How to Use L298N Motor Driver H-Bridge (Motor Driver): Examples, Pinouts, and Specs

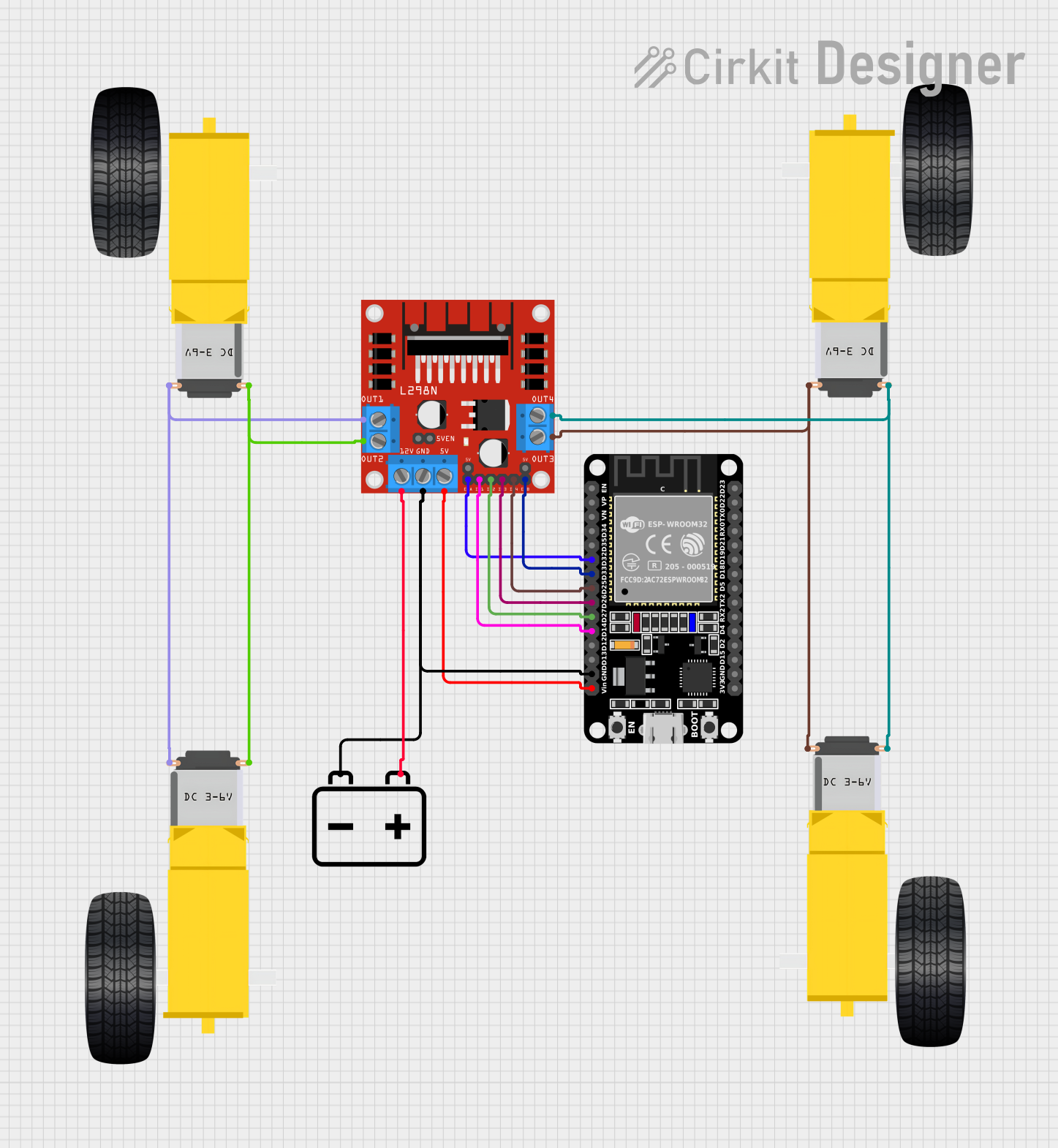

Design with L298N Motor Driver H-Bridge (Motor Driver) in Cirkit Designer

Design with L298N Motor Driver H-Bridge (Motor Driver) in Cirkit DesignerL298N Motor Driver H-Bridge Documentation

1. Introduction

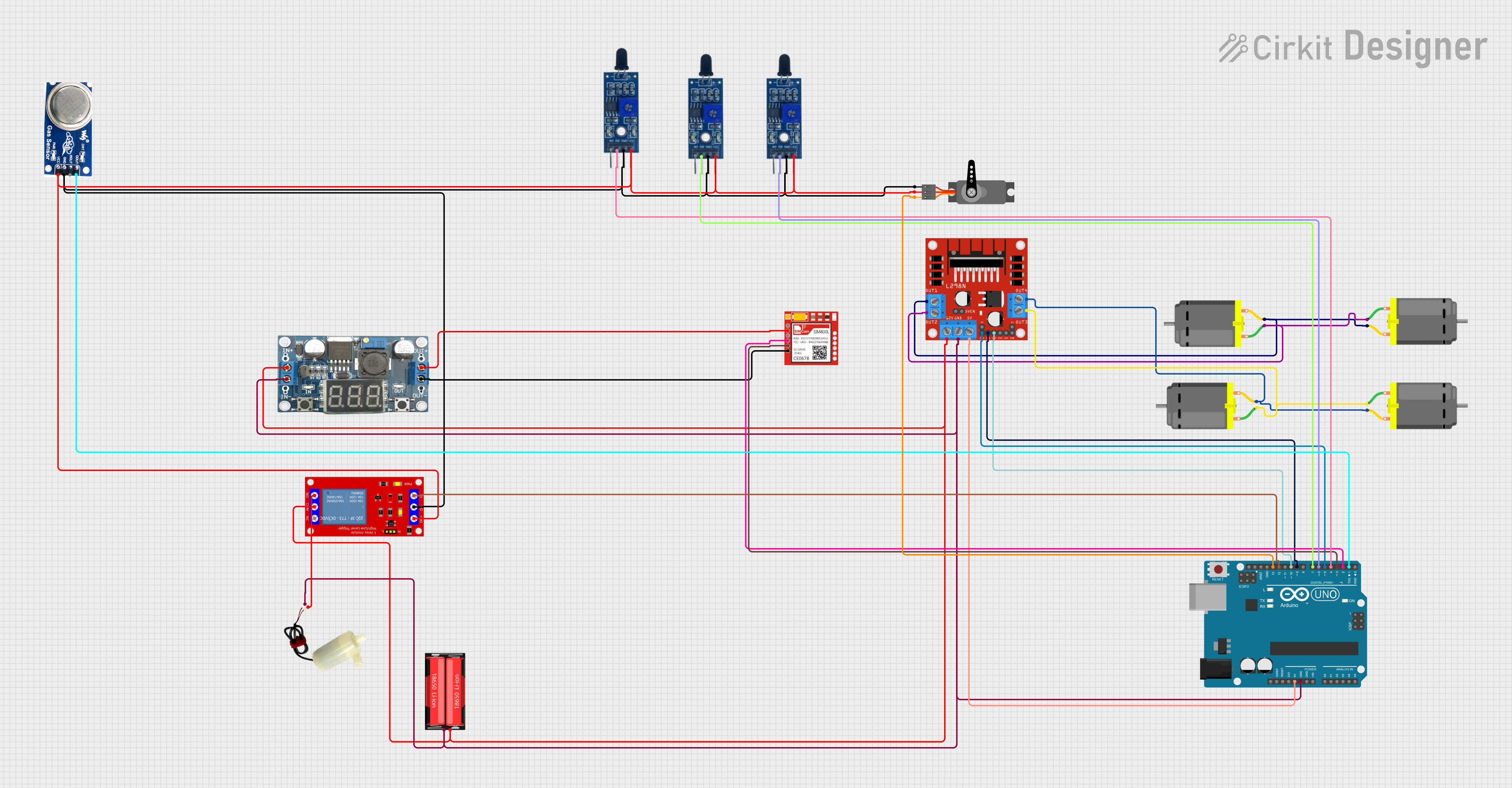

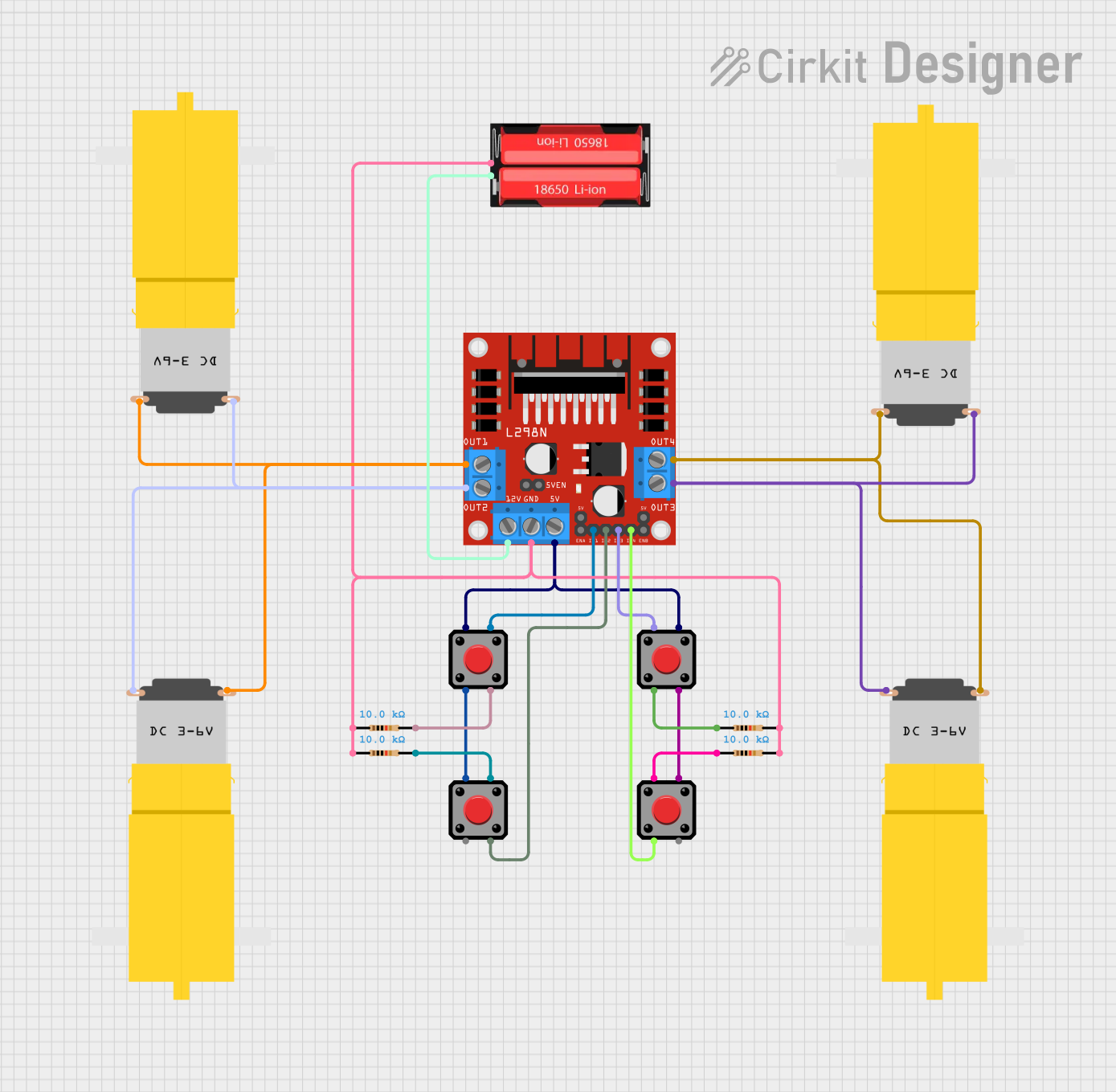

The L298N Motor Driver H-Bridge, manufactured by STMicroelectronics (Part ID: L298N), is a robust and versatile dual H-Bridge motor driver. It is designed to control the direction and speed of DC motors and stepper motors, making it an essential component in robotics, automation, and motor control applications. The L298N can drive two motors simultaneously, supporting bidirectional control and pulse-width modulation (PWM) for speed regulation.

Common Applications:

- Robotics (e.g., controlling robot wheels)

- Conveyor belt systems

- Automated gates and doors

- CNC machines and 3D printers

- DIY motorized projects

- Stepper motor control in precision systems

2. Technical Specifications

The L298N is a high-power motor driver capable of handling significant current and voltage levels. Below are its key specifications and pin configuration details.

Key Technical Details:

| Parameter | Value |

|---|---|

| Operating Voltage | 5V to 46V |

| Output Current (per channel) | 2A (continuous), 3A (peak) |

| Logic Voltage | 5V |

| Power Dissipation | 25W (with proper heat sinking) |

| Control Logic Levels | High: 2.3V to 5V, Low: 0V to 1.5V |

| Number of Channels | 2 (dual H-Bridge) |

| PWM Frequency | Up to 20 kHz |

| Operating Temperature Range | -25°C to +130°C |

Pin Configuration and Descriptions:

The L298N module typically includes additional components like a voltage regulator and terminal blocks for easy wiring. Below is the pinout for the L298N IC and its corresponding module.

L298N IC Pinout:

| Pin | Name | Description |

|---|---|---|

| 1 | Enable A | Enables/Disables Motor A (High = Enabled, Low = Disabled) |

| 2 | Input 1 | Logic input to control Motor A direction (works with Input 2) |

| 3 | Input 2 | Logic input to control Motor A direction (works with Input 1) |

| 4 | Output 1 | Motor A output terminal 1 |

| 5 | Output 2 | Motor A output terminal 2 |

| 6 | VSS (Logic) | Logic voltage supply (5V) |

| 7 | Ground | Common ground |

| 8 | VS (Motor) | Motor power supply (up to 46V) |

| 9 | Output 3 | Motor B output terminal 1 |

| 10 | Output 4 | Motor B output terminal 2 |

| 11 | Input 3 | Logic input to control Motor B direction (works with Input 4) |

| 12 | Input 4 | Logic input to control Motor B direction (works with Input 3) |

| 13 | Enable B | Enables/Disables Motor B (High = Enabled, Low = Disabled) |

| 14 | Ground | Common ground |

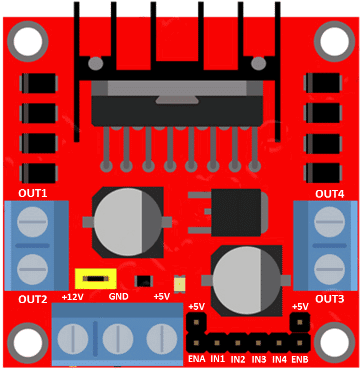

L298N Module Pinout:

| Pin | Description |

|---|---|

| ENA | Enable pin for Motor A (connect to PWM for speed control) |

| IN1, IN2 | Control pins for Motor A direction |

| OUT1, OUT2 | Output terminals for Motor A |

| ENB | Enable pin for Motor B (connect to PWM for speed control) |

| IN3, IN4 | Control pins for Motor B direction |

| OUT3, OUT4 | Output terminals for Motor B |

| 12V (VS) | Motor power supply (up to 46V) |

| 5V | Logic voltage supply (can be used to power external logic circuits) |

| GND | Common ground |

3. Usage Instructions

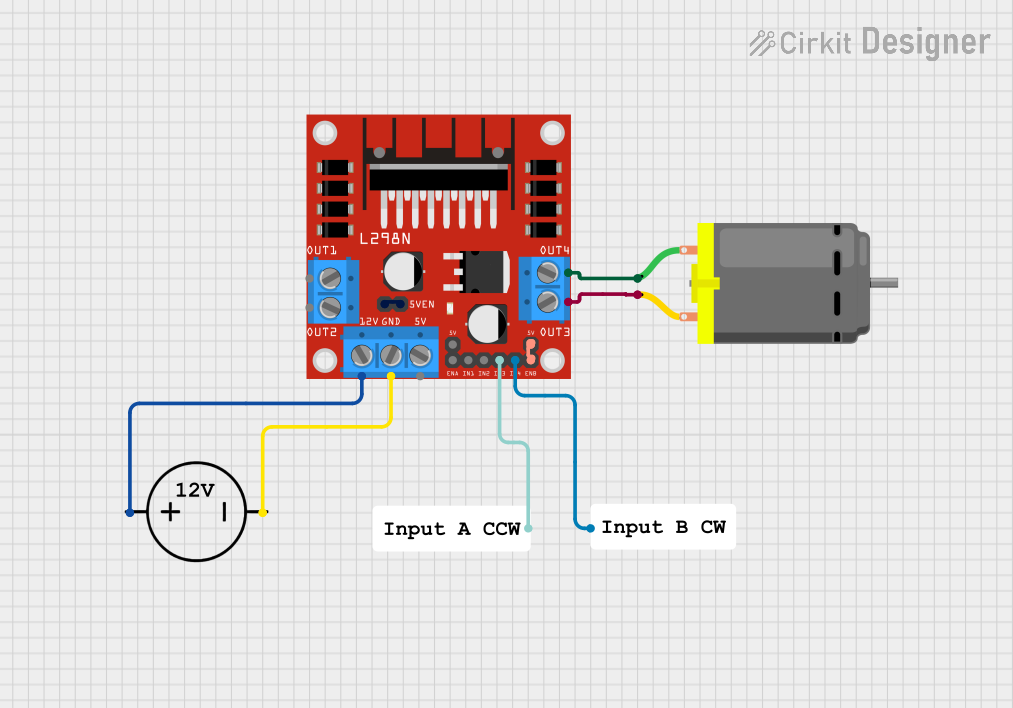

Connecting the L298N to a Circuit:

Power Supply:

- Connect the motor power supply (up to 46V) to the

12V(VS) pin. - Connect the logic power supply (5V) to the

5Vpin. - Ensure all grounds (GND) are connected to a common ground.

- Connect the motor power supply (up to 46V) to the

Motor Connections:

- Connect the motor terminals to

OUT1andOUT2for Motor A, andOUT3andOUT4for Motor B.

- Connect the motor terminals to

Control Pins:

- Use

IN1andIN2to control the direction of Motor A. - Use

IN3andIN4to control the direction of Motor B. - Use

ENAandENBfor enabling/disabling motors or for speed control via PWM.

- Use

Direction Control Logic:

- Set

IN1HIGH andIN2LOW to rotate Motor A in one direction. - Set

IN1LOW andIN2HIGH to rotate Motor A in the opposite direction. - Similarly, use

IN3andIN4for Motor B.

- Set

Speed Control:

- Connect a PWM signal to

ENA(for Motor A) orENB(for Motor B) to control speed.

- Connect a PWM signal to

Important Considerations:

- Use a heat sink or cooling fan for high-current applications to prevent overheating.

- Ensure the motor power supply voltage matches the motor's rated voltage.

- Avoid exceeding the maximum current rating to prevent damage to the IC.

4. Example Arduino Code

Below is an example of how to control two DC motors using the L298N and an Arduino UNO.

// Define motor control pins

#define ENA 9 // PWM pin for Motor A speed control

#define IN1 8 // Motor A direction control pin 1

#define IN2 7 // Motor A direction control pin 2

#define ENB 10 // PWM pin for Motor B speed control

#define IN3 6 // Motor B direction control pin 1

#define IN4 5 // Motor B direction control pin 2

void setup() {

// Set motor control pins as outputs

pinMode(ENA, OUTPUT);

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

pinMode(ENB, OUTPUT);

pinMode(IN3, OUTPUT);

pinMode(IN4, OUTPUT);

}

void loop() {

// Motor A: Forward at 50% speed

digitalWrite(IN1, HIGH); // Set IN1 HIGH

digitalWrite(IN2, LOW); // Set IN2 LOW

analogWrite(ENA, 128); // Set ENA to 50% duty cycle (128/255)

// Motor B: Reverse at 75% speed

digitalWrite(IN3, LOW); // Set IN3 LOW

digitalWrite(IN4, HIGH); // Set IN4 HIGH

analogWrite(ENB, 192); // Set ENB to 75% duty cycle (192/255)

delay(2000); // Run motors for 2 seconds

// Stop both motors

analogWrite(ENA, 0); // Set ENA to 0% duty cycle (stop Motor A)

analogWrite(ENB, 0); // Set ENB to 0% duty cycle (stop Motor B)

delay(2000); // Wait for 2 seconds

}

5. Troubleshooting and FAQs

Common Issues and Solutions:

Motors Not Running:

- Ensure the power supply is connected and providing sufficient voltage.

- Verify that the

ENAandENBpins are set HIGH or receiving a PWM signal.

Overheating:

- Use a heat sink or cooling fan for high-current applications.

- Check for short circuits or excessive current draw from the motors.

Erratic Motor Behavior:

- Ensure all ground connections are properly connected.

- Verify the logic control signals are correct and stable.

No Speed Control:

- Confirm that the PWM signal is being sent to the

ENAorENBpins. - Check the Arduino code for errors in the

analogWrite()function.

- Confirm that the PWM signal is being sent to the

FAQs:

Q1: Can the L298N drive stepper motors?

Yes, the L298N can drive bipolar stepper motors by controlling the two H-Bridge channels.

Q2: Can I power the Arduino from the L298N module?

Yes, if the module has a 5V regulator, you can use the 5V pin to power the Arduino. Ensure the motor power supply is at least 7V.

Q3: What is the maximum PWM frequency supported?

The L298N supports PWM frequencies up to 20 kHz.

This documentation provides a comprehensive guide to using the L298N Motor Driver H-Bridge. For further details, refer to the official

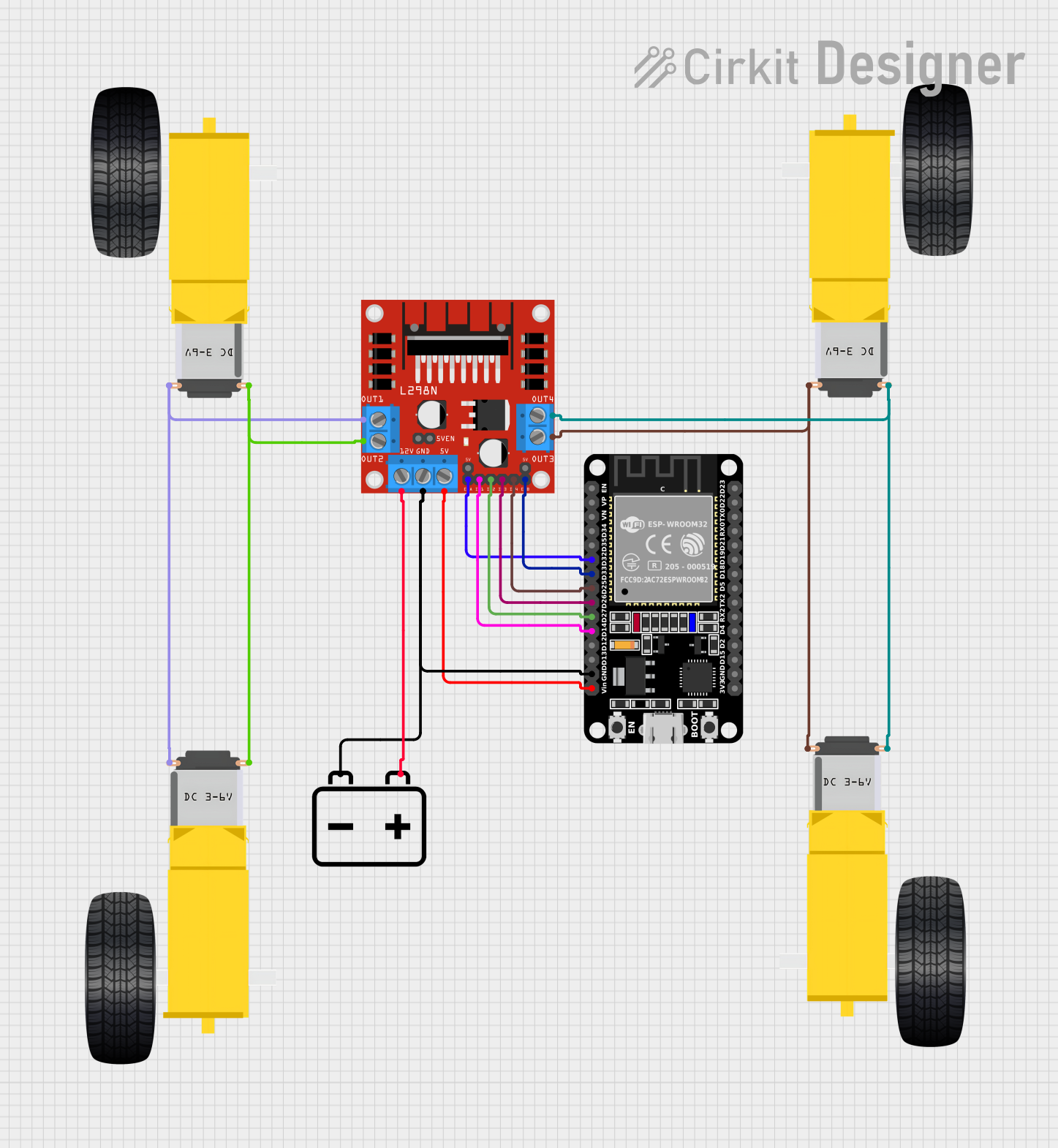

Explore Projects Built with L298N Motor Driver H-Bridge (Motor Driver)

Open Project in Cirkit Designer

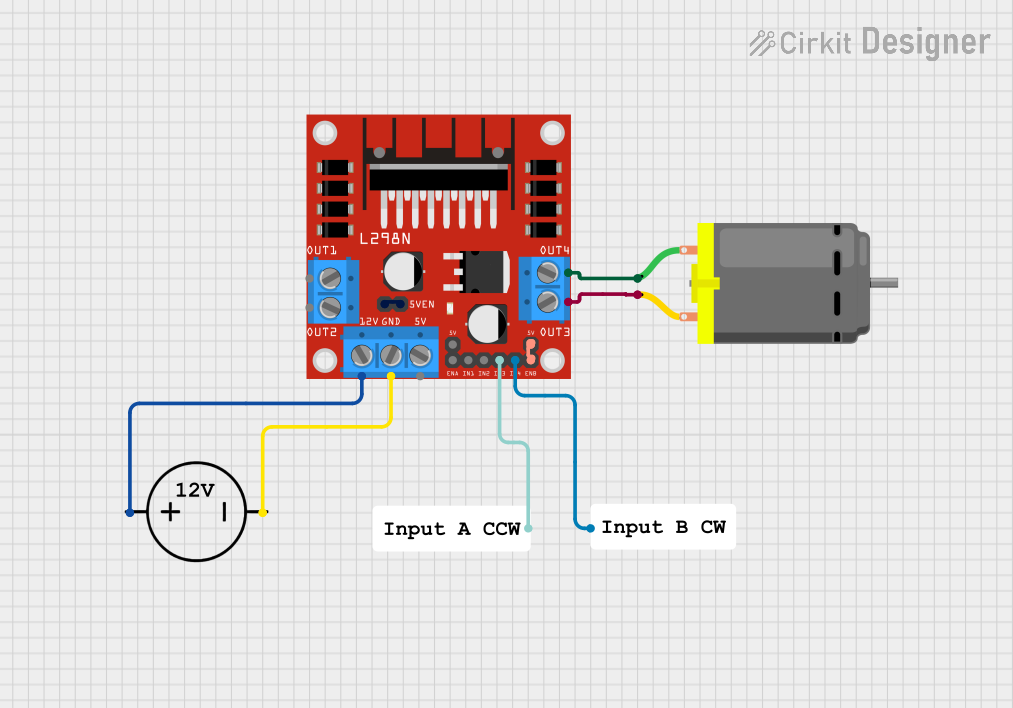

Open Project in Cirkit Designer

Open Project in Cirkit Designer

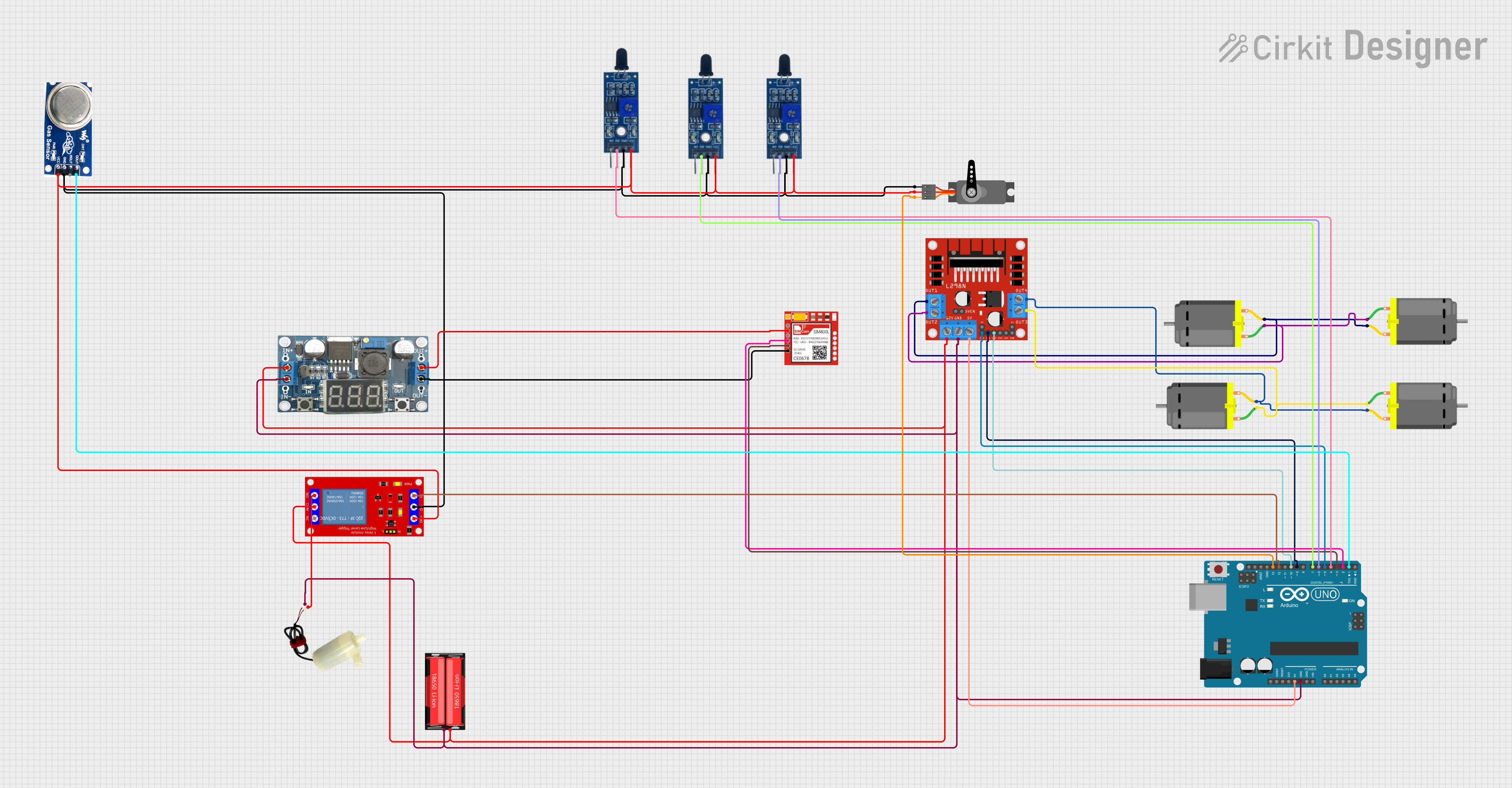

Open Project in Cirkit Designer

Open Project in Cirkit Designer

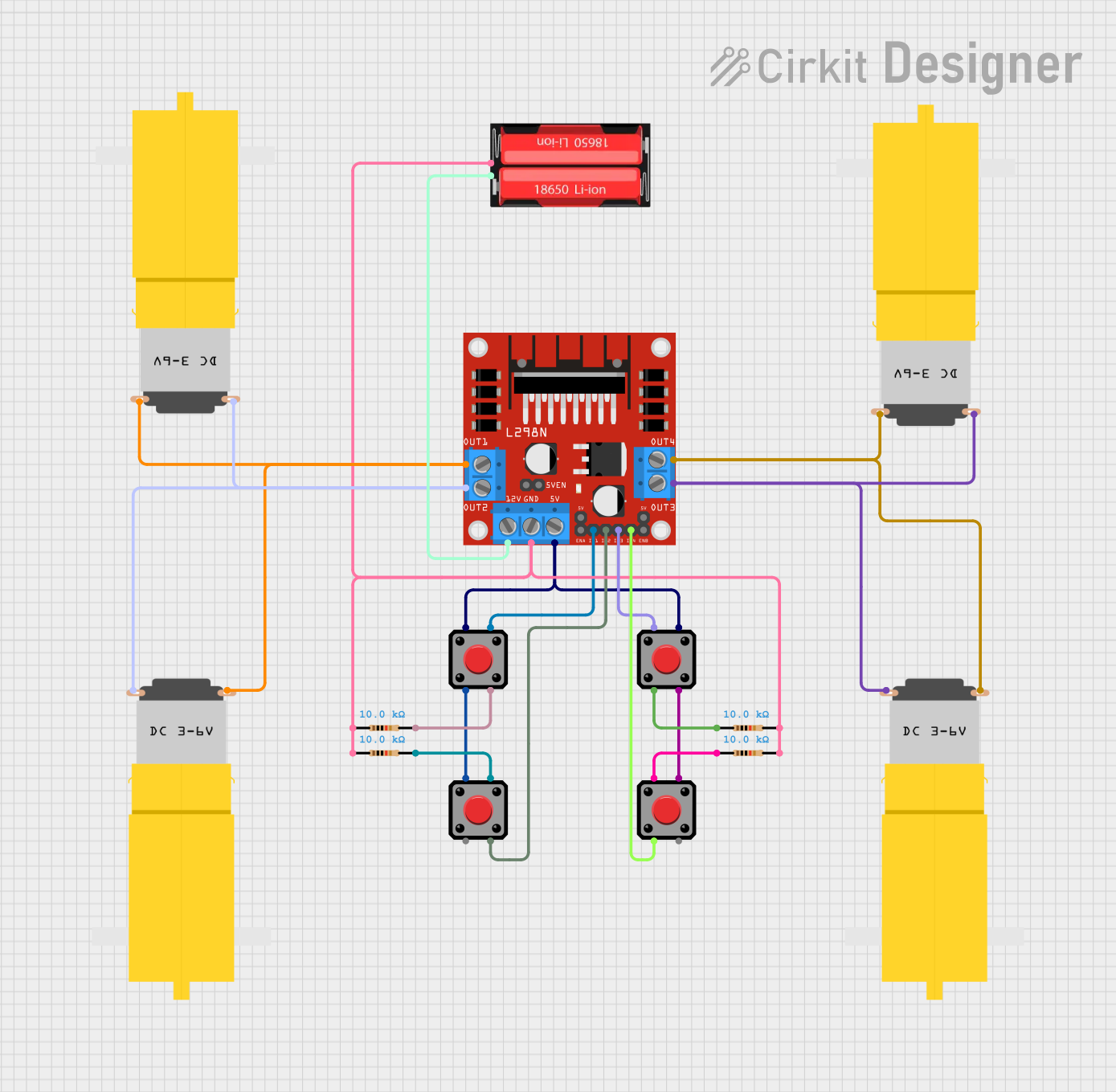

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with L298N Motor Driver H-Bridge (Motor Driver)

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer