How to Use HUB75E: Examples, Pinouts, and Specs

Design with HUB75E in Cirkit Designer

Design with HUB75E in Cirkit DesignerIntroduction

The HUB75E is a standardized interface designed for connecting LED displays, particularly in large-scale video walls and digital signage applications. It serves as a bridge between the display controller and LED modules, enabling efficient data transfer and precise control of pixel information. The HUB75E interface is widely used in RGB LED matrices due to its simplicity, scalability, and ability to handle high-speed data communication.

Explore Projects Built with HUB75E

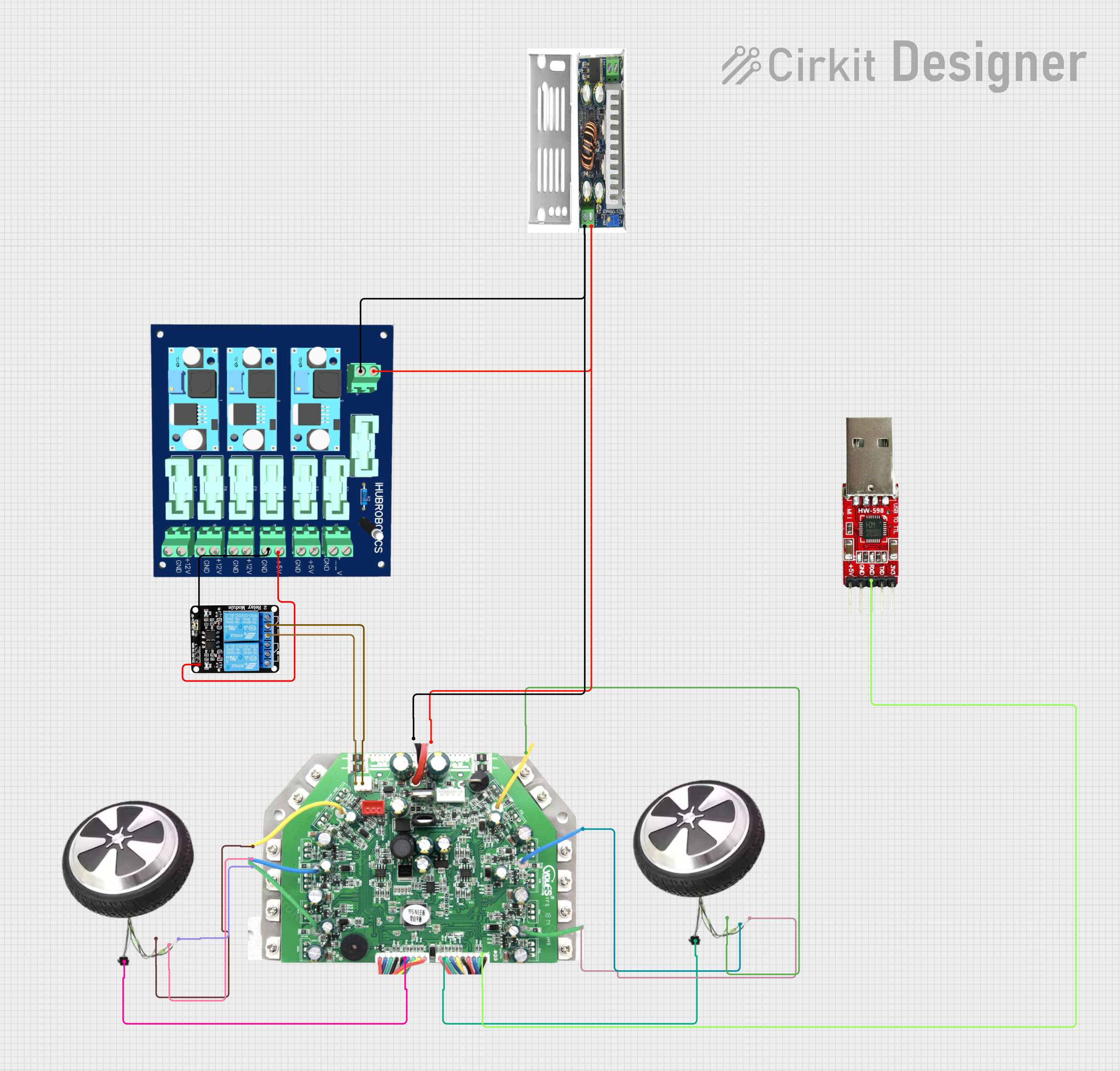

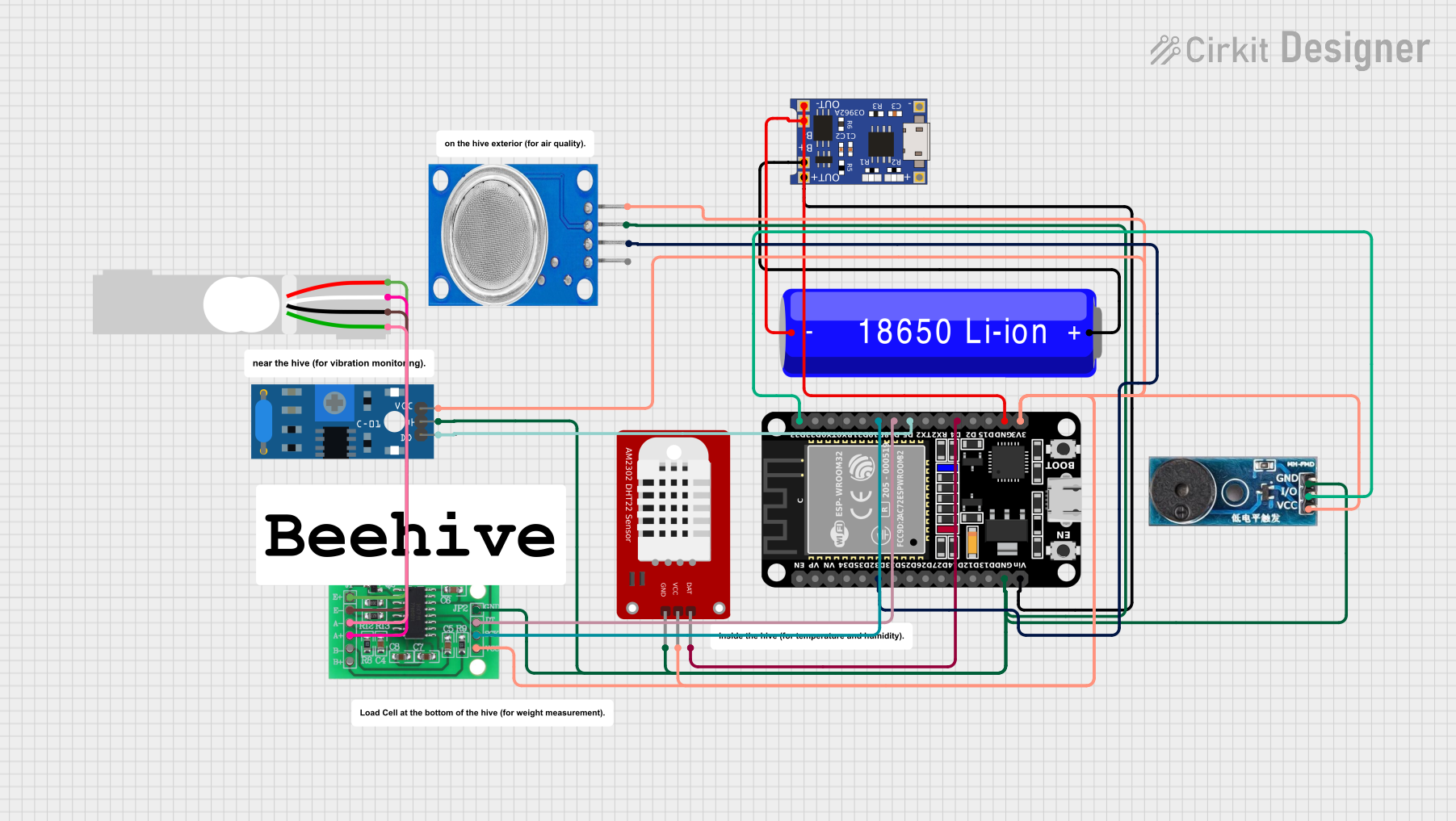

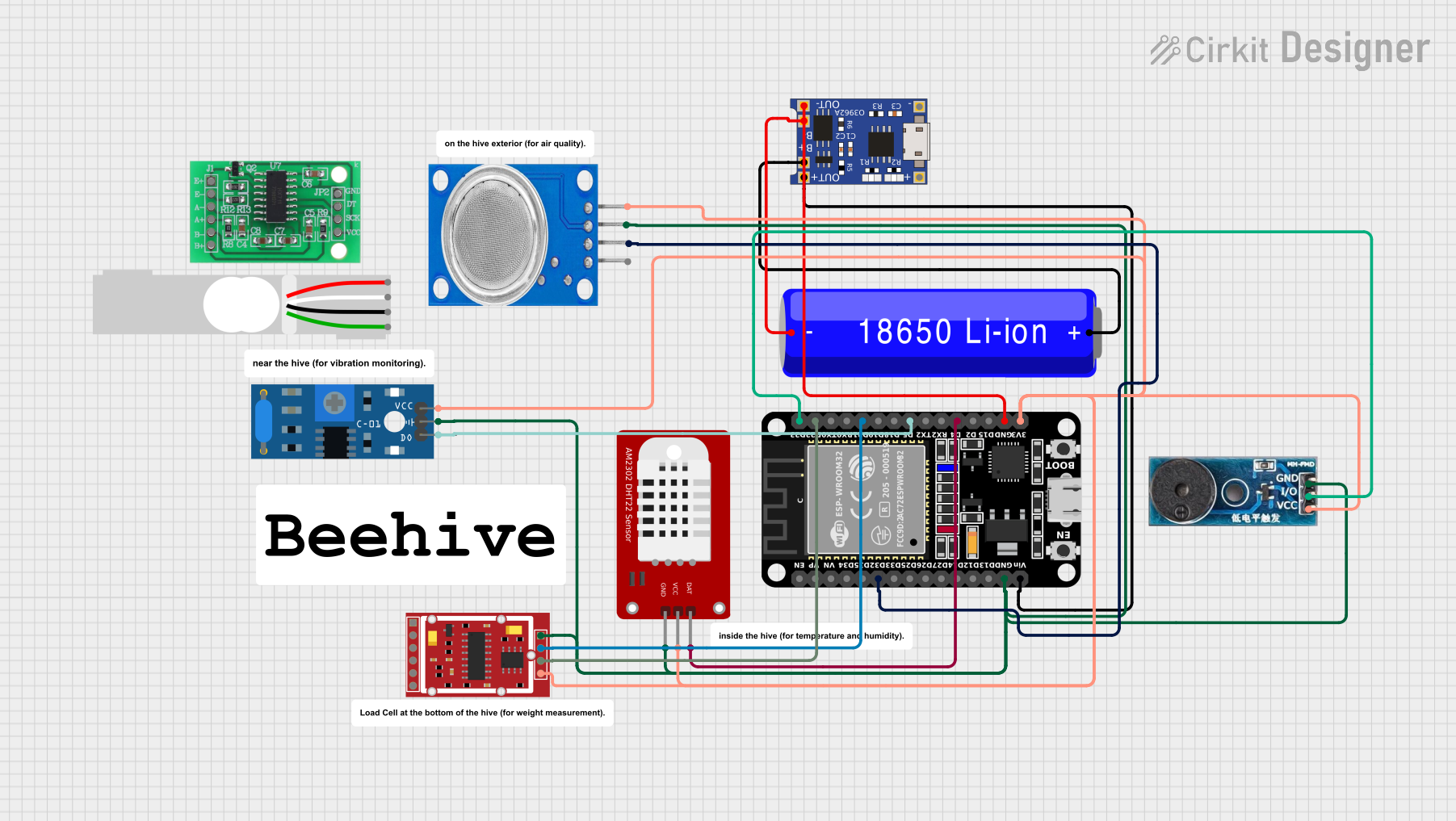

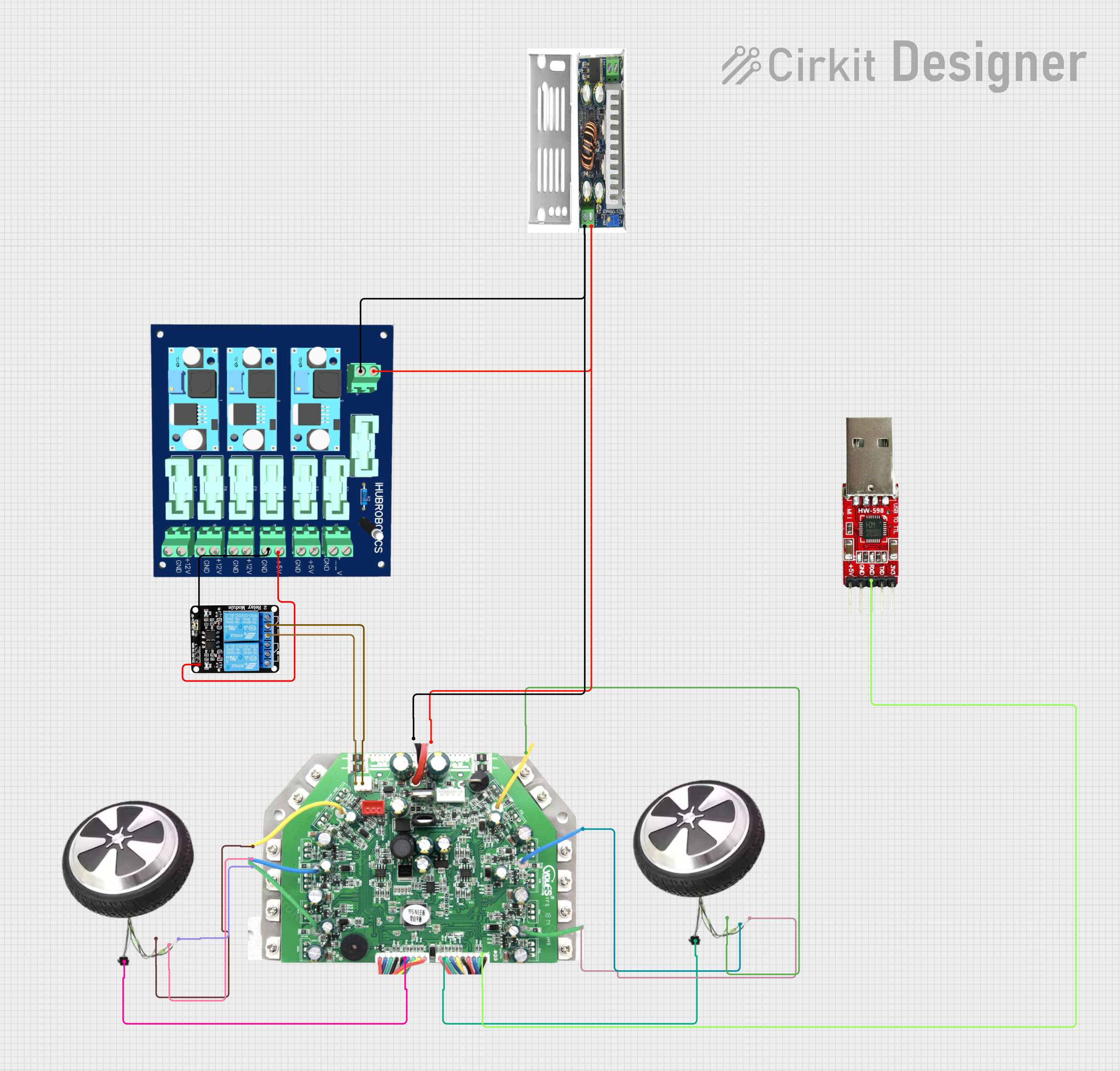

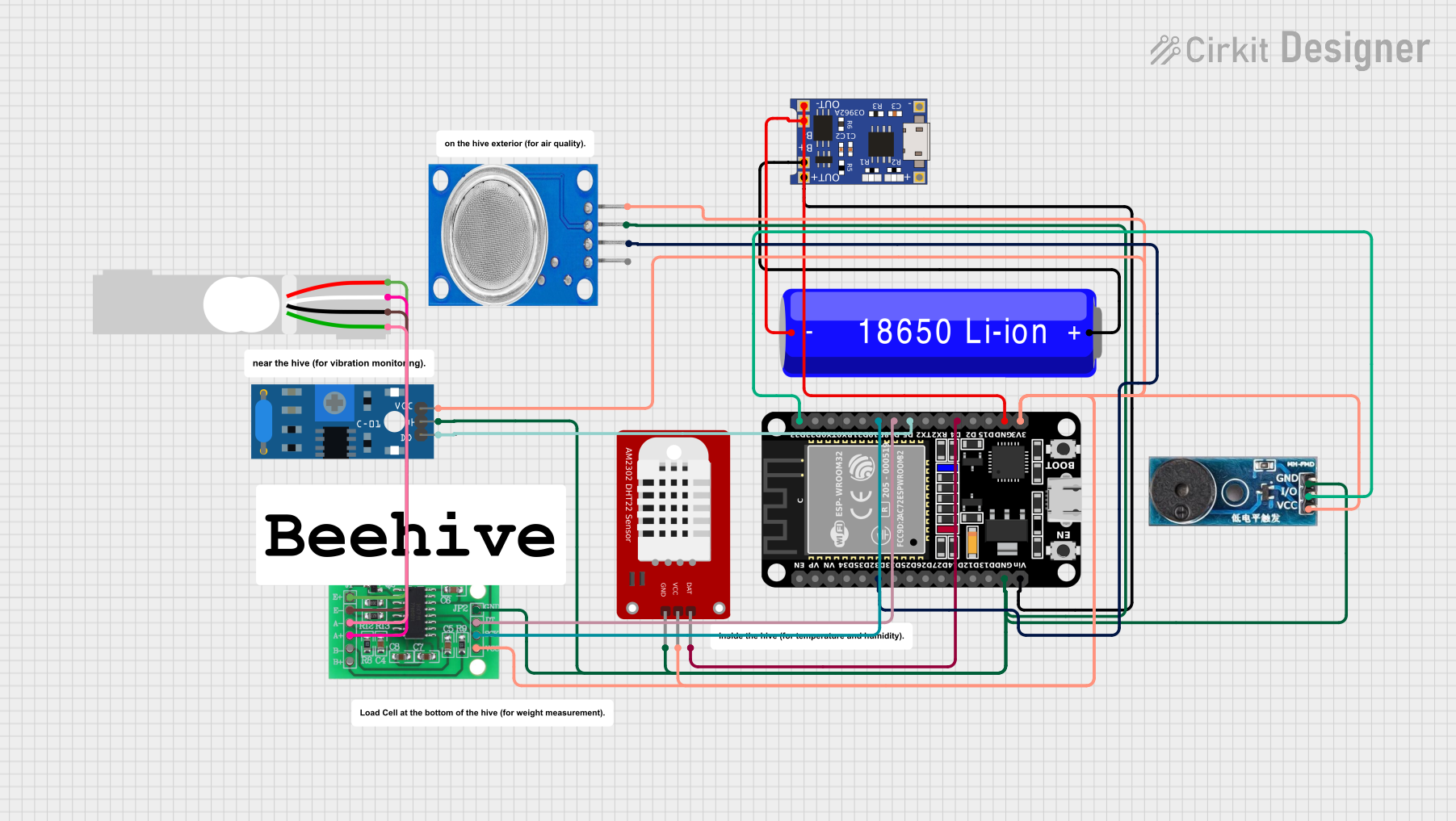

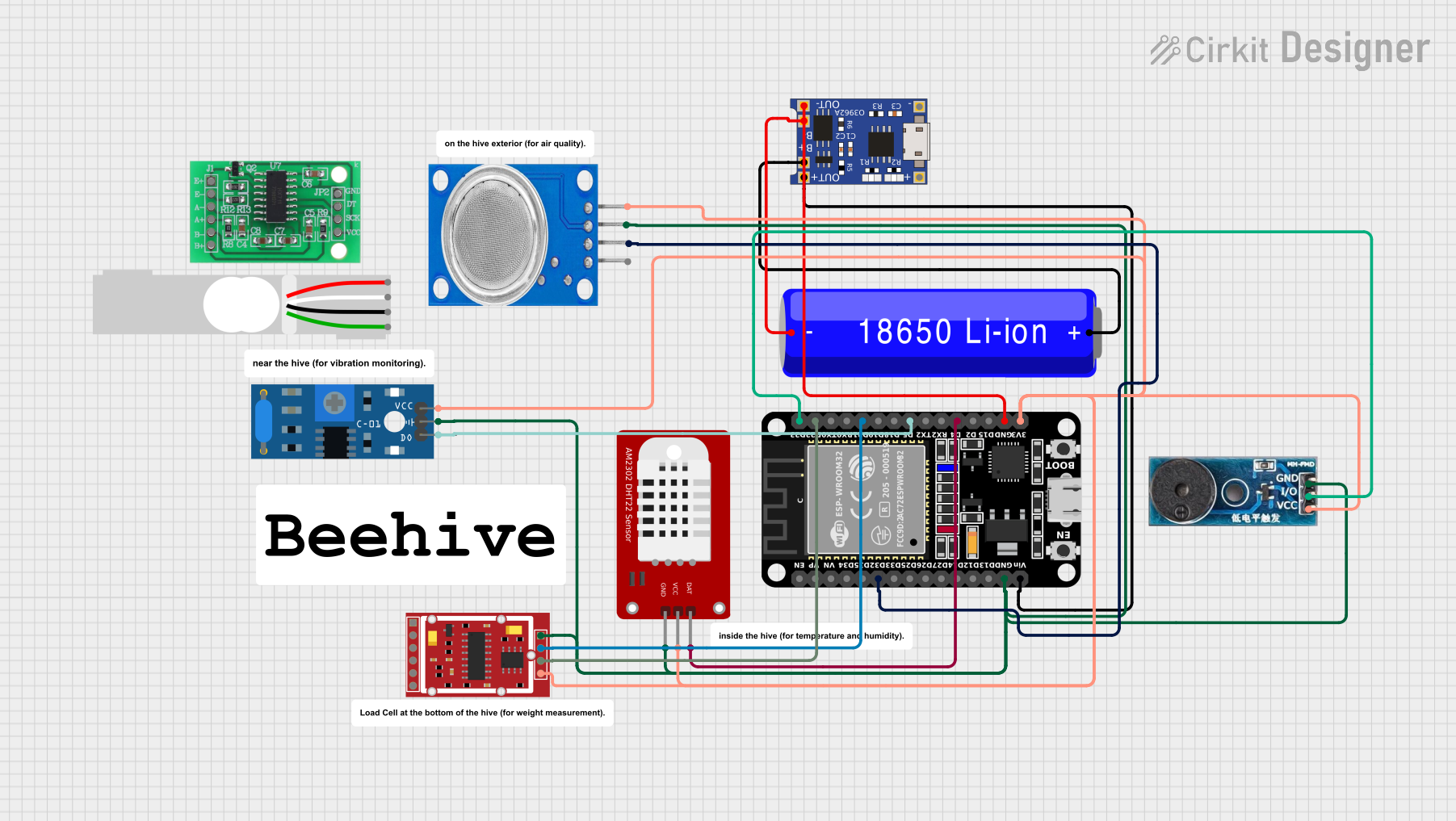

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with HUB75E

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Large-scale video walls in stadiums, malls, and public spaces

- Digital signage for advertising and information display

- Interactive LED displays for events and exhibitions

- Indoor and outdoor RGB LED matrix panels

Technical Specifications

Key Technical Details

- Voltage Range: 3.3V to 5V (logic level)

- Data Protocol: Parallel data transfer

- Supported LED Configurations: RGB (1/8, 1/16, or 1/32 scan modes)

- Maximum Refresh Rate: Up to 1920Hz (depending on the controller and panel)

- Connector Type: 16-pin IDC (2x8 pin header)

- Compatibility: Commonly used with LED matrix panels such as P10, P6, and P4

Pin Configuration and Descriptions

The HUB75E interface uses a 16-pin connector with the following pinout:

| Pin | Name | Description |

|---|---|---|

| 1 | R1 | Red data for the first row of LEDs |

| 2 | G1 | Green data for the first row of LEDs |

| 3 | B1 | Blue data for the first row of LEDs |

| 4 | GND | Ground connection |

| 5 | R2 | Red data for the second row of LEDs |

| 6 | G2 | Green data for the second row of LEDs |

| 7 | B2 | Blue data for the second row of LEDs |

| 8 | GND | Ground connection |

| 9 | A | Row address selection bit A |

| 10 | B | Row address selection bit B |

| 11 | C | Row address selection bit C |

| 12 | D | Row address selection bit D |

| 13 | CLK | Clock signal for synchronizing data transfer |

| 14 | LAT | Latch signal to store data in the LED driver |

| 15 | OE | Output enable signal (active low) |

| 16 | E | Row address selection bit E (used in higher scan modes, e.g., 1/32 scan panels) |

Usage Instructions

How to Use the HUB75E in a Circuit

Connect the HUB75E Interface to the LED Panel:

- Use a 16-pin ribbon cable to connect the HUB75E interface on the LED panel to the controller board.

- Ensure proper alignment of the pins to avoid damage to the components.

Power the LED Panel:

- Provide a stable 5V power supply to the LED panel. Ensure the power supply can handle the current requirements of the panel.

Connect the Controller Board:

- Use a compatible controller (e.g., Arduino, Raspberry Pi, or dedicated LED controllers) to send data to the HUB75E interface.

- Match the controller's output pins to the corresponding HUB75E pins (e.g., R1, G1, B1, CLK, LAT, OE).

Program the Controller:

- Write or upload code to the controller to send pixel data to the LED panel. Libraries such as Adafruit_GFX and PxMatrix can simplify this process.

Important Considerations and Best Practices

- Power Supply: Ensure the power supply is capable of delivering sufficient current for the LED panel. A typical P10 panel may require up to 4-5A at 5V.

- Signal Integrity: Use short, high-quality cables to minimize signal degradation, especially for high refresh rates.

- Heat Management: LED panels can generate significant heat. Ensure proper ventilation or cooling to prevent overheating.

- Scan Mode Compatibility: Verify the scan mode of your LED panel (e.g., 1/8, 1/16) and configure your controller accordingly.

Example Code for Arduino UNO

Below is an example of how to control a HUB75E-compatible LED panel using an Arduino UNO and the PxMatrix library:

#include <PxMatrix.h>

// Define the display size (e.g., 32x16 for a P10 panel)

#define DISPLAY_WIDTH 32

#define DISPLAY_HEIGHT 16

// Define the pins connected to the HUB75E interface

#define P_LAT 10 // Latch pin

#define P_A A0 // Row address A

#define P_B A1 // Row address B

#define P_C A2 // Row address C

#define P_D A3 // Row address D

#define P_E A4 // Row address E (if applicable)

#define P_OE 9 // Output enable pin

// Create a PxMatrix object

PxMatrix display(DISPLAY_WIDTH, DISPLAY_HEIGHT, P_LAT, P_OE, P_A, P_B, P_C, P_D);

// Setup function

void setup() {

// Initialize the display

display.begin(16); // 1/16 scan mode

display.setBrightness(50); // Set brightness (0-255)

}

// Loop function

void loop() {

// Clear the display

display.clearDisplay();

// Draw some text

display.setTextColor(display.color565(255, 0, 0)); // Red text

display.setCursor(0, 0);

display.print("Hello!");

// Update the display

display.showBuffer();

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues and Solutions

LED Panel Not Lighting Up:

- Check the power supply connection and ensure it is providing 5V.

- Verify that the ribbon cable is securely connected to the HUB75E interface.

Incorrect Colors or Flickering:

- Ensure the data pins (R1, G1, B1, etc.) are correctly connected to the controller.

- Check the scan mode configuration in your code and match it to the panel's specifications.

Low Brightness:

- Increase the brightness setting in your code.

- Ensure the power supply can handle the current requirements of the panel.

No Response from the Panel:

- Verify the clock (CLK) and latch (LAT) signals are being sent from the controller.

- Check for loose or damaged cables.

FAQs

Can I use a 3.3V controller with HUB75E panels? Yes, but you may need level shifters to convert 3.3V logic to 5V logic for reliable operation.

What is the maximum cable length for HUB75E connections? For best performance, keep the cable length under 50cm to avoid signal degradation.

Can I daisy-chain multiple panels with HUB75E? Yes, most HUB75E panels support daisy-chaining. Ensure your controller can handle the increased data load.

By following this documentation, you can effectively integrate and troubleshoot HUB75E interfaces in your LED display projects.