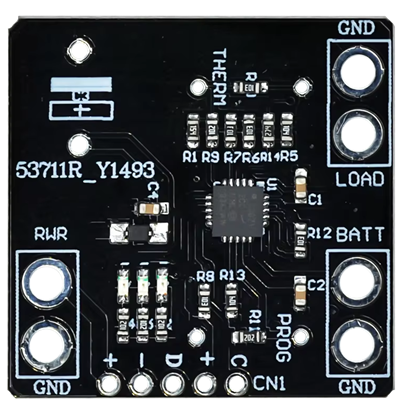

How to Use MCP73871: Examples, Pinouts, and Specs

Design with MCP73871 in Cirkit Designer

Design with MCP73871 in Cirkit DesignerIntroduction

The MCP73871 is a highly integrated Li-Ion/Li-Polymer battery charge management controller with an integrated power path selector. It is designed for space-limited and cost-sensitive applications. This component is ideal for managing the charging process of single-cell Li-Ion or Li-Polymer batteries, ensuring safe and efficient charging while providing power to the system.

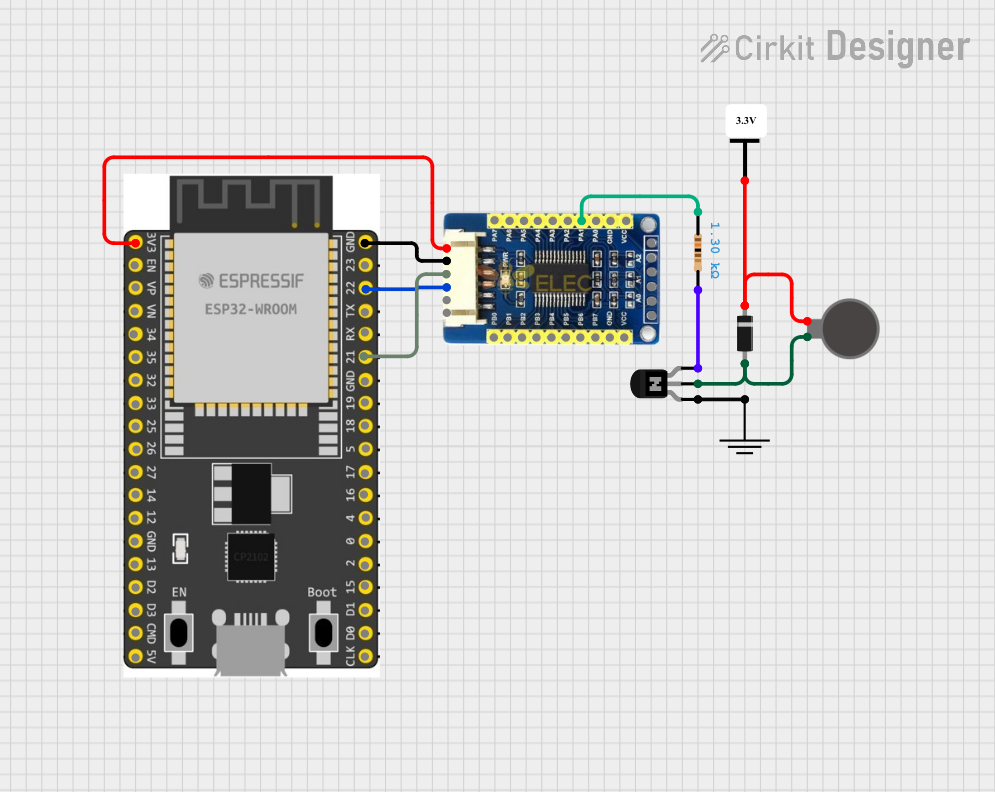

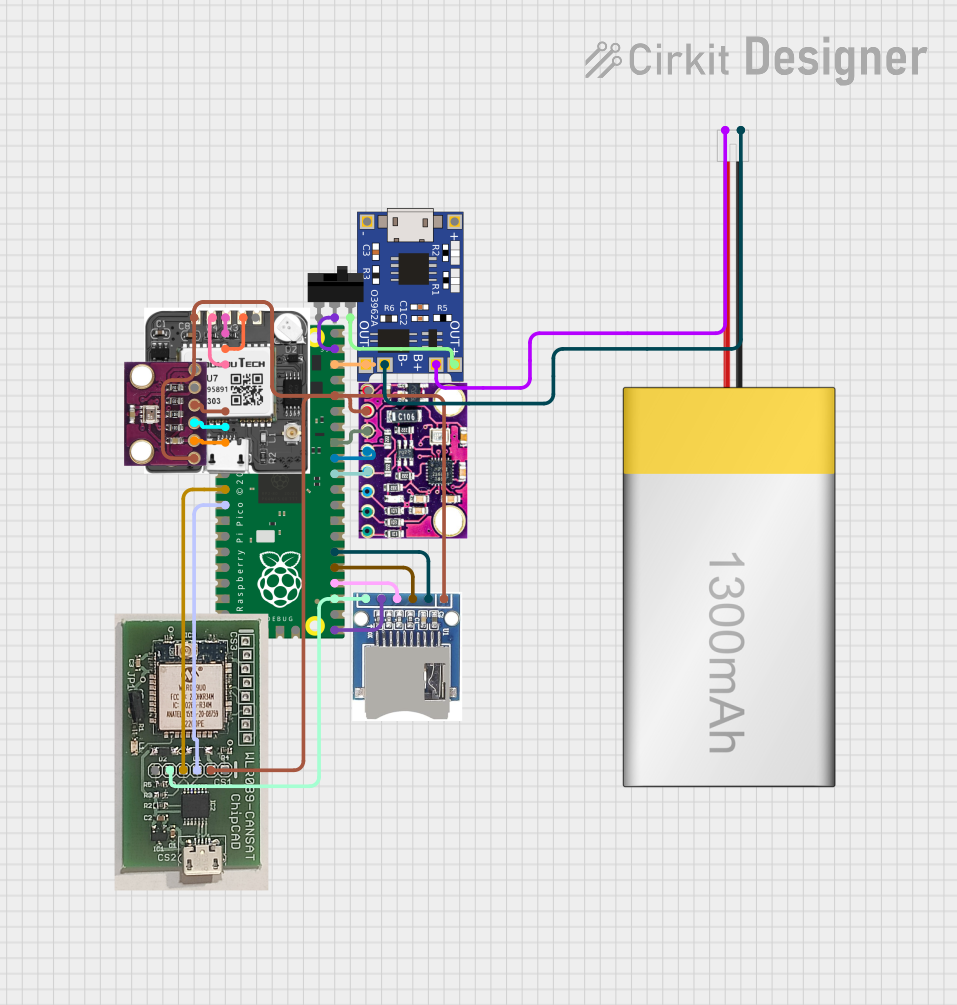

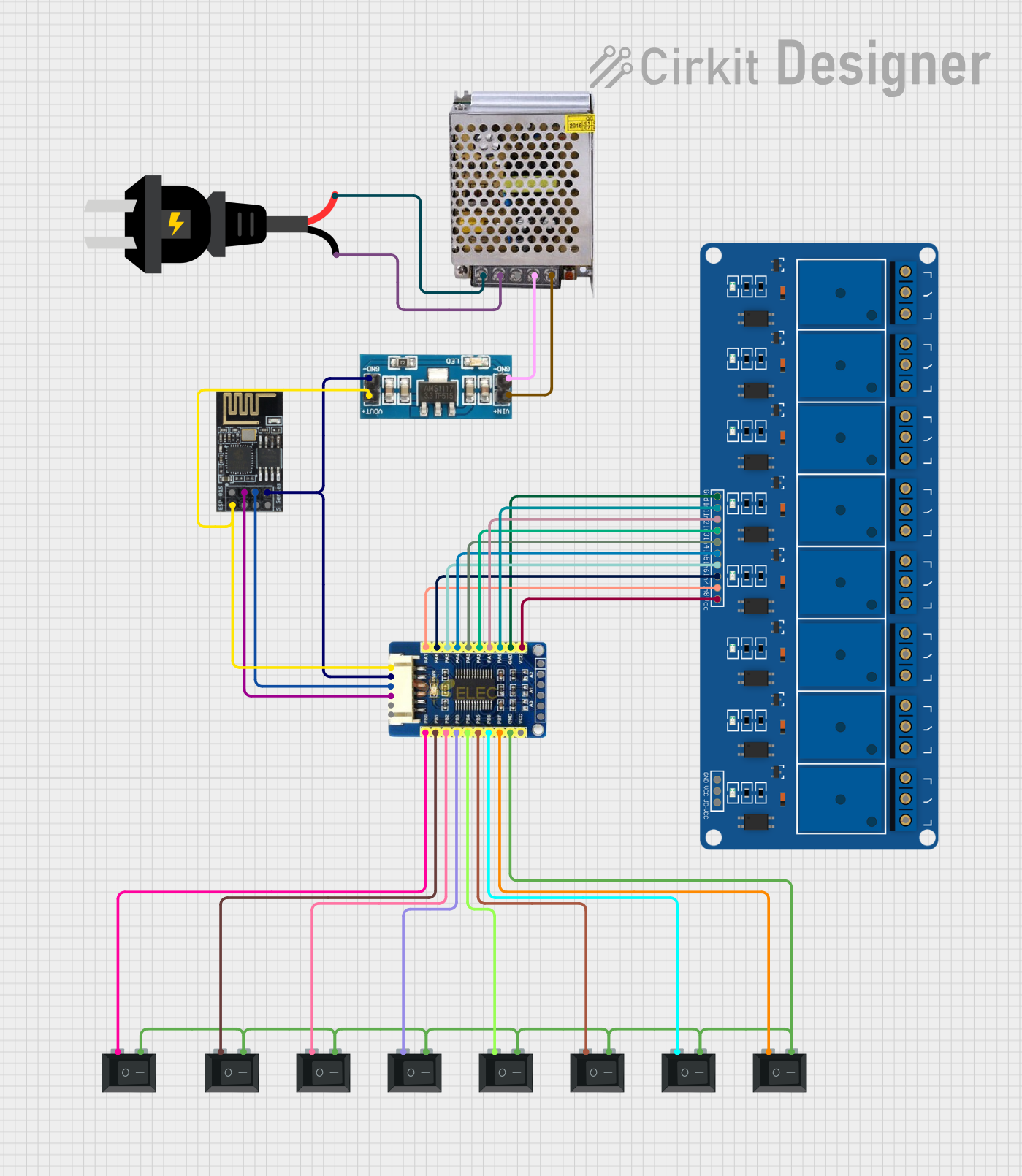

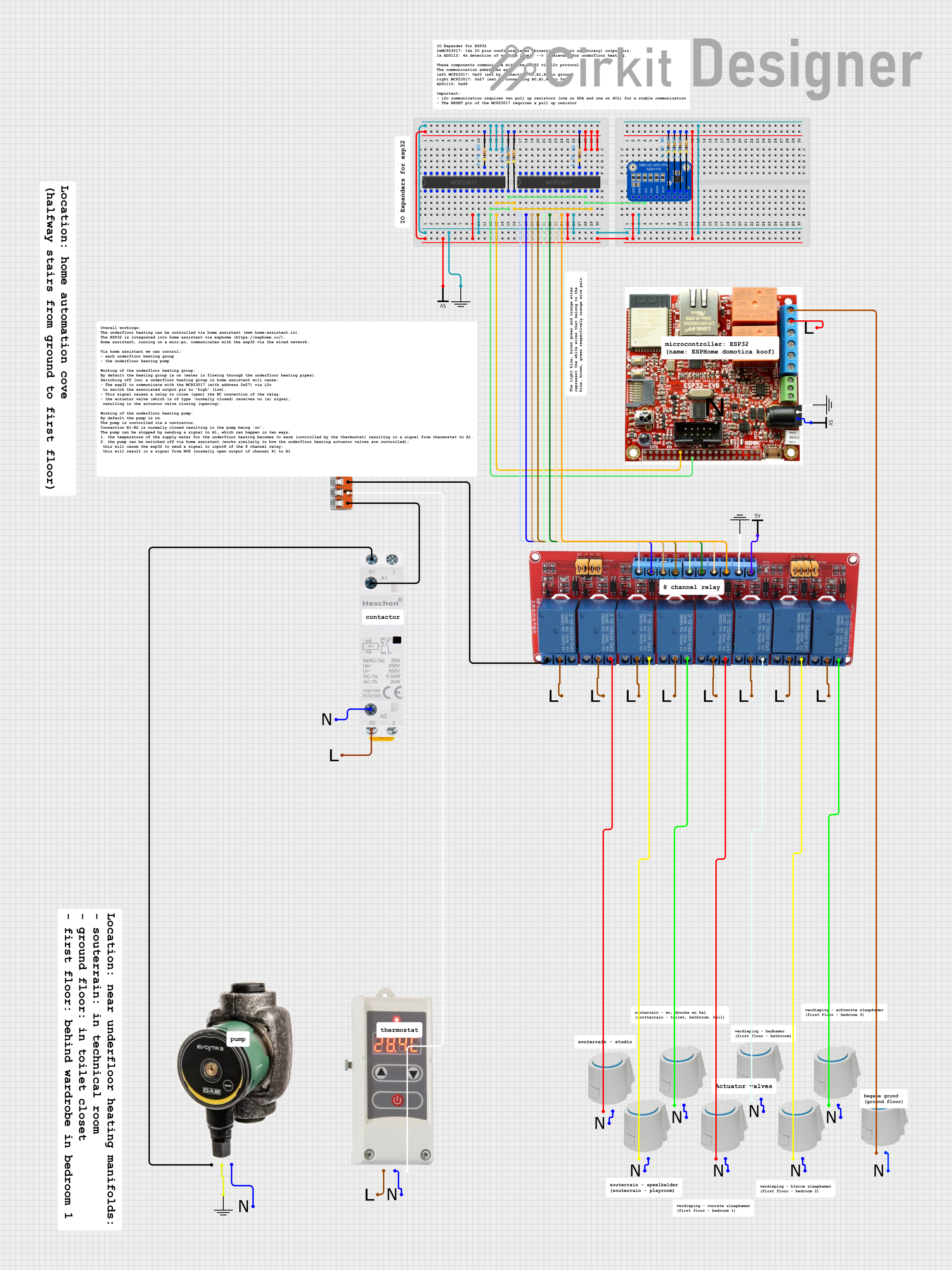

Explore Projects Built with MCP73871

Open Project in Cirkit Designer

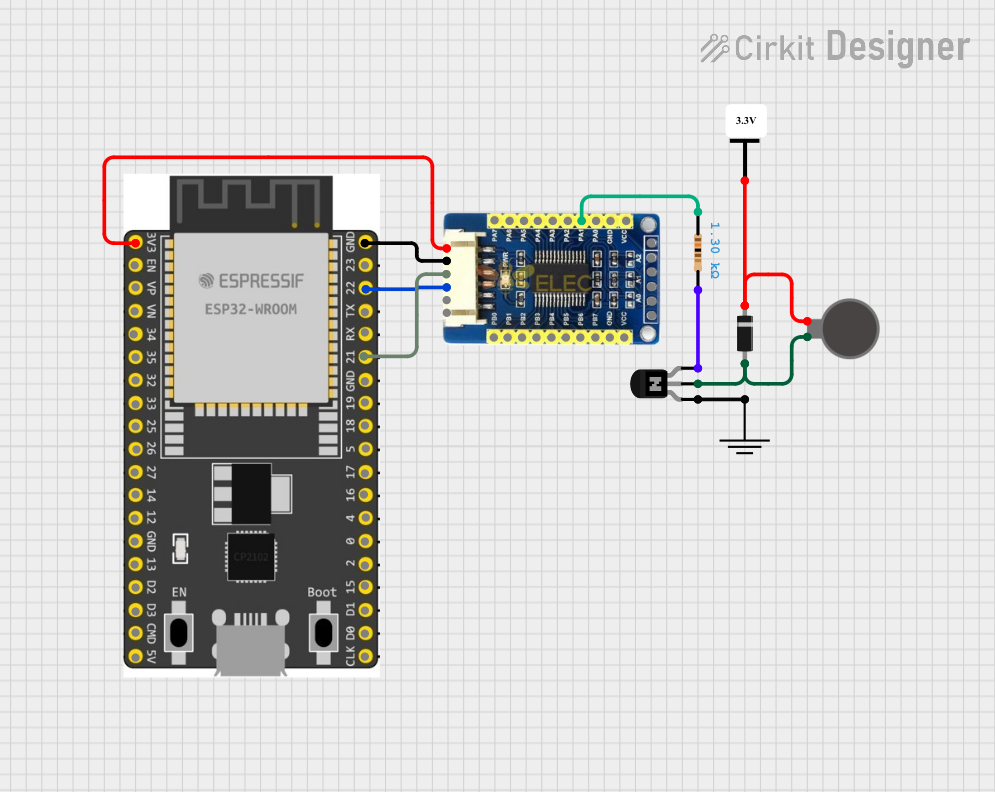

Open Project in Cirkit Designer

Open Project in Cirkit Designer

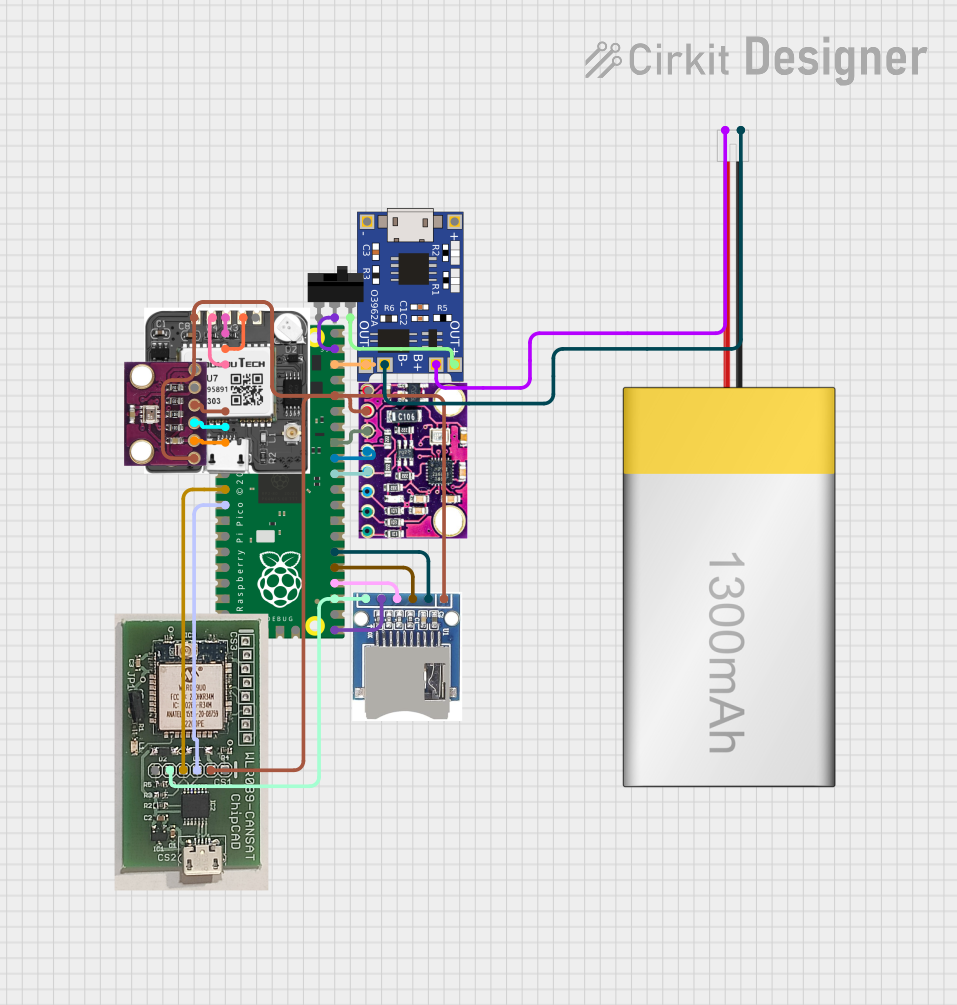

Open Project in Cirkit Designer

Open Project in Cirkit Designer

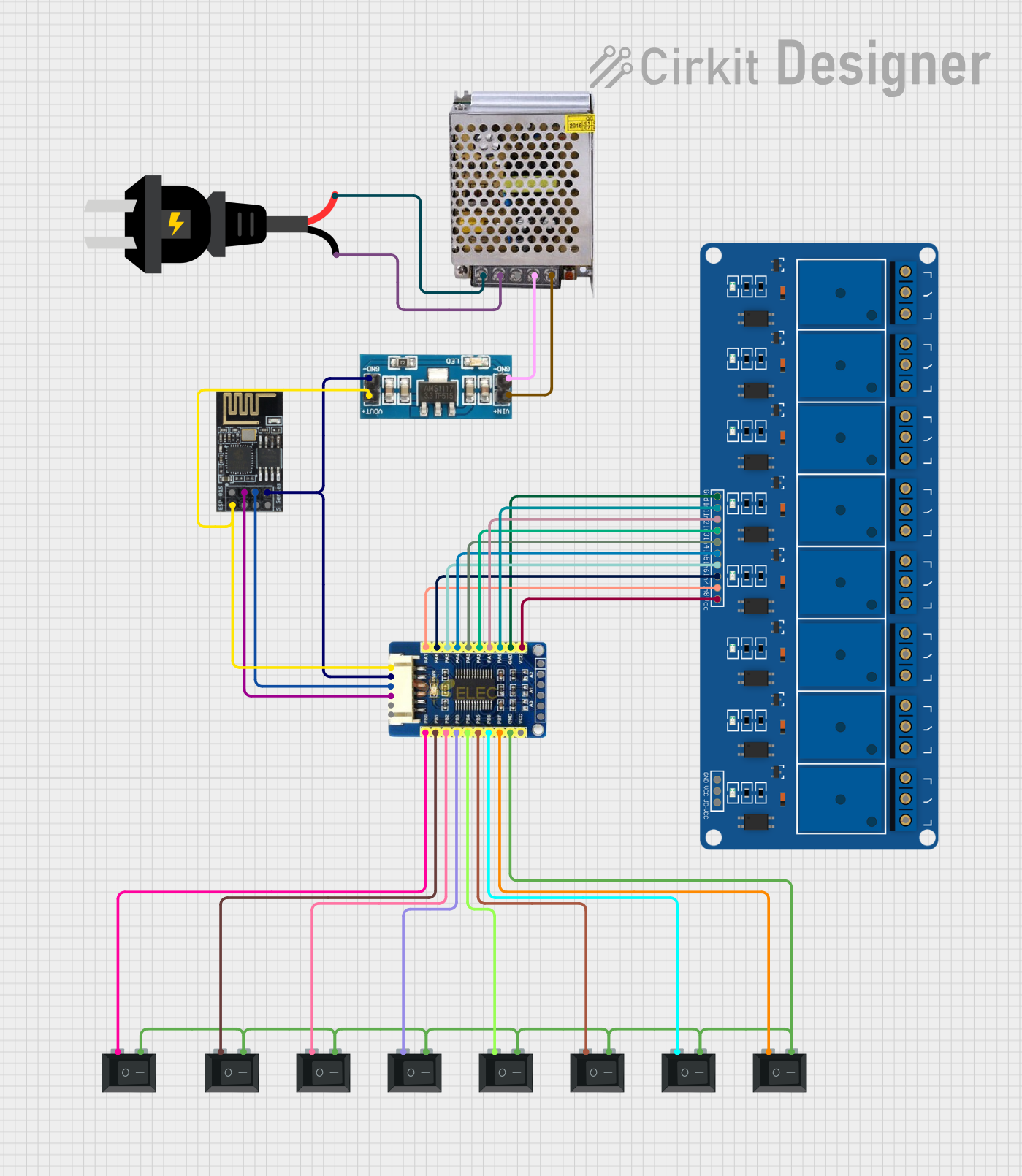

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with MCP73871

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Portable electronic devices

- Wearable technology

- Handheld instruments

- Backup battery systems

- USB-powered devices

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Input Voltage Range | 3.75V to 6V |

| Battery Charge Voltage | 4.2V (typical) |

| Charge Current | Programmable up to 1.8A |

| Power Path Selector | Integrated |

| Operating Temperature | -40°C to +85°C |

| Package | 20-Lead QFN (4x4 mm) |

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VDD | Input supply voltage |

| 2 | VBAT | Battery connection |

| 3 | VSS | Ground |

| 4 | PROG | Charge current programming |

| 5 | STAT1 | Charge status indicator 1 |

| 6 | STAT2 | Charge status indicator 2 |

| 7 | CE | Charge enable |

| 8 | TE | Termination enable |

| 9 | PG | Power good indicator |

| 10 | THERM | Thermistor input for battery temperature sensing |

| 11 | VUSB | USB input voltage |

| 12 | VBUS | Bus voltage input |

| 13 | VOUT | Output voltage |

| 14 | ISET | Charge current set |

| 15 | EN | Enable |

| 16 | PSEL | Power source selection |

| 17 | D+ | USB D+ line |

| 18 | D- | USB D- line |

| 19 | NC | No connection |

| 20 | NC | No connection |

Usage Instructions

How to Use the MCP73871 in a Circuit

- Power Supply Connection: Connect the input supply voltage (3.75V to 6V) to the VDD pin.

- Battery Connection: Connect the battery to the VBAT pin.

- Ground Connection: Connect the VSS pin to the ground of the circuit.

- Programming Charge Current: Use a resistor between the PROG pin and ground to set the desired charge current.

- Status Indicators: Connect LEDs to STAT1 and STAT2 pins to monitor the charging status.

- Enable Charging: Use the CE pin to enable or disable charging.

- Thermistor Connection: Connect a thermistor to the THERM pin for battery temperature monitoring.

- USB and Bus Voltage: Connect the USB input voltage to the VUSB pin and the bus voltage to the VBUS pin.

- Output Voltage: The VOUT pin provides the regulated output voltage.

Important Considerations and Best Practices

- Ensure proper heat dissipation by using a suitable PCB layout with thermal vias.

- Use appropriate decoupling capacitors on the VDD and VBAT pins to filter out noise.

- Monitor the battery temperature using a thermistor to prevent overheating.

- Follow the recommended resistor values for programming the charge current to avoid overcharging the battery.

Troubleshooting and FAQs

Common Issues and Solutions

Issue: The battery is not charging.

- Solution: Check the input voltage at the VDD pin. Ensure it is within the specified range (3.75V to 6V). Verify the connections to the battery and the ground.

Issue: The charge current is too low.

- Solution: Verify the resistor value connected to the PROG pin. Ensure it is correctly set to achieve the desired charge current.

Issue: The charge status indicators (STAT1 and STAT2) are not working.

- Solution: Check the connections to the LEDs. Ensure they are connected correctly and not damaged.

Issue: The device is overheating.

- Solution: Ensure proper heat dissipation by using a suitable PCB layout with thermal vias. Monitor the battery temperature using a thermistor.

FAQs

Can the MCP73871 be used with a 2-cell battery?

- No, the MCP73871 is designed for single-cell Li-Ion or Li-Polymer batteries only.

What is the maximum charge current supported by the MCP73871?

- The MCP73871 supports a programmable charge current up to 1.8A.

How do I select the power source (USB or bus voltage)?

- Use the PSEL pin to select the power source. Refer to the datasheet for detailed instructions on configuring the PSEL pin.

Example Code for Arduino UNO

Here is an example code to monitor the charging status using an Arduino UNO:

// Define pin connections

const int stat1Pin = 2; // STAT1 connected to digital pin 2

const int stat2Pin = 3; // STAT2 connected to digital pin 3

void setup() {

// Initialize serial communication

Serial.begin(9600);

// Set pin modes

pinMode(stat1Pin, INPUT);

pinMode(stat2Pin, INPUT);

}

void loop() {

// Read the status pins

int stat1 = digitalRead(stat1Pin);

int stat2 = digitalRead(stat2Pin);

// Print the charging status

if (stat1 == LOW && stat2 == HIGH) {

Serial.println("Charging in progress");

} else if (stat1 == HIGH && stat2 == LOW) {

Serial.println("Charge complete");

} else {

Serial.println("No battery or fault");

}

// Wait for a second before the next reading

delay(1000);

}

This code reads the status pins (STAT1 and STAT2) and prints the charging status to the serial monitor. Connect the STAT1 and STAT2 pins of the MCP73871 to the digital pins 2 and 3 of the Arduino UNO, respectively.

By following this documentation, users can effectively integrate the MCP73871 into their projects, ensuring safe and efficient battery charging management.