How to Use Step Down Buck converter: Examples, Pinouts, and Specs

Design with Step Down Buck converter in Cirkit Designer

Design with Step Down Buck converter in Cirkit DesignerIntroduction

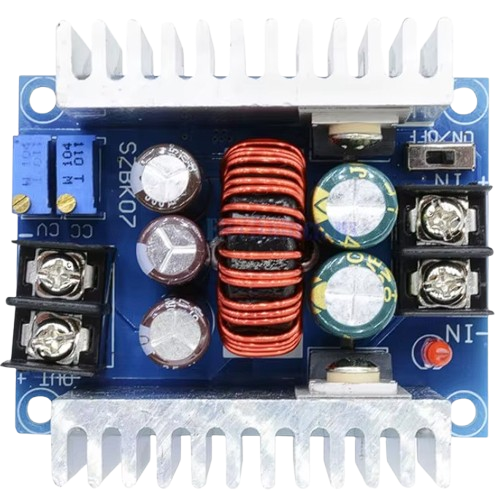

The Step Down Buck Converter (Manufacturer Part ID: 20A 300W) is a type of DC-DC converter designed to step down voltage from its input to its output while maintaining high efficiency. This component is essential in power supply circuits where there is a need to reduce voltage levels. It is widely used in various applications, including battery-powered devices, power management systems, and embedded systems.

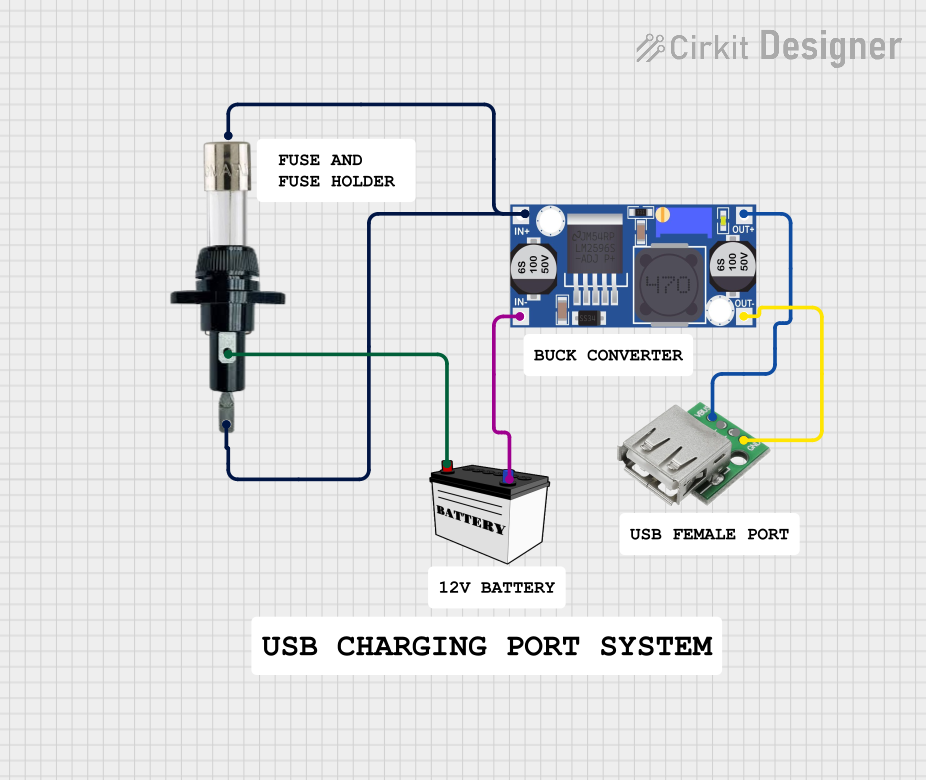

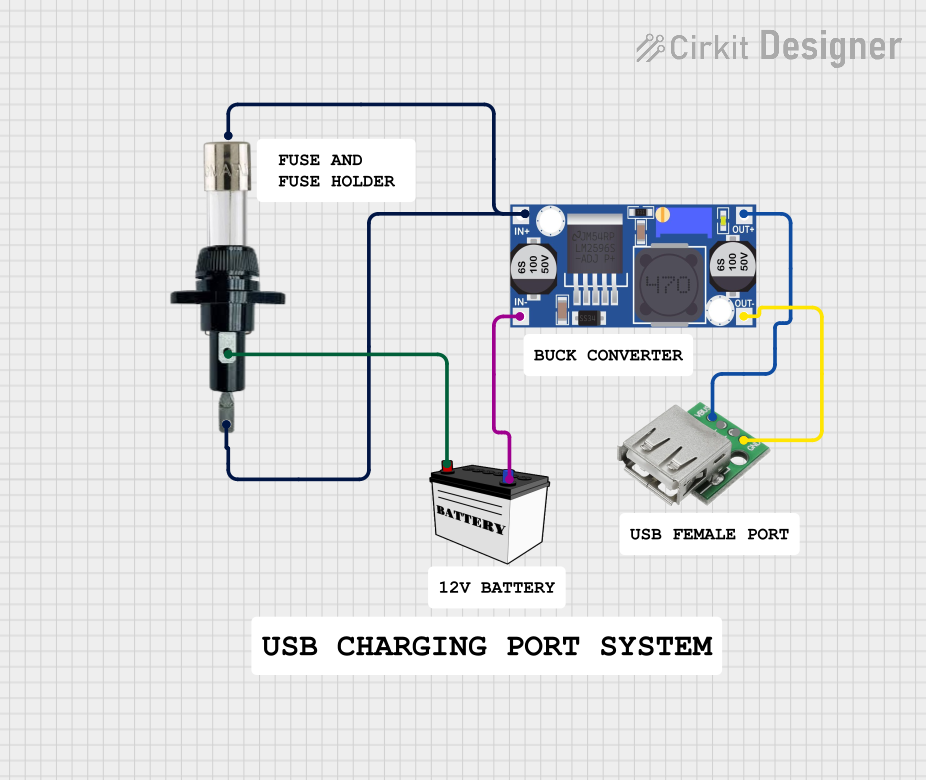

Explore Projects Built with Step Down Buck converter

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Step Down Buck converter

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Input Voltage | 6V - 40V |

| Output Voltage | 1.2V - 36V |

| Output Current | Up to 20A |

| Power Rating | 300W |

| Efficiency | Up to 95% |

| Switching Frequency | 150kHz |

| Operating Temperature | -40°C to +85°C |

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VIN | Input Voltage (6V - 40V) |

| 2 | GND | Ground |

| 3 | VOUT | Output Voltage (1.2V - 36V) |

| 4 | ADJ | Output Voltage Adjustment |

Usage Instructions

How to Use the Component in a Circuit

- Connect the Input Voltage (VIN): Connect the positive terminal of your power source to the VIN pin and the negative terminal to the GND pin.

- Connect the Output Load (VOUT): Connect the load that requires the stepped-down voltage to the VOUT pin and the GND pin.

- Adjust the Output Voltage (ADJ): Use a potentiometer or a fixed resistor to adjust the output voltage to the desired level. The ADJ pin allows fine-tuning of the output voltage.

Important Considerations and Best Practices

- Heat Dissipation: Ensure proper heat dissipation by using a heatsink or placing the converter in a well-ventilated area, especially when operating at high currents.

- Input Voltage Range: Always ensure that the input voltage is within the specified range (6V - 40V) to avoid damaging the converter.

- Output Voltage Adjustment: When adjusting the output voltage, start with a low setting and gradually increase to the desired level to prevent overshooting.

- Load Requirements: Ensure that the load connected to the output does not exceed the maximum current rating (20A) to avoid overloading the converter.

Example Circuit with Arduino UNO

Here is an example of how to use the Step Down Buck Converter with an Arduino UNO to power a 5V sensor:

Circuit Diagram

+---------+ +-------------------+

| Arduino | | Step Down Buck |

| UNO | | Converter |

| | | |

| VIN |-------| VIN |

| GND |-------| GND |

| 5V |-------| VOUT |

| | | |

+---------+ +-------------------+

Arduino Code

// Example code to read a sensor powered by the Step Down Buck Converter

const int sensorPin = A0; // Analog pin connected to the sensor

int sensorValue = 0; // Variable to store the sensor value

void setup() {

Serial.begin(9600); // Initialize serial communication at 9600 baud

}

void loop() {

sensorValue = analogRead(sensorPin); // Read the sensor value

Serial.print("Sensor Value: ");

Serial.println(sensorValue); // Print the sensor value to the serial monitor

delay(1000); // Wait for 1 second before reading again

}

Troubleshooting and FAQs

Common Issues Users Might Face

No Output Voltage:

- Solution: Check the input voltage to ensure it is within the specified range. Verify all connections are secure and correct.

Overheating:

- Solution: Ensure proper heat dissipation by using a heatsink or placing the converter in a well-ventilated area. Reduce the load if necessary.

Output Voltage Not Adjustable:

- Solution: Verify the connection to the ADJ pin and ensure the potentiometer or resistor used for adjustment is functioning correctly.

FAQs

Can I use this converter with a battery?

- Yes, the Step Down Buck Converter can be used with a battery as long as the input voltage is within the specified range (6V - 40V).

What is the maximum output current?

- The maximum output current is 20A. Ensure that the load connected does not exceed this rating.

How do I adjust the output voltage?

- Use a potentiometer or a fixed resistor connected to the ADJ pin to adjust the output voltage. Start with a low setting and gradually increase to the desired level.

By following this documentation, users can effectively utilize the Step Down Buck Converter in their projects, ensuring efficient and reliable voltage regulation.