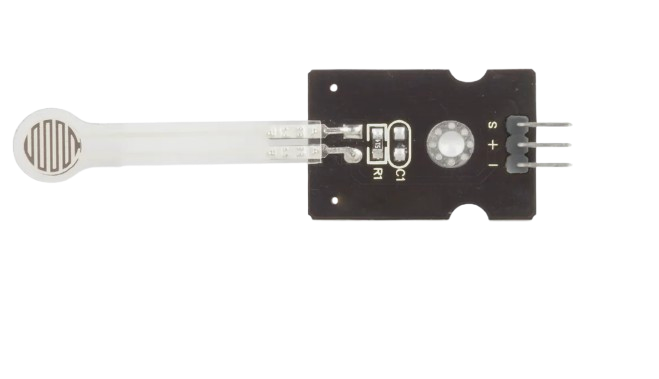

How to Use thin film pressure sensor: Examples, Pinouts, and Specs

Design with thin film pressure sensor in Cirkit Designer

Design with thin film pressure sensor in Cirkit DesignerIntroduction

A thin film pressure sensor is a highly sensitive electronic component designed to measure pressure by detecting changes in resistance or capacitance within a thin film material. These sensors are compact, lightweight, and versatile, making them ideal for applications where space and precision are critical.

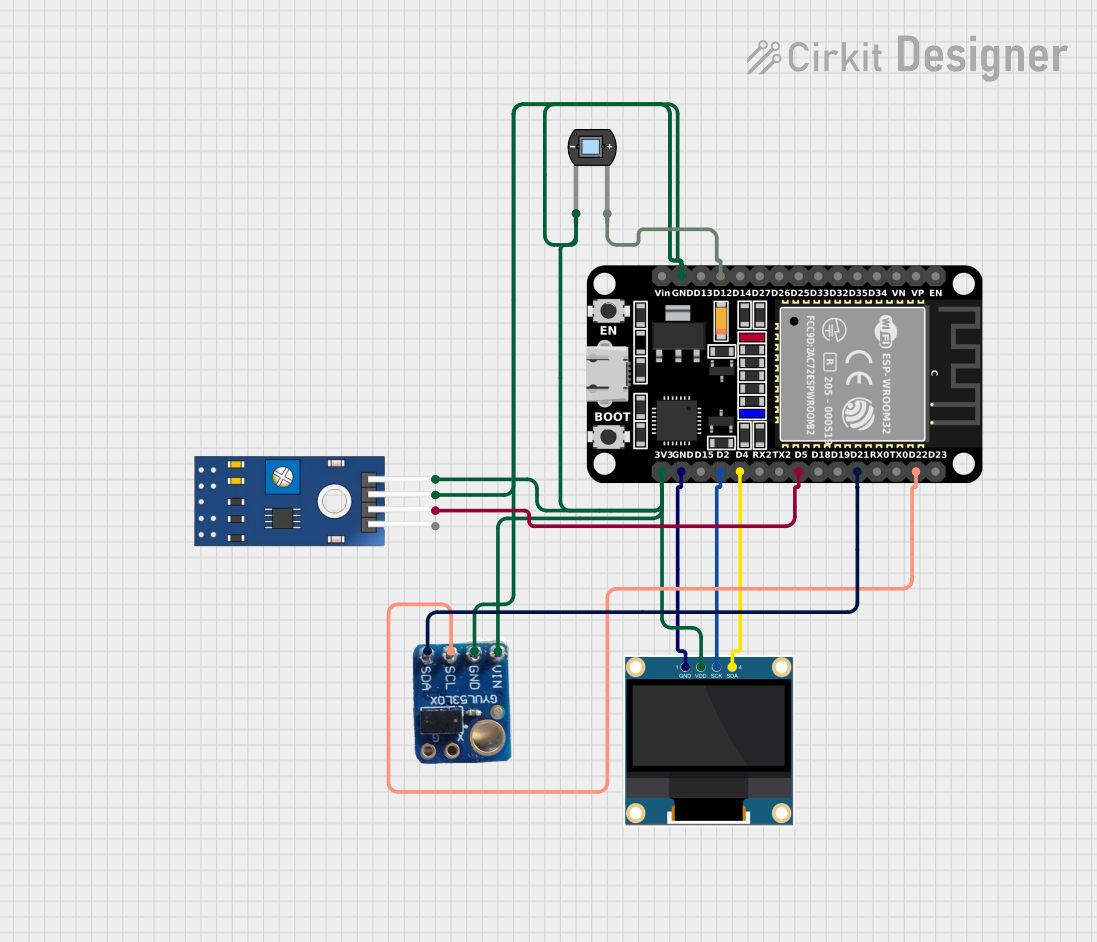

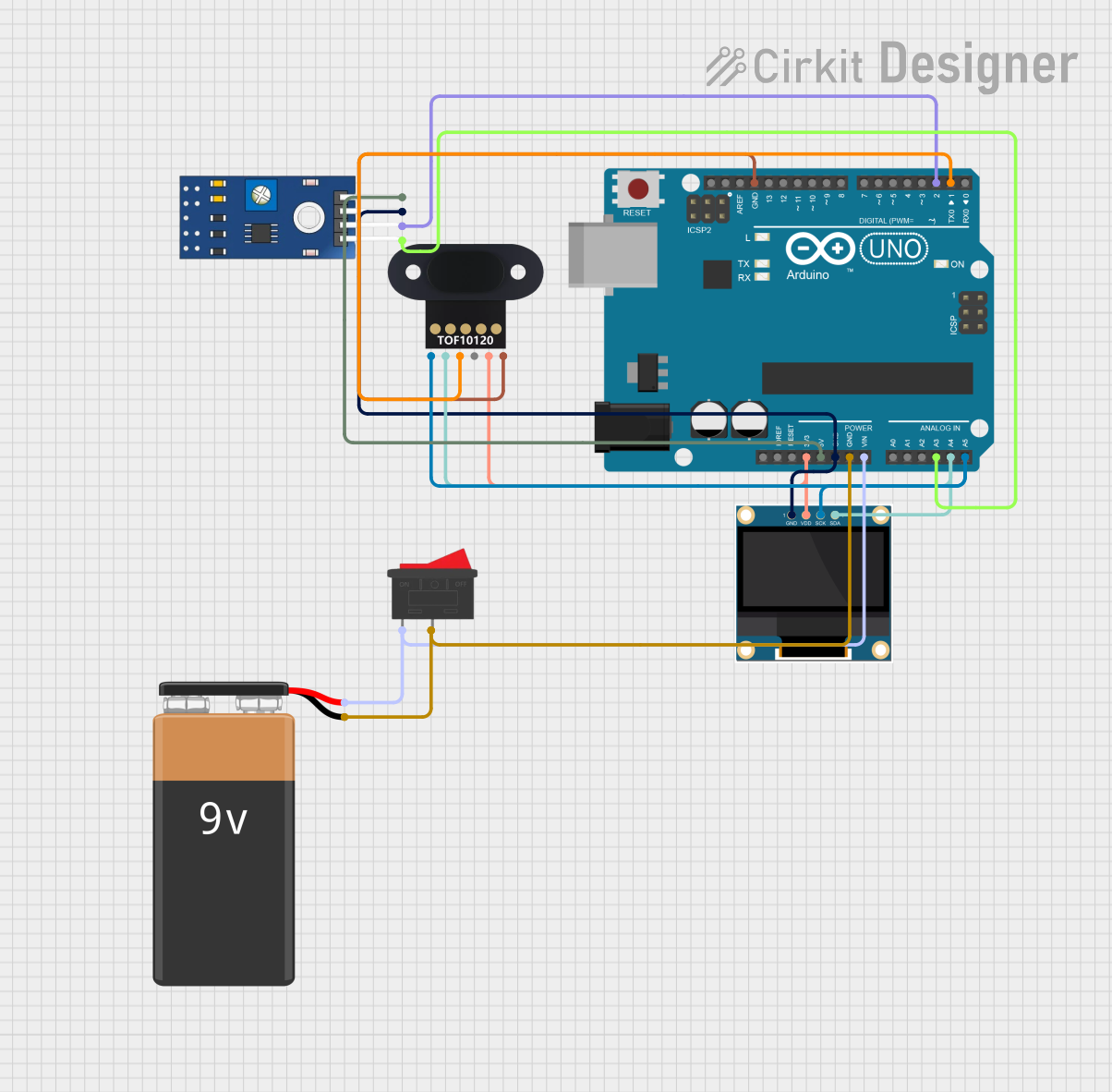

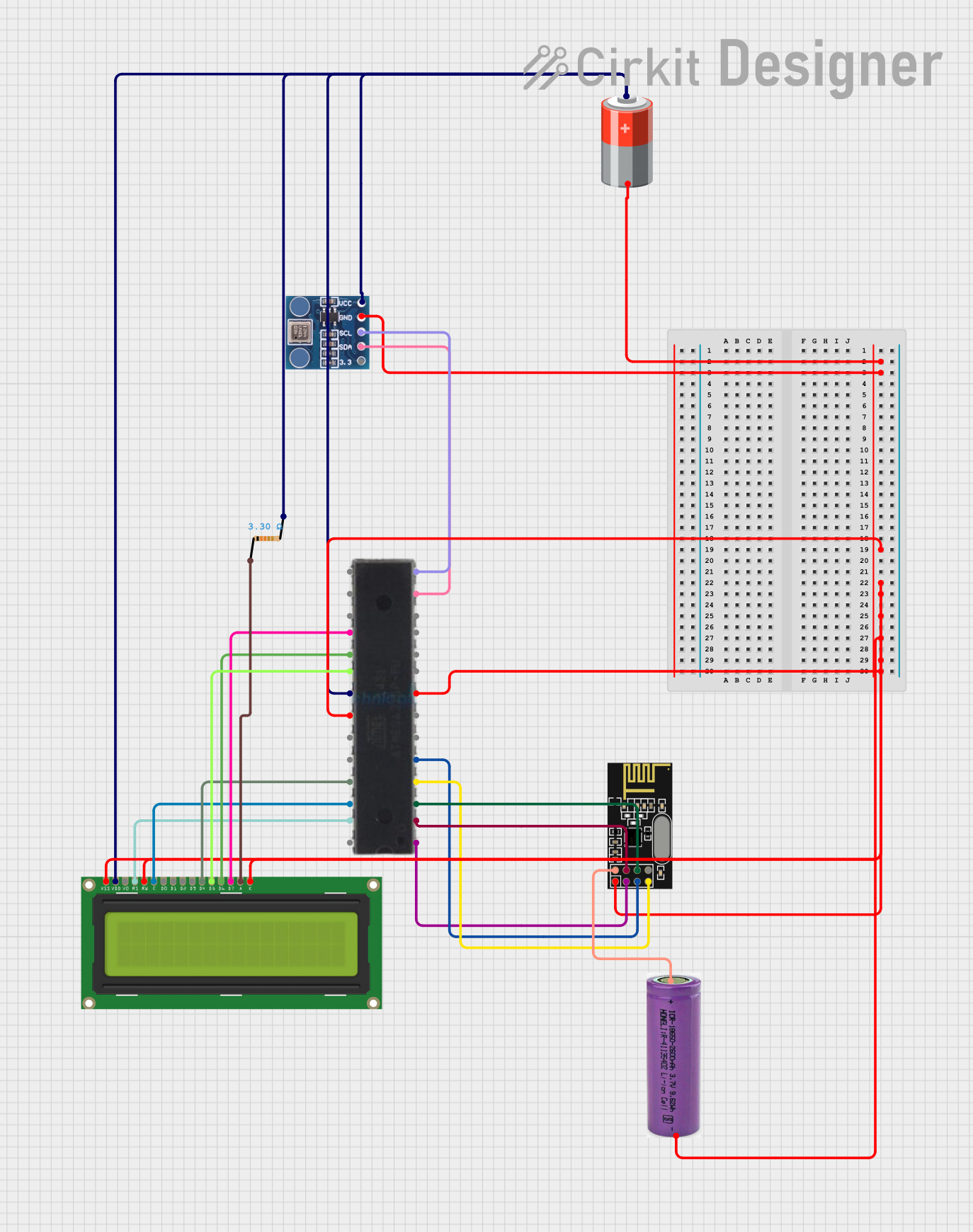

Explore Projects Built with thin film pressure sensor

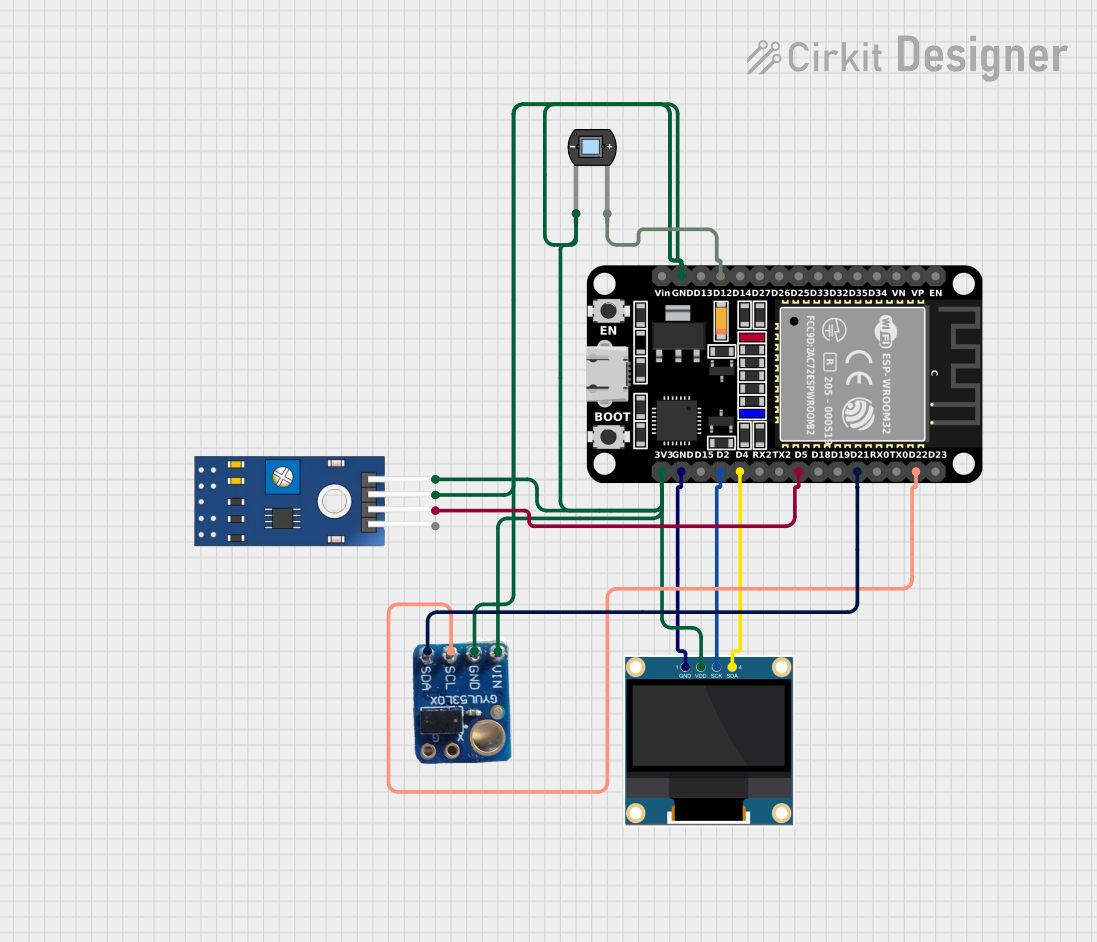

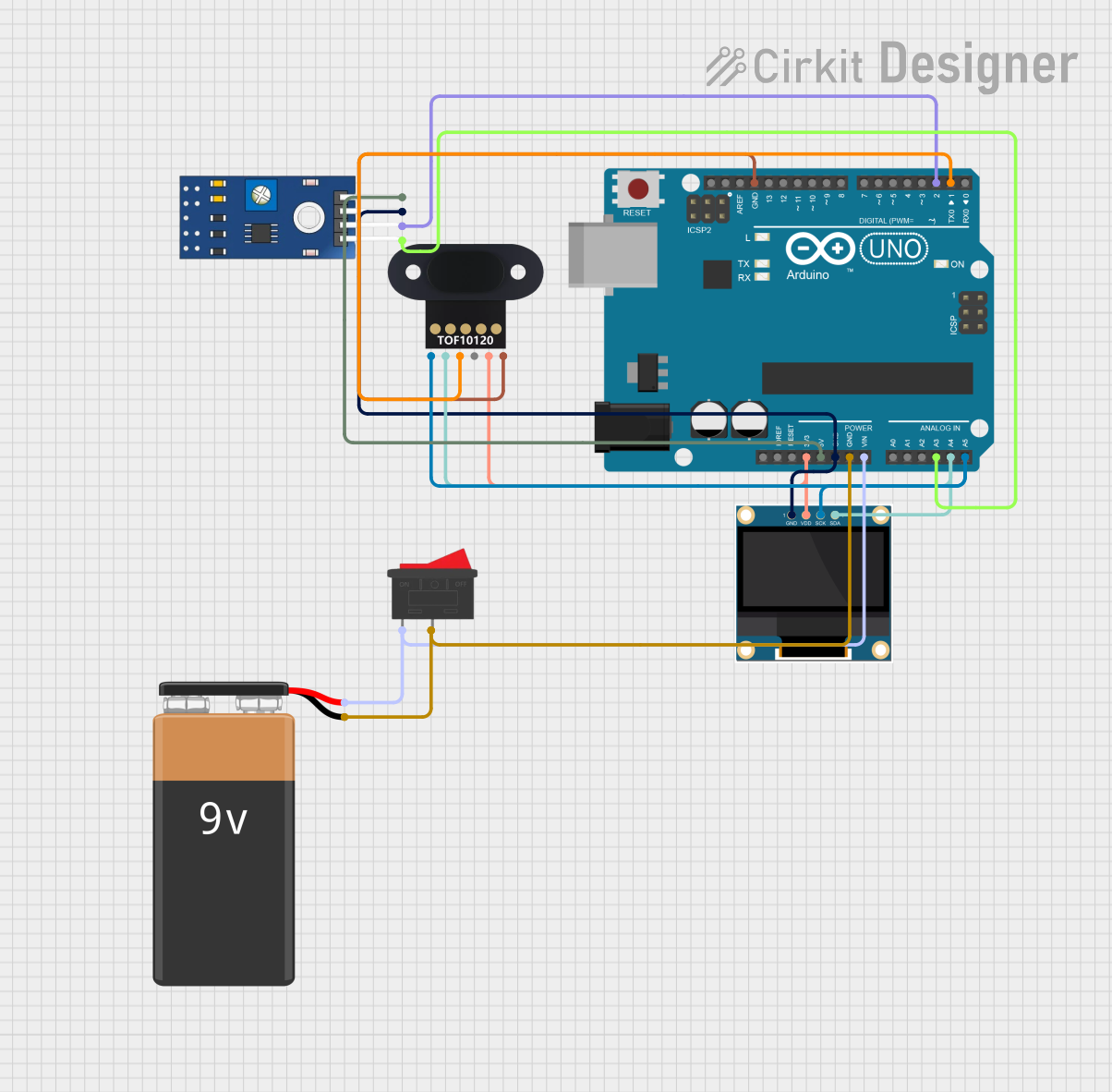

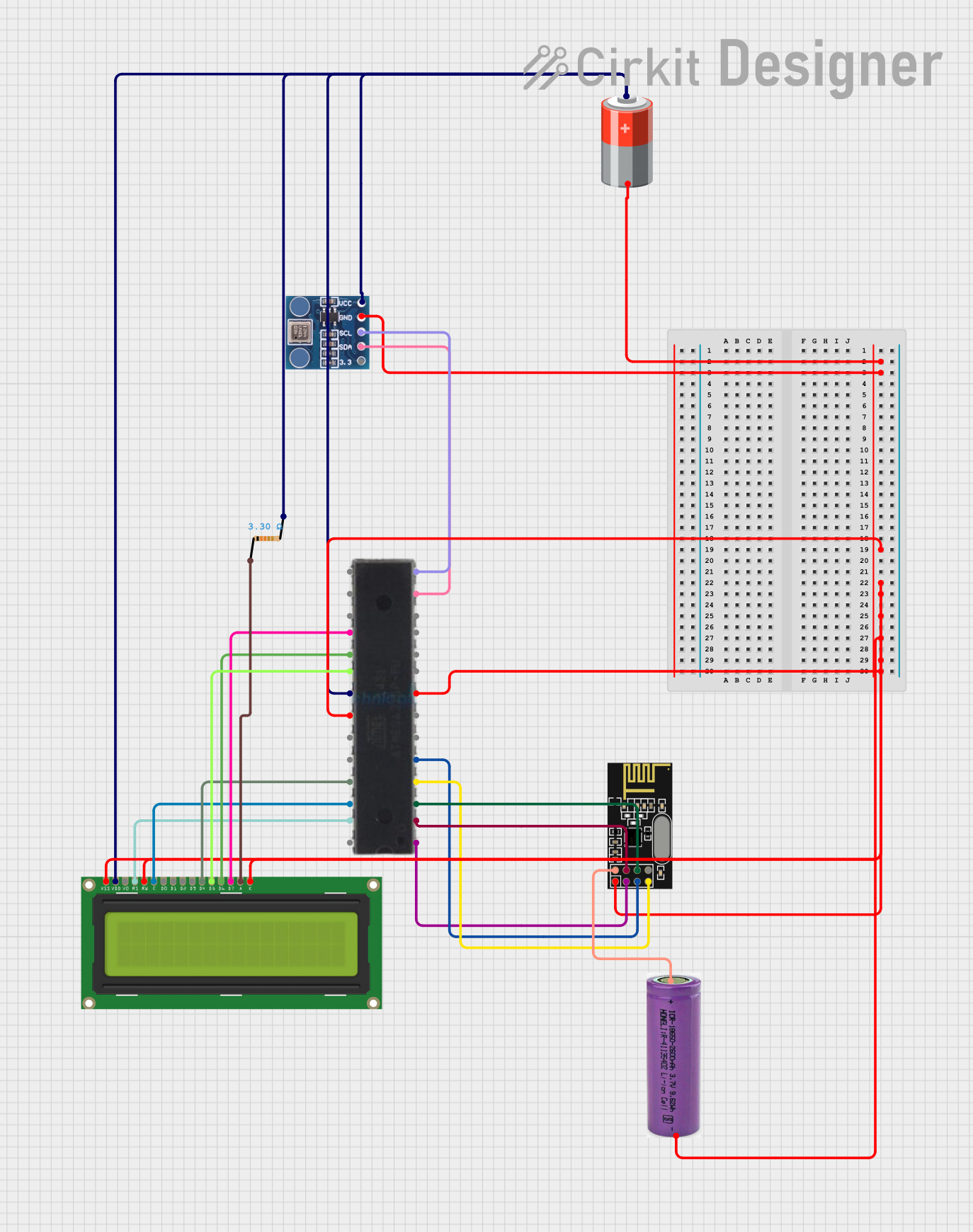

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with thin film pressure sensor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Medical Devices: Used in devices like blood pressure monitors and respiratory equipment.

- Industrial Equipment: Employed in robotics, automation systems, and pressure monitoring tools.

- Consumer Electronics: Integrated into touch-sensitive devices and wearable technology.

- Automotive Systems: Used for tire pressure monitoring and seat occupancy detection.

Technical Specifications

Below are the general technical specifications for a typical thin film pressure sensor. Note that specific values may vary depending on the manufacturer and model.

Key Technical Details

- Operating Voltage: 3.3V to 5V

- Operating Current: < 10mA

- Pressure Range: 0 to 10 bar (varies by model)

- Output Type: Analog (resistance or voltage change)

- Response Time: < 1ms

- Operating Temperature: -20°C to 85°C

- Durability: Up to 1 million pressure cycles

Pin Configuration and Descriptions

The thin film pressure sensor typically has a 2-pin or 3-pin configuration. Below is a table describing the pinout for a common 3-pin model:

| Pin | Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (3.3V to 5V). Connect to the positive terminal of the power source. |

| 2 | GND | Ground connection. Connect to the negative terminal of the power source. |

| 3 | Signal Output | Analog output signal proportional to the applied pressure. |

For 2-pin models, the pins are typically:

- Pin 1: Signal and power input (combined)

- Pin 2: Ground

Usage Instructions

How to Use the Component in a Circuit

- Power the Sensor: Connect the VCC pin to a 3.3V or 5V power source and the GND pin to ground.

- Read the Output: Connect the Signal Output pin to an analog input pin of a microcontroller (e.g., Arduino UNO) or an analog-to-digital converter (ADC).

- Calibrate the Sensor: Apply known pressure values to the sensor and record the corresponding output to create a calibration curve.

- Implement in Circuit: Use the sensor in your application circuit, ensuring proper placement to avoid mechanical stress or damage.

Important Considerations and Best Practices

- Avoid Overloading: Do not exceed the sensor's maximum pressure rating to prevent damage.

- Stable Power Supply: Use a regulated power source to ensure accurate readings.

- Environmental Protection: If used in harsh environments, protect the sensor from moisture, dust, and extreme temperatures.

- Calibration: Regularly calibrate the sensor for consistent performance, especially in critical applications.

Example: Connecting to an Arduino UNO

Below is an example of how to connect and read data from a thin film pressure sensor using an Arduino UNO.

Circuit Diagram

- VCC: Connect to the Arduino's 5V pin.

- GND: Connect to the Arduino's GND pin.

- Signal Output: Connect to an analog input pin (e.g., A0).

Arduino Code

// Define the analog pin connected to the sensor

const int sensorPin = A0;

// Variable to store the sensor reading

int sensorValue = 0;

void setup() {

// Initialize serial communication for debugging

Serial.begin(9600);

}

void loop() {

// Read the analog value from the sensor

sensorValue = analogRead(sensorPin);

// Convert the analog value to a voltage (assuming 5V reference)

float voltage = sensorValue * (5.0 / 1023.0);

// Print the sensor value and voltage to the Serial Monitor

Serial.print("Sensor Value: ");

Serial.print(sensorValue);

Serial.print(" | Voltage: ");

Serial.println(voltage);

// Add a small delay for stability

delay(500);

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output Signal

- Cause: Incorrect wiring or power supply.

- Solution: Double-check the connections and ensure the power supply is within the specified range.

Inconsistent Readings

- Cause: Electrical noise or unstable power supply.

- Solution: Use decoupling capacitors near the sensor and ensure a stable power source.

Sensor Not Responding to Pressure

- Cause: Sensor damage or improper placement.

- Solution: Inspect the sensor for physical damage and ensure it is properly mounted.

Output Signal Saturates

- Cause: Pressure exceeds the sensor's maximum range.

- Solution: Ensure the applied pressure is within the specified range.

FAQs

Q: Can the sensor measure negative pressure (vacuum)?

- A: Some models are designed to measure both positive and negative pressures. Check the datasheet for details.

Q: How do I protect the sensor in a wet environment?

- A: Use a waterproof enclosure or apply a conformal coating to shield the sensor.

Q: Can I use this sensor with a 3.3V microcontroller?

- A: Yes, as long as the sensor's operating voltage range includes 3.3V.

Q: How do I improve the accuracy of the sensor?

- A: Regularly calibrate the sensor, use a stable power supply, and minimize environmental noise.

This documentation provides a comprehensive guide to understanding, using, and troubleshooting thin film pressure sensors. For specific details, always refer to the manufacturer's datasheet.