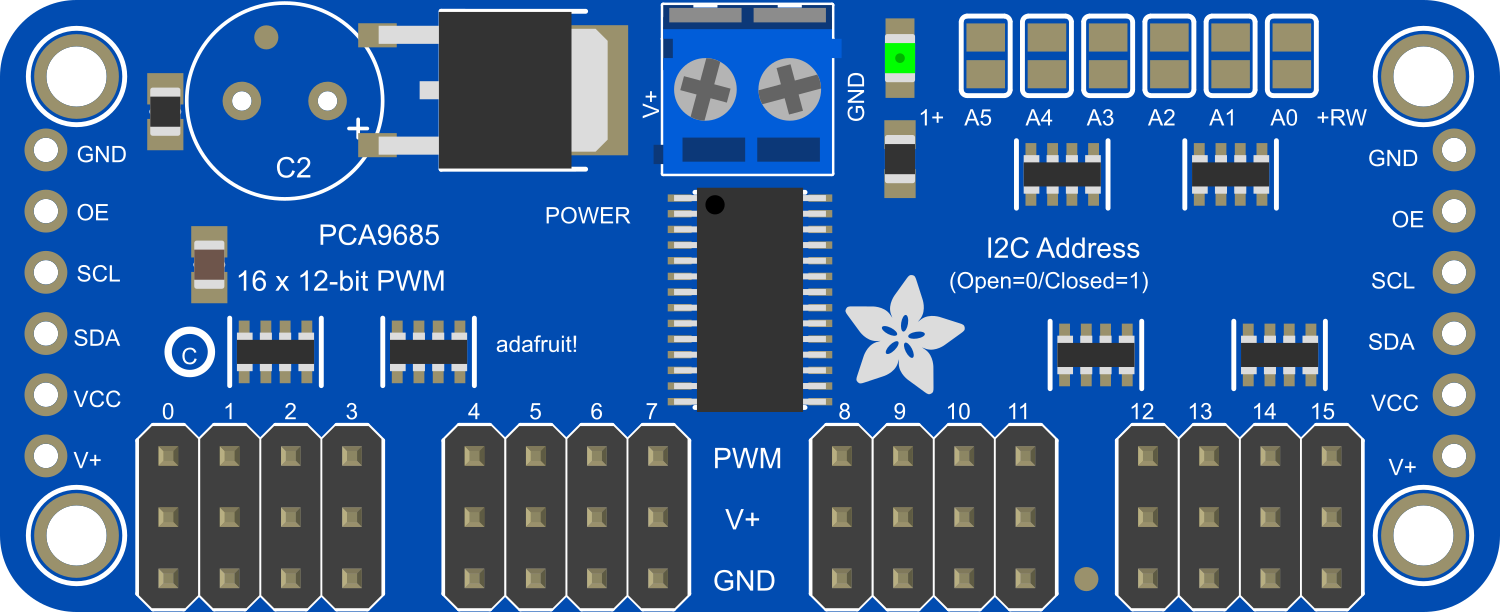

How to Use Adafruit 16-Channel 12-bit PWM Servo Driver - I2C: Examples, Pinouts, and Specs

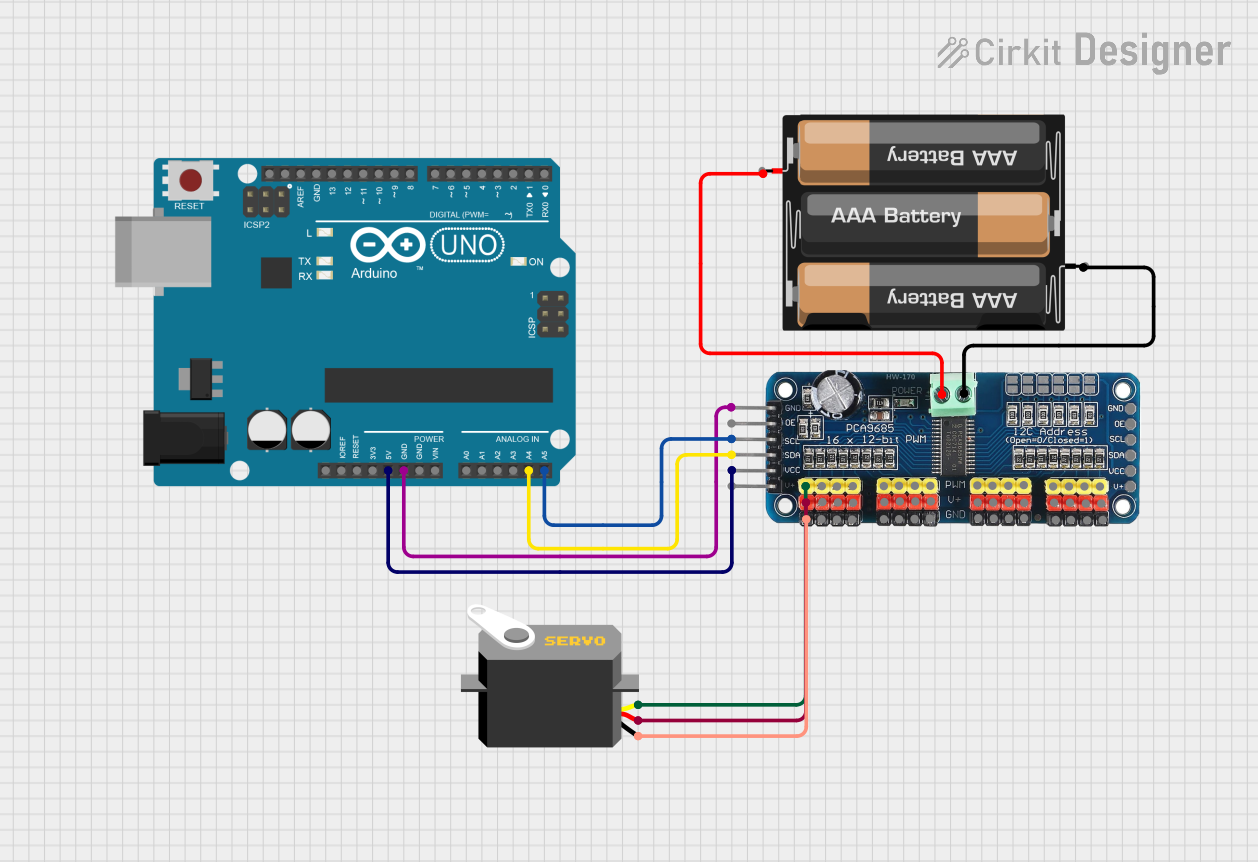

Design with Adafruit 16-Channel 12-bit PWM Servo Driver - I2C in Cirkit Designer

Design with Adafruit 16-Channel 12-bit PWM Servo Driver - I2C in Cirkit DesignerIntroduction

The Adafruit 16-Channel 12-bit PWM Servo Driver is an essential tool for hobbyists and engineers alike, enabling the control of up to 16 servos with precision and ease. Utilizing the I2C communication protocol, this driver board minimizes pin usage on a microcontroller, such as an Arduino UNO, by requiring only two pins for control. It is ideal for robotics, automation projects, and any application where multiple PWM outputs are needed, such as LED lighting control.

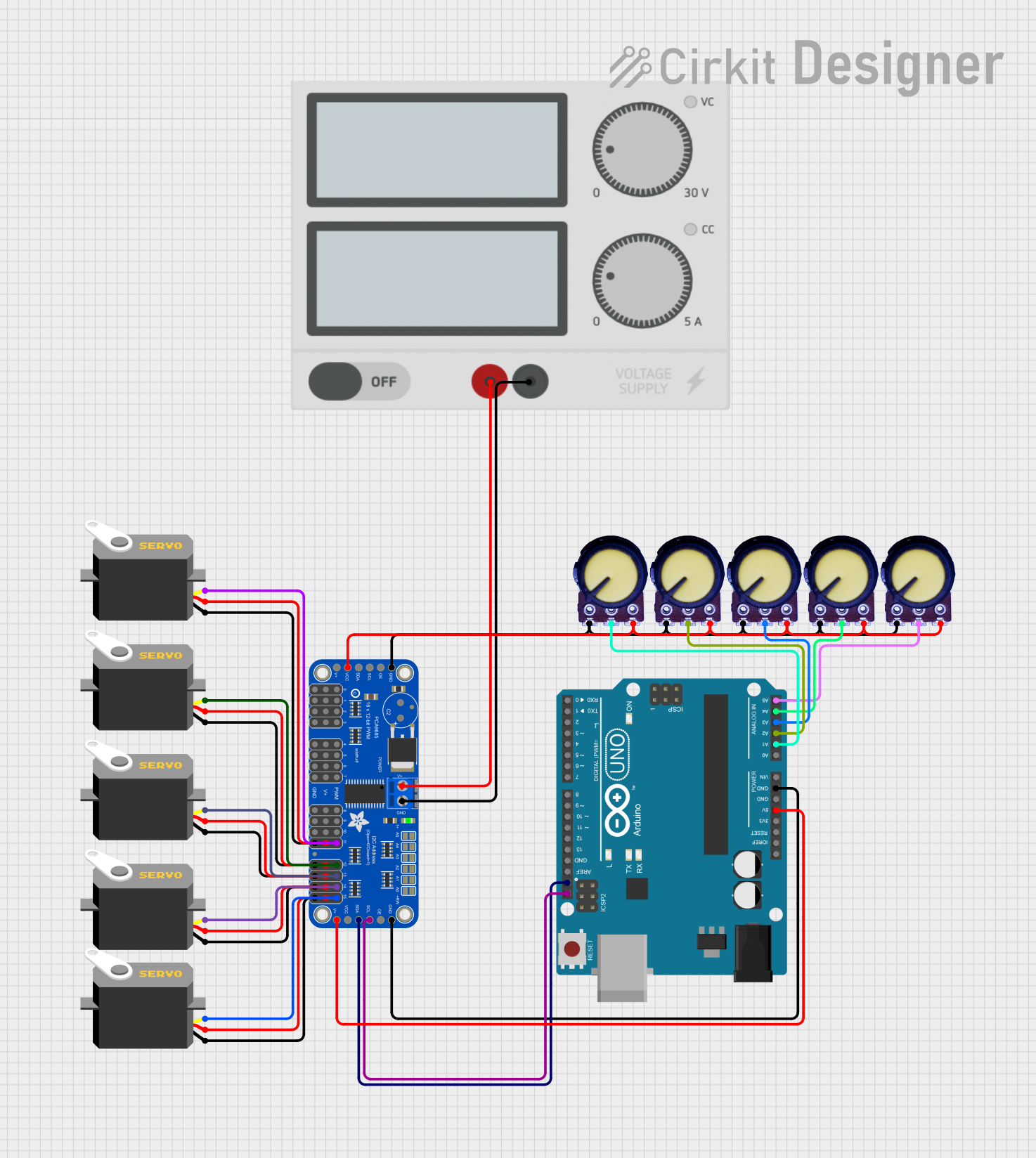

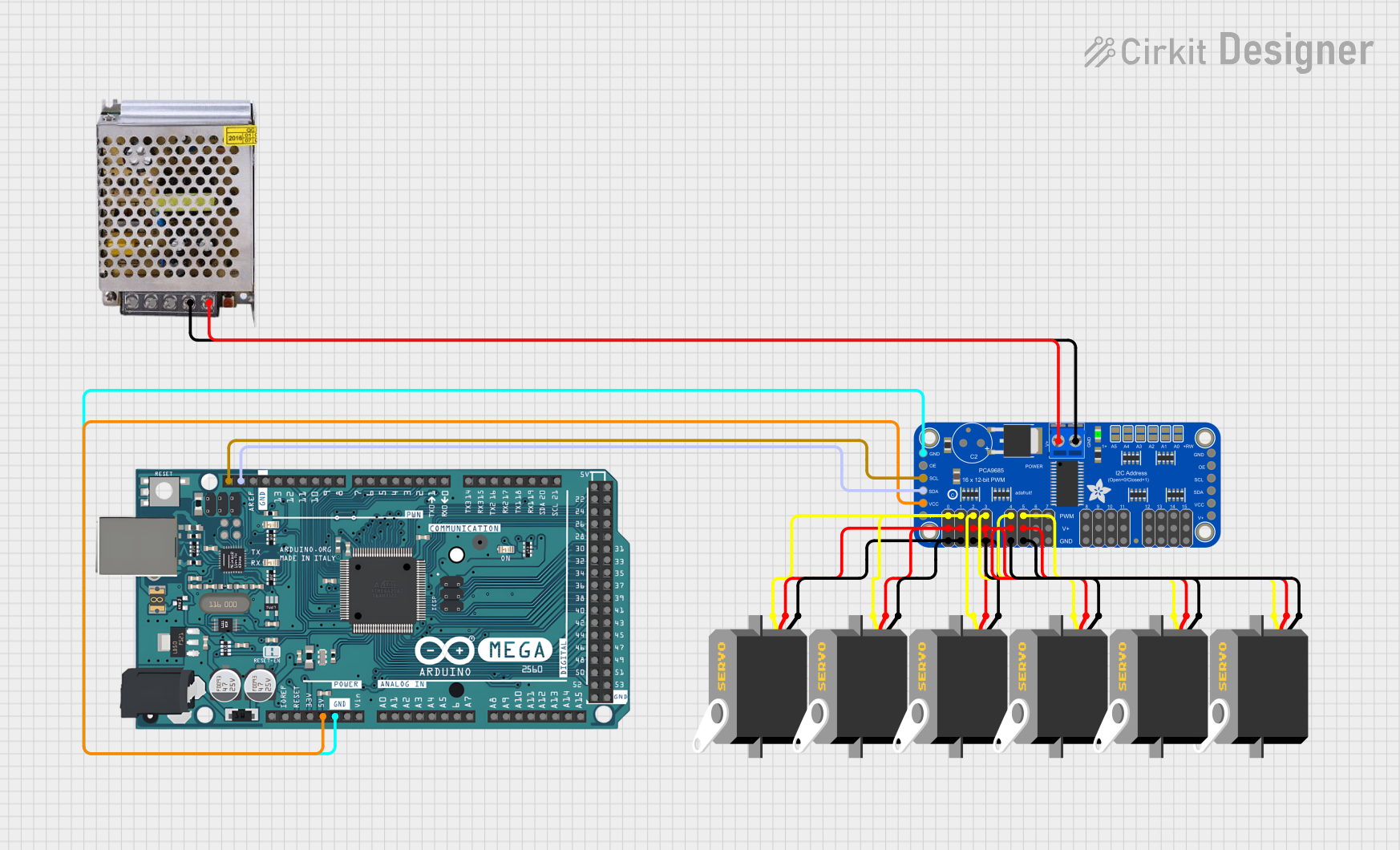

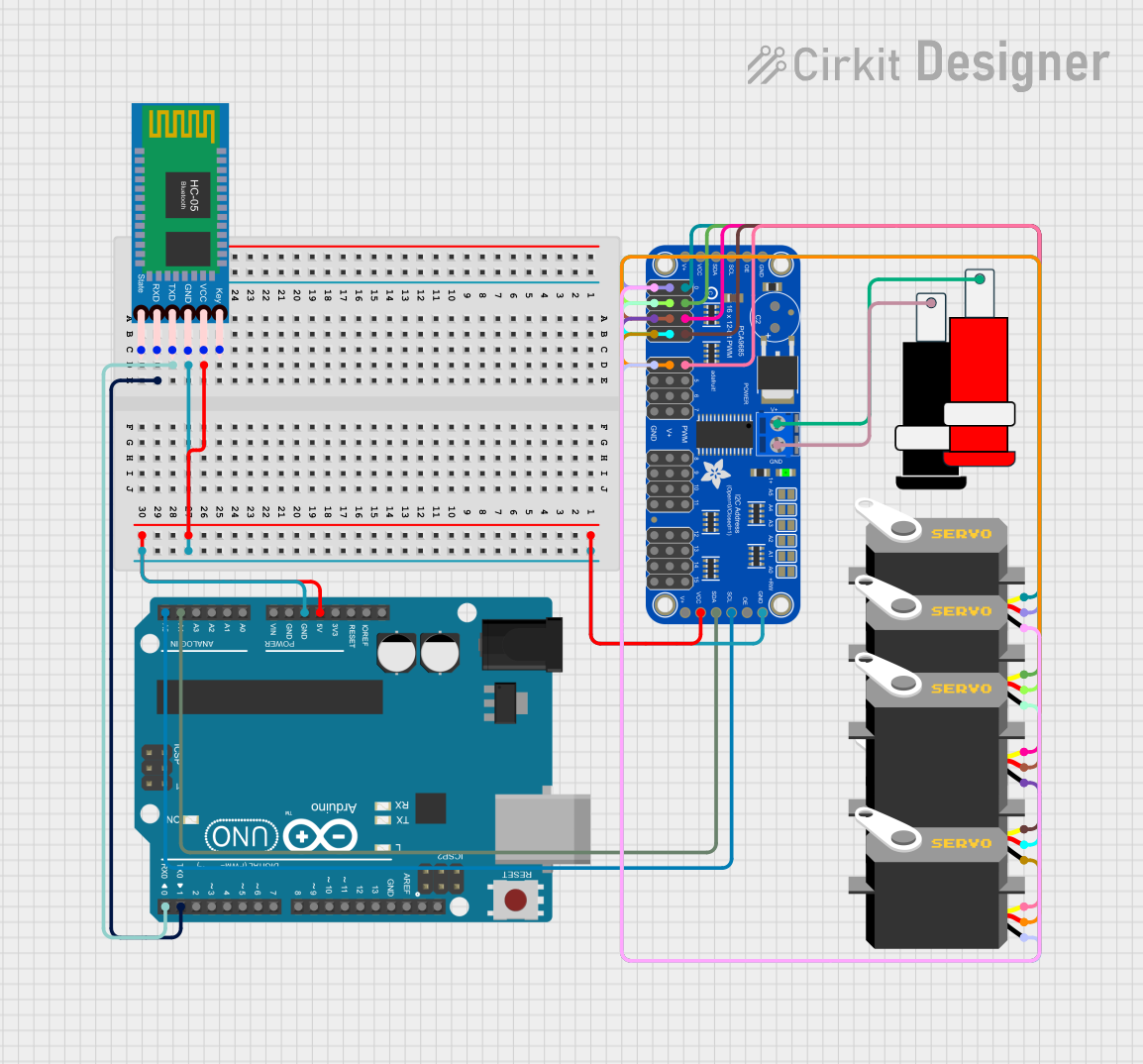

Explore Projects Built with Adafruit 16-Channel 12-bit PWM Servo Driver - I2C

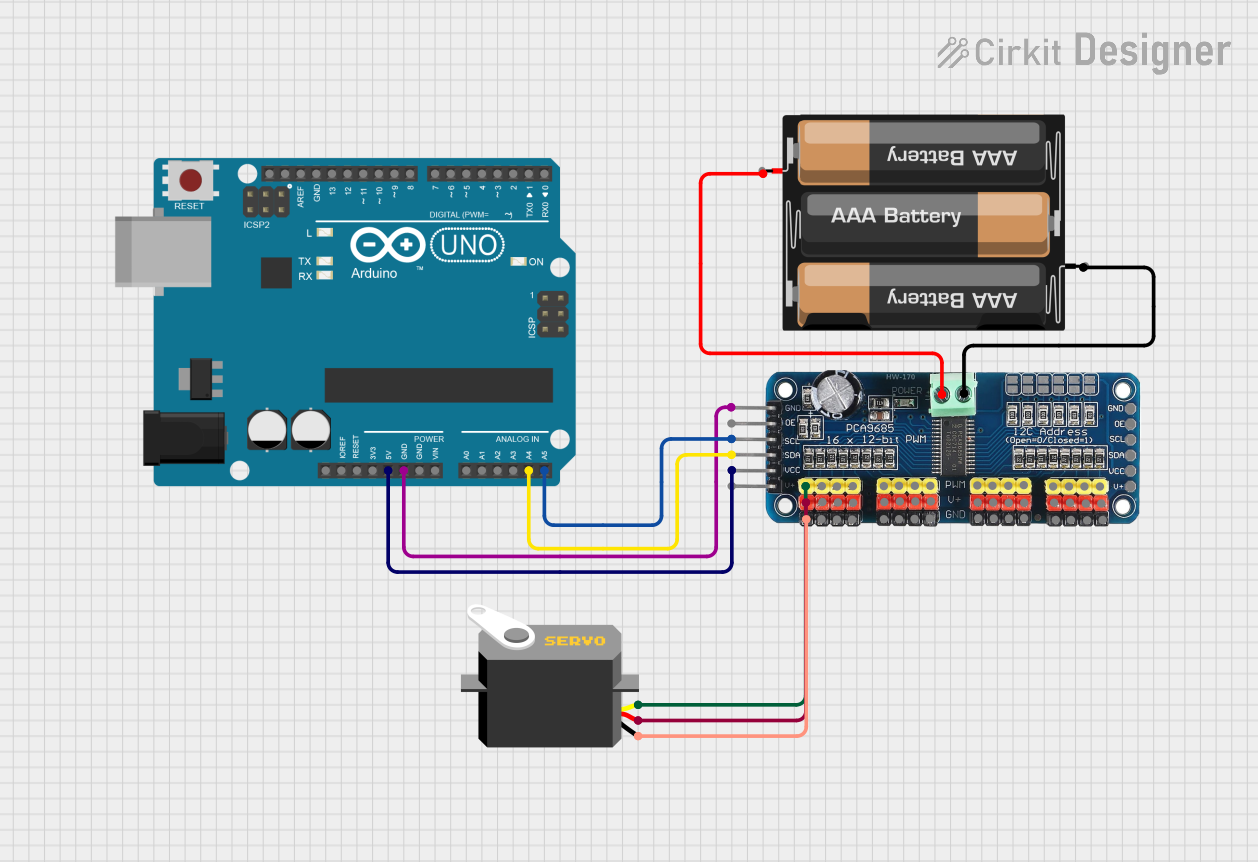

Open Project in Cirkit Designer

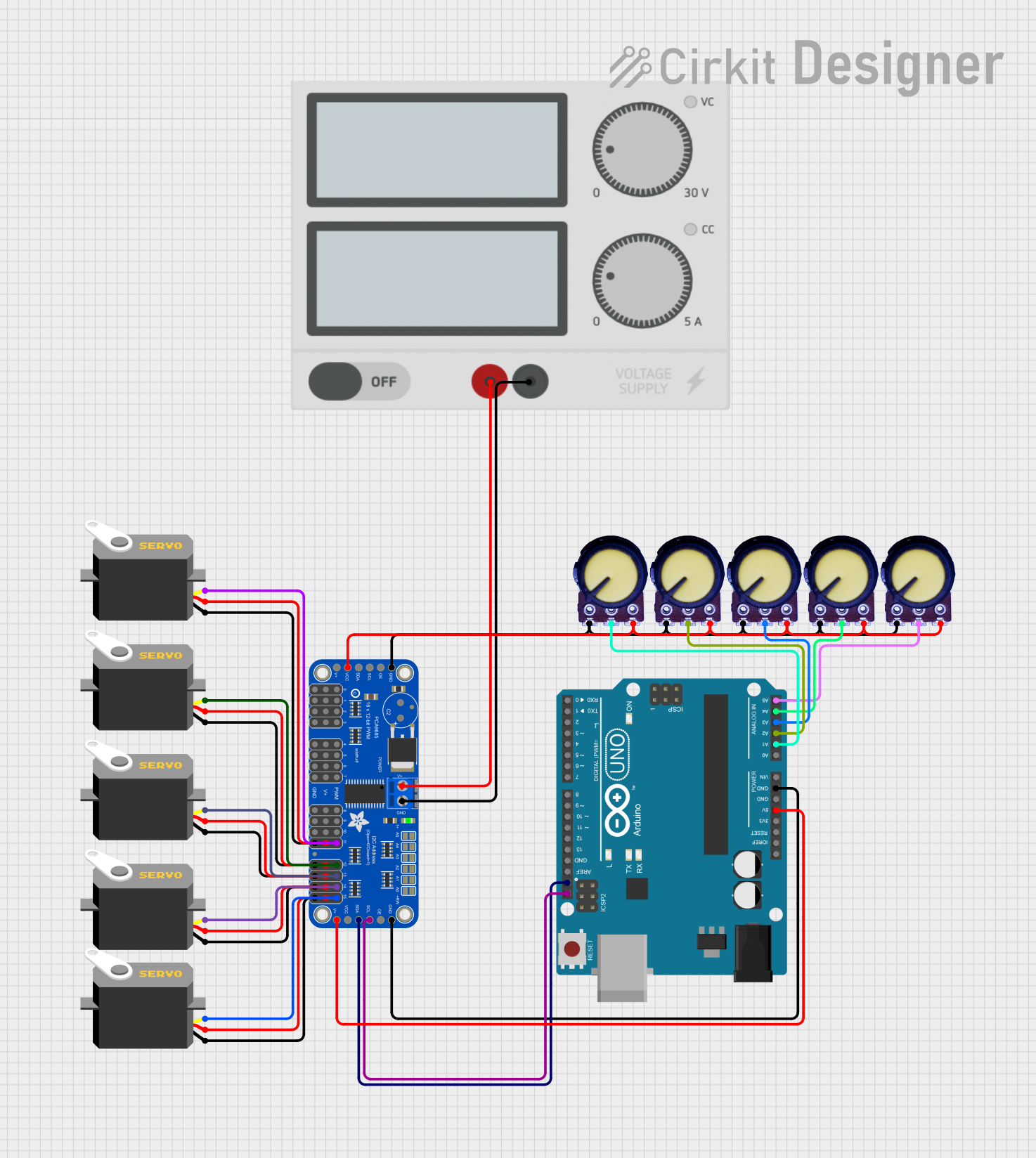

Open Project in Cirkit Designer

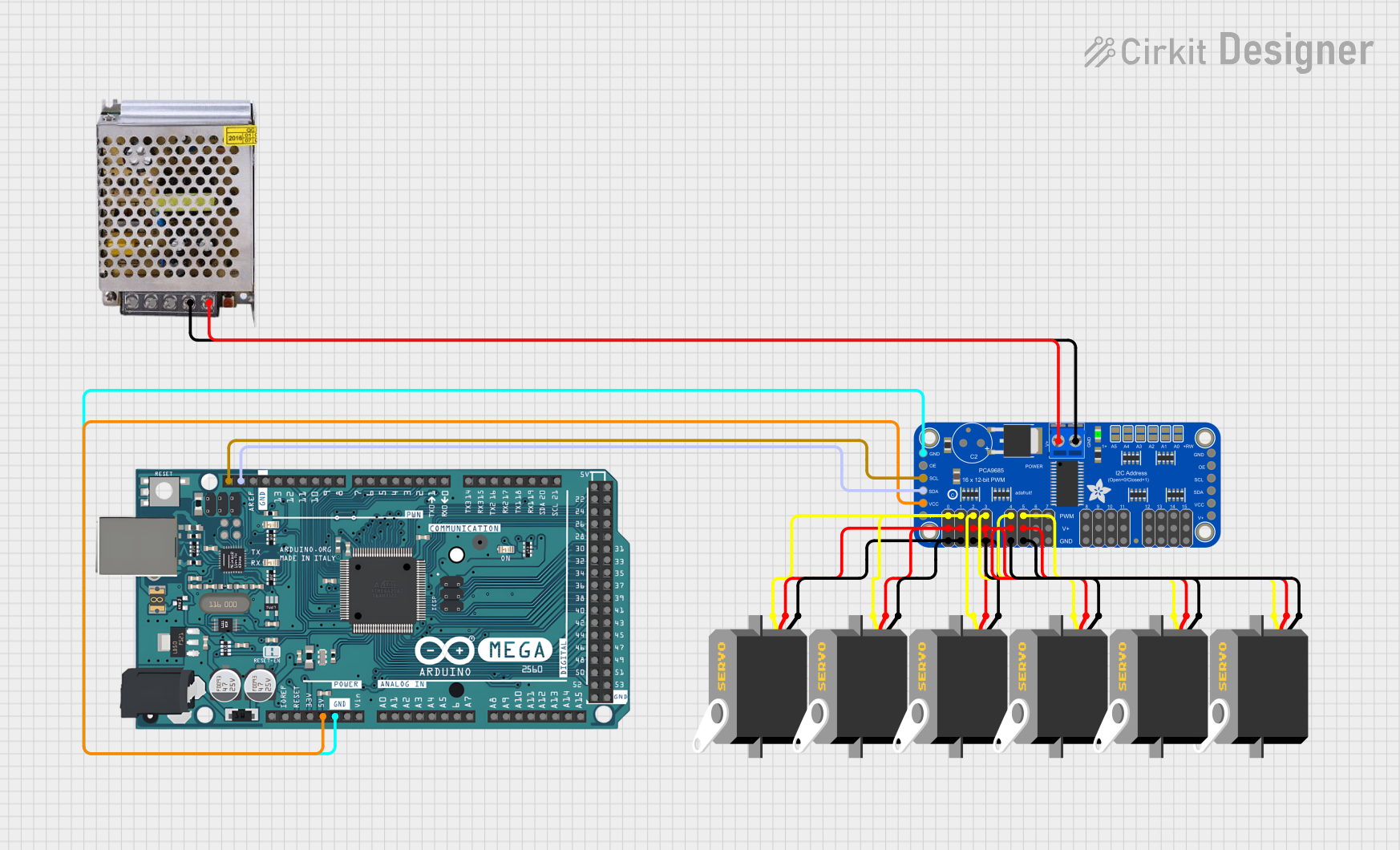

Open Project in Cirkit Designer

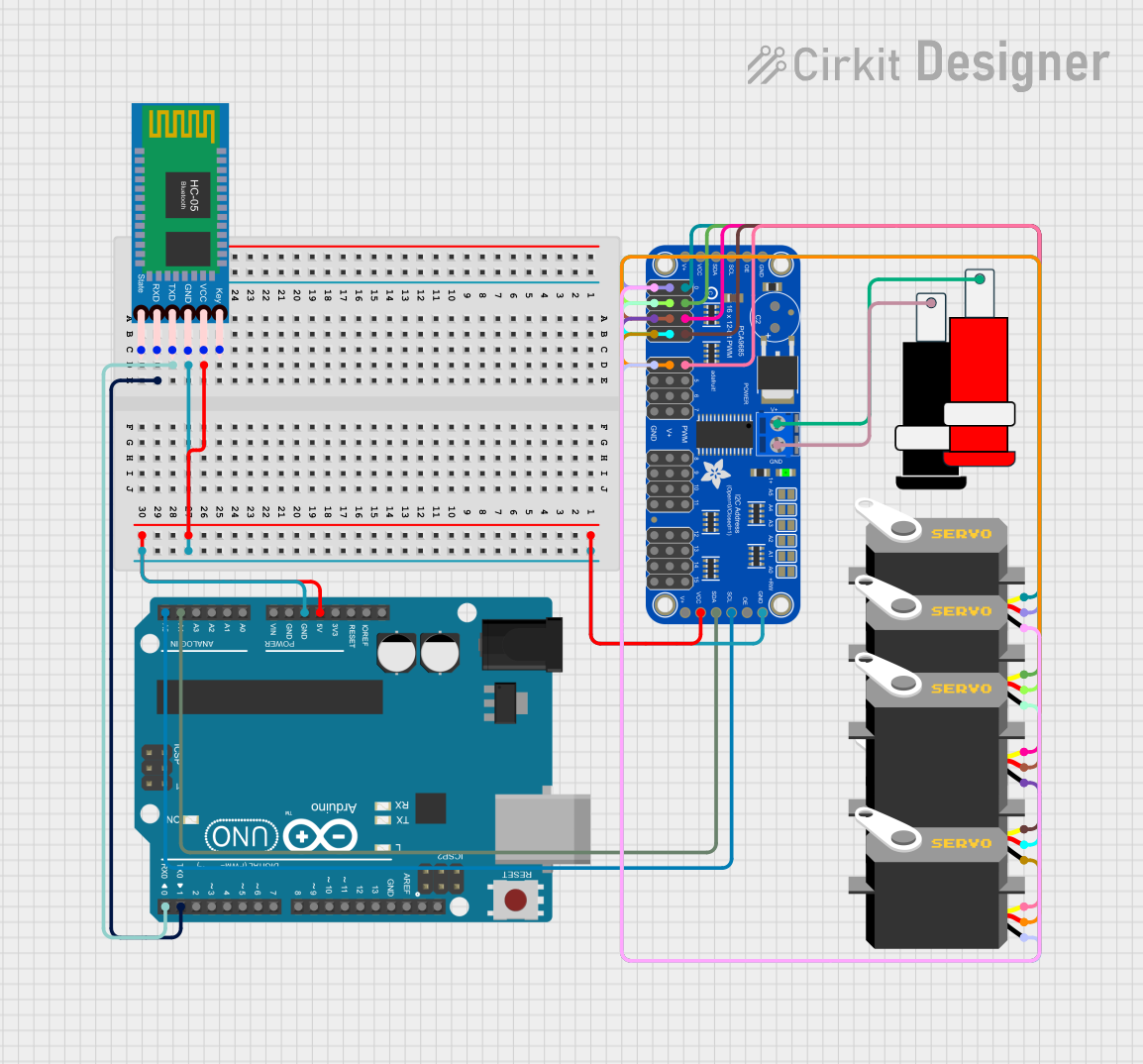

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Adafruit 16-Channel 12-bit PWM Servo Driver - I2C

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Features

- Channels: 16 PWM outputs

- Resolution: 12-bit (4096 steps)

- Frequency: 40Hz to 1000Hz PWM

- Voltage: 5V to 6V for V+ (Servo Power Supply)

- Logic Voltage: 3.3V or 5V compatible

- Interface: I2C

- Dimensions: 62.5mm x 25.4mm x 3mm / 2.5" x 1.0" x 0.1"

Pin Configuration and Descriptions

| Pin Number | Name | Description |

|---|---|---|

| 1 | GND | Ground connection |

| 2 | VCC | Logic power supply (3.3V to 5V) |

| 3 | SDA | I2C Data Line |

| 4 | SCL | I2C Clock Line |

| 5-20 | PWM0 to PWM15 | PWM output to servos |

| 21 | OE | Output enable (active low) |

| 22 | OUTDRV | Output driver mode (totem pole/ open-drain) |

| 23 | V+ | Servo power supply (5V to 6V) |

Usage Instructions

Connecting to an Arduino UNO

- Connect

GNDon the driver to the Arduino's ground. - Connect

VCCto the Arduino's 5V pin. - Connect

SDAto the Arduino's A4 (SDA) pin. - Connect

SCLto the Arduino's A5 (SCL) pin. - Connect

V+to an external 5V to 6V power supply. - Connect your servos to the PWM outputs (PWM0 to PWM15).

Library Installation

Before using the driver with an Arduino, install the Adafruit PWM Servo Driver library via the Library Manager in the Arduino IDE.

Example Code

#include <Wire.h>

#include <Adafruit_PWMServoDriver.h>

// Initialize the PWM driver

Adafruit_PWMServoDriver pwm = Adafruit_PWMServoDriver();

void setup() {

pwm.begin();

pwm.setPWMFreq(60); // Set the frequency to 60 Hz

}

void loop() {

// Example: Turn servo on channel 0 to the middle position

pwm.setPWM(0, 0, 2048);

delay(1000);

// Turn servo on channel 0 to the minimum position

pwm.setPWM(0, 0, 409);

delay(1000);

// Turn servo on channel 0 to the maximum position

pwm.setPWM(0, 0, 3687);

delay(1000);

}

Important Considerations and Best Practices

- Ensure that the external power supply for

V+is capable of providing sufficient current for all connected servos. - Do not exceed the recommended voltage range for

V+. - Use a separate power supply for the servos to prevent noise and voltage drops on the logic side.

- Always use common ground for the Arduino, driver board, and external power supply.

Troubleshooting and FAQs

Common Issues

- Servos not responding: Check connections, ensure that the I2C address is correct, and that the external power supply is properly connected and turned on.

- Inaccurate servo movement: Verify that the PWM frequency and pulse widths are set correctly for your specific servos.

- Noise or erratic behavior: Ensure that the power supply is adequate and that there is a common ground.

FAQs

Q: Can I chain multiple boards together? A: Yes, you can chain up to 62 boards for a total of 992 PWM outputs. Set unique I2C addresses for each board using the address jumpers.

Q: What is the maximum number of servos I can control with one board? A: You can control up to 16 servos per board.

Q: Do I need to use an external power supply for the servos? A: Yes, an external power supply is necessary to provide sufficient current for the servos without affecting the microcontroller's operation.

Q: Can I use this board with a Raspberry Pi or other microcontrollers? A: Absolutely, as long as the device supports I2C communication, you can use this board with it.

For further assistance, consult the Adafruit support forums or the product's official documentation.