How to Use 45X45X15 V Blower Fan: Examples, Pinouts, and Specs

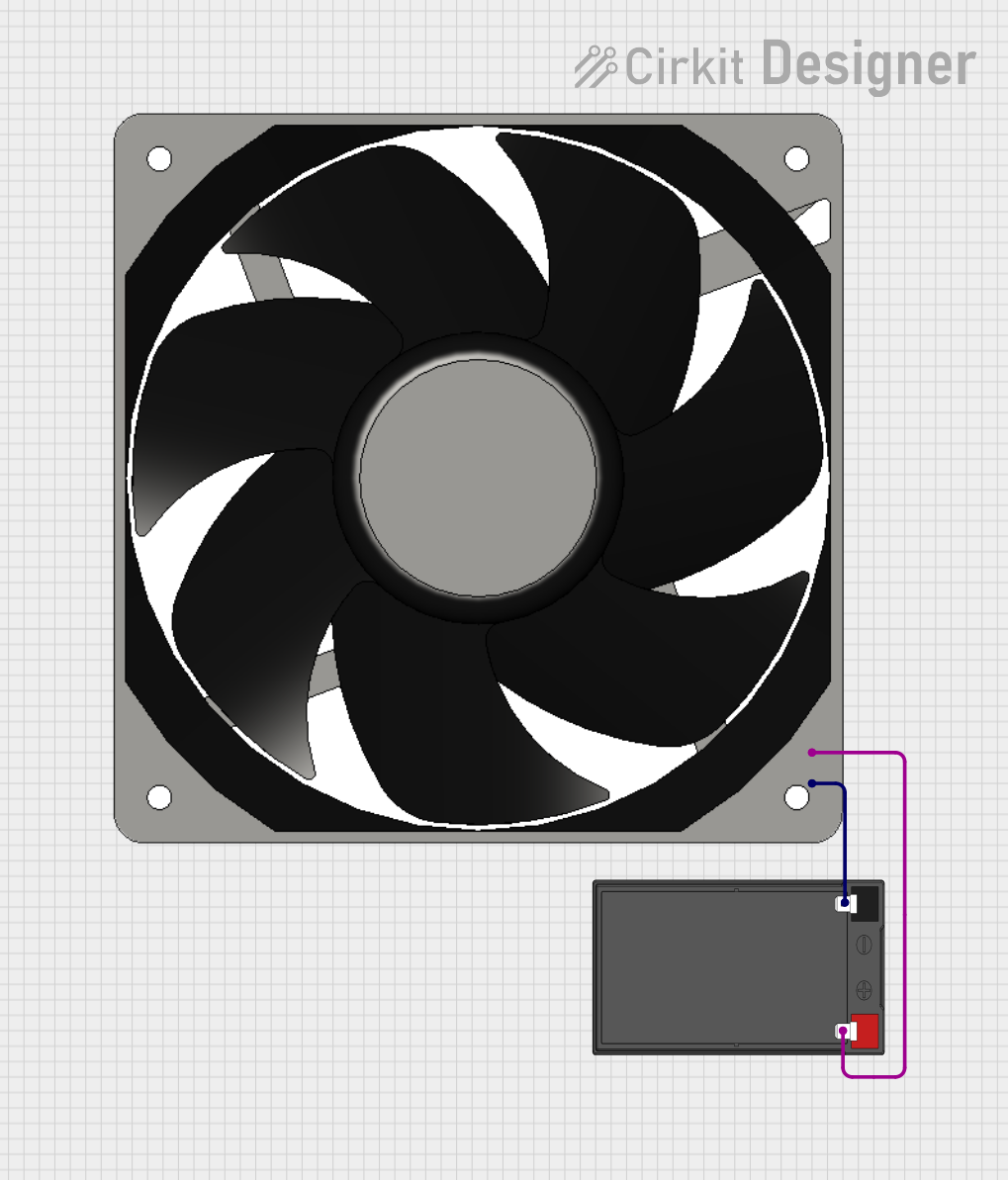

Design with 45X45X15 V Blower Fan in Cirkit Designer

Design with 45X45X15 V Blower Fan in Cirkit DesignerIntroduction

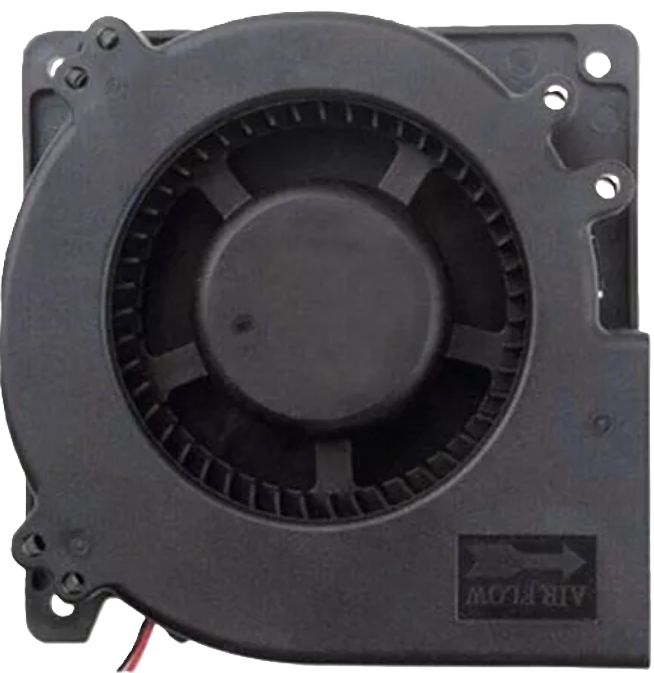

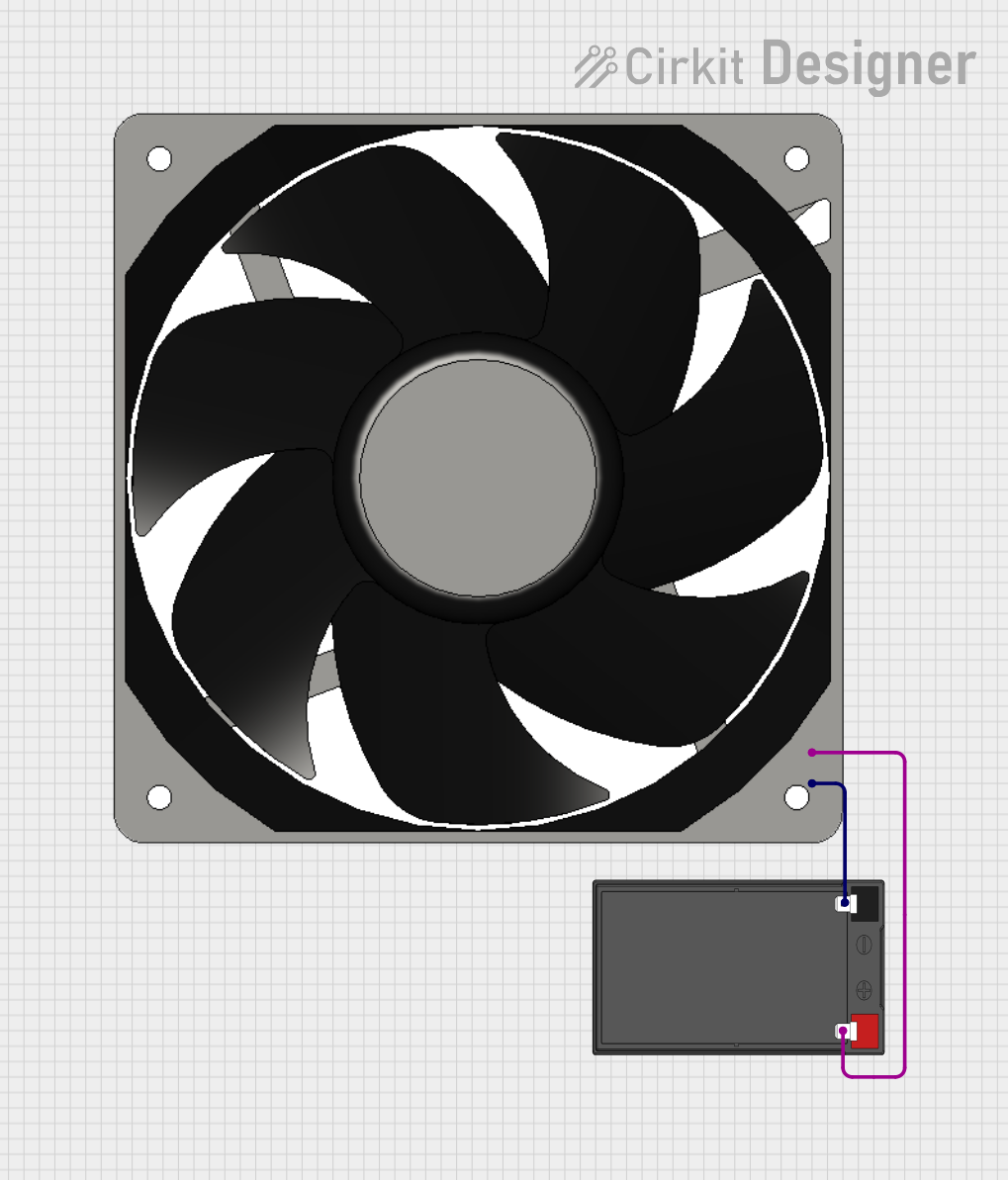

The 45X45X15 V Blower Fan is a compact, high-efficiency cooling and ventilation component. With its small form factor of 45mm x 45mm x 15mm, it is ideal for applications requiring effective heat dissipation in confined spaces. This fan is commonly used in electronics enclosures, 3D printers, computer systems, and other devices where thermal management is critical. Its reliable performance and low power consumption make it a popular choice for both hobbyists and professionals.

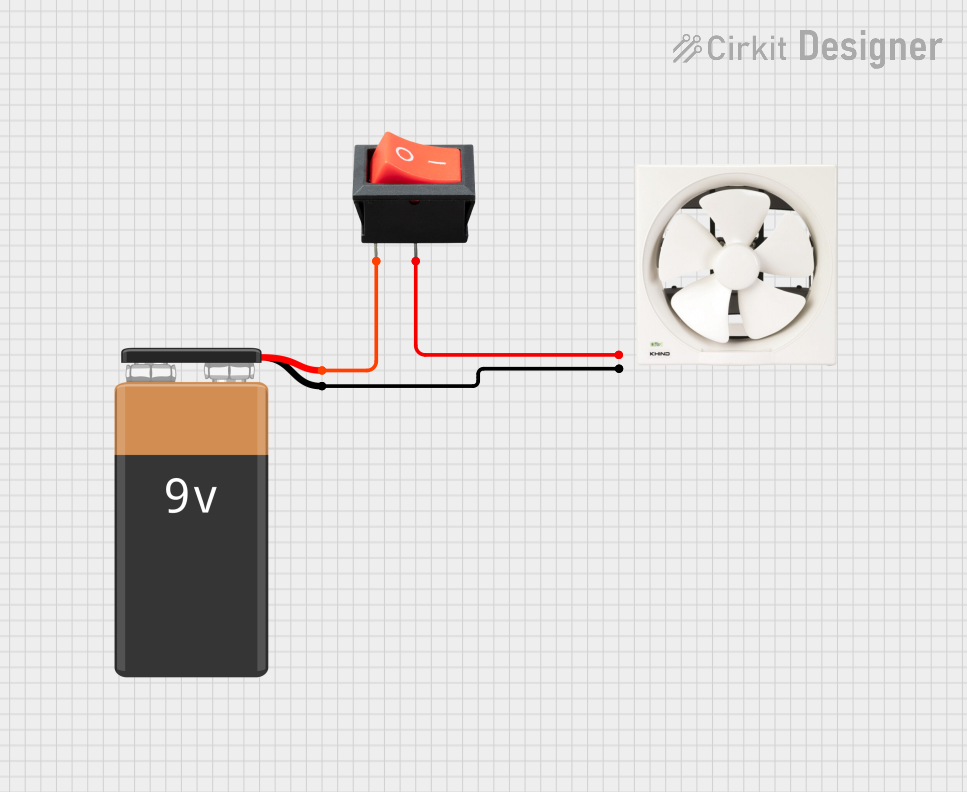

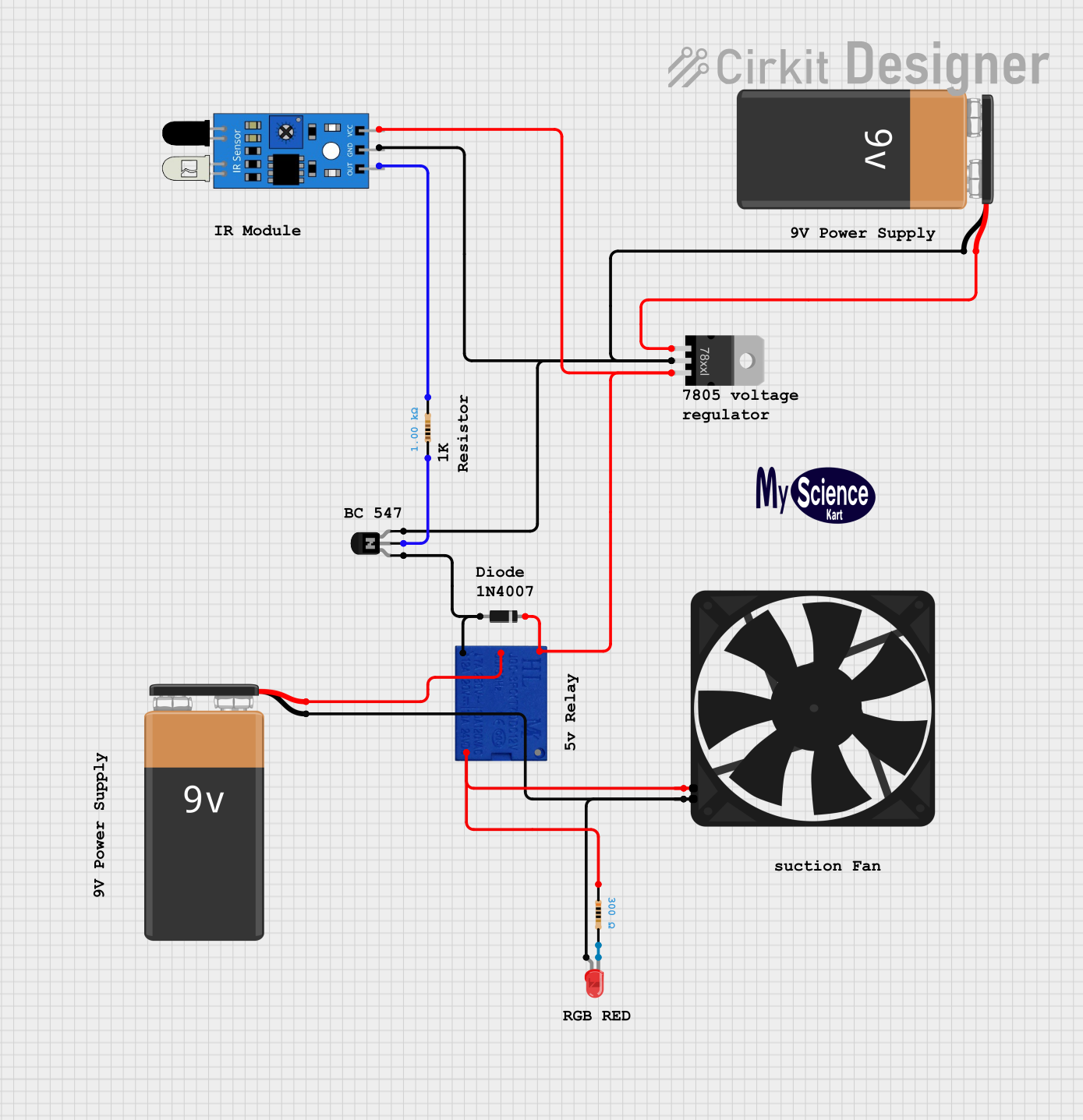

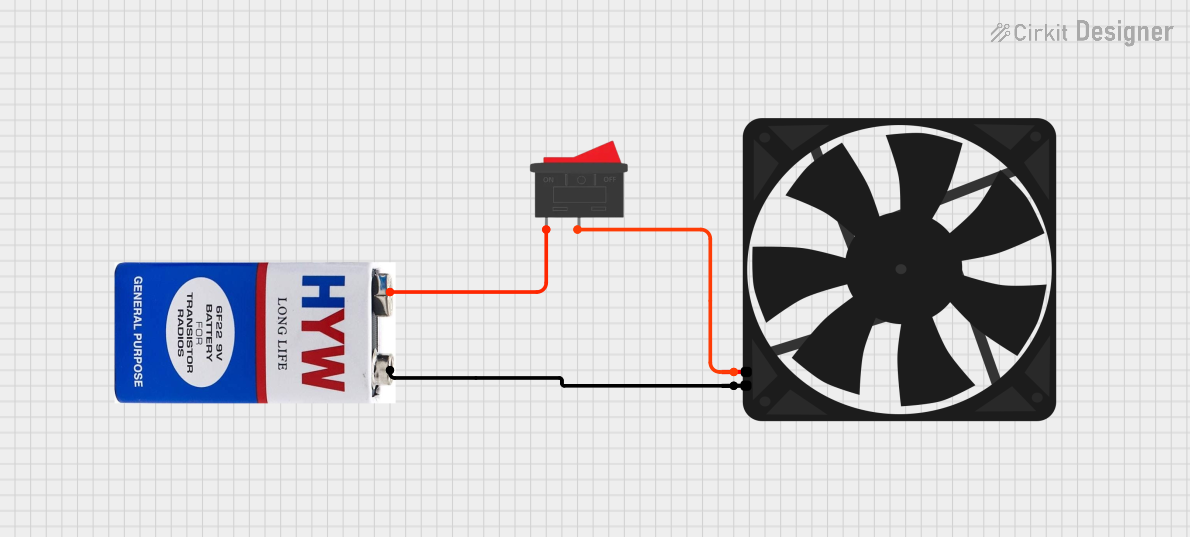

Explore Projects Built with 45X45X15 V Blower Fan

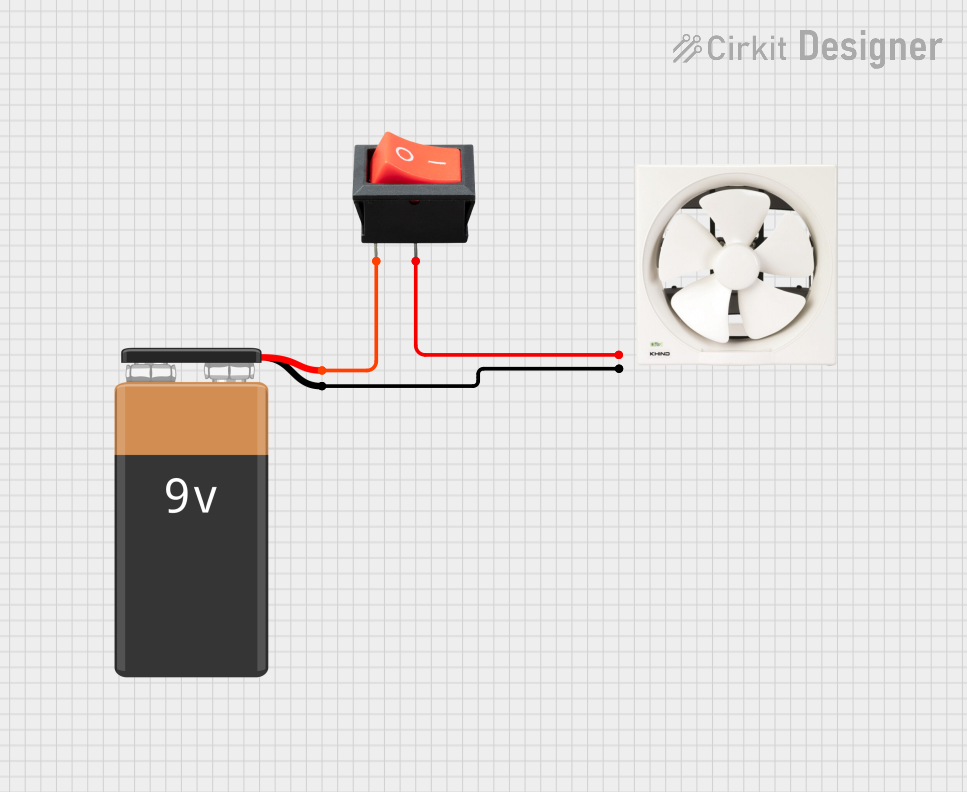

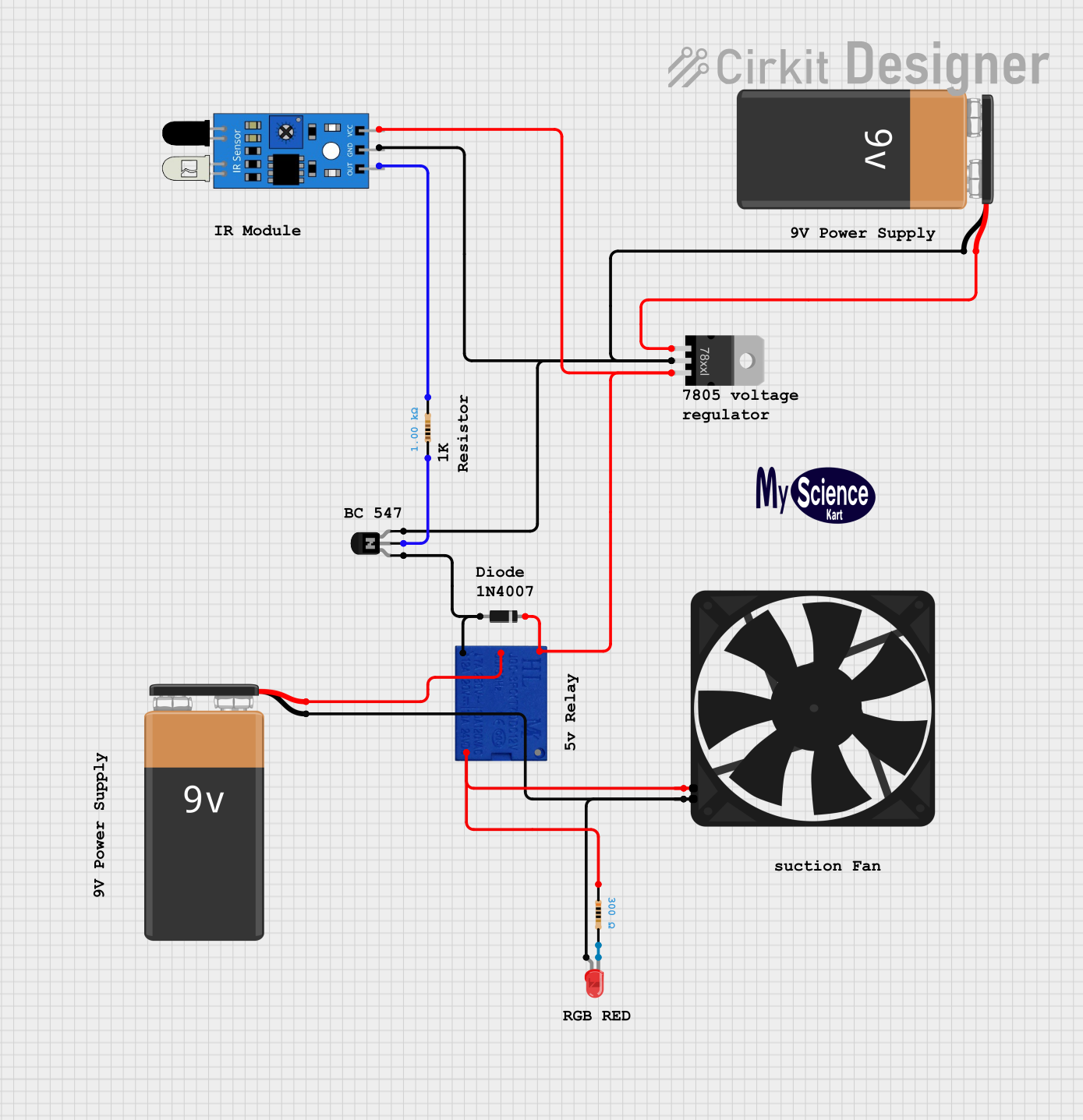

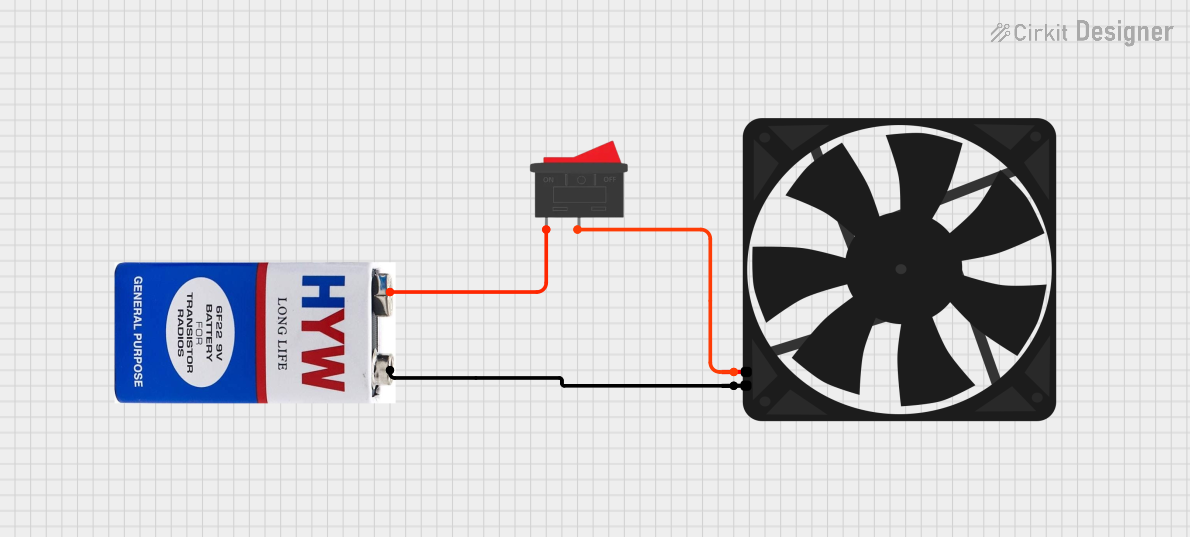

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 45X45X15 V Blower Fan

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Below are the key technical details of the 45X45X15 V Blower Fan:

| Parameter | Value |

|---|---|

| Dimensions | 45mm x 45mm x 15mm |

| Operating Voltage | 5V or 12V (model-dependent) |

| Current Rating | 0.1A to 0.2A (typical) |

| Power Consumption | 0.5W to 2.4W (depending on model) |

| Airflow | 3.5 CFM to 5.5 CFM |

| Noise Level | 20 dBA to 30 dBA |

| Bearing Type | Sleeve or Ball Bearing |

| Connector Type | 2-pin or 3-pin JST |

| Operating Temperature | -10°C to 70°C |

| Weight | ~15g |

Pin Configuration and Descriptions

The fan typically comes with a 2-pin or 3-pin connector. Below is the pin configuration:

2-Pin Connector

| Pin | Wire Color | Description |

|---|---|---|

| 1 | Red | Positive Voltage (VCC) |

| 2 | Black | Ground (GND) |

3-Pin Connector

| Pin | Wire Color | Description |

|---|---|---|

| 1 | Red | Positive Voltage (VCC) |

| 2 | Black | Ground (GND) |

| 3 | Yellow | Tachometer Signal (RPM Feedback) |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Ensure the fan is powered with the correct voltage (5V or 12V, depending on the model). Exceeding the rated voltage can damage the fan.

- Connection:

- For a 2-pin fan, connect the red wire to the positive terminal of the power supply and the black wire to ground.

- For a 3-pin fan, connect the red and black wires as above. The yellow wire can be connected to a microcontroller or monitoring circuit to read the fan's RPM.

- Mounting: Secure the fan using screws or adhesive mounts. Ensure the airflow direction aligns with your cooling requirements (airflow direction is typically indicated by an arrow on the fan housing).

Important Considerations and Best Practices

- Airflow Direction: Verify the airflow direction before installation. The fan typically blows air out from the side with the motor housing.

- Noise Reduction: Use rubber mounts or grommets to minimize vibration and noise.

- Power Supply Stability: Use a stable power source to avoid voltage fluctuations that could affect performance.

- Dust and Maintenance: Periodically clean the fan to prevent dust buildup, which can reduce efficiency and increase noise.

- Arduino Integration: The fan can be controlled using an Arduino UNO for applications requiring variable speed or on/off control.

Example Arduino Code for Fan Control

Below is an example of how to control the fan using an Arduino UNO and a transistor for switching:

// Define the pin connected to the transistor's base

const int fanPin = 9;

void setup() {

pinMode(fanPin, OUTPUT); // Set the fan control pin as an output

}

void loop() {

// Turn the fan ON

digitalWrite(fanPin, HIGH);

delay(5000); // Keep the fan ON for 5 seconds

// Turn the fan OFF

digitalWrite(fanPin, LOW);

delay(5000); // Keep the fan OFF for 5 seconds

}

Note: Use a suitable NPN transistor (e.g., 2N2222) and a base resistor (e.g., 1kΩ) to control the fan. The fan's positive terminal should be connected to the power supply, and the negative terminal should be connected to the transistor's collector.

Troubleshooting and FAQs

Common Issues and Solutions

Fan Does Not Spin:

- Cause: Incorrect wiring or insufficient voltage.

- Solution: Verify the wiring and ensure the power supply matches the fan's rated voltage.

Excessive Noise:

- Cause: Dust buildup or loose mounting.

- Solution: Clean the fan blades and check that the fan is securely mounted.

Fan Spins Slowly:

- Cause: Insufficient current or power supply issues.

- Solution: Check the power supply's current rating and ensure it meets the fan's requirements.

No RPM Signal (3-Pin Fan):

- Cause: Tachometer wire not connected or incompatible microcontroller.

- Solution: Verify the yellow wire is connected to a digital input pin capable of reading pulses.

FAQs

Can I use a 5V fan with a 12V power supply? No, using a higher voltage than the fan's rating can damage the motor. Use a voltage regulator or a power supply that matches the fan's rated voltage.

How do I reverse the airflow direction? The airflow direction is fixed by the fan's design. To reverse airflow, physically rotate the fan or use a fan designed for reverse airflow.

Can I control the fan speed? Yes, you can control the fan speed using PWM (Pulse Width Modulation) with a microcontroller like Arduino. Ensure the fan supports PWM control or use an external circuit.

What is the lifespan of the fan? The lifespan depends on the bearing type. Sleeve bearings typically last 30,000 hours, while ball bearings can last up to 50,000 hours under normal operating conditions.