Cirkit Designer

Your all-in-one circuit design IDE

Home /

Component Documentation

How to Use Stepper Motor (Unipolar): Examples, Pinouts, and Specs

Design with Stepper Motor (Unipolar) in Cirkit Designer

Design with Stepper Motor (Unipolar) in Cirkit DesignerIntroduction

A unipolar stepper motor is a type of electric motor that divides a full rotation into a series of discrete steps. It is called 'unipolar' because of the way the coils are wired, allowing for simpler driving circuitry. Stepper motors are commonly used in precision positioning devices like 3D printers, CNC machines, and robotics due to their ability to accurately control motion.

Explore Projects Built with Stepper Motor (Unipolar)

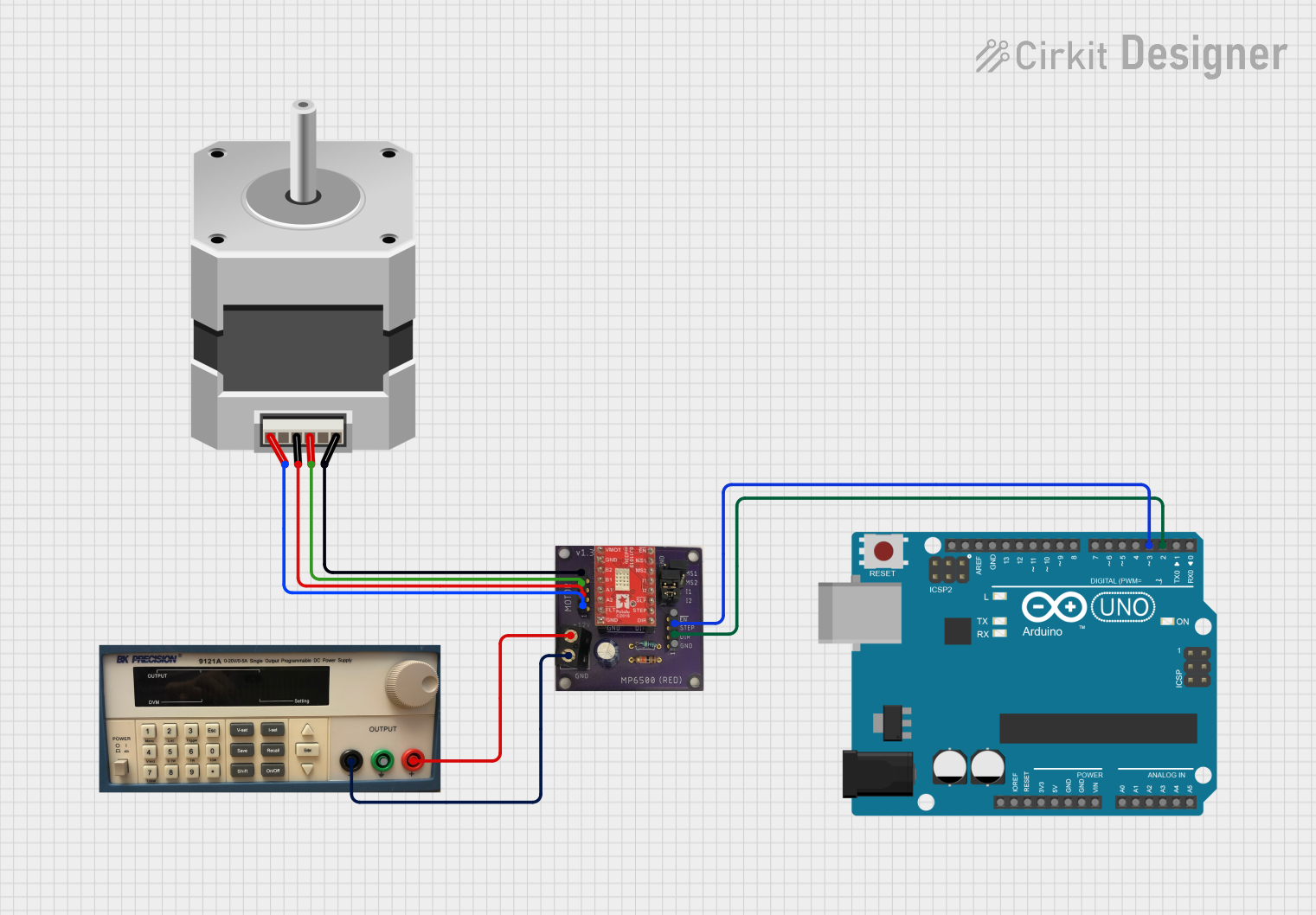

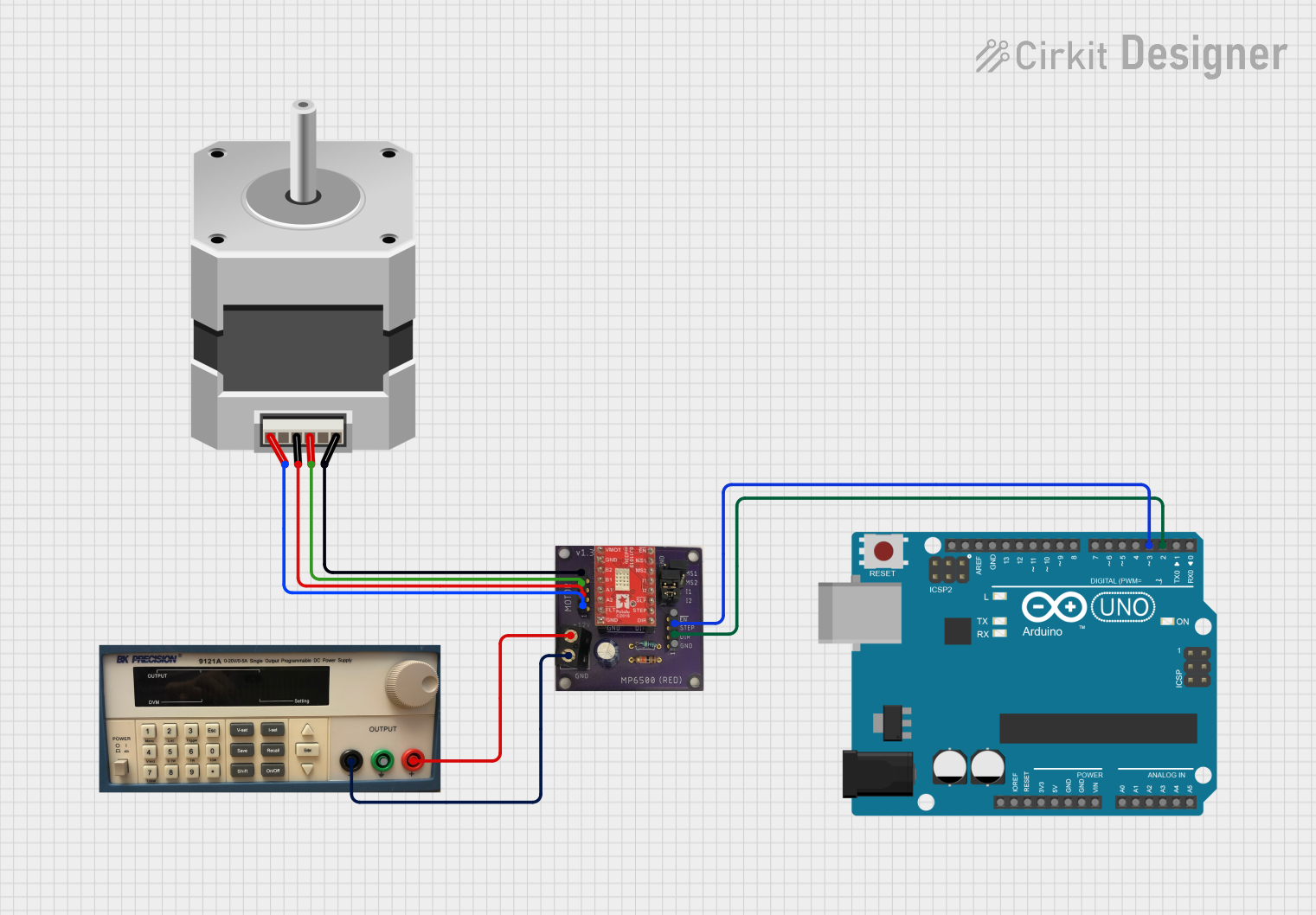

Arduino-Controlled Bipolar Stepper Motor with MP6500 Driver

This circuit controls a bipolar stepper motor using an Arduino UNO and an MP6500 stepper motor driver. The Arduino generates step and direction signals to the driver, which in turn powers the motor coils to create precise rotational movements. The motor's rotation direction and step count are programmable, allowing for controlled positioning in applications such as robotics or CNC machines.

Open Project in Cirkit Designer

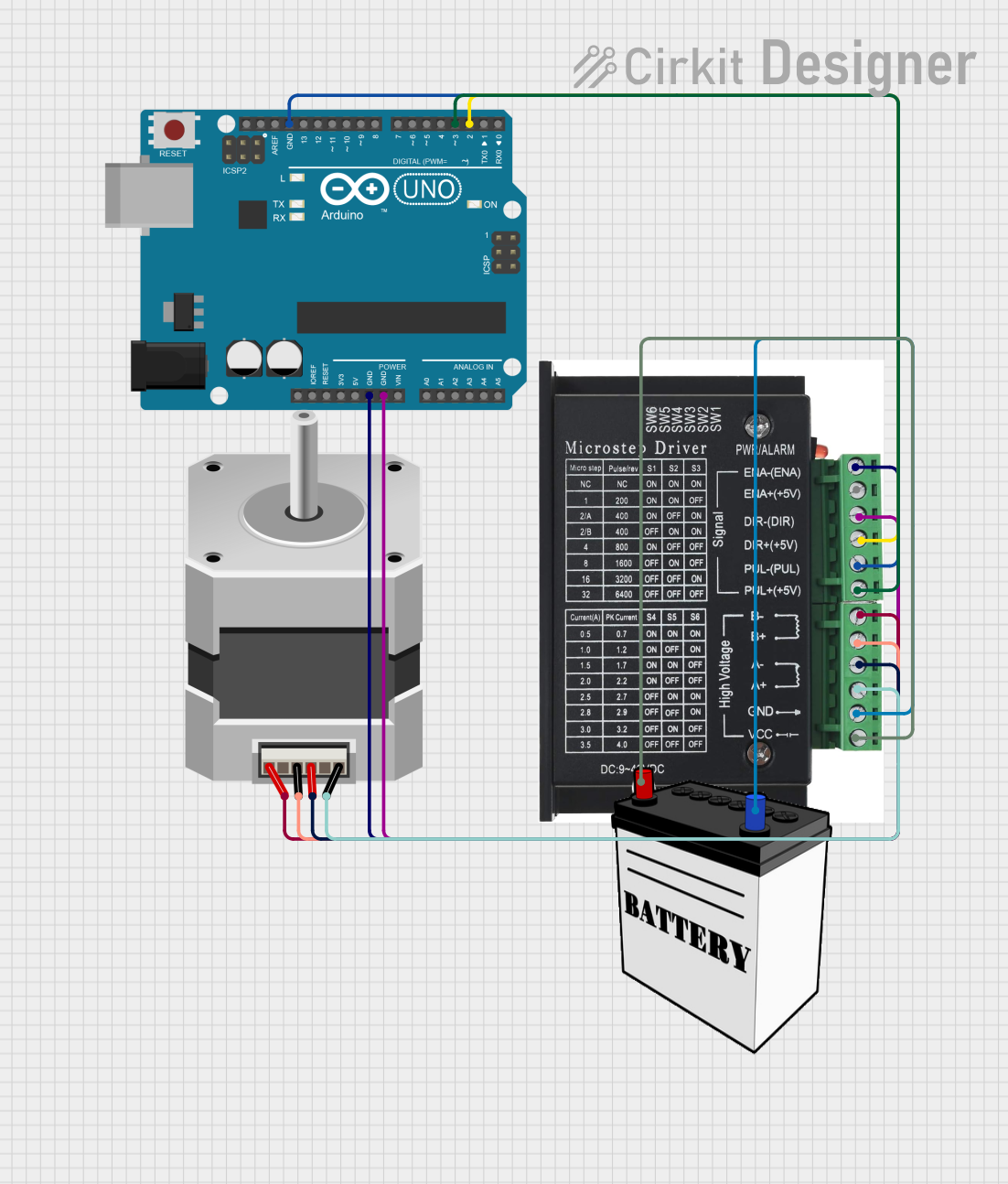

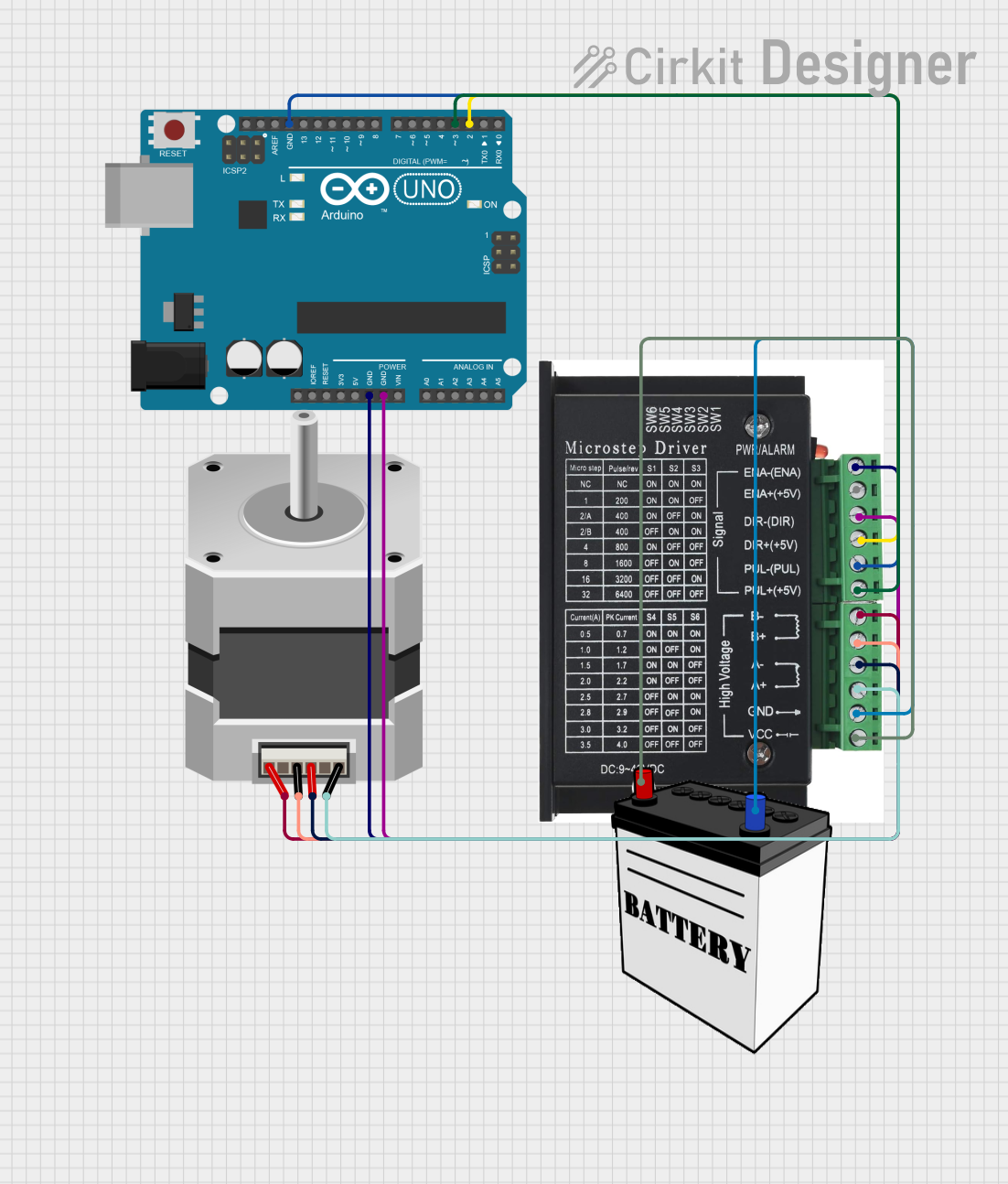

Open Project in Cirkit DesignerArduino-Controlled Bipolar Stepper Motor with 12V Battery Power

This circuit controls a bipolar stepper motor using an Arduino UNO and a dedicated stepper motor driver. The Arduino generates pulse (step) and direction signals to the driver, which in turn powers the motor coils to rotate the motor in precise increments. The circuit is powered by a 12V battery, and the embedded code on the Arduino allows for the motor to rotate 180 degrees in one direction and then back in the opposite direction.

Open Project in Cirkit Designer

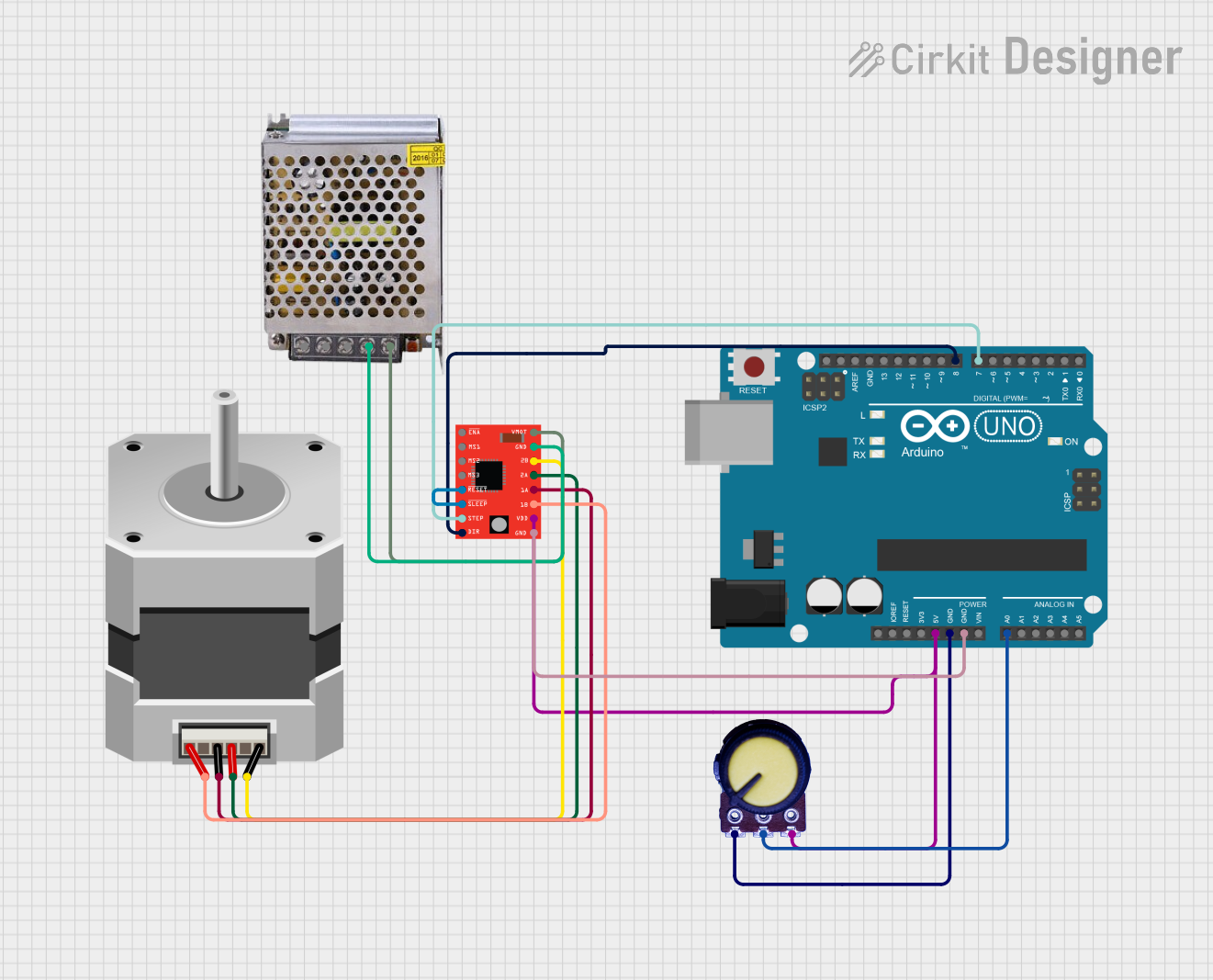

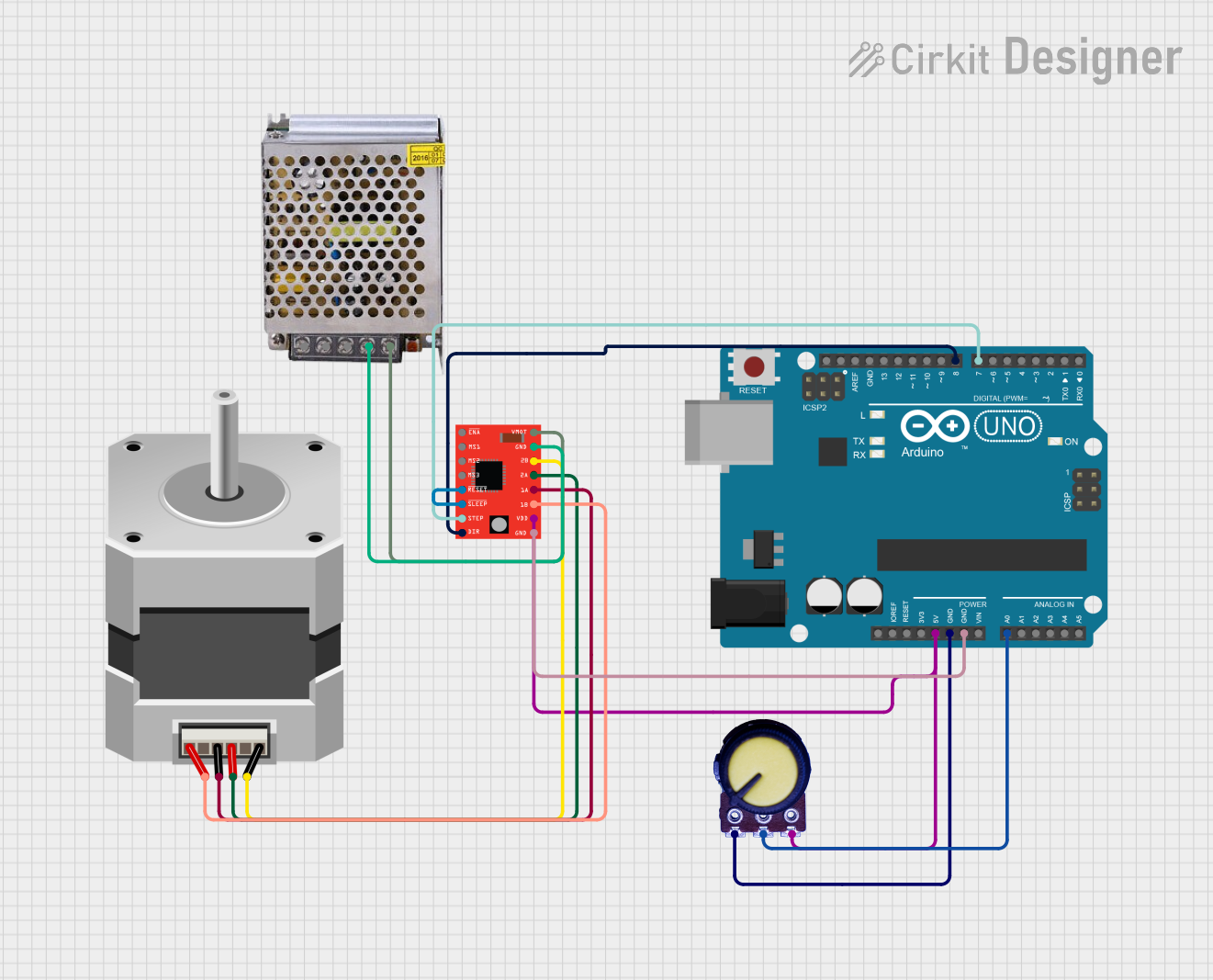

Open Project in Cirkit DesignerArduino-Controlled Bipolar Stepper Motor with A4988 Driver

This circuit controls a bipolar stepper motor using an A4988 stepper motor driver, which is interfaced with an Arduino UNO microcontroller. The Arduino provides control signals for the direction (DIR) and stepping (STEP) of the motor, while a potentiometer connected to an analog input (A0) may be used for speed or position feedback. The motor driver is powered by a 12V power supply, and the RESET and SLEEP pins of the driver are connected together, likely to enable the motor driver to operate immediately upon power-up.

Open Project in Cirkit Designer

Open Project in Cirkit DesignerArduino-Controlled Stepper Motor with Potentiometer Feedback

This circuit controls a bipolar stepper motor using an Arduino UNO and an SN754410 quadruple half-H driver. The Arduino adjusts the motor's position based on the input from a rotary potentiometer, allowing for precise control of the stepper motor's steps. The motor's power is supplied through a 2.1mm barrel jack connected to the driver's motor supply pin.

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Stepper Motor (Unipolar)

Arduino-Controlled Bipolar Stepper Motor with MP6500 Driver

This circuit controls a bipolar stepper motor using an Arduino UNO and an MP6500 stepper motor driver. The Arduino generates step and direction signals to the driver, which in turn powers the motor coils to create precise rotational movements. The motor's rotation direction and step count are programmable, allowing for controlled positioning in applications such as robotics or CNC machines.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Arduino-Controlled Bipolar Stepper Motor with 12V Battery Power

This circuit controls a bipolar stepper motor using an Arduino UNO and a dedicated stepper motor driver. The Arduino generates pulse (step) and direction signals to the driver, which in turn powers the motor coils to rotate the motor in precise increments. The circuit is powered by a 12V battery, and the embedded code on the Arduino allows for the motor to rotate 180 degrees in one direction and then back in the opposite direction.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Arduino-Controlled Bipolar Stepper Motor with A4988 Driver

This circuit controls a bipolar stepper motor using an A4988 stepper motor driver, which is interfaced with an Arduino UNO microcontroller. The Arduino provides control signals for the direction (DIR) and stepping (STEP) of the motor, while a potentiometer connected to an analog input (A0) may be used for speed or position feedback. The motor driver is powered by a 12V power supply, and the RESET and SLEEP pins of the driver are connected together, likely to enable the motor driver to operate immediately upon power-up.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Arduino-Controlled Stepper Motor with Potentiometer Feedback

This circuit controls a bipolar stepper motor using an Arduino UNO and an SN754410 quadruple half-H driver. The Arduino adjusts the motor's position based on the input from a rotary potentiometer, allowing for precise control of the stepper motor's steps. The motor's power is supplied through a 2.1mm barrel jack connected to the driver's motor supply pin.

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Precision control in robotics

- Positioning in 3D printers

- Movement control in CNC machines

- Automated equipment in manufacturing

Technical Specifications

Key Technical Details

- Step Angle: The angle covered in one step (e.g., 1.8 degrees)

- Voltage Rating: The rated voltage for optimal performance (e.g., 5V)

- Current Rating: The maximum current per phase (e.g., 500mA)

- Resistance: The resistance per phase (e.g., 100 ohms)

- Number of Phases: Typically 4 for unipolar motors

- Holding Torque: The torque when the motor is stationary and powered (e.g., 0.3 Nm)

Pin Configuration and Descriptions

| Pin Number | Description | Color (Typical) |

|---|---|---|

| 1 | Coil 1 Start (A) | Red |

| 2 | Coil 1 End (A') | Yellow |

| 3 | Coil 2 Start (B) | White |

| 4 | Coil 2 End (B') | Blue |

| 5 | Common Wire 1 | Orange |

| 6 | Common Wire 2 | Black |

Usage Instructions

How to Use the Component in a Circuit

- Connect the Coils: Connect the coil start and end pins to the motor driver outputs.

- Power Supply: Ensure the power supply matches the voltage rating of the motor.

- Control Signals: Use a microcontroller to send control signals to the motor driver.

Important Considerations and Best Practices

- Current Limiting: Use a current-limiting driver to prevent damage to the motor.

- Microstepping: For smoother motion, use a driver that supports microstepping.

- Heat Dissipation: Ensure adequate cooling if the motor is operated near its maximum ratings.

Example Code for Arduino UNO

#include <Stepper.h>

// Change these values based on your motor's specifications

const int stepsPerRevolution = 200; // typically 200 steps for a 1.8 degree step angle

const int motorPin1 = 8; // Coil 1 Start (A)

const int motorPin2 = 9; // Coil 1 End (A')

const int motorPin3 = 10; // Coil 2 Start (B)

const int motorPin4 = 11; // Coil 2 End (B')

// Initialize the stepper library

Stepper myStepper(stepsPerRevolution, motorPin1, motorPin3, motorPin2, motorPin4);

void setup() {

// Set the speed in RPMs

myStepper.setSpeed(60);

}

void loop() {

// Step one revolution in one direction:

myStepper.step(stepsPerRevolution);

delay(500);

// Step one revolution in the other direction:

myStepper.step(-stepsPerRevolution);

delay(500);

}

Troubleshooting and FAQs

Common Issues Users Might Face

- Motor Does Not Rotate: Check wiring and ensure the power supply is correctly rated.

- Motor Vibrates but Does Not Turn: This could be due to incorrect sequencing. Check the control signals.

- Motor Gets Hot: Ensure the current is not exceeding the motor's rating. Improve cooling if necessary.

Solutions and Tips for Troubleshooting

- Check Connections: Verify that all connections are secure and correct.

- Test Power Supply: Use a multimeter to ensure the power supply is delivering the correct voltage.

- Review Code: Ensure the stepping sequence in the code matches the motor's requirements.

FAQs

Q: Can I run a unipolar stepper motor with a bipolar driver?

- A: It is possible by not connecting the common wires, but it's not recommended as it may not utilize the motor efficiently.

Q: How do I know if my stepper motor is unipolar or bipolar?

- A: Unipolar motors typically have 5 or 6 wires, while bipolar motors have 4 wires.

Q: What is the purpose of the common wires in a unipolar stepper motor?

- A: The common wires are used to power the coils and are connected to the positive supply voltage.

Remember to always refer to the specific datasheet of your stepper motor model for precise information and ratings.