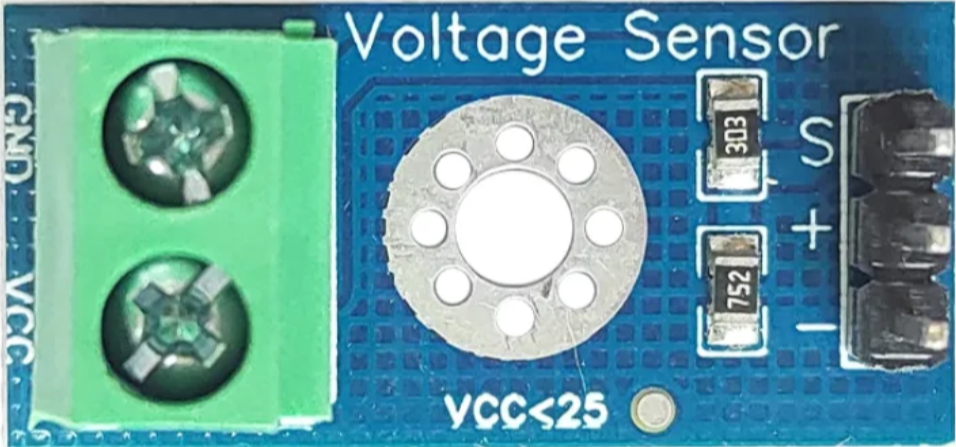

How to Use Voltage Sensor DC 25V: Examples, Pinouts, and Specs

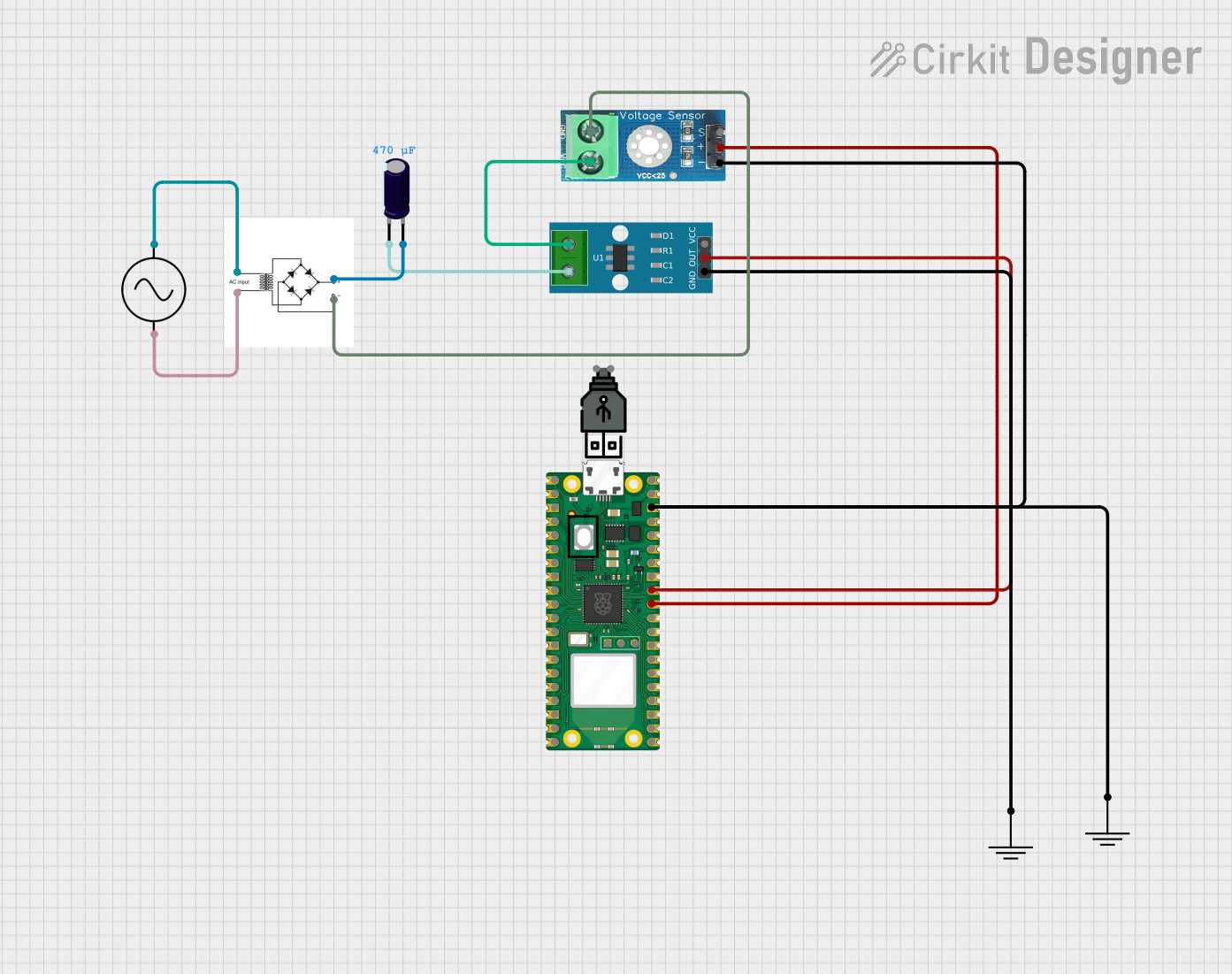

Design with Voltage Sensor DC 25V in Cirkit Designer

Design with Voltage Sensor DC 25V in Cirkit DesignerIntroduction

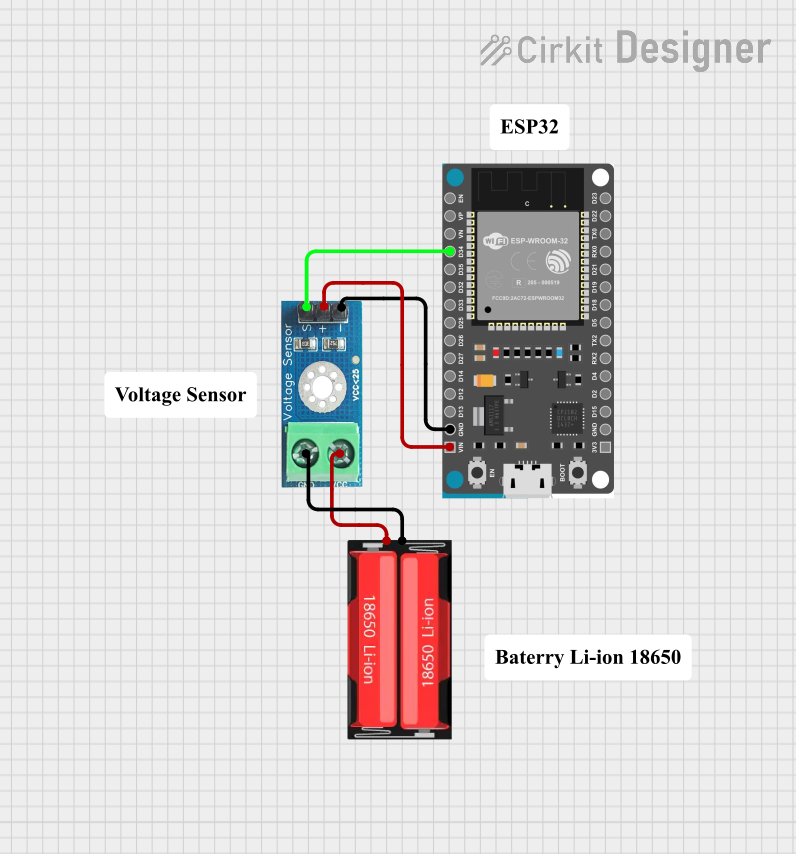

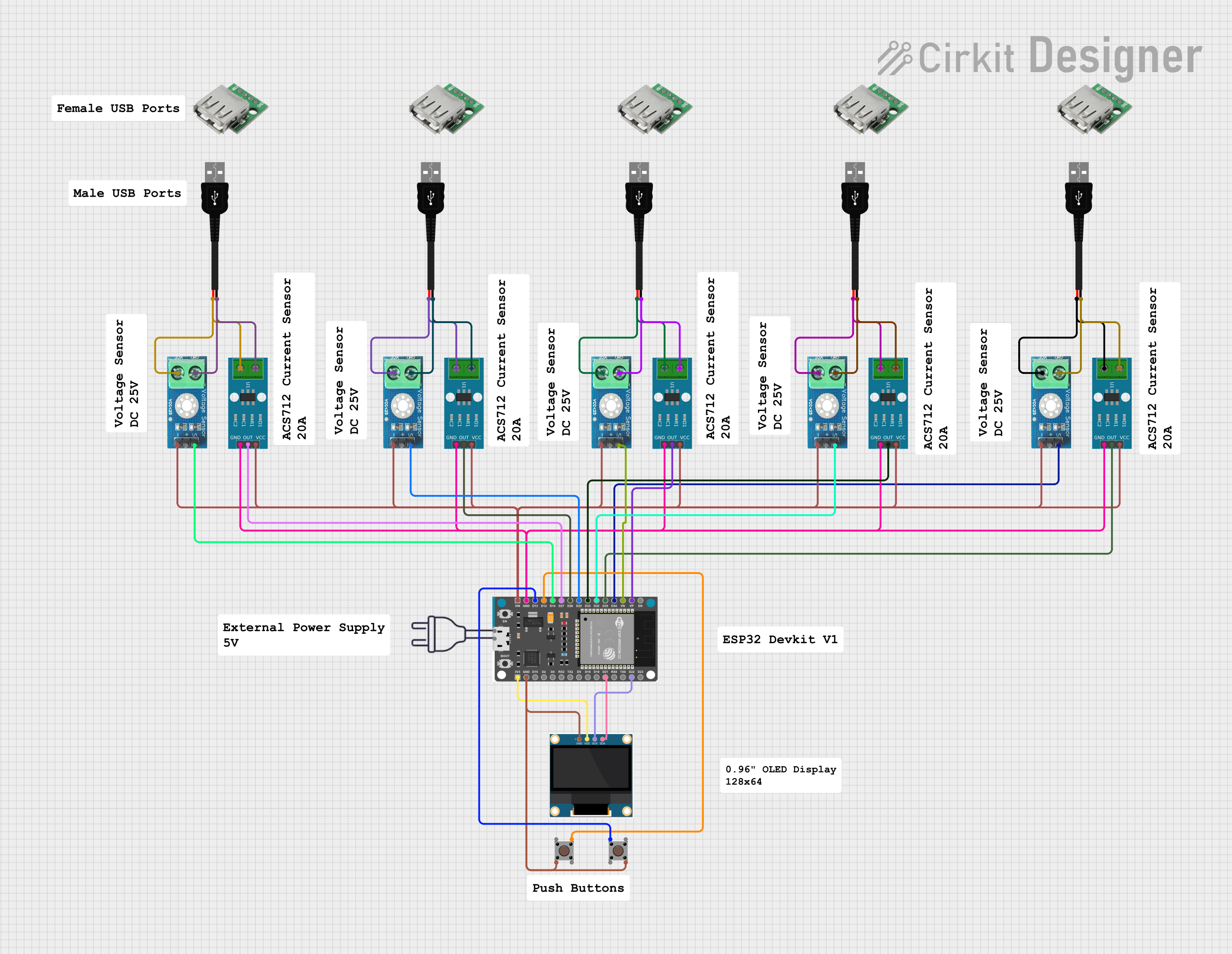

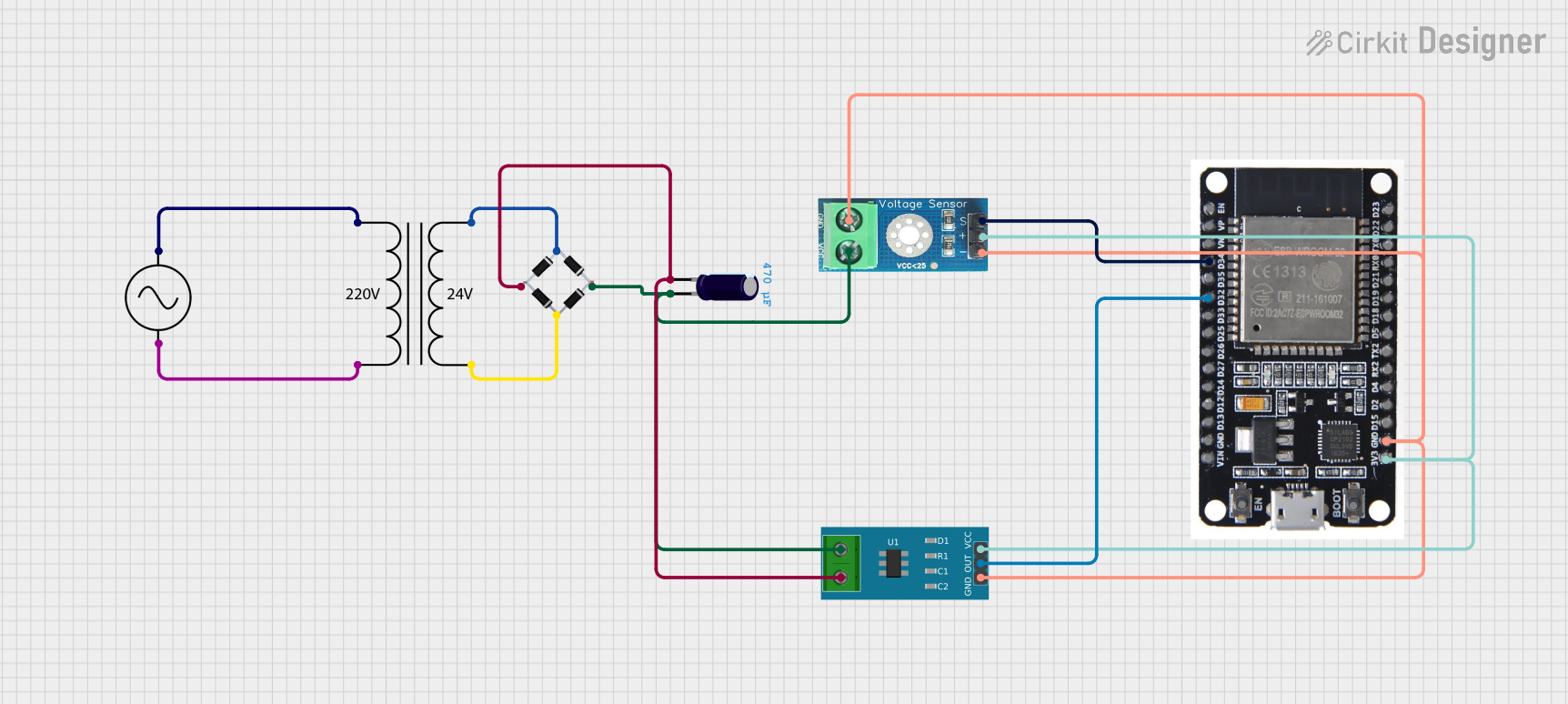

The Voltage Sensor DC 25V is a compact and efficient device designed to measure the voltage level in a DC circuit, with a maximum input voltage of 25 volts. It provides real-time feedback, making it an essential tool for monitoring and control applications. This sensor is widely used in battery monitoring systems, power supply diagnostics, and embedded systems where voltage measurement is critical.

Explore Projects Built with Voltage Sensor DC 25V

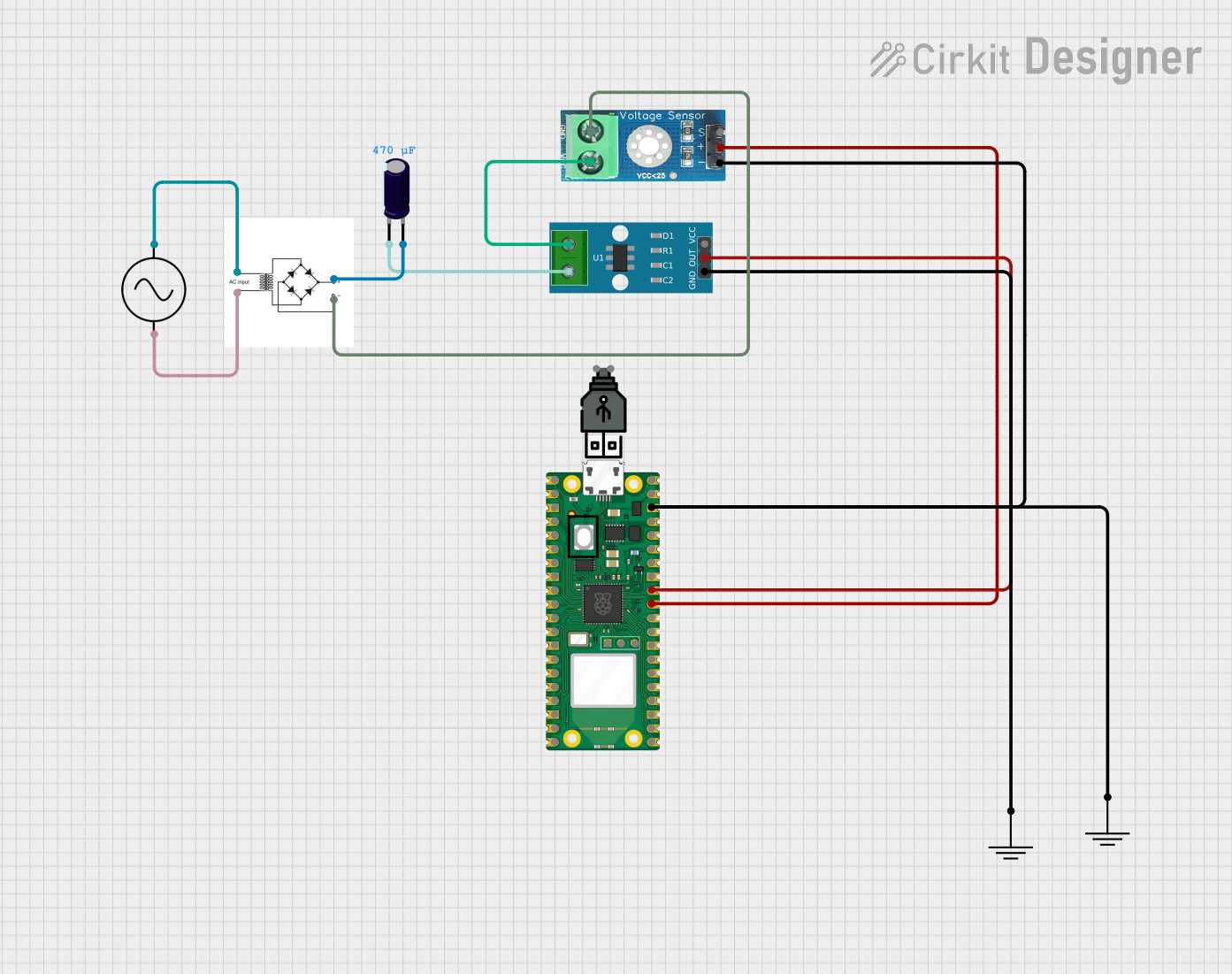

Open Project in Cirkit Designer

Open Project in Cirkit Designer

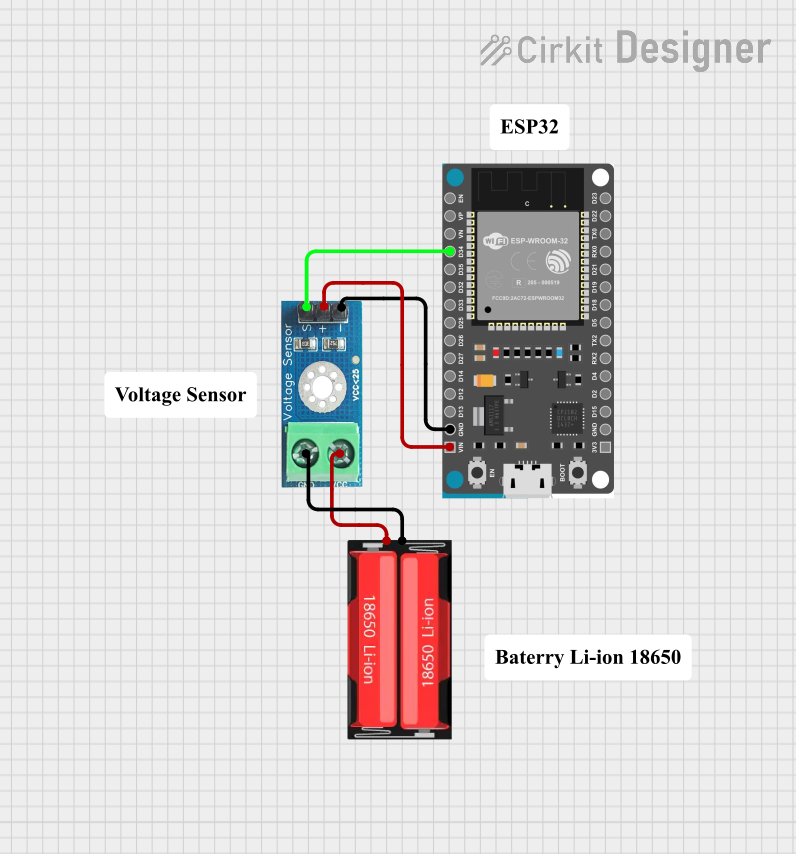

Open Project in Cirkit Designer

Open Project in Cirkit Designer

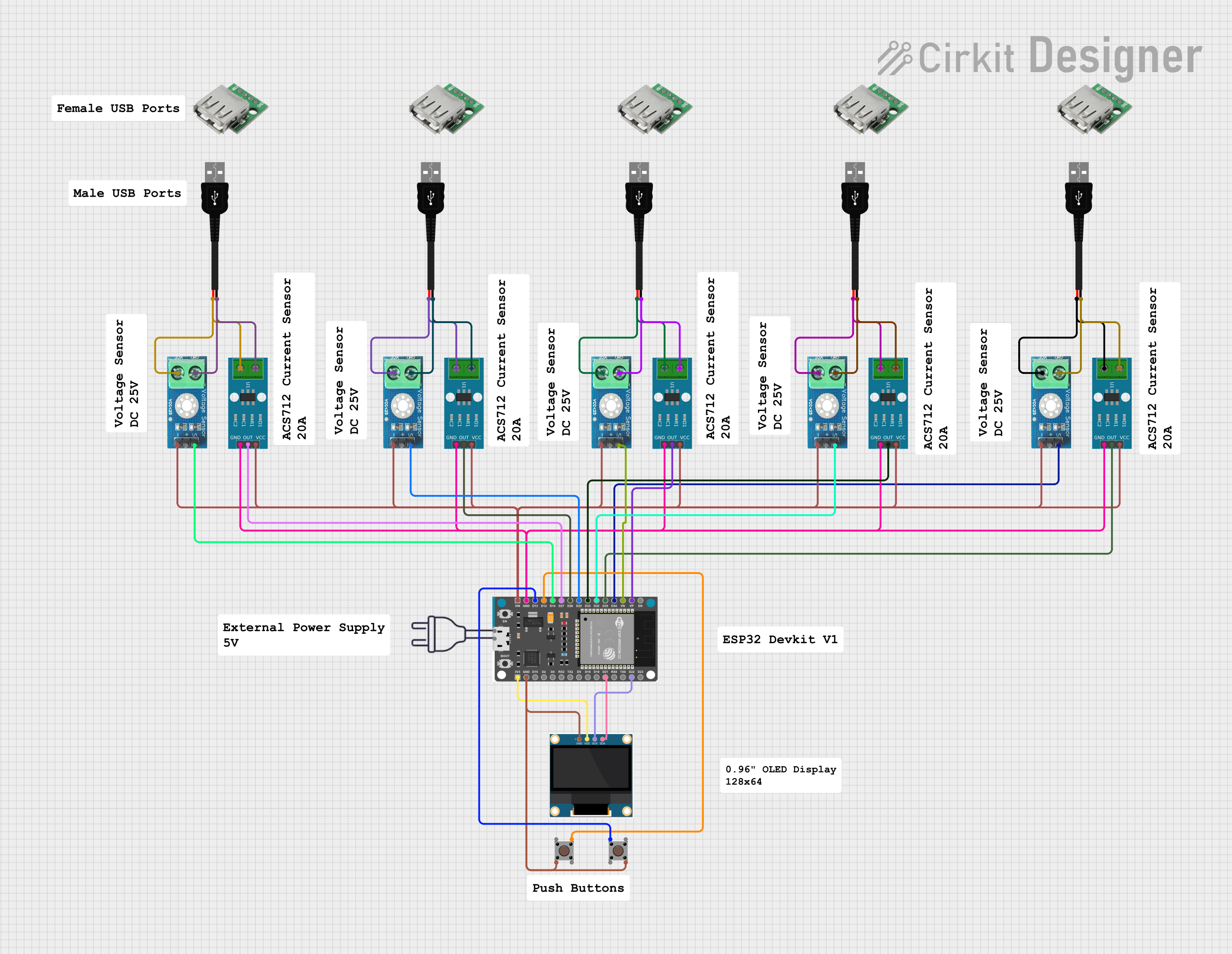

Open Project in Cirkit Designer

Open Project in Cirkit Designer

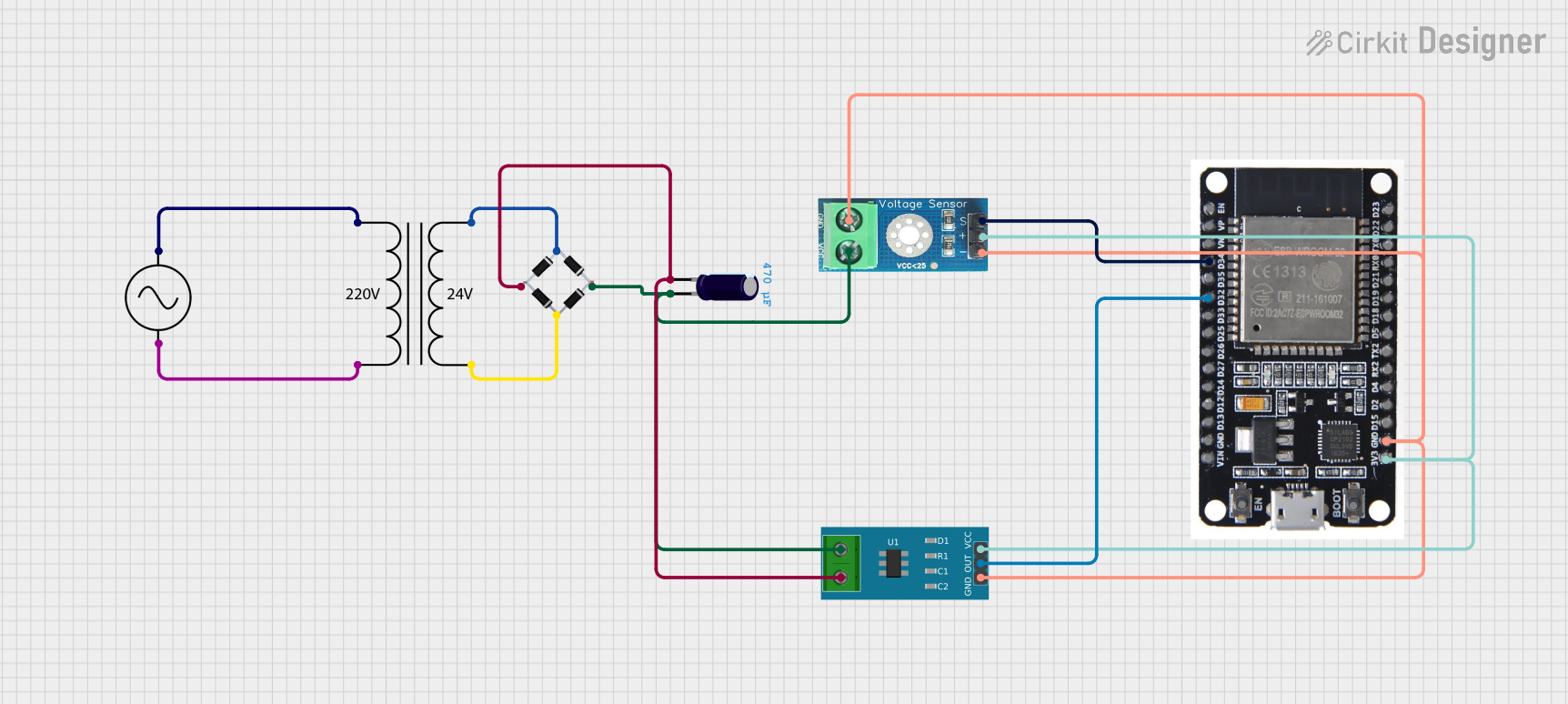

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Voltage Sensor DC 25V

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Battery voltage monitoring in renewable energy systems

- Power supply diagnostics in electronic circuits

- Voltage measurement in robotics and IoT projects

- Integration with microcontrollers like Arduino and Raspberry Pi for real-time data logging

Technical Specifications

The Voltage Sensor DC 25V is designed for ease of use and compatibility with a wide range of systems. Below are its key technical details:

Key Specifications

| Parameter | Value |

|---|---|

| Input Voltage Range | 0 - 25V DC |

| Output Voltage Range | 0 - 5V DC (scaled output) |

| Voltage Divider Ratio | 5:1 |

| Accuracy | ±1% |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 30mm x 15mm x 10mm |

Pin Configuration

The Voltage Sensor DC 25V typically has a 3-pin interface. Below is the pinout description:

| Pin Name | Description |

|---|---|

| VCC | Power supply input (3.3V or 5V DC) |

| GND | Ground connection |

| OUT | Scaled voltage output (0-5V DC) |

Usage Instructions

The Voltage Sensor DC 25V is straightforward to use in a circuit. Follow the steps below to integrate it into your project:

Connecting the Sensor

- Power the Sensor: Connect the

VCCpin to a 3.3V or 5V DC power source, depending on your system's requirements. - Ground Connection: Connect the

GNDpin to the ground of your circuit. - Voltage Input: Connect the positive terminal of the voltage source to be measured to the sensor's input terminal.

- Output Signal: The

OUTpin provides a scaled voltage output (0-5V DC) proportional to the input voltage.

Important Considerations

- Voltage Divider Ratio: The sensor uses a 5:1 voltage divider. For example, an input voltage of 25V will produce an output of 5V.

- Input Voltage Limit: Do not exceed the maximum input voltage of 25V, as this may damage the sensor.

- Calibration: For precise measurements, calibrate the sensor using a multimeter to account for any minor inaccuracies.

Example: Using with Arduino UNO

The Voltage Sensor DC 25V can be easily interfaced with an Arduino UNO for real-time voltage monitoring. Below is an example code snippet:

// Define the analog pin connected to the sensor's OUT pin

const int sensorPin = A0;

// Define the voltage divider ratio (5:1)

const float voltageDividerRatio = 5.0;

// Define the Arduino's reference voltage (5V for most boards)

const float referenceVoltage = 5.0;

void setup() {

Serial.begin(9600); // Initialize serial communication at 9600 baud

}

void loop() {

// Read the analog value from the sensor

int sensorValue = analogRead(sensorPin);

// Convert the analog value to a voltage (0-5V range)

float outputVoltage = (sensorValue / 1023.0) * referenceVoltage;

// Calculate the actual input voltage using the voltage divider ratio

float inputVoltage = outputVoltage * voltageDividerRatio;

// Print the input voltage to the Serial Monitor

Serial.print("Input Voltage: ");

Serial.print(inputVoltage);

Serial.println(" V");

delay(1000); // Wait for 1 second before the next reading

}

Best Practices

- Use short and thick wires for connections to minimize resistance and noise.

- Avoid placing the sensor near high-frequency components to reduce interference.

- If measuring high voltages, ensure proper insulation and safety precautions.

Troubleshooting and FAQs

Common Issues and Solutions

No Output Voltage

- Cause: Incorrect wiring or no power supply.

- Solution: Verify all connections, especially the

VCCandGNDpins.

Inaccurate Voltage Readings

- Cause: Calibration error or noise in the circuit.

- Solution: Calibrate the sensor using a multimeter and ensure proper grounding.

Output Voltage Exceeds 5V

- Cause: Input voltage exceeds the sensor's maximum limit.

- Solution: Ensure the input voltage does not exceed 25V.

Arduino Reads Incorrect Values

- Cause: Incorrect reference voltage or code error.

- Solution: Verify the Arduino's reference voltage and check the code for errors.

FAQs

Q: Can this sensor measure AC voltage?

A: No, the Voltage Sensor DC 25V is designed for DC voltage measurement only.

Q: Is the sensor compatible with 3.3V systems?

A: Yes, the sensor can operate with a 3.3V power supply, but ensure the output voltage does not exceed the ADC range of your microcontroller.

Q: How do I extend the voltage measurement range?

A: You can modify the voltage divider circuit to increase the range, but this requires careful design and testing.

By following this documentation, you can effectively use the Voltage Sensor DC 25V in your projects for accurate and reliable voltage measurements.