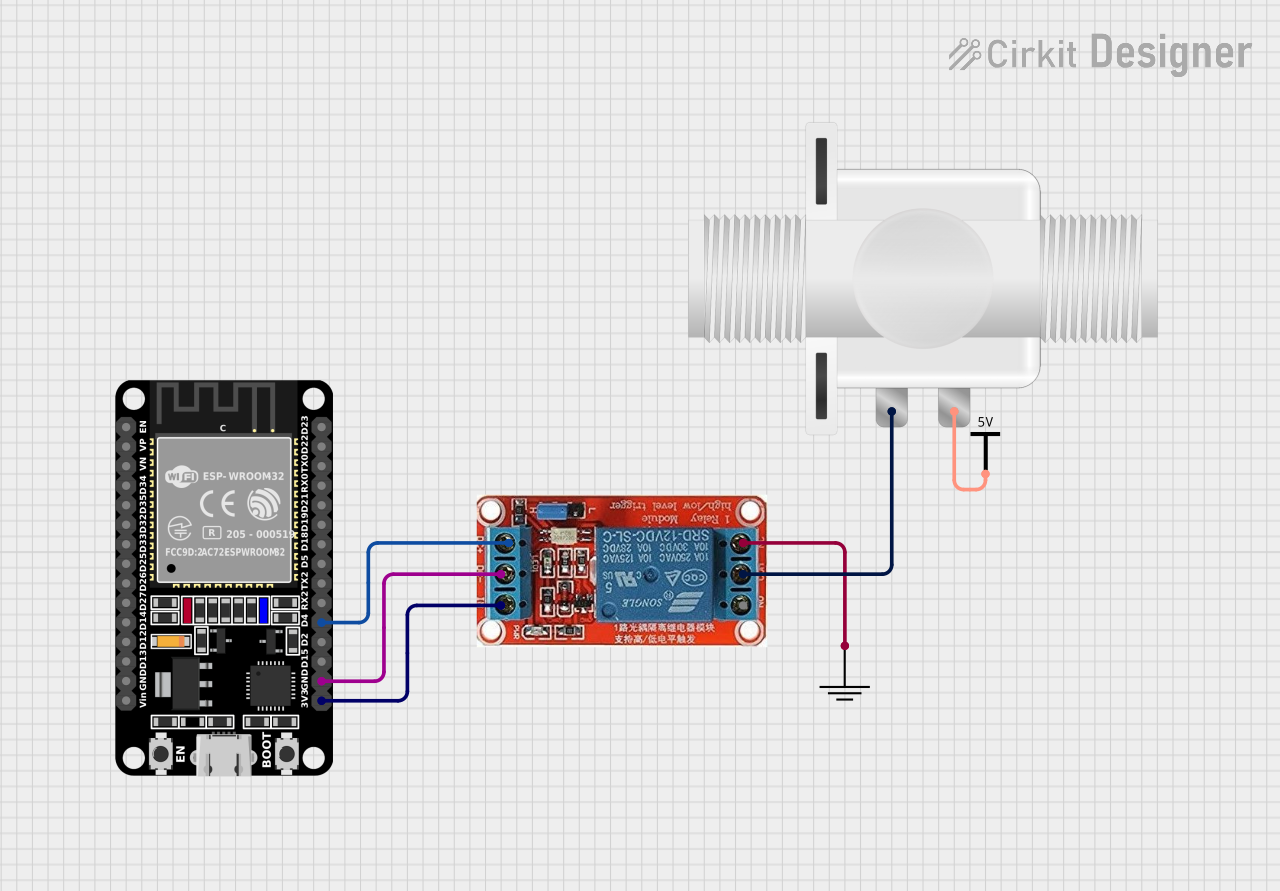

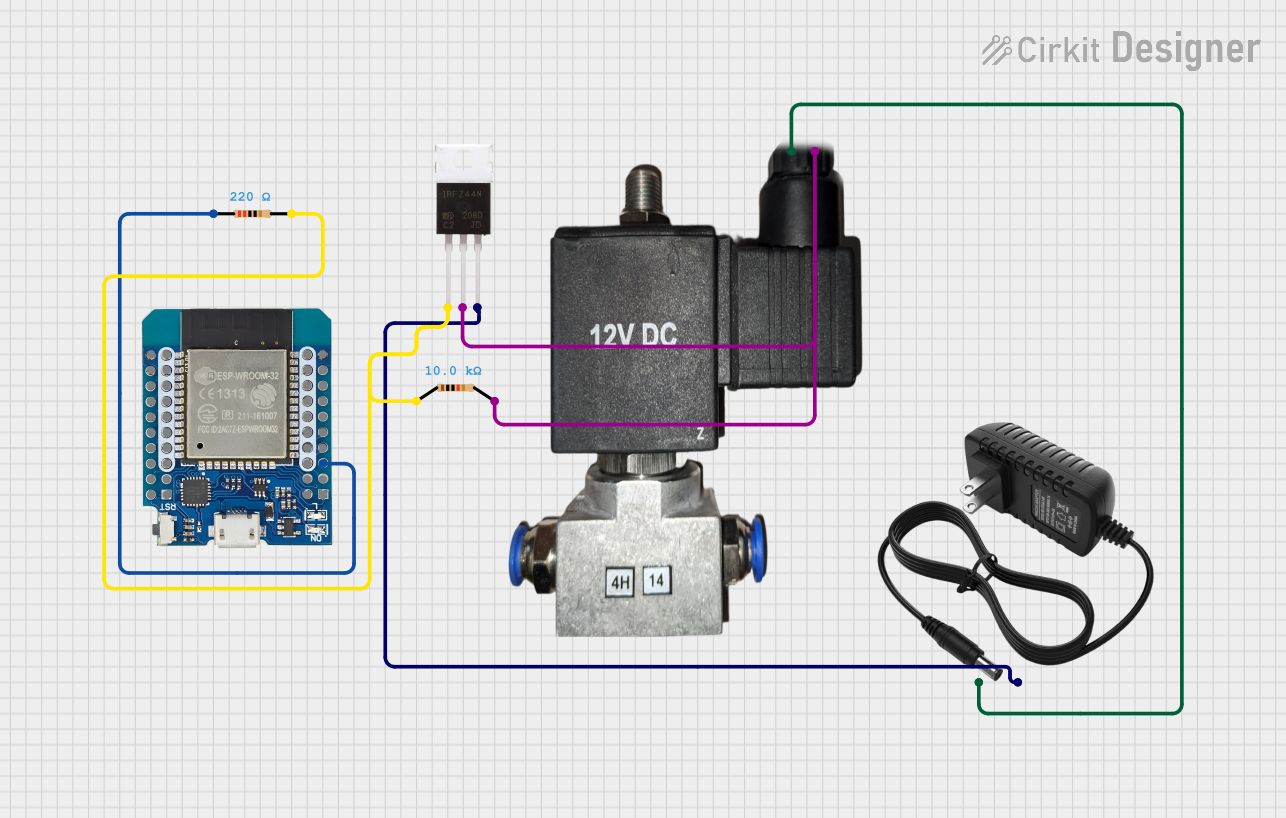

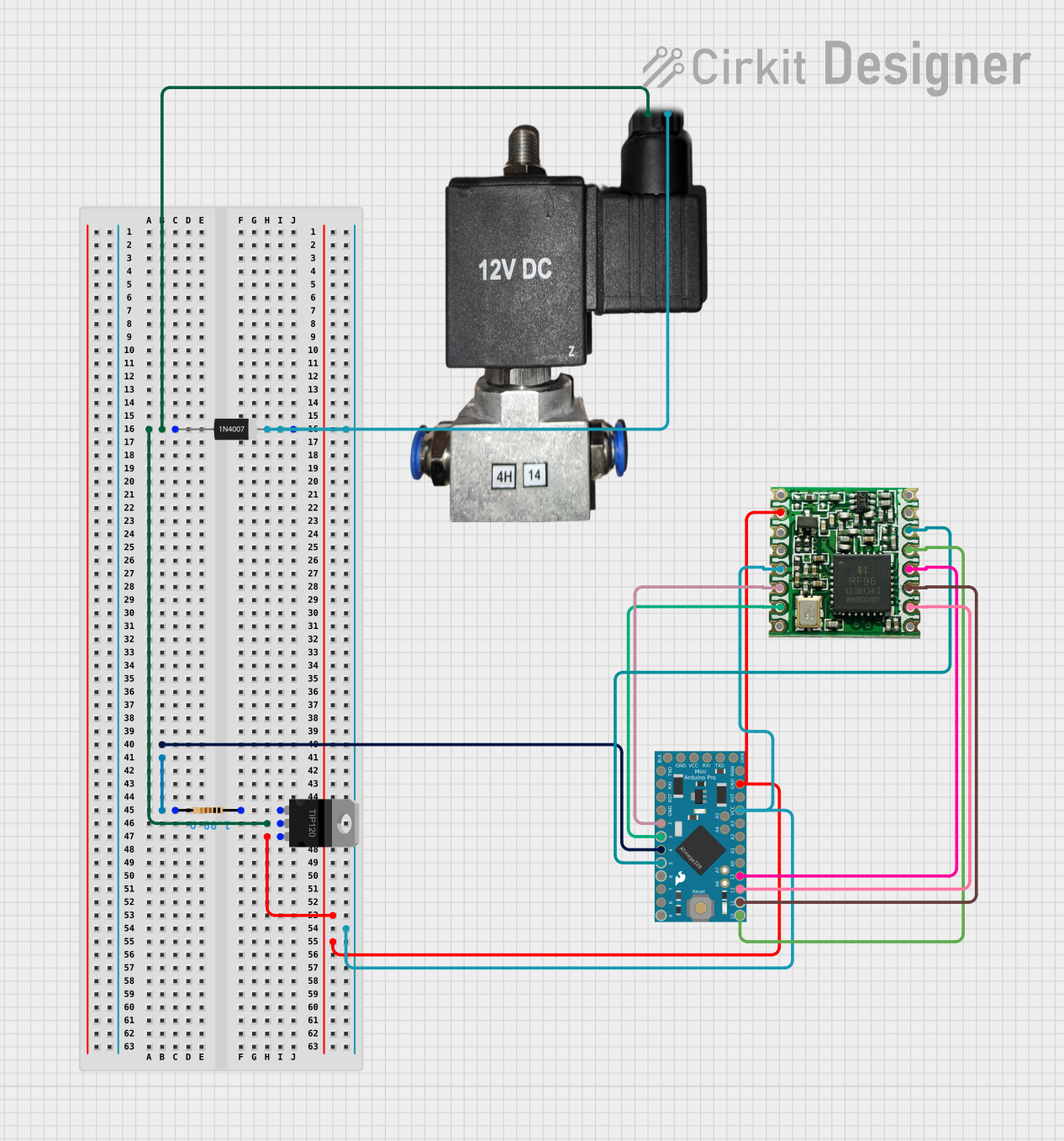

Explore Projects Built with Solenoid Valve 12V

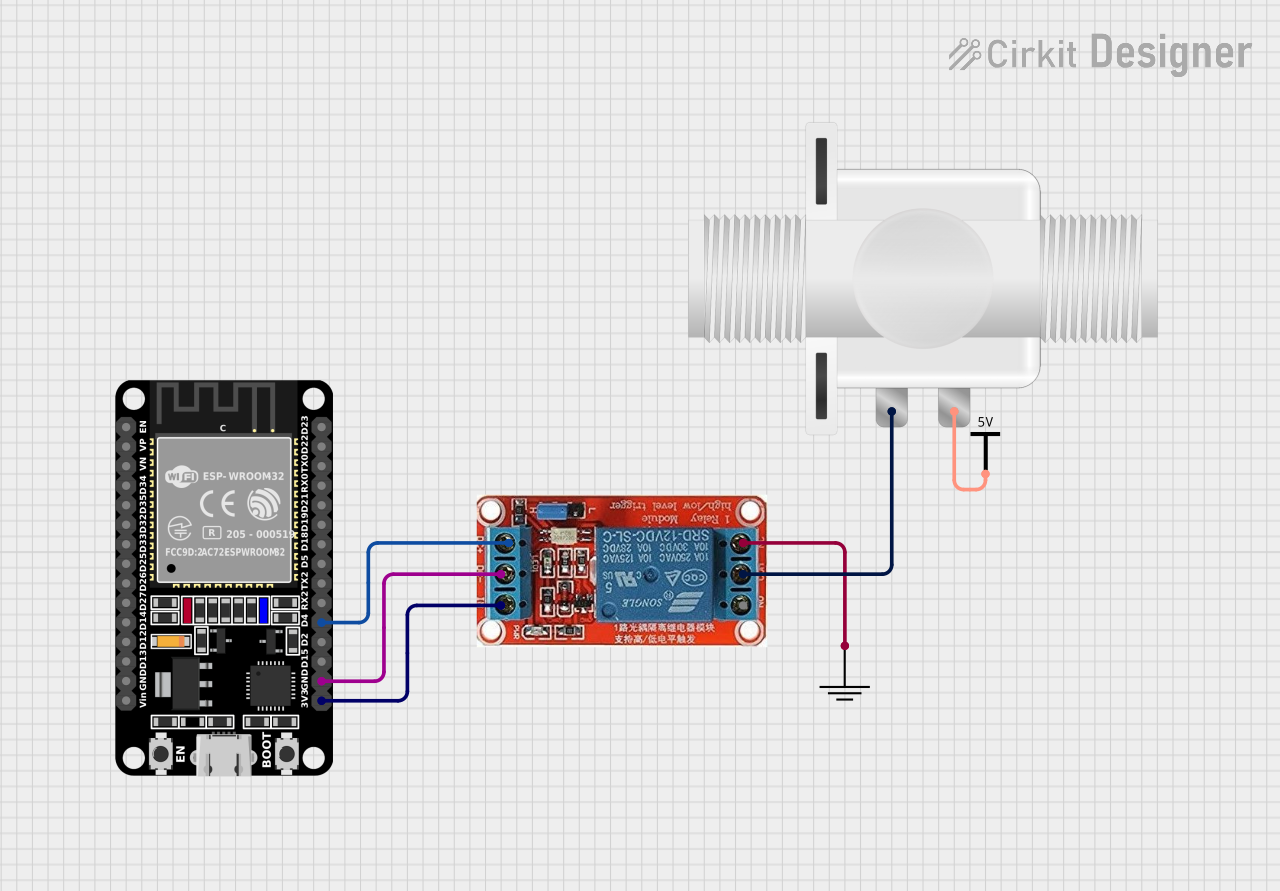

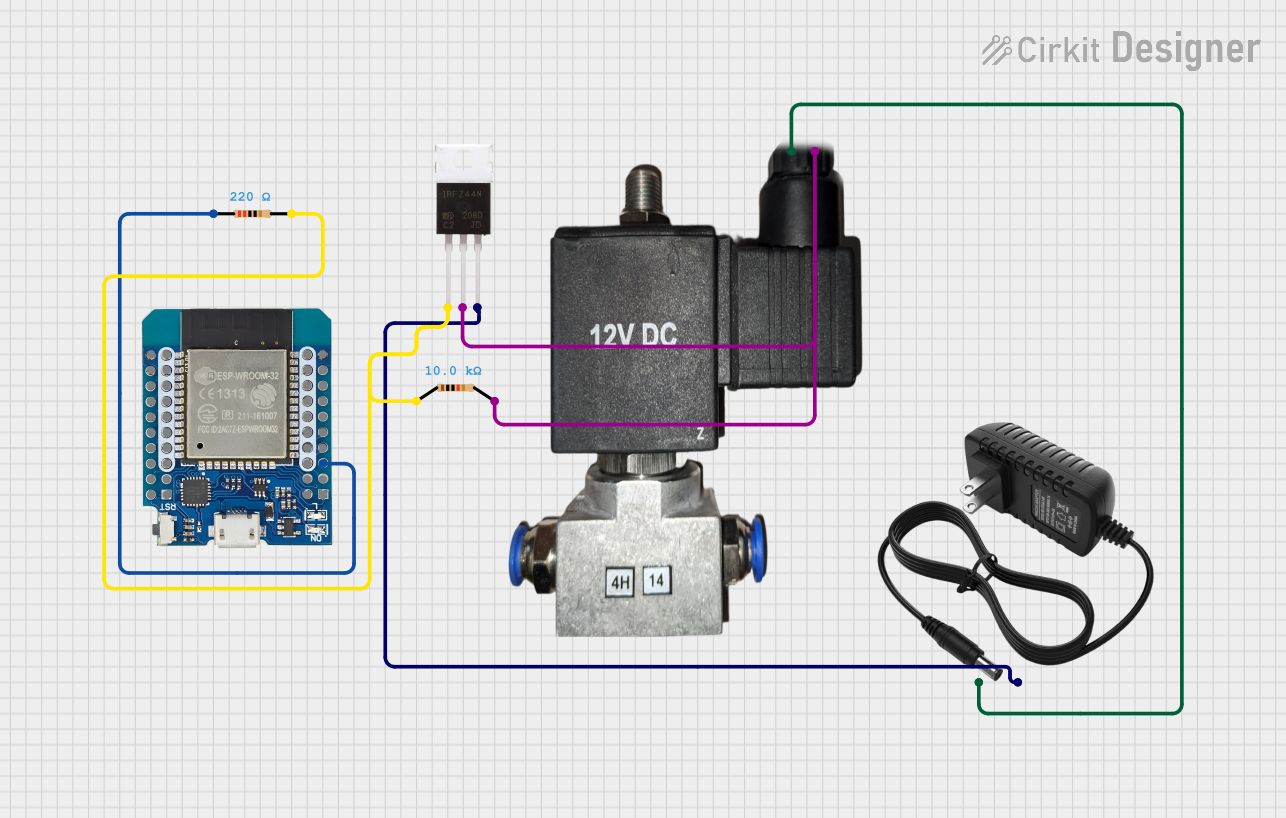

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Solenoid Valve 12V

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Automated irrigation systems

- Fluid control in HVAC systems

- Pneumatic or hydraulic controls

- Medical devices for fluid regulation

- Automatic dispensing systems

Technical Specifications

Key Technical Details

- Operating Voltage: 12V DC

- Current Rating: Typically ranges from 200mA to 500mA

- Pressure Range: Suitable for low to medium pressure applications

- Seal Material: Commonly NBR (Nitrile Butadiene Rubber), Viton, or EPDM

- Body Material: Brass, stainless steel, or plastic

- Temperature Range: Varies with seal and body material, often -5°C to 80°C

- Response Time: Typically less than 100 ms

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | Positive Voltage (V+) | Connect to 12V power supply |

| 2 | Ground (GND) | Connect to system ground |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Ensure that a 12V DC power supply is available and capable of supplying the necessary current.

- Wiring: Connect the positive terminal of the power supply to the V+ pin of the solenoid valve. Connect the ground terminal of the power supply to the GND pin.

- Control Signal: Use a relay or a transistor to switch the solenoid valve on and off. This can be controlled by a microcontroller like an Arduino UNO.

- Safety: Include a flyback diode across the solenoid coil to prevent voltage spikes when the solenoid is turned off.

Important Considerations and Best Practices

- Voltage Matching: Ensure that the solenoid valve is rated for 12V operation.

- Current Capacity: Verify that the power supply and control circuit can handle the current drawn by the solenoid.

- Heat Dissipation: Solenoid valves can generate heat; ensure adequate ventilation and consider heat sinks if necessary.

- Waterproofing: If the valve is used in a wet environment, ensure that the electrical connections are waterproof.

Example Arduino UNO Code

// Define the solenoid valve control pin

const int solenoidPin = 7;

void setup() {

// Set the solenoid pin as an output

pinMode(solenoidPin, OUTPUT);

}

void loop() {

// Open the solenoid valve

digitalWrite(solenoidPin, HIGH);

delay(1000); // Keep the valve open for 1 second

// Close the solenoid valve

digitalWrite(solenoidPin, LOW);

delay(1000); // Keep the valve closed for 1 second

}

Troubleshooting and FAQs

Common Issues Users Might Face

- Valve Does Not Actuate: Check the power supply and wiring connections. Ensure the control signal is being sent.

- Insufficient Flow: Verify that the valve is the correct size for the application and that there are no obstructions.

- Overheating: Ensure the duty cycle is not too high for the solenoid's rating.

Solutions and Tips for Troubleshooting

- Check Voltage: Use a multimeter to ensure the solenoid is receiving 12V.

- Listen for Clicking: A healthy solenoid valve should make a distinct clicking sound when actuated.

- Reduce Duty Cycle: If overheating, reduce the time the solenoid is energized or increase the off time.

FAQs

Q: Can I control the solenoid valve with a PWM signal? A: Yes, but ensure the solenoid is rated for PWM control and that the frequency is appropriate.

Q: How long can I continuously power the solenoid valve? A: This depends on the duty cycle rating of the valve. Continuous operation may lead to overheating and should be avoided unless the valve is rated for it.

Q: Can the solenoid valve be used with any liquid or gas? A: The compatibility depends on the materials used in the valve. Check the manufacturer's specifications for compatibility with specific fluids.