How to Use L298N: Examples, Pinouts, and Specs

Design with L298N in Cirkit Designer

Design with L298N in Cirkit DesignerIntroduction

The L298N is a dual H-bridge motor driver IC designed to control the direction and speed of DC motors and stepper motors. It is capable of driving two motors simultaneously, making it a versatile choice for robotics, automation, and other motor control applications. The L298N can handle high currents and voltages, making it suitable for a wide range of projects, from small robots to industrial automation systems.

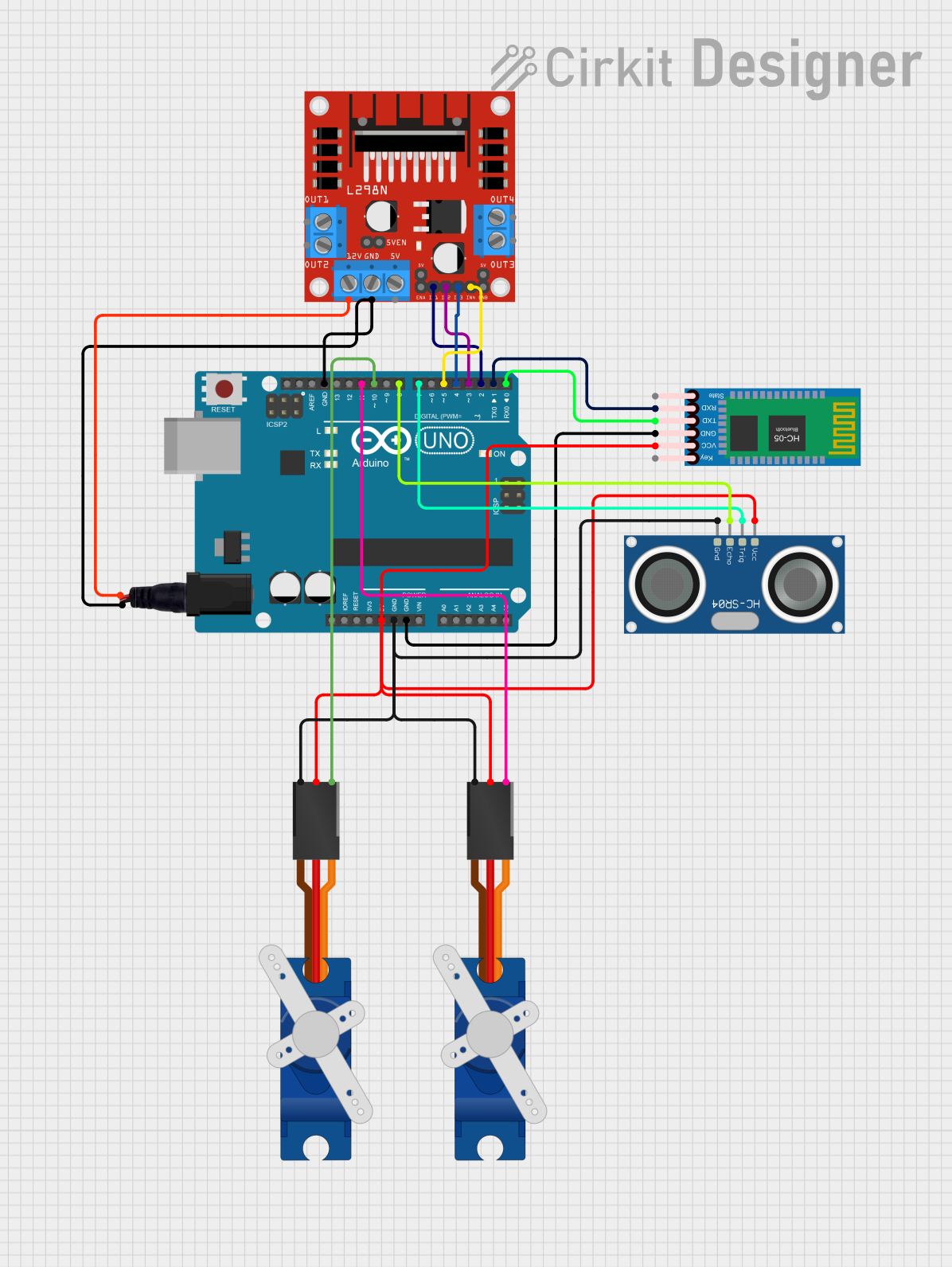

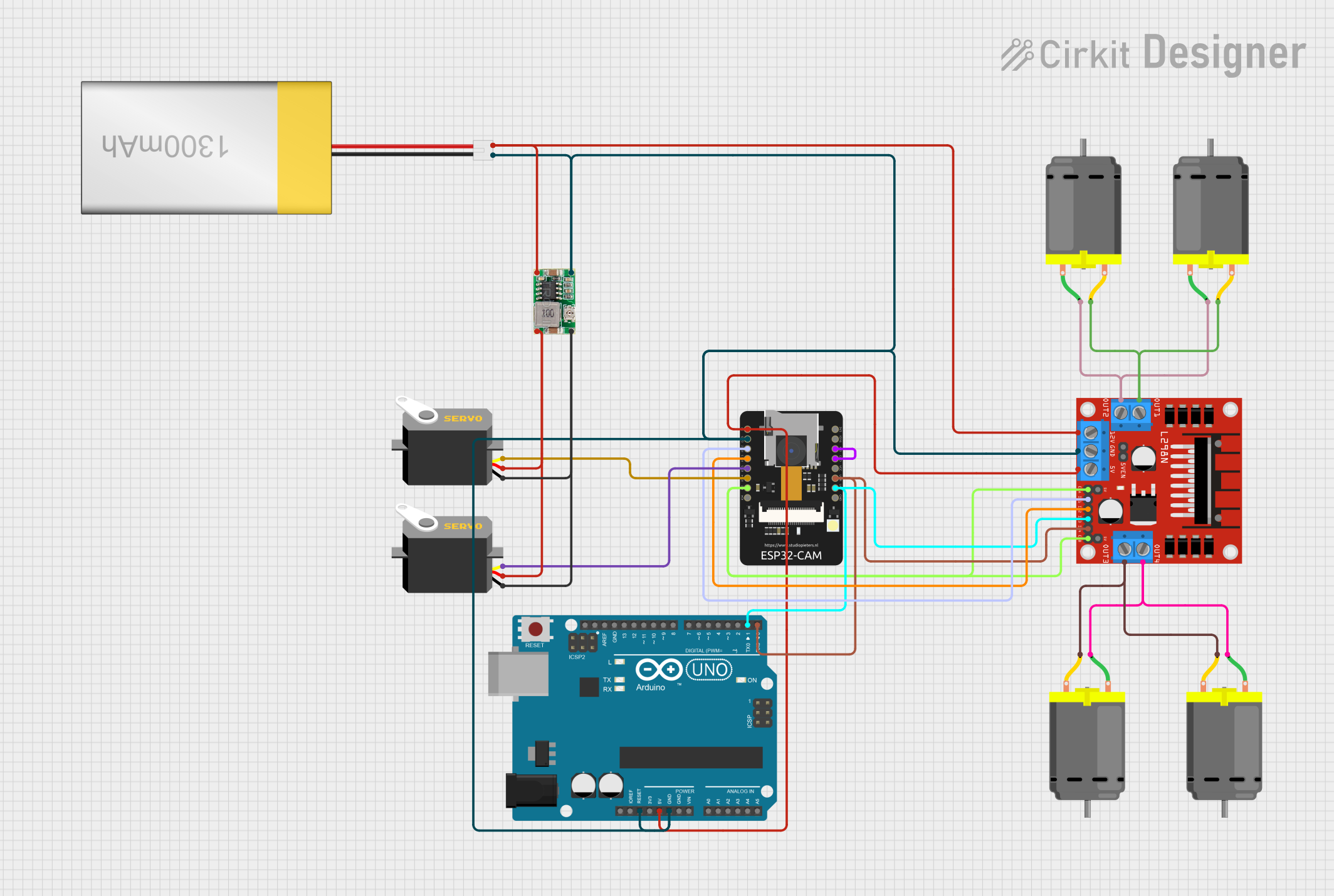

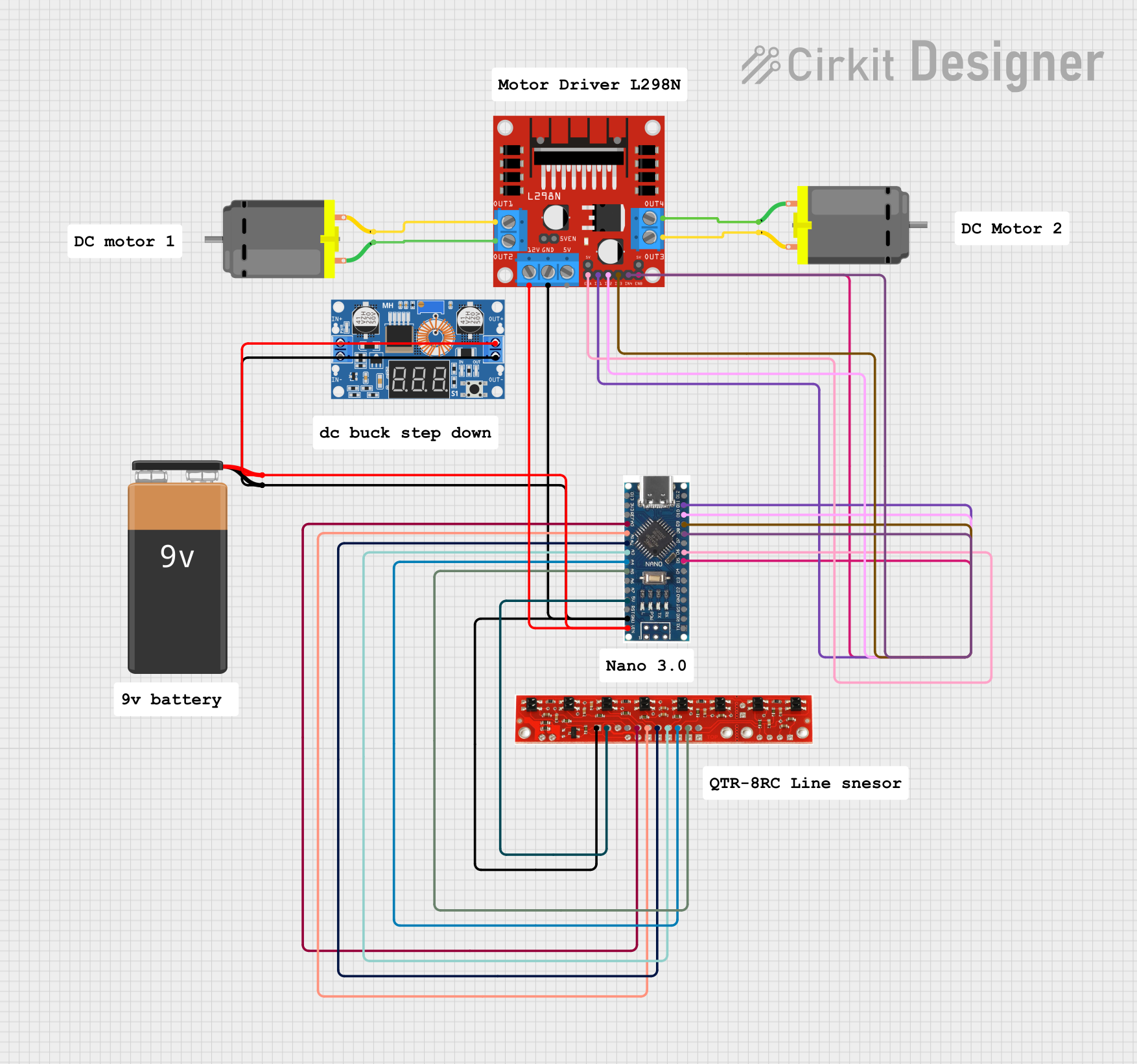

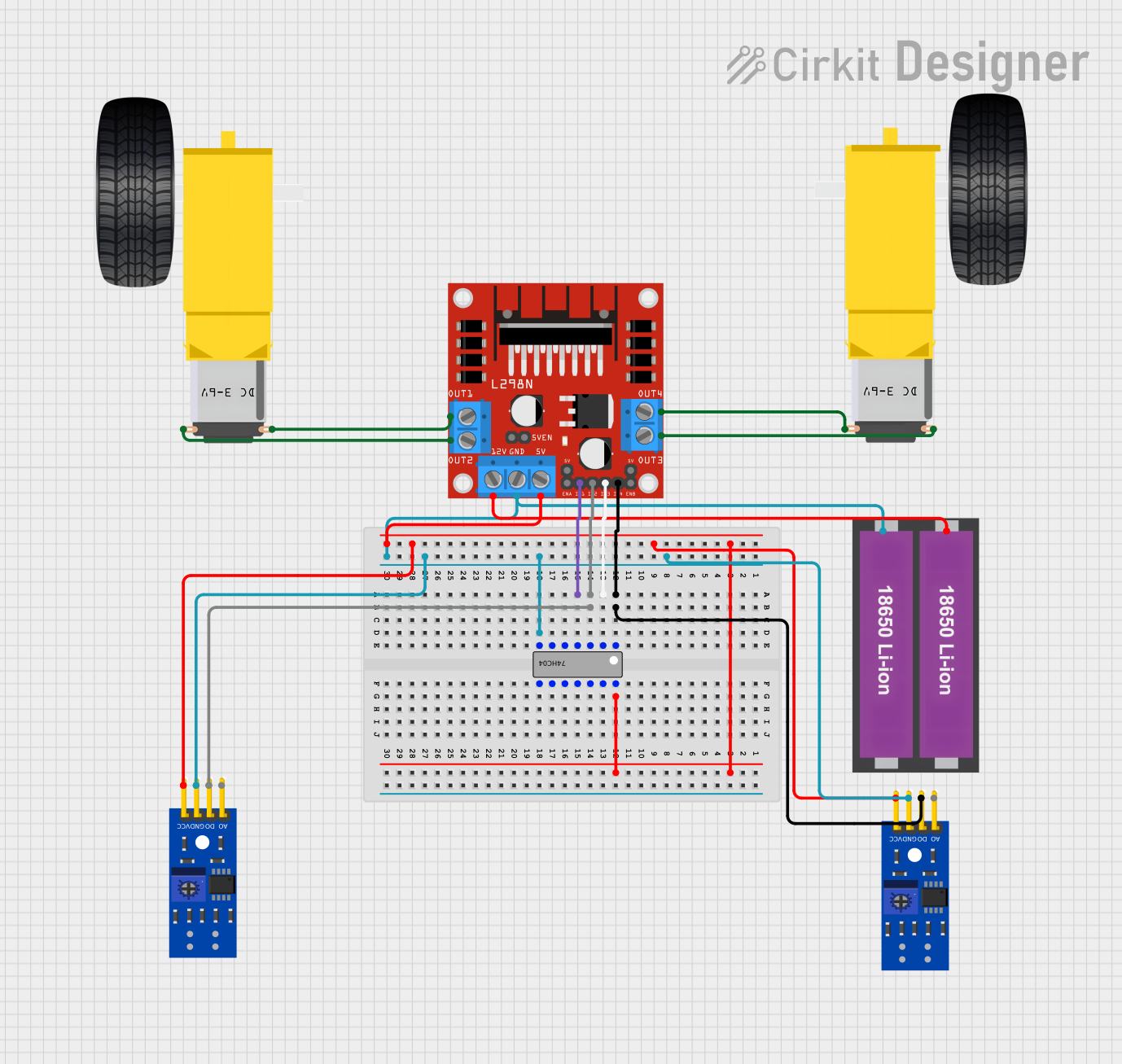

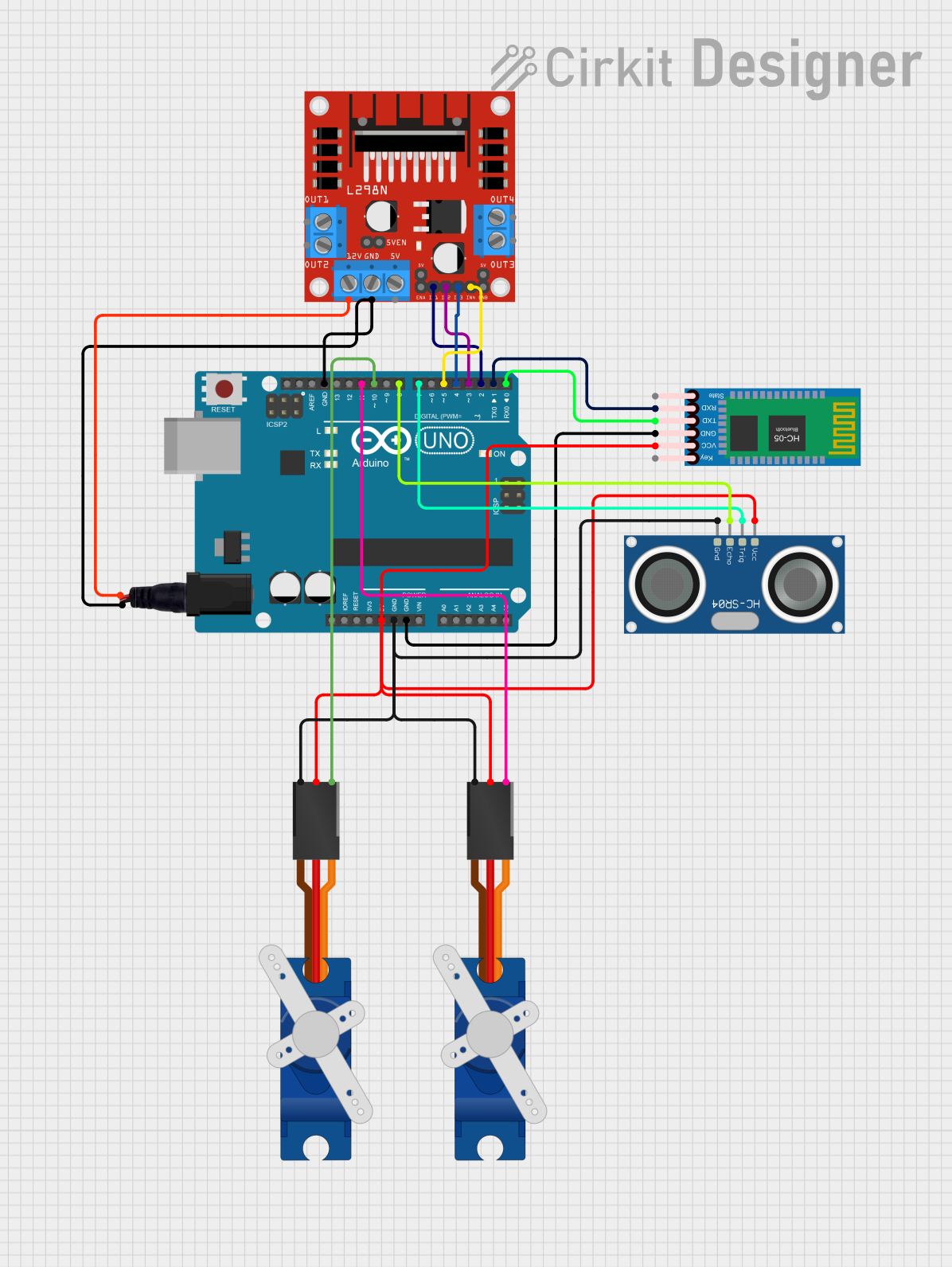

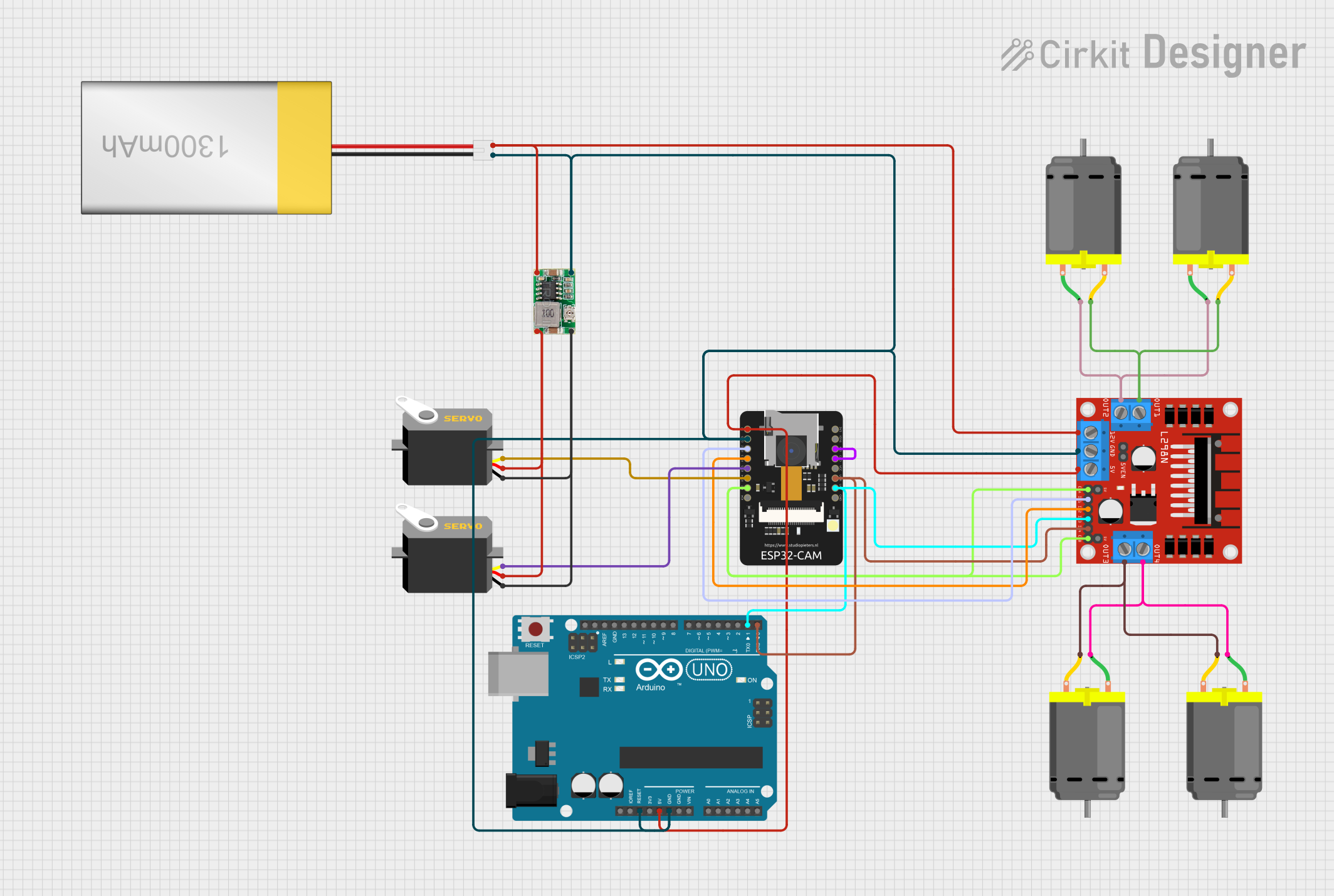

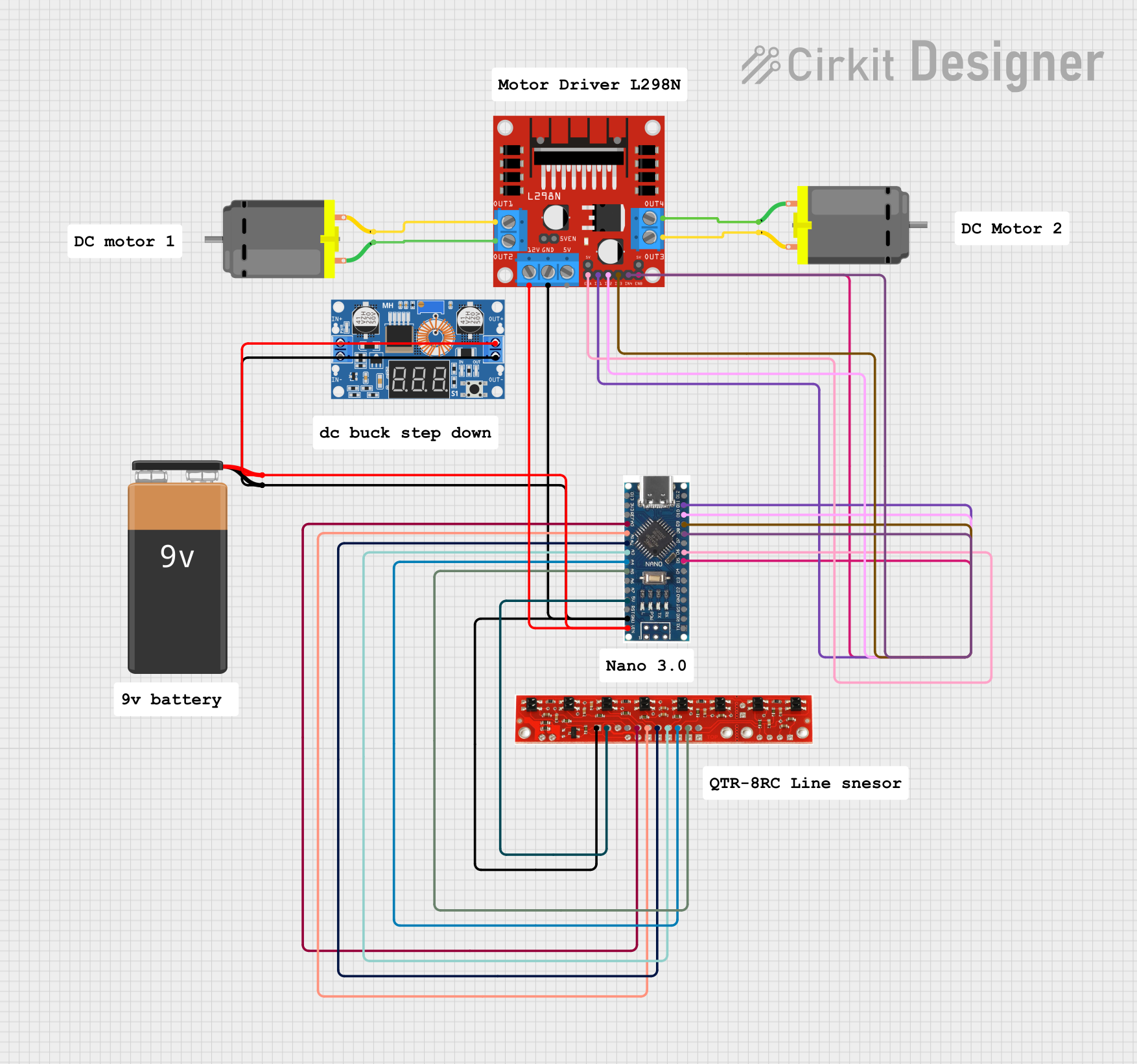

Explore Projects Built with L298N

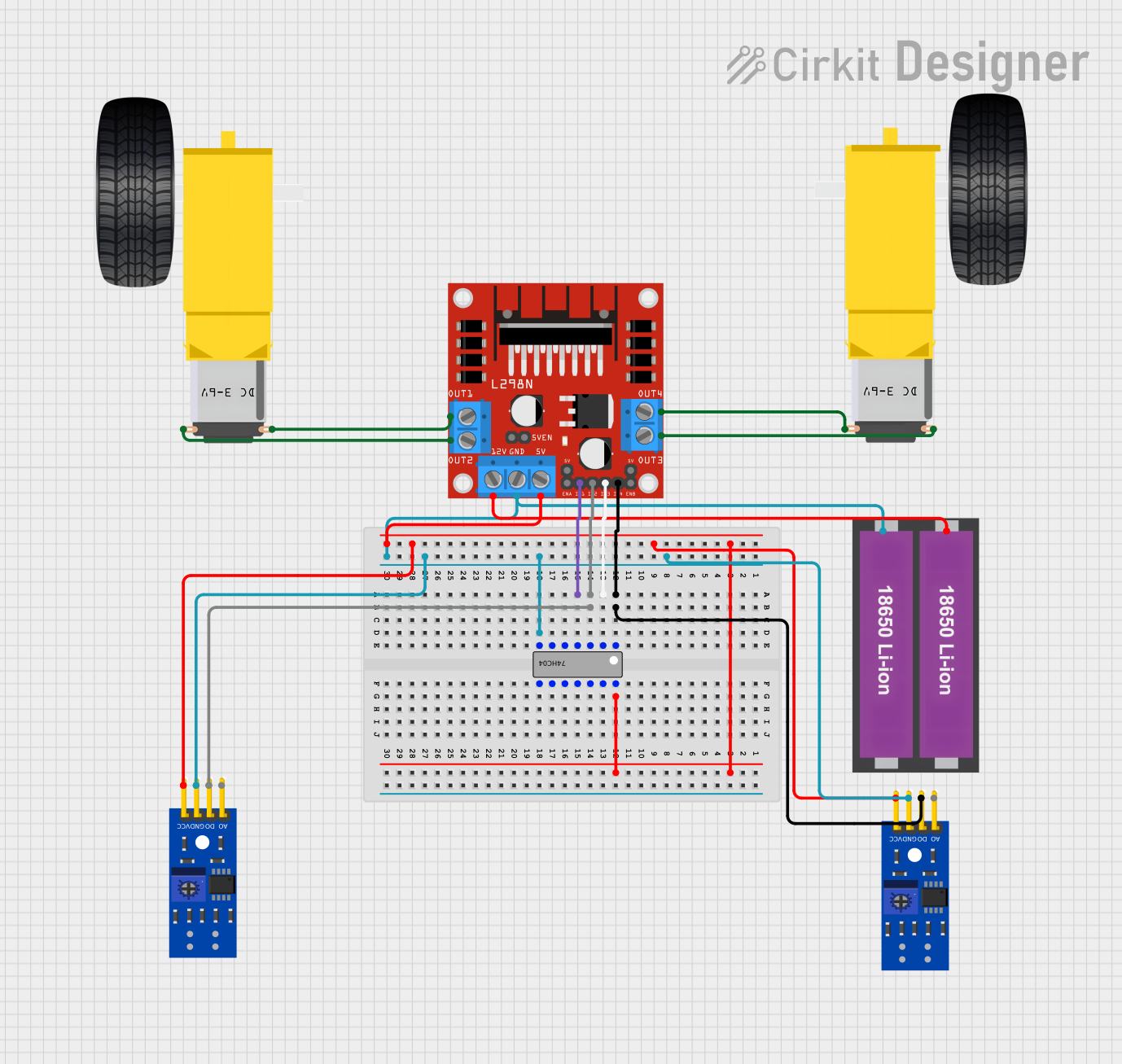

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with L298N

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications:

- Robotics (e.g., controlling wheels or robotic arms)

- Automation systems

- Conveyor belts

- Stepper motor control

- DIY motorized projects

Technical Specifications

The L298N is a robust and reliable motor driver IC with the following key specifications:

| Parameter | Value |

|---|---|

| Operating Voltage | 5V to 46V |

| Maximum Output Current | 2A per channel (4A total) |

| Logic Voltage | 5V |

| Power Dissipation | 25W (with proper heat sinking) |

| Control Logic Levels | High: 2.3V to 5V, Low: 0V to 1.5V |

| Number of Channels | 2 (dual H-bridge) |

| Motor Types Supported | DC motors, stepper motors |

| Operating Temperature | -25°C to +130°C |

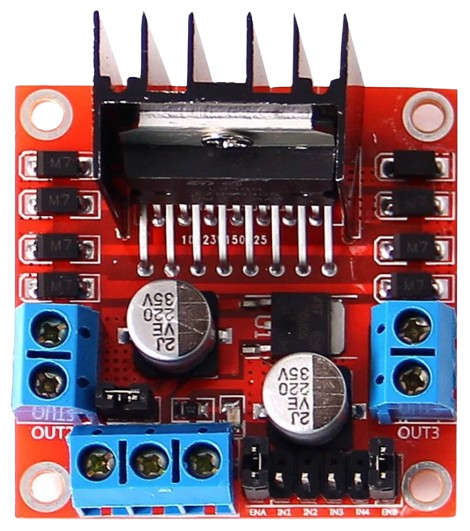

Pin Configuration and Descriptions

The L298N module typically comes with a breakout board for easier use. Below is the pin configuration for the module:

| Pin Name | Type | Description |

|---|---|---|

| IN1 | Input | Controls the direction of Motor A (High/Low). |

| IN2 | Input | Controls the direction of Motor A (High/Low). |

| IN3 | Input | Controls the direction of Motor B (High/Low). |

| IN4 | Input | Controls the direction of Motor B (High/Low). |

| ENA | Enable/Input | Enables or disables Motor A. Can be used for PWM speed control. |

| ENB | Enable/Input | Enables or disables Motor B. Can be used for PWM speed control. |

| OUT1 | Output | Motor A terminal 1. |

| OUT2 | Output | Motor A terminal 2. |

| OUT3 | Output | Motor B terminal 1. |

| OUT4 | Output | Motor B terminal 2. |

| VCC | Power Input | Motor power supply (5V to 46V). |

| GND | Ground | Common ground for the circuit. |

| 5V | Power Output | Provides 5V output (used when the onboard regulator is active). |

Usage Instructions

How to Use the L298N in a Circuit

Power Connections:

- Connect the motor power supply to the

VCCpin (ensure it matches the motor's voltage rating). - Connect the

GNDpin to the ground of your power supply and microcontroller. - If your motor power supply is above 7V, you can use the onboard 5V regulator to power your microcontroller by connecting the

5Vpin to the microcontroller's 5V input.

- Connect the motor power supply to the

Motor Connections:

- Connect the motor terminals to the

OUT1andOUT2pins for Motor A, andOUT3andOUT4pins for Motor B.

- Connect the motor terminals to the

Control Connections:

- Use the

IN1andIN2pins to control the direction of Motor A, andIN3andIN4for Motor B. - Use the

ENAandENBpins for speed control via PWM signals.

- Use the

Logic Power:

- Provide 5V logic power to the control pins from your microcontroller.

Example Arduino Code

Below is an example of how to control a DC motor using the L298N and an Arduino UNO:

// Define control pins for Motor A

const int IN1 = 9; // Direction control pin 1 for Motor A

const int IN2 = 8; // Direction control pin 2 for Motor A

const int ENA = 10; // Speed control (PWM) pin for Motor A

void setup() {

// Set motor control pins as outputs

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

pinMode(ENA, OUTPUT);

}

void loop() {

// Rotate Motor A forward at 50% speed

digitalWrite(IN1, HIGH); // Set IN1 high

digitalWrite(IN2, LOW); // Set IN2 low

analogWrite(ENA, 128); // Set ENA to 50% duty cycle (128/255)

delay(2000); // Run motor for 2 seconds

// Rotate Motor A backward at 75% speed

digitalWrite(IN1, LOW); // Set IN1 low

digitalWrite(IN2, HIGH); // Set IN2 high

analogWrite(ENA, 192); // Set ENA to 75% duty cycle (192/255)

delay(2000); // Run motor for 2 seconds

// Stop Motor A

digitalWrite(IN1, LOW); // Set IN1 low

digitalWrite(IN2, LOW); // Set IN2 low

analogWrite(ENA, 0); // Set ENA to 0% duty cycle (motor off)

delay(2000); // Wait for 2 seconds before repeating

}

Important Considerations and Best Practices

- Heat Dissipation: The L298N can get hot during operation. Use a heat sink or active cooling for high-current applications.

- Power Supply: Ensure the motor power supply voltage matches the motor's requirements and does not exceed the L298N's maximum voltage rating.

- Current Limitation: The L298N can handle up to 2A per channel. For higher currents, consider using a different motor driver.

- PWM Frequency: Use a PWM frequency between 1kHz and 20kHz for optimal performance.

Troubleshooting and FAQs

Common Issues and Solutions

Motors Not Running:

- Check all power connections and ensure the motor power supply is sufficient.

- Verify that the

ENAorENBpins are enabled (HIGH or receiving a PWM signal).

Overheating:

- Ensure the L298N has a heat sink attached.

- Reduce the motor load or use a lower current motor.

Erratic Motor Behavior:

- Check for loose connections or poor solder joints.

- Ensure the control signals from the microcontroller are correct.

No 5V Output:

- Ensure the onboard regulator jumper is in place.

- Verify that the motor power supply is above 7V.

FAQs

Q: Can the L298N drive stepper motors?

A: Yes, the L298N can drive bipolar stepper motors by controlling the two H-bridges. You will need to sequence the control signals appropriately.

Q: Can I use the L298N with a 3.3V microcontroller?

A: The L298N is designed for 5V logic levels. You may need a level shifter to interface it with a 3.3V microcontroller.

Q: What is the maximum motor voltage the L298N can handle?

A: The L298N can handle motor voltages up to 46V.

Q: Can I control the speed of the motors?

A: Yes, you can control motor speed using PWM signals on the ENA and ENB pins.

By following this documentation, you can effectively use the L298N motor driver in your projects!