How to Use INA219: Examples, Pinouts, and Specs

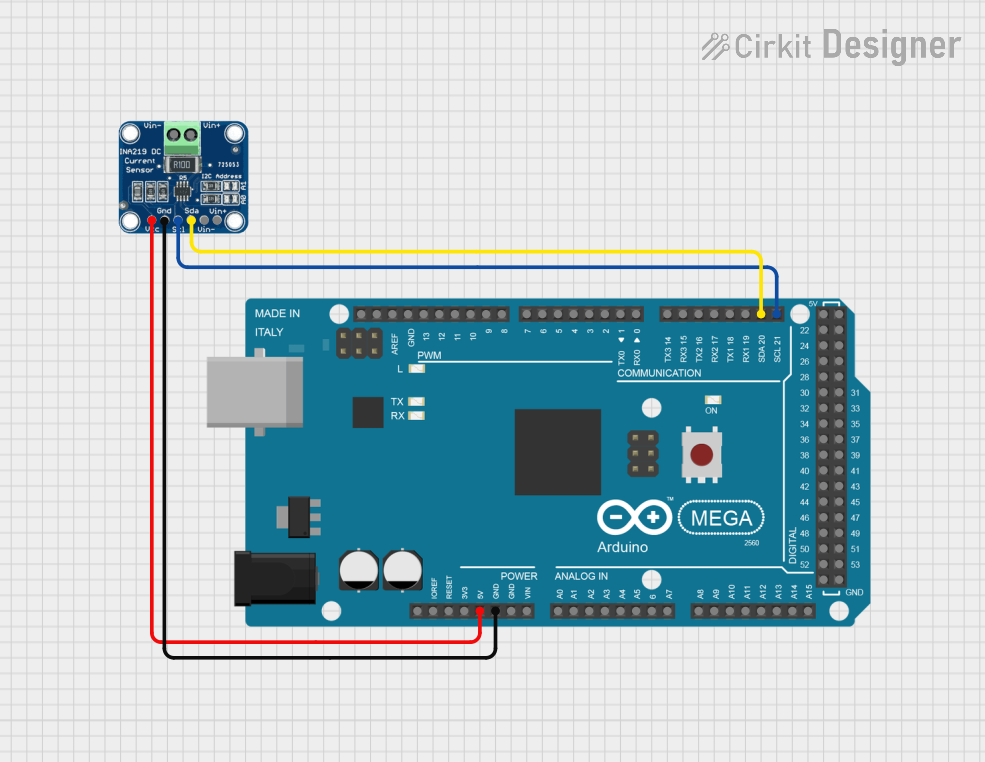

Design with INA219 in Cirkit Designer

Design with INA219 in Cirkit DesignerIntroduction

The INA219 is a high-side current shunt monitor with an integrated I2C interface, designed for precise measurement of current, voltage, and power. It is widely used in applications requiring accurate power monitoring, such as battery management systems, power supply diagnostics, and energy monitoring in embedded systems. By measuring both the voltage across a shunt resistor and the bus voltage, the INA219 calculates power consumption with high accuracy.

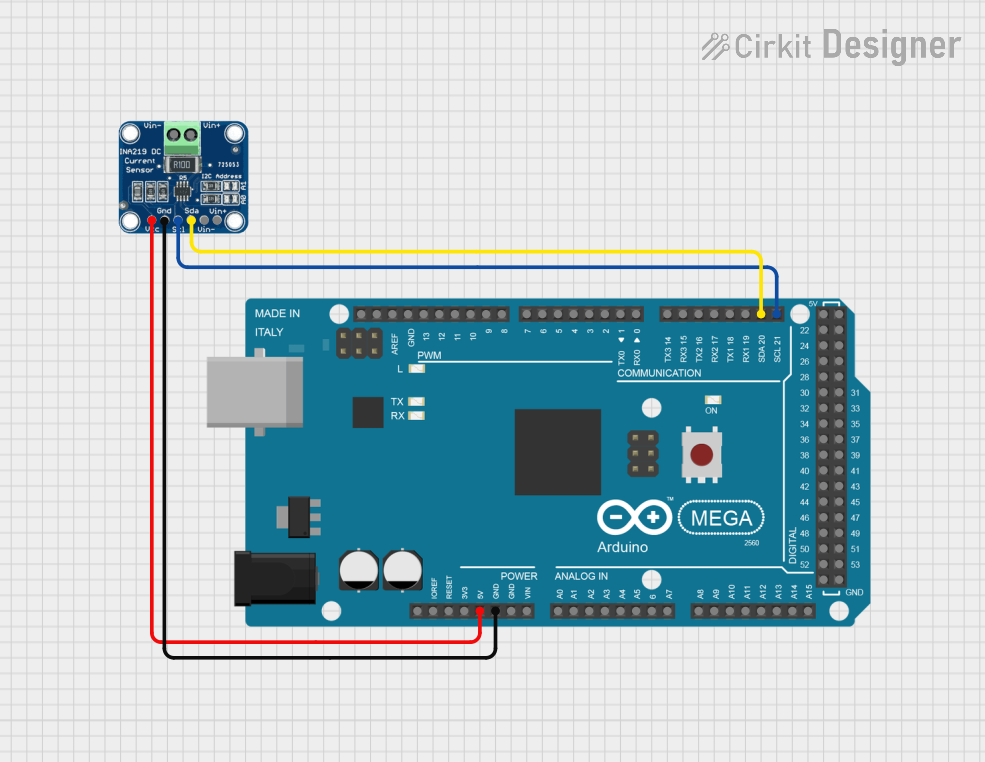

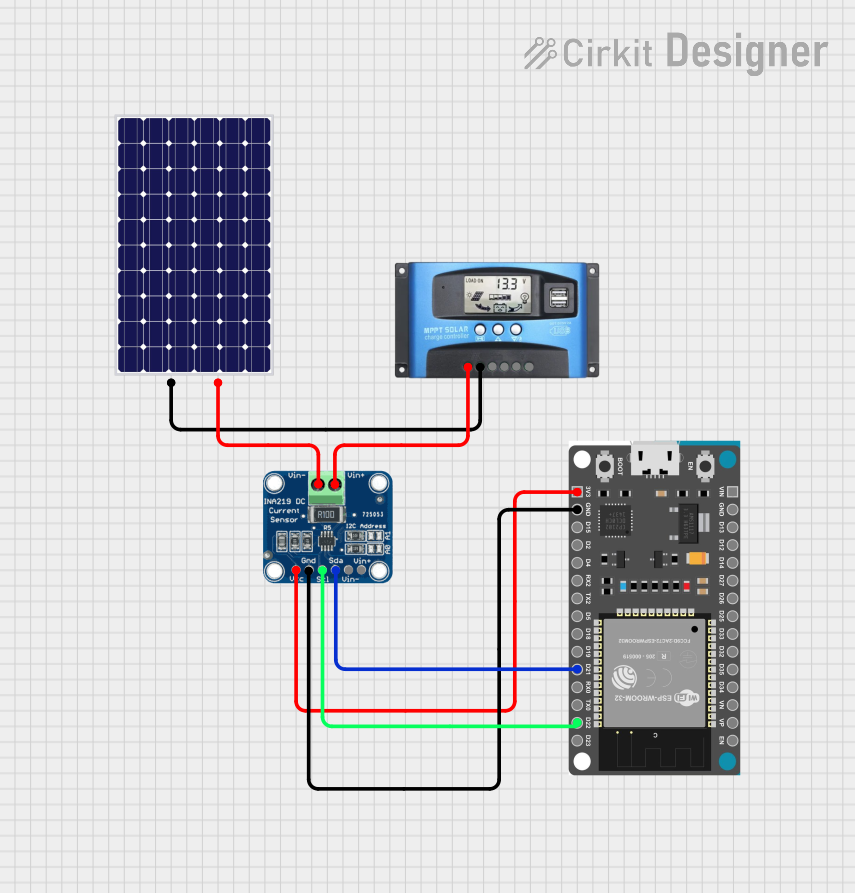

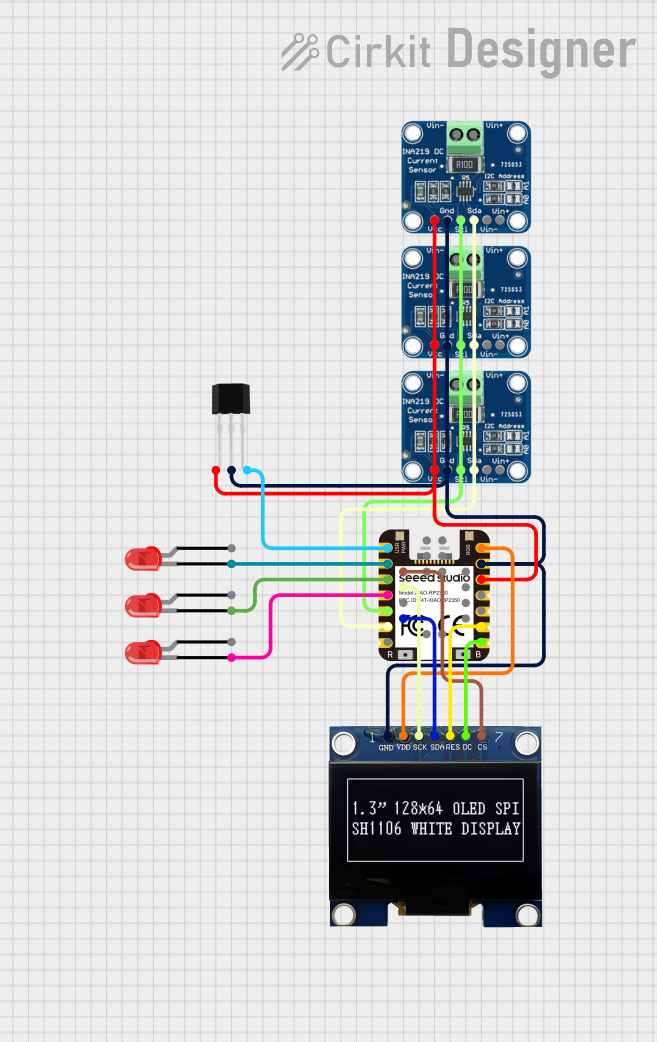

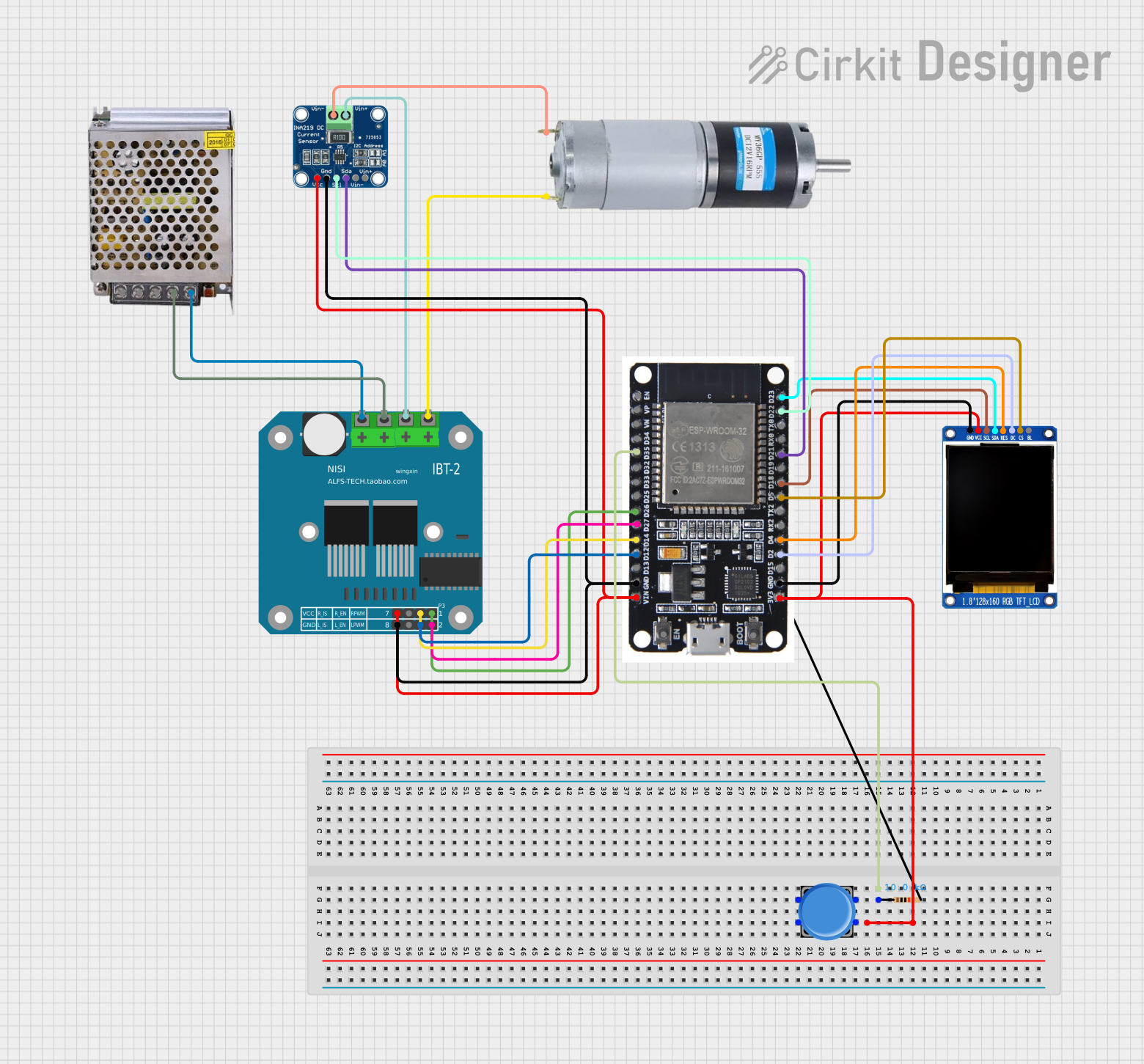

Explore Projects Built with INA219

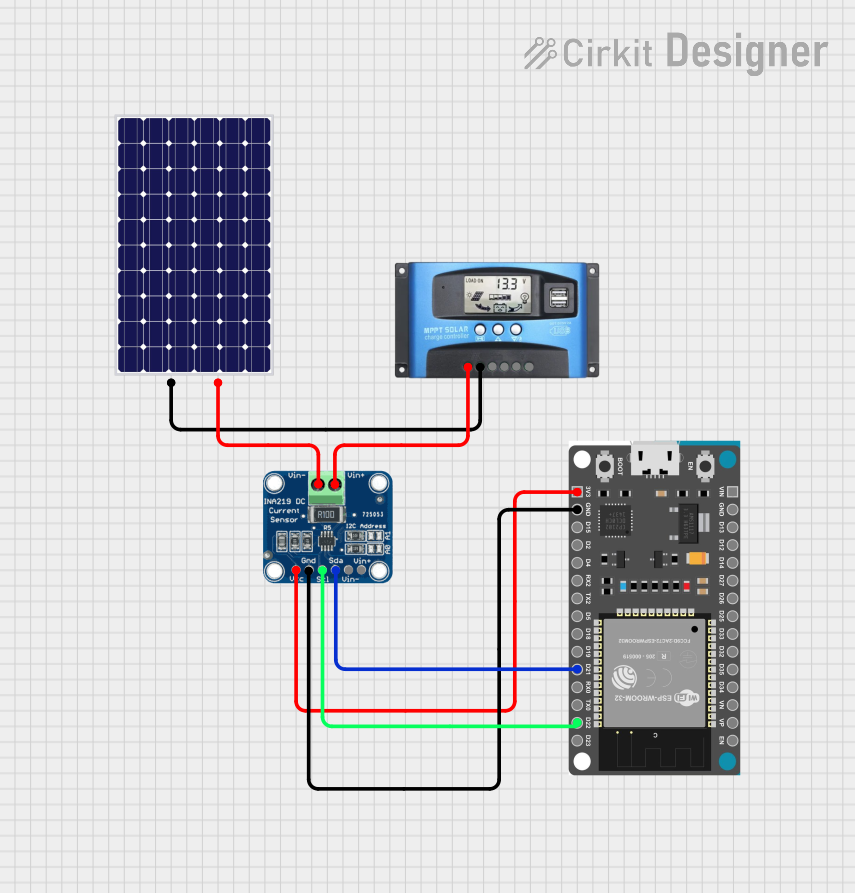

Open Project in Cirkit Designer

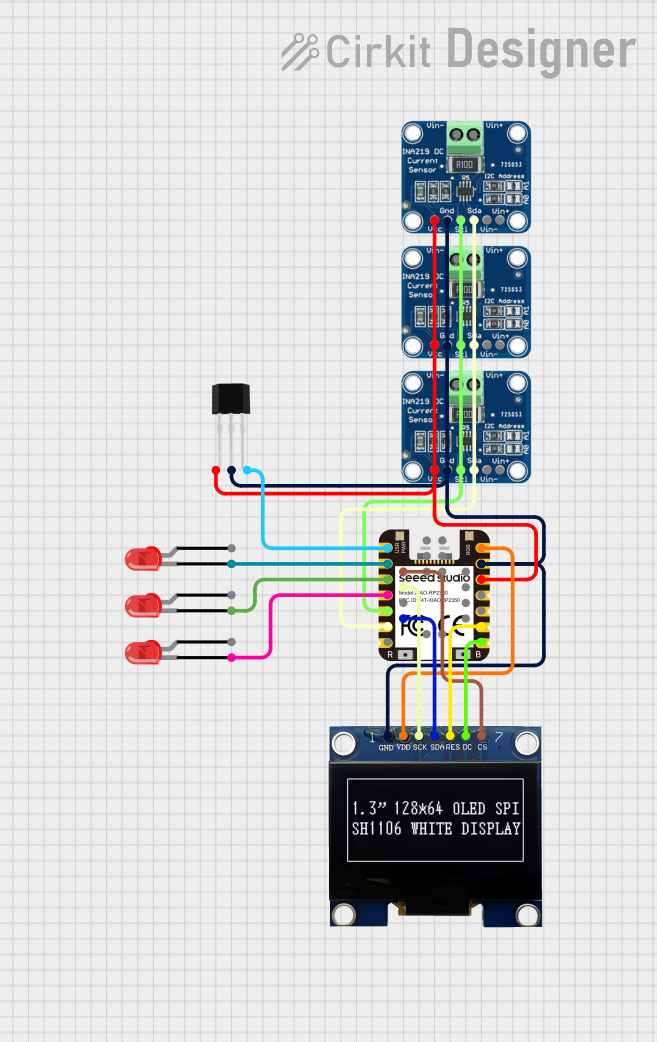

Open Project in Cirkit Designer

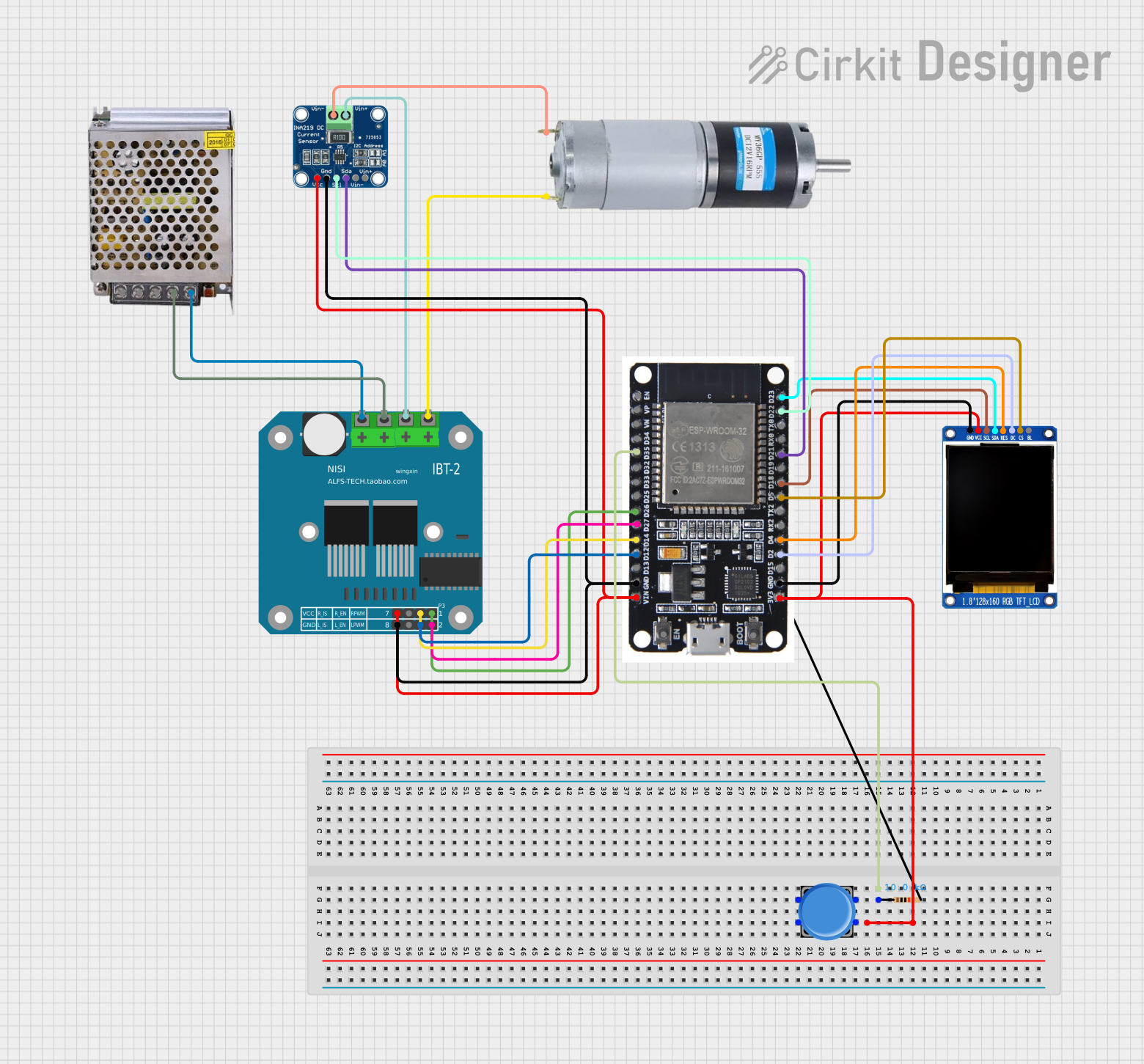

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with INA219

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications:

- Battery-powered devices for power consumption monitoring

- Solar power systems

- DC motor control and diagnostics

- Power supply efficiency analysis

- IoT devices requiring energy usage tracking

Technical Specifications

The INA219 offers a range of features that make it versatile and reliable for power monitoring applications. Below are its key technical details:

Key Technical Details:

- Supply Voltage (Vcc): 3.0V to 5.5V

- Bus Voltage Range: 0V to 26V

- Current Measurement Range: ±3.2A (with a 0.1Ω shunt resistor, configurable)

- Shunt Voltage Range: ±320mV

- Communication Interface: I2C (up to 3.4 MHz)

- Resolution: 12-bit ADC

- Accuracy: ±1% (typical)

- Operating Temperature Range: -40°C to +125°C

- Power Consumption: 1 mA (typical)

Pin Configuration and Descriptions:

The INA219 is typically available in an 8-pin SOIC package. Below is the pinout and description:

| Pin | Name | Description |

|---|---|---|

| 1 | V+ | High-side connection to the positive terminal of the shunt resistor. |

| 2 | V- | High-side connection to the negative terminal of the shunt resistor. |

| 3 | GND | Ground connection. |

| 4 | SDA | I2C data line for communication. |

| 5 | SCL | I2C clock line for communication. |

| 6 | ALERT | Configurable alert output for overcurrent or other fault conditions. |

| 7 | Vcc | Power supply input (3.0V to 5.5V). |

| 8 | NC | No connection (leave unconnected or grounded). |

Usage Instructions

The INA219 is straightforward to use in a circuit, thanks to its I2C interface and built-in ADC. Below are the steps and considerations for using the INA219:

Steps to Use the INA219:

Connect the Shunt Resistor:

- Place a shunt resistor (e.g., 0.1Ω) in series with the load whose current you want to measure.

- Connect the

V+pin to the positive terminal of the shunt resistor and theV-pin to the negative terminal.

Power the INA219:

- Connect the

Vccpin to a 3.3V or 5V power supply. - Connect the

GNDpin to the ground of the circuit.

- Connect the

Set Up I2C Communication:

- Connect the

SDAandSCLpins to the corresponding I2C pins on your microcontroller (e.g., Arduino UNO). - Use pull-up resistors (typically 4.7kΩ) on the

SDAandSCLlines if not already present.

- Connect the

Configure the INA219:

- Use an I2C library to communicate with the INA219.

- Configure the INA219 for your specific application (e.g., shunt resistor value, bus voltage range).

Read Measurements:

- Use I2C commands to read the shunt voltage, bus voltage, and current.

- Calculate power using the formula:

Power = Voltage × Current.

Example Arduino Code:

Below is an example of how to use the INA219 with an Arduino UNO to measure current, voltage, and power:

#include <Wire.h>

#include <Adafruit_INA219.h>

// Create an instance of the INA219 class

Adafruit_INA219 ina219;

void setup() {

Serial.begin(9600); // Initialize serial communication at 9600 baud

while (!Serial) {

delay(10); // Wait for the serial monitor to open

}

// Initialize the INA219 sensor

if (!ina219.begin()) {

Serial.println("Failed to find INA219 chip");

while (1) {

delay(10); // Halt if the INA219 is not detected

}

}

Serial.println("INA219 initialized successfully");

}

void loop() {

float shuntVoltage = ina219.getShuntVoltage_mV(); // Get shunt voltage in mV

float busVoltage = ina219.getBusVoltage_V(); // Get bus voltage in V

float current = ina219.getCurrent_mA(); // Get current in mA

float power = ina219.getPower_mW(); // Get power in mW

// Print the measurements to the serial monitor

Serial.print("Shunt Voltage: ");

Serial.print(shuntVoltage);

Serial.println(" mV");

Serial.print("Bus Voltage: ");

Serial.print(busVoltage);

Serial.println(" V");

Serial.print("Current: ");

Serial.print(current);

Serial.println(" mA");

Serial.print("Power: ");

Serial.print(power);

Serial.println(" mW");

delay(1000); // Wait 1 second before taking the next measurement

}

Important Considerations:

- Shunt Resistor Selection: Choose a shunt resistor with a low resistance value to minimize power loss, but ensure it provides a measurable voltage drop.

- I2C Address: The INA219 has a default I2C address of

0x40, but it can be changed by configuring the address pins. - Pull-Up Resistors: Ensure proper pull-up resistors are present on the I2C lines for reliable communication.

- Voltage Limits: Do not exceed the maximum bus voltage of 26V to avoid damaging the device.

Troubleshooting and FAQs

Common Issues and Solutions:

INA219 Not Detected on I2C Bus:

- Solution: Check the wiring of the

SDAandSCLpins. Ensure pull-up resistors are present. - Tip: Use an I2C scanner sketch to verify the INA219's address.

- Solution: Check the wiring of the

Incorrect Current or Voltage Readings:

- Solution: Verify the shunt resistor value and ensure it matches the configuration in your code.

- Tip: Check for loose connections or incorrect wiring.

No Output on Serial Monitor:

- Solution: Ensure the correct baud rate is set in the serial monitor (e.g., 9600).

- Tip: Verify that the INA219 is properly powered and initialized.

Overcurrent or Fault Alerts:

- Solution: Check the load current and ensure it does not exceed the configured range.

- Tip: Use the

ALERTpin to monitor fault conditions programmatically.

FAQs:

Q: Can the INA219 measure negative currents?

A: Yes, the INA219 can measure bidirectional currents if configured appropriately.Q: What is the maximum sampling rate of the INA219?

A: The INA219's ADC can sample at up to 12-bit resolution, with a configurable conversion time.Q: Can I use the INA219 with a 3.3V microcontroller?

A: Yes, the INA219 is compatible with both 3.3V and 5V logic levels.Q: How do I change the I2C address of the INA219?

A: The I2C address can be changed by connecting the address pins (A0andA1) toGNDorVccin different combinations.

By following this documentation, you can effectively integrate the INA219 into your projects for accurate power monitoring and diagnostics.