How to Use IRF520 PWM: Examples, Pinouts, and Specs

Design with IRF520 PWM in Cirkit Designer

Design with IRF520 PWM in Cirkit DesignerIntroduction

The IRF520 PWM module is a versatile and powerful electronic component designed for controlling high-power loads with digital signals. It is based on the IRF520 power MOSFET and is capable of handling high currents and voltages. This module is commonly used in applications involving Pulse Width Modulation (PWM) to control the power delivered to devices such as motors, LEDs, and heating elements. Its ease of use and robustness make it a popular choice for hobbyists and professionals alike.

Explore Projects Built with IRF520 PWM

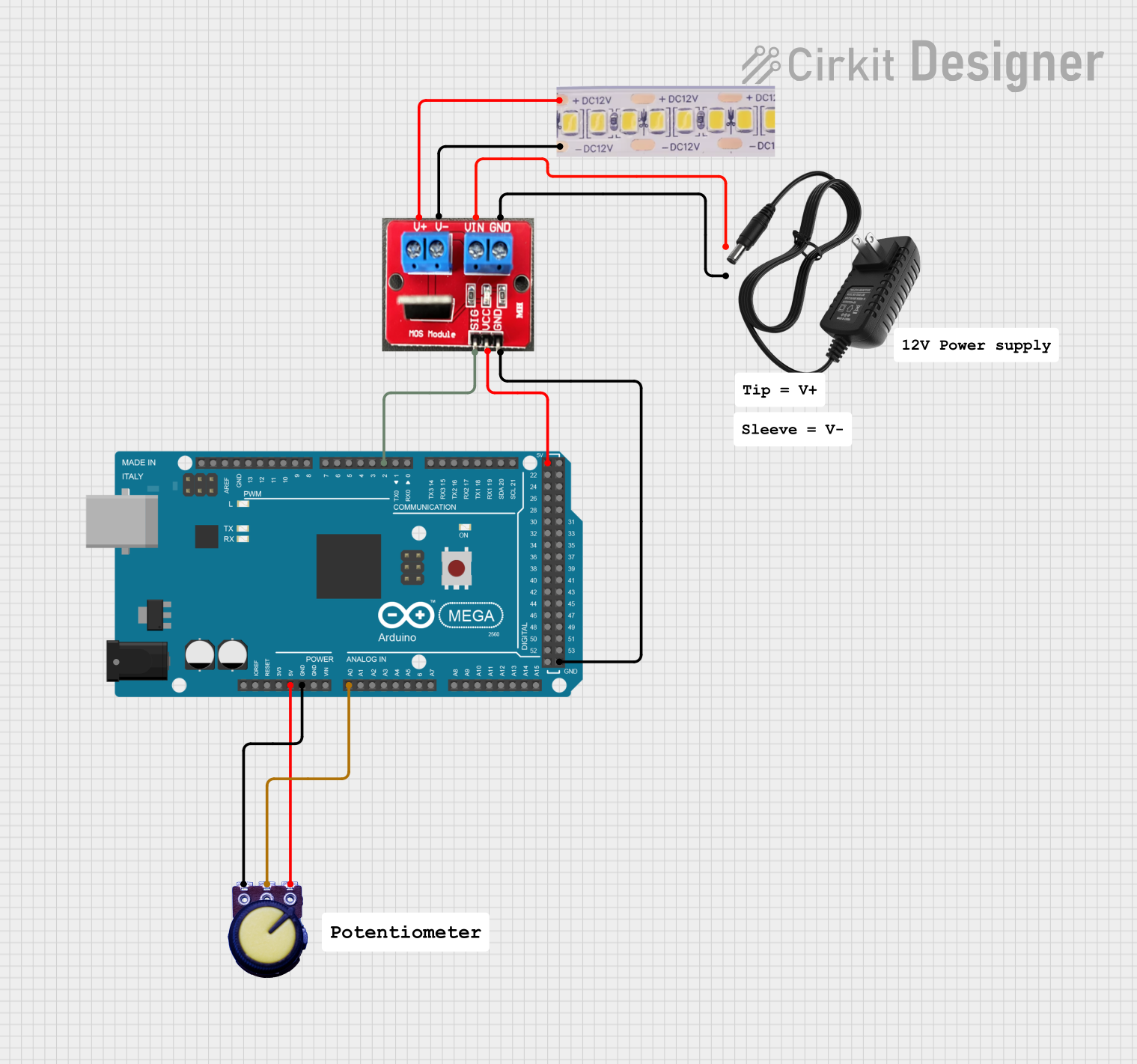

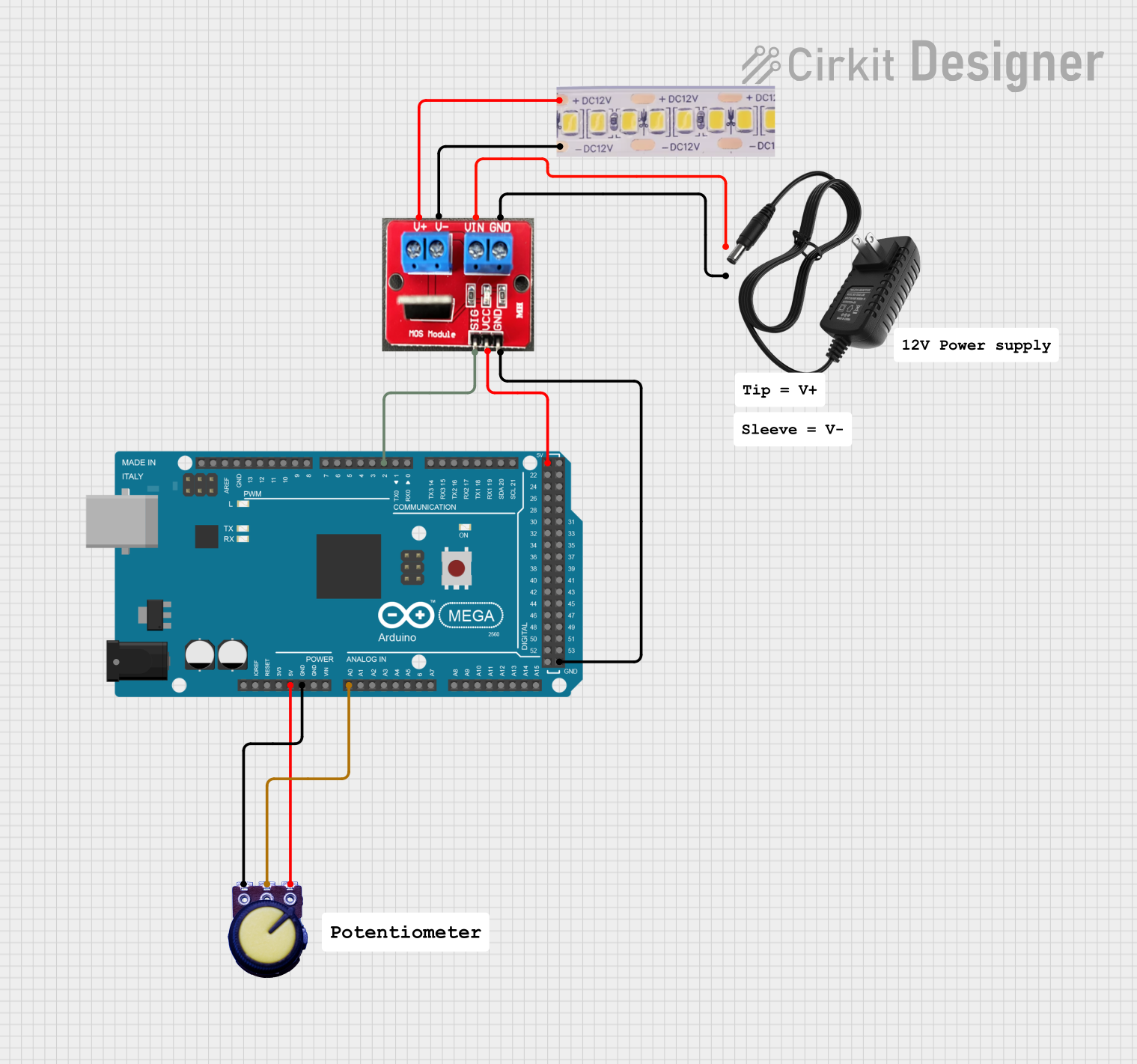

Open Project in Cirkit Designer

Open Project in Cirkit Designer

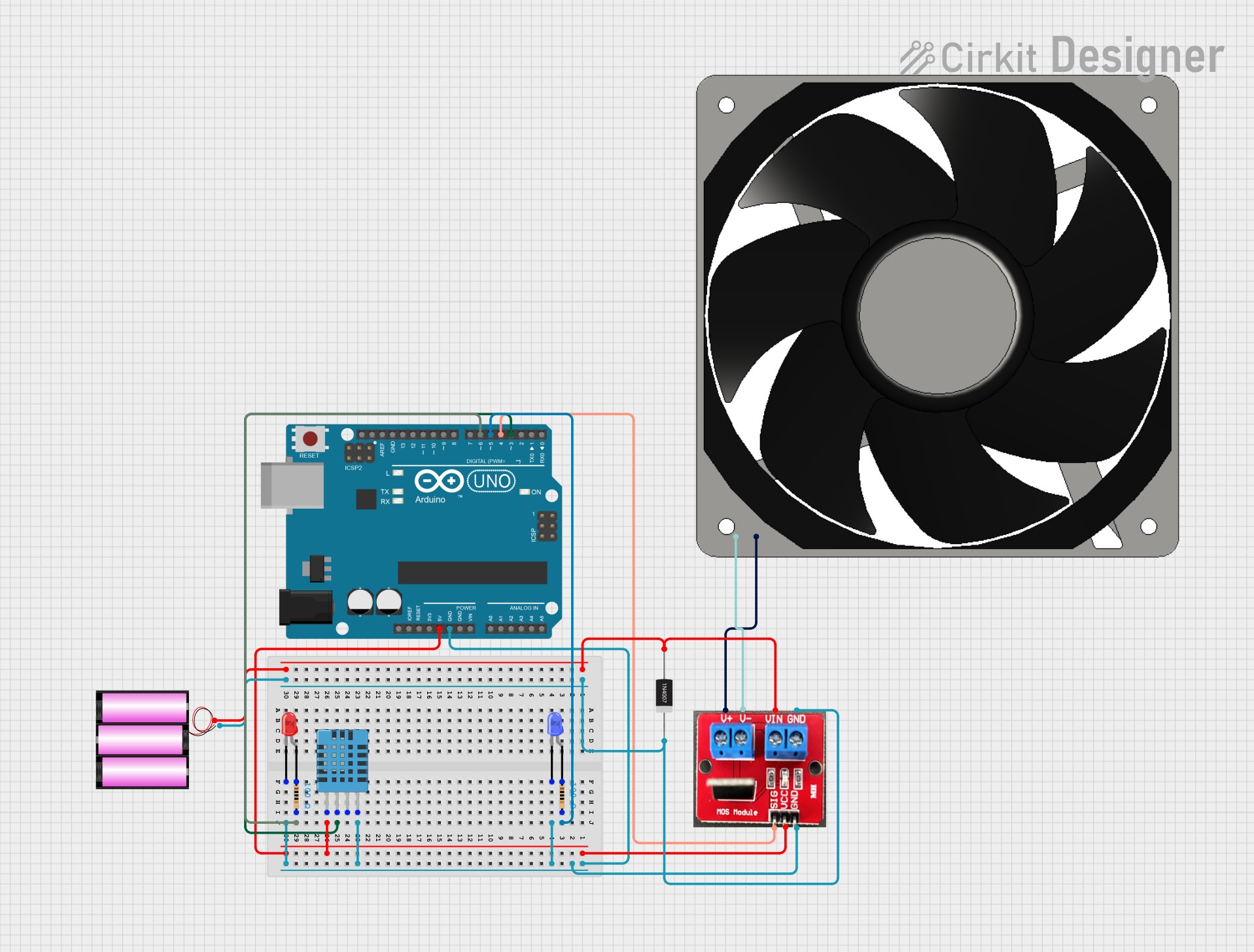

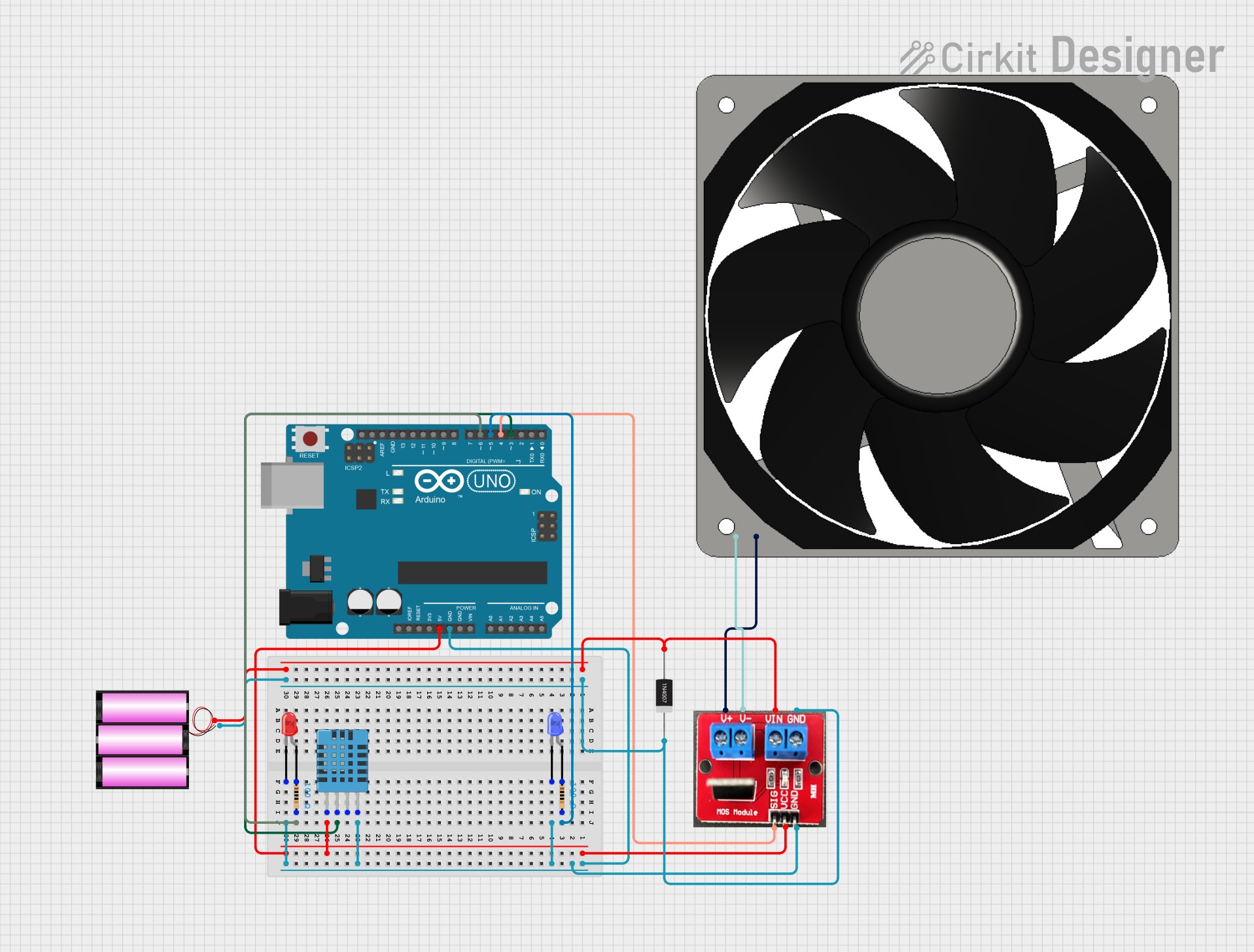

Open Project in Cirkit Designer

Open Project in Cirkit Designer

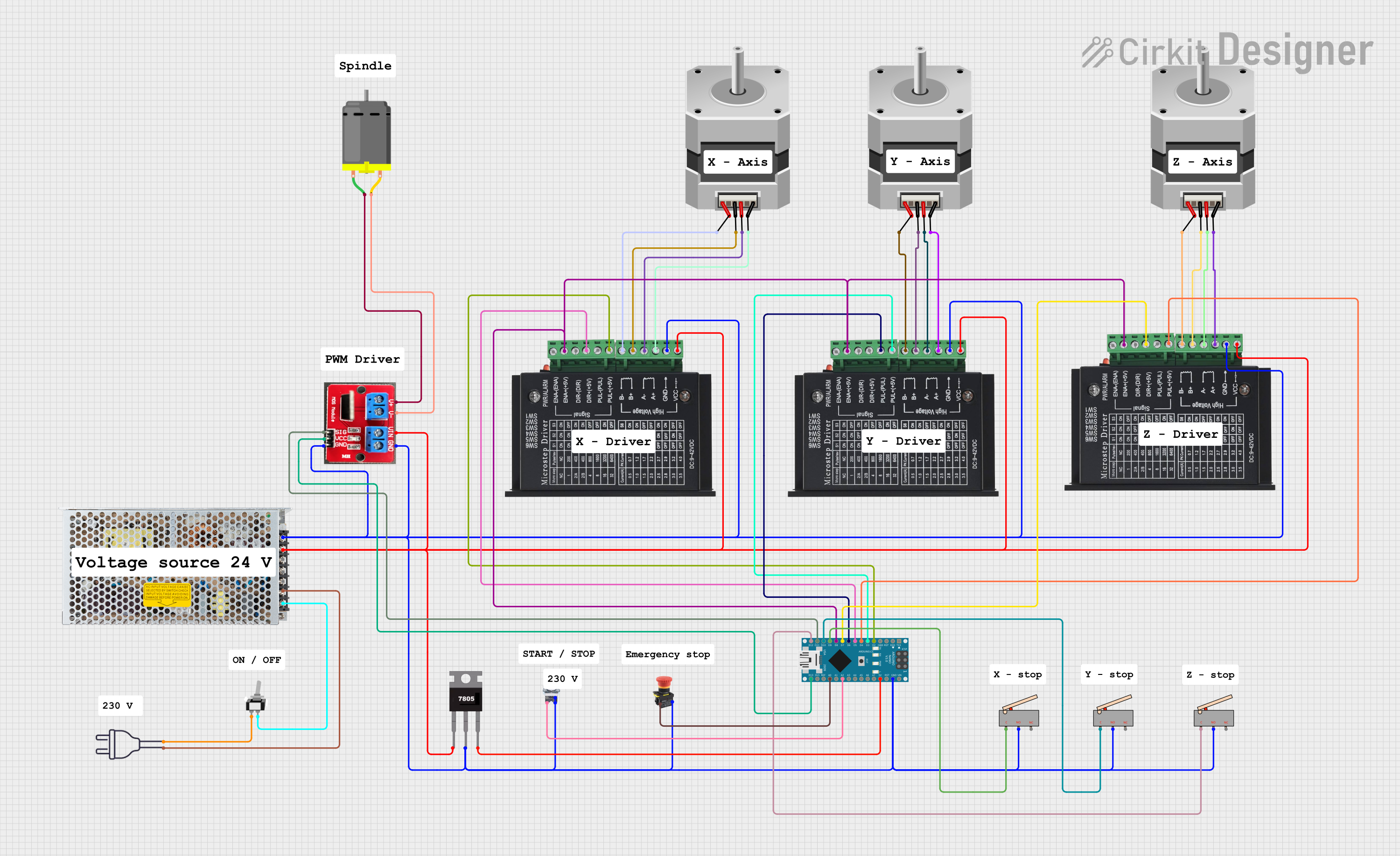

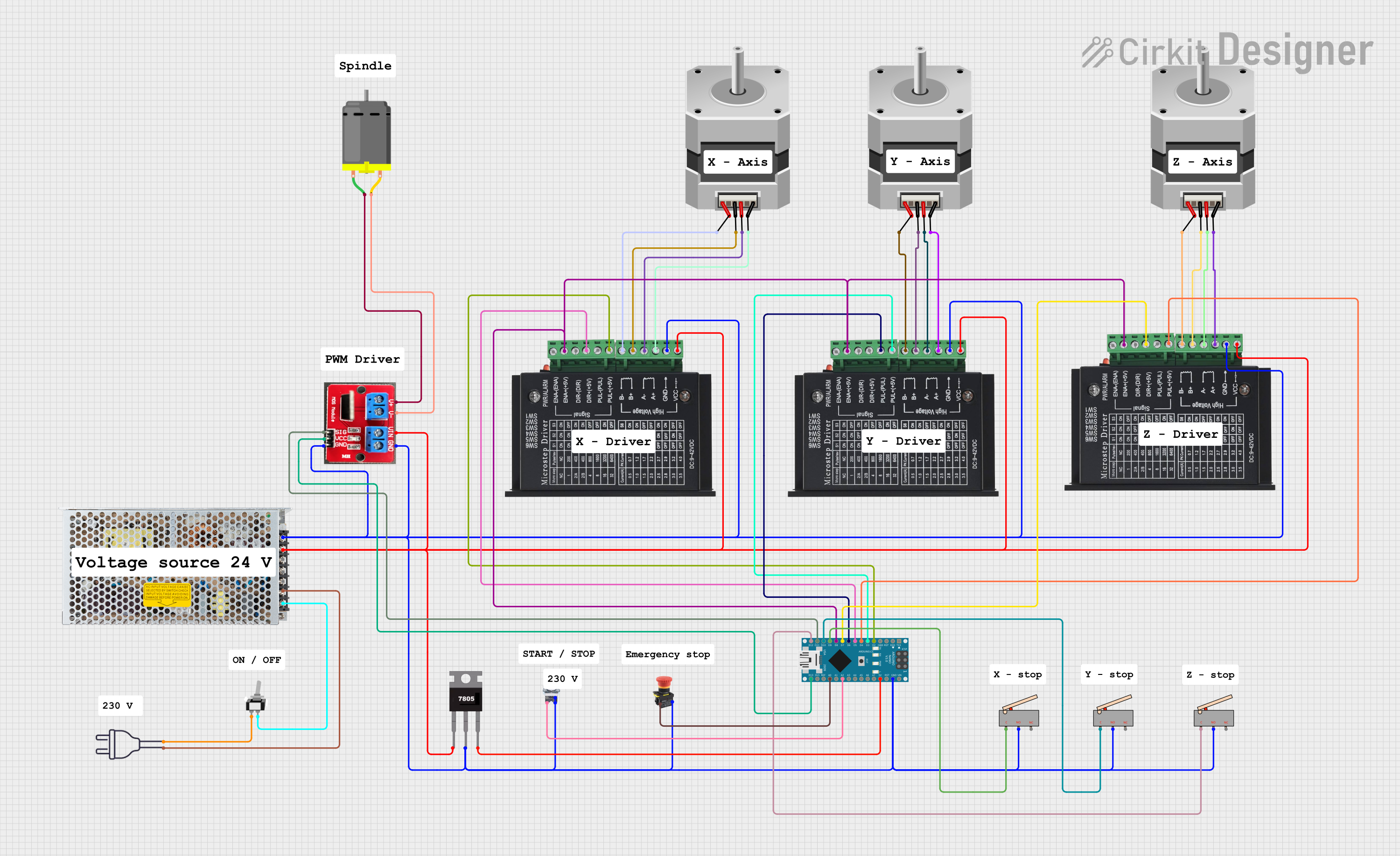

Open Project in Cirkit Designer

Open Project in Cirkit Designer

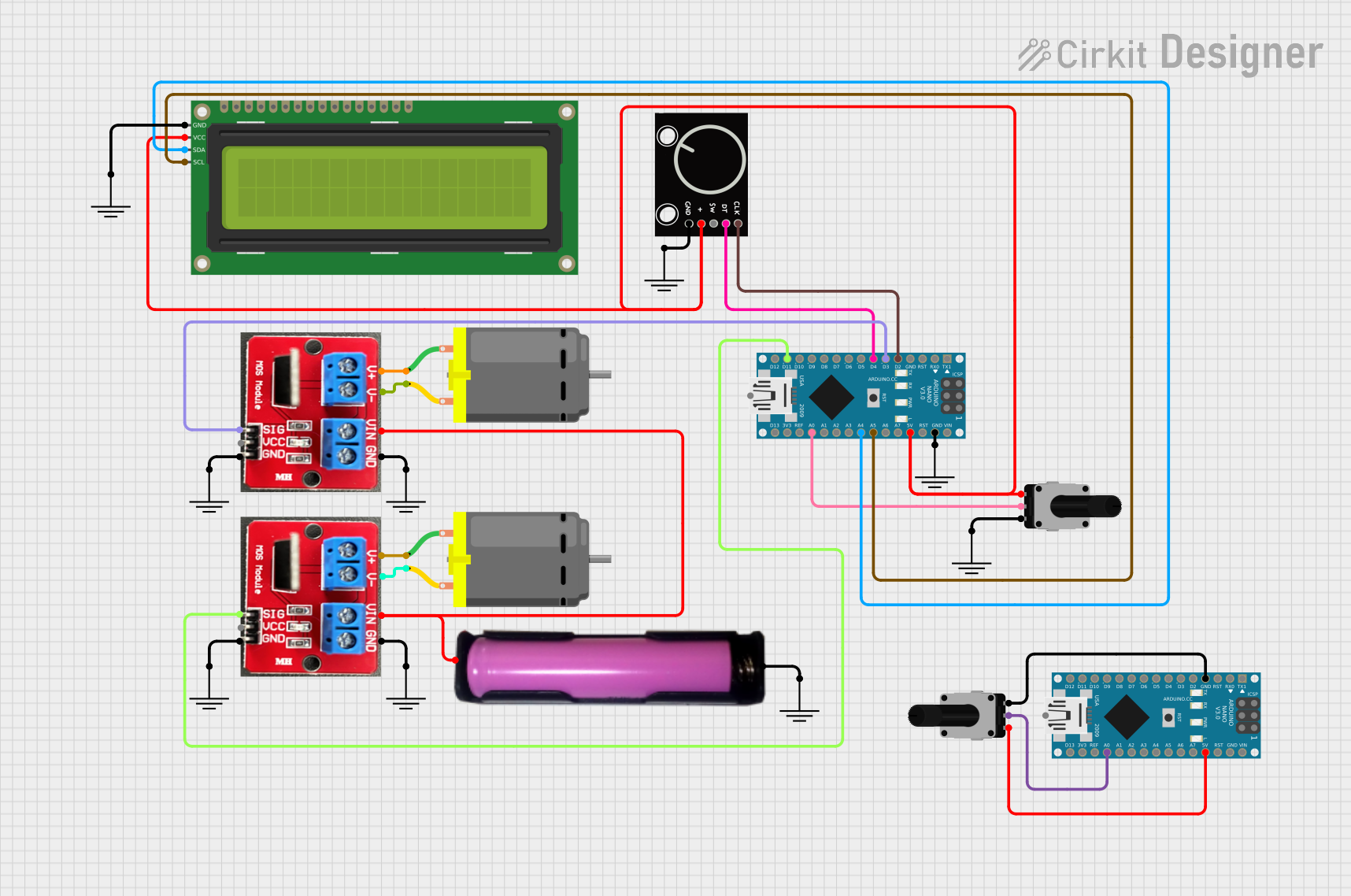

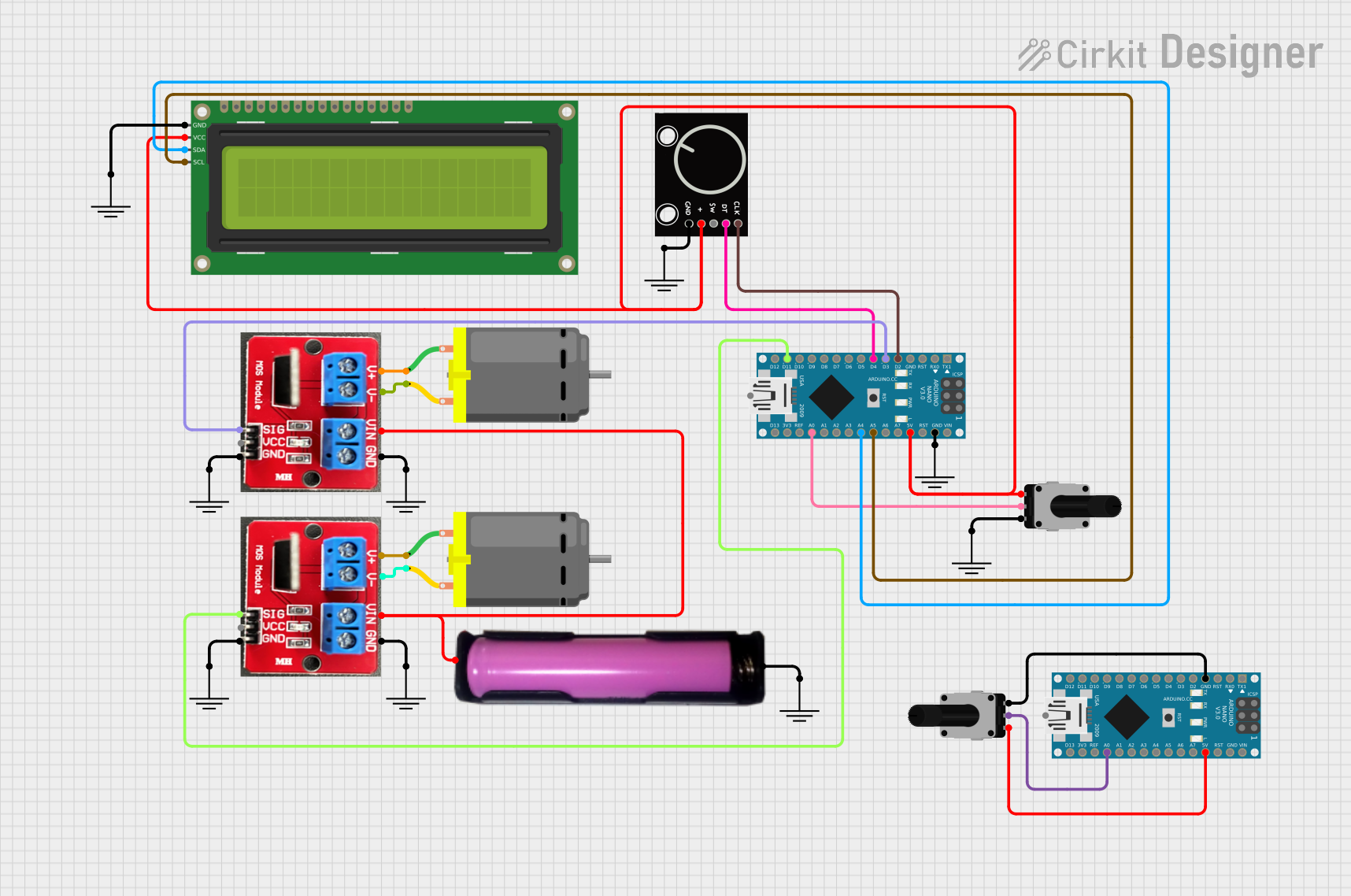

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with IRF520 PWM

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Motor speed control

- LED dimming and RGB lighting

- Heating elements control

- Switching high-power loads with microcontrollers

Technical Specifications

Key Technical Details

- Voltage Rating (VDS): 100V

- Drain Current (ID): 9.7A

- Power Dissipation (PD): 60W

- RDS(on): 0.27Ω at VGS = 10V

- Gate Threshold Voltage (VGS(th)): 2.0V to 4.0V

Pin Configuration and Descriptions

| Pin Number | Name | Description |

|---|---|---|

| 1 | V+ | Power supply input, connects to the positive voltage source |

| 2 | GND | Ground connection |

| 3 | SIG | Signal input, accepts PWM signal from a microcontroller |

| 4 | V- | Power output to the load, connects to the negative side of the load |

| 5 | GND | Ground for the load |

Usage Instructions

How to Use the Component in a Circuit

- Connect the V+ pin to a positive voltage source suitable for your load.

- Connect the GND pin to the common ground of your power supply and microcontroller.

- Connect the SIG pin to a PWM-capable digital output on your microcontroller.

- Connect the load between the V- pin and the positive terminal of your power supply.

Important Considerations and Best Practices

- Ensure the power supply voltage does not exceed the maximum VDS rating of the module.

- The total current through the load should not exceed the maximum ID rating.

- Use a heatsink if the power dissipation is expected to be high during operation.

- Always provide a proper gate signal; floating gate can lead to unpredictable behavior.

- Use a flyback diode when controlling inductive loads to prevent voltage spikes.

Example Code for Arduino UNO

// Define the PWM signal pin connected to the IRF520 module

const int pwmPin = 3;

void setup() {

// Set the PWM pin as an output

pinMode(pwmPin, OUTPUT);

}

void loop() {

// Increase the brightness gradually

for (int dutyCycle = 0; dutyCycle <= 255; dutyCycle++) {

// Write the PWM signal to the IRF520 module

analogWrite(pwmPin, dutyCycle);

delay(10);

}

// Decrease the brightness gradually

for (int dutyCycle = 255; dutyCycle >= 0; dutyCycle--) {

analogWrite(pwmPin, dutyCycle);

delay(10);

}

}

Troubleshooting and FAQs

Common Issues Users Might Face

- LEDs or motor not responding to PWM signal: Check the connections and ensure the signal pin is configured correctly in the code.

- Module overheating: Ensure the current through the MOSFET does not exceed the rated ID and that a heatsink is used if necessary.

- Unexpected behavior when switching inductive loads: Make sure a flyback diode is installed across the load.

Solutions and Tips for Troubleshooting

- Double-check wiring against the pin configuration table.

- Use a multimeter to verify the presence of the PWM signal at the SIG pin.

- If using a microcontroller, ensure the code is uploaded correctly and the correct pin is defined for PWM output.

FAQs

Q: Can I control the IRF520 PWM module with a 3.3V logic level? A: Yes, but the performance may be reduced as the gate threshold voltage is between 2.0V and 4.0V.

Q: What is the maximum frequency for the PWM signal? A: The IRF520 can typically handle PWM frequencies up to several kHz. Check the datasheet for exact figures.

Q: Is it necessary to use a heatsink? A: It depends on the current through the MOSFET and the ambient temperature. If the MOSFET is getting hot to the touch, a heatsink is recommended.

Q: Can I use this module to switch AC loads? A: No, the IRF520 is designed for DC loads only. Switching AC loads requires different types of components such as TRIACs or relays designed for AC operation.