How to Use MIBL 0520: Examples, Pinouts, and Specs

Design with MIBL 0520 in Cirkit Designer

Design with MIBL 0520 in Cirkit DesignerIntroduction

The MIBL 0520 is a high-performance, low-power integrated circuit (IC) designed for a wide range of applications, including signal processing and data conversion. Its compact design makes it an excellent choice for space-constrained environments, such as portable devices, embedded systems, and IoT applications. The MIBL 0520 is engineered to deliver reliable performance while maintaining low power consumption, making it ideal for energy-efficient designs.

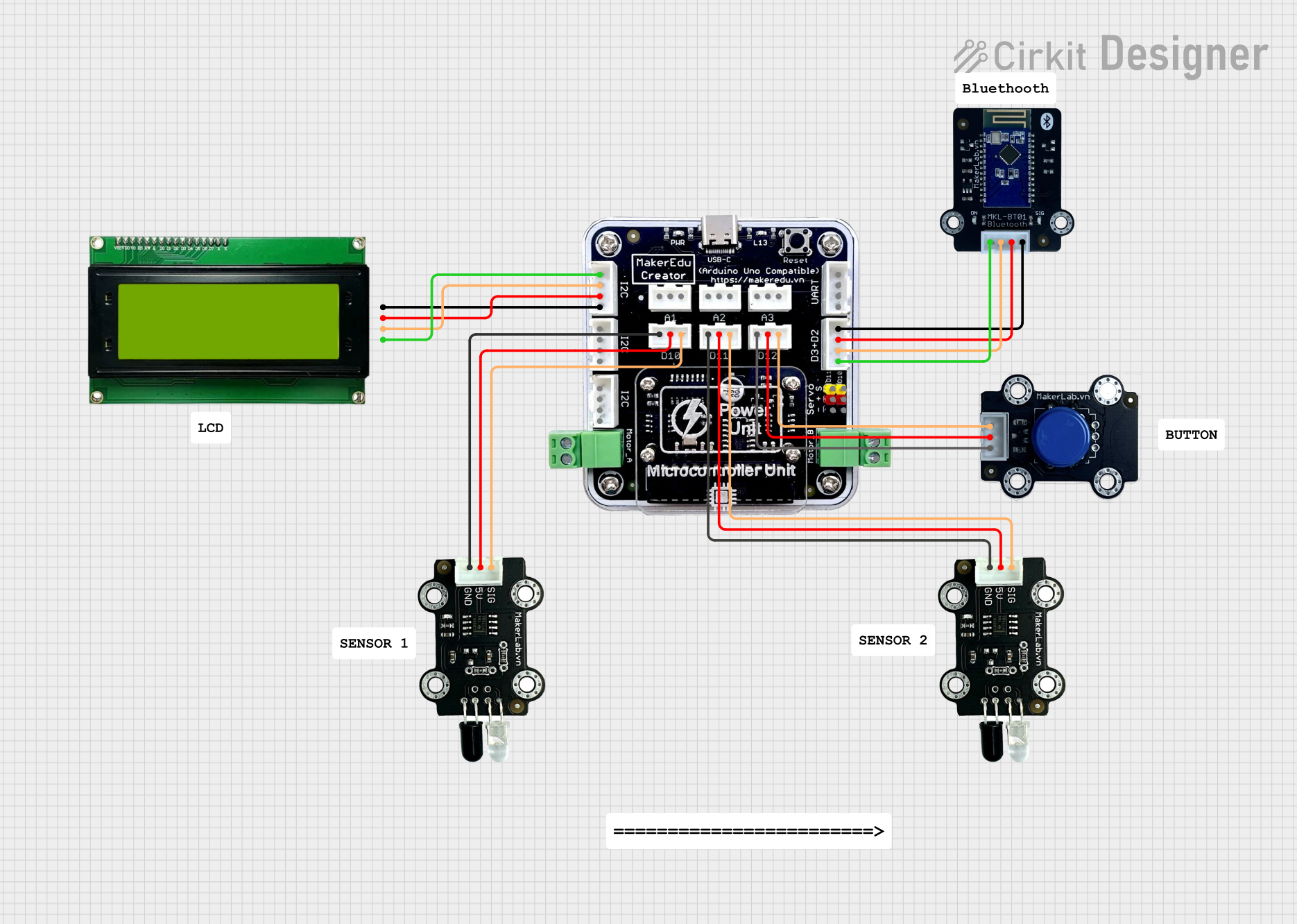

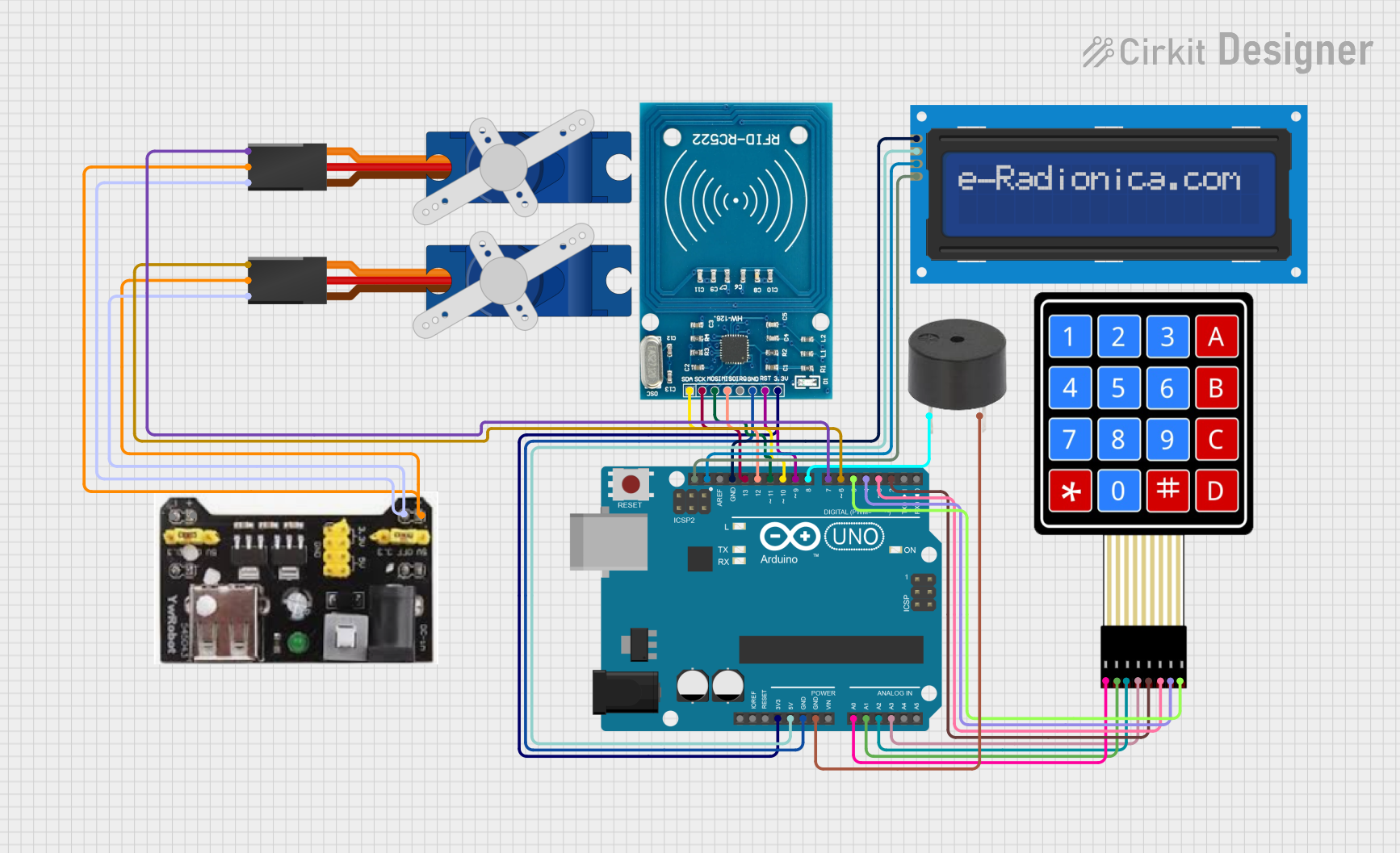

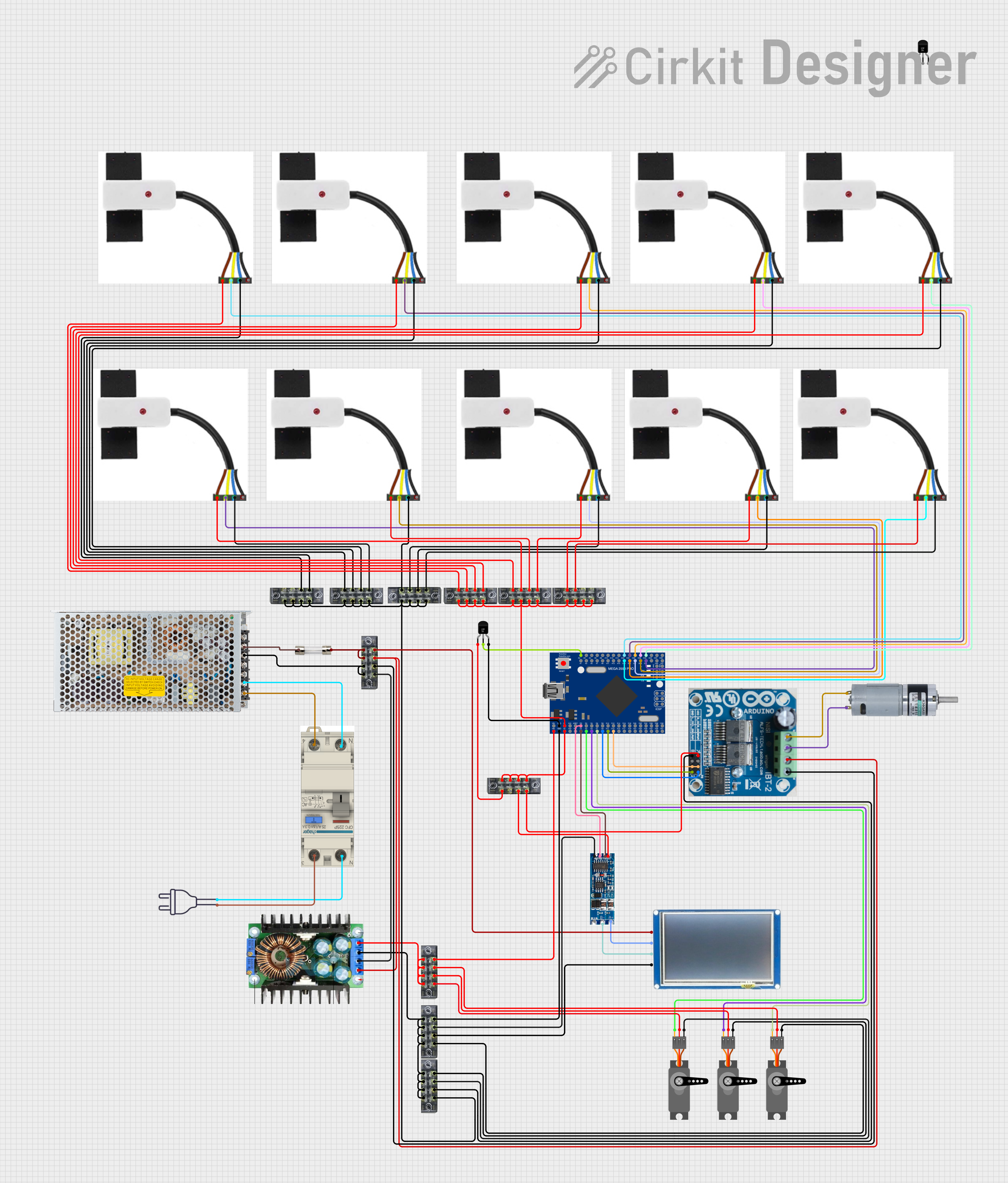

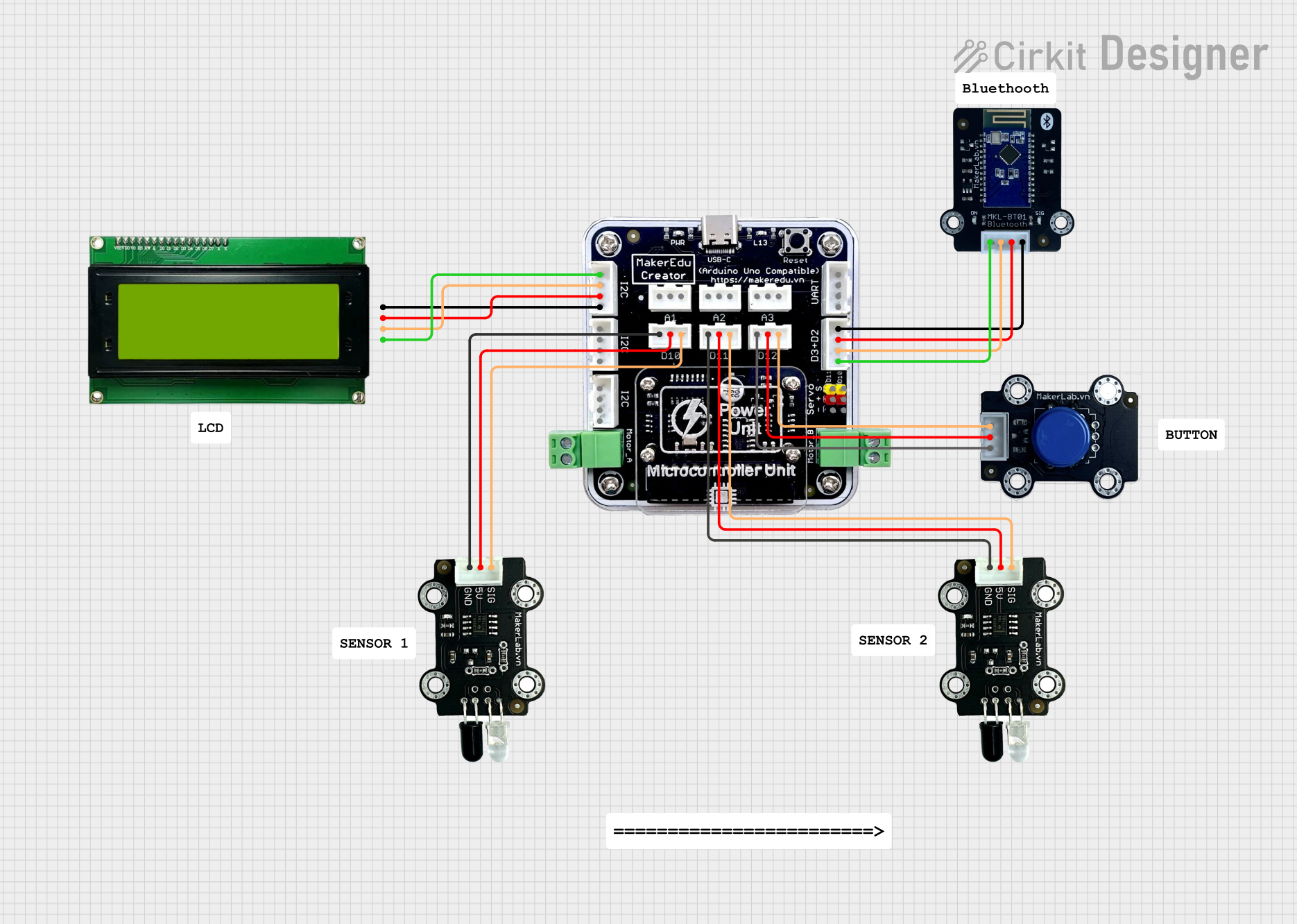

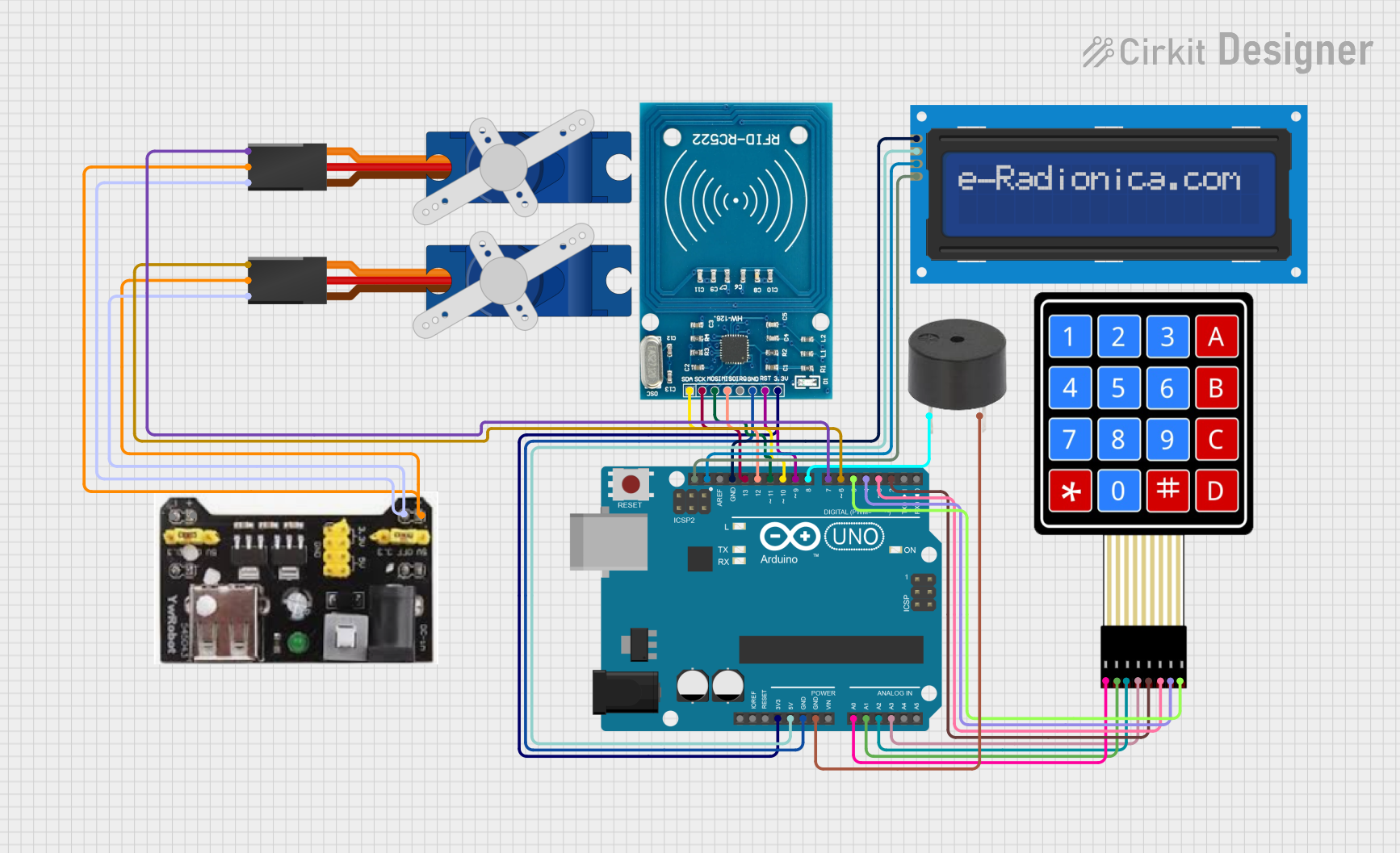

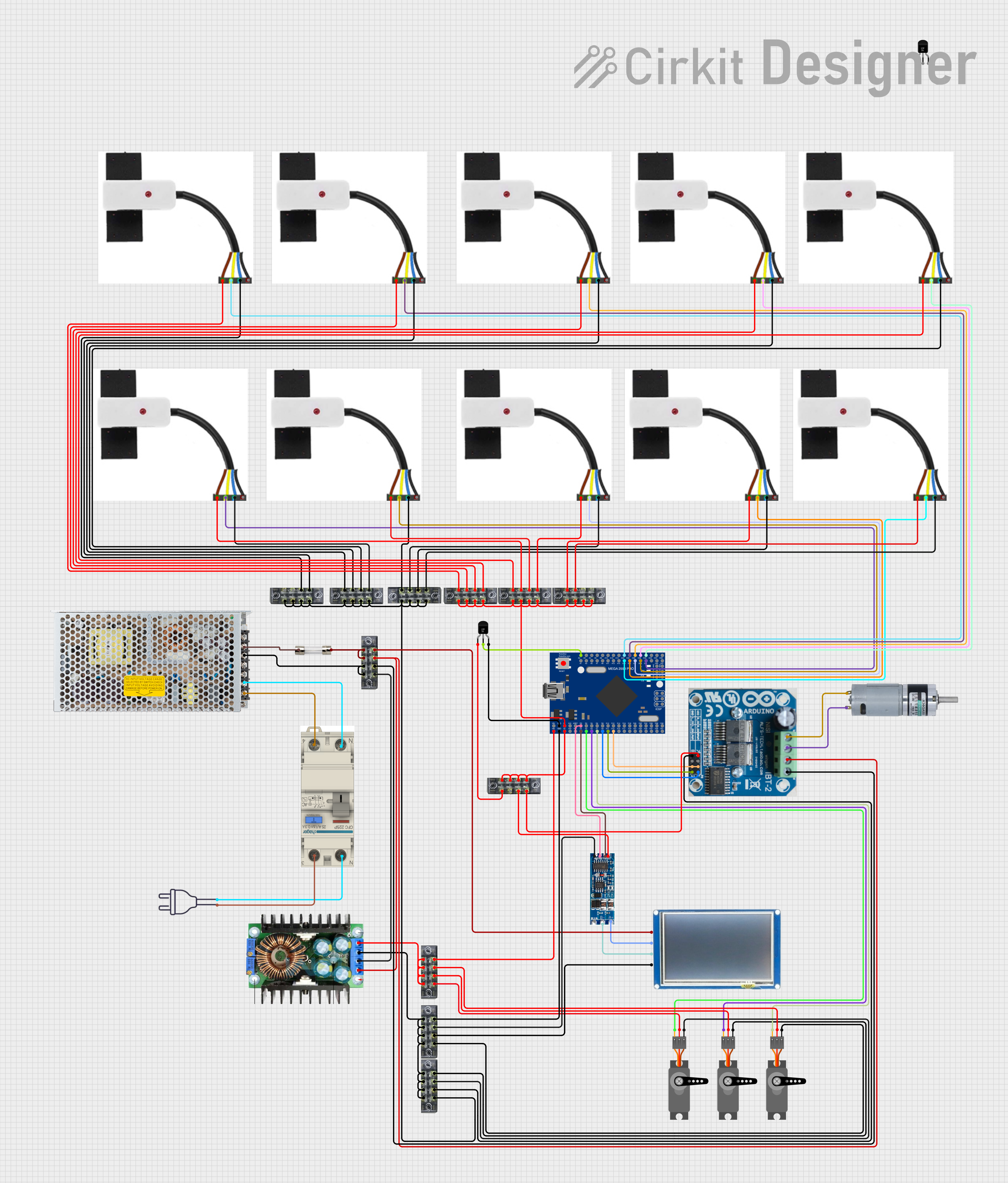

Explore Projects Built with MIBL 0520

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with MIBL 0520

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Signal processing in audio and communication systems

- Data conversion in analog-to-digital or digital-to-analog systems

- Portable and battery-powered devices

- IoT devices requiring compact and efficient ICs

- Embedded systems with space and power constraints

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Supply Voltage (Vcc) | 2.7V to 5.5V |

| Operating Current | 1.2 mA (typical) |

| Power Consumption | Low power, < 10 mW |

| Operating Temperature | -40°C to +85°C |

| Package Type | 8-pin SOIC (Small Outline IC) |

| Signal Bandwidth | Up to 20 MHz |

| Data Conversion Accuracy | 12-bit resolution |

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | Vcc | Power supply input (2.7V to 5.5V) |

| 2 | GND | Ground connection |

| 3 | IN+ | Positive input for signal processing |

| 4 | IN- | Negative input for signal processing |

| 5 | OUT | Output signal pin |

| 6 | CLK | Clock input for synchronization |

| 7 | CS | Chip select for enabling/disabling the IC |

| 8 | NC | No connection (leave unconnected or grounded) |

Usage Instructions

How to Use the MIBL 0520 in a Circuit

- Power Supply: Connect the Vcc pin to a stable power source within the range of 2.7V to 5.5V. Connect the GND pin to the circuit ground.

- Signal Input: Feed the input signal to the IN+ and IN- pins. Ensure the signal levels are within the IC's operating range.

- Output Signal: The processed or converted signal will be available at the OUT pin. Connect this pin to the next stage of your circuit.

- Clock Input: Provide a clock signal to the CLK pin for synchronization. The clock frequency should match the IC's requirements for optimal performance.

- Chip Select: Use the CS pin to enable or disable the IC. Pull the CS pin low to activate the IC and high to deactivate it.

Important Considerations and Best Practices

- Decoupling Capacitors: Place a 0.1 µF ceramic capacitor close to the Vcc pin to filter out noise and ensure stable operation.

- Signal Integrity: Use short and shielded wires for the input and output signals to minimize noise and interference.

- Thermal Management: Ensure adequate ventilation or heat dissipation if the IC operates in high-temperature environments.

- Unused Pins: Leave the NC pin unconnected or tie it to ground to avoid floating inputs.

Example: Connecting MIBL 0520 to an Arduino UNO

The MIBL 0520 can be interfaced with an Arduino UNO for signal processing or data conversion tasks. Below is an example code snippet:

// Example: Interfacing MIBL 0520 with Arduino UNO

// This code demonstrates how to send a clock signal and read the output signal.

const int clkPin = 9; // Pin 9 connected to CLK pin of MIBL 0520

const int csPin = 10; // Pin 10 connected to CS pin of MIBL 0520

const int outPin = A0; // Analog pin A0 connected to OUT pin of MIBL 0520

void setup() {

pinMode(clkPin, OUTPUT); // Set CLK pin as output

pinMode(csPin, OUTPUT); // Set CS pin as output

digitalWrite(csPin, HIGH); // Disable the IC initially

Serial.begin(9600); // Initialize serial communication

}

void loop() {

digitalWrite(csPin, LOW); // Enable the IC

digitalWrite(clkPin, HIGH); // Send a clock pulse

delayMicroseconds(10); // Short delay for clock pulse

digitalWrite(clkPin, LOW);

int outputValue = analogRead(outPin); // Read the output signal

Serial.println(outputValue); // Print the output value to the Serial Monitor

delay(100); // Wait before the next reading

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output Signal:

- Ensure the IC is powered correctly (check Vcc and GND connections).

- Verify that the CS pin is pulled low to enable the IC.

- Check the input signal levels and ensure they are within the IC's operating range.

Excessive Noise in Output:

- Use decoupling capacitors near the power supply pins.

- Minimize the length of input and output signal wires.

- Ensure proper grounding in the circuit.

Overheating:

- Verify that the supply voltage does not exceed the maximum rating.

- Check for short circuits or incorrect connections.

Clock Signal Issues:

- Ensure the clock frequency matches the IC's requirements.

- Use a stable clock source to avoid synchronization problems.

FAQs

Q1: Can the MIBL 0520 operate without a clock signal?

A1: No, the MIBL 0520 requires a clock signal on the CLK pin for proper operation.

Q2: What happens if the CS pin is left floating?

A2: The IC may behave unpredictably. Always pull the CS pin high or low as needed.

Q3: Can I use the MIBL 0520 with a 3.3V power supply?

A3: Yes, the IC supports a supply voltage range of 2.7V to 5.5V, so 3.3V is within the acceptable range.

Q4: Is the MIBL 0520 suitable for high-frequency applications?

A4: The IC supports signal bandwidths up to 20 MHz, making it suitable for many high-frequency applications.