How to Use Endstop: Examples, Pinouts, and Specs

Design with Endstop in Cirkit Designer

Design with Endstop in Cirkit DesignerIntroduction

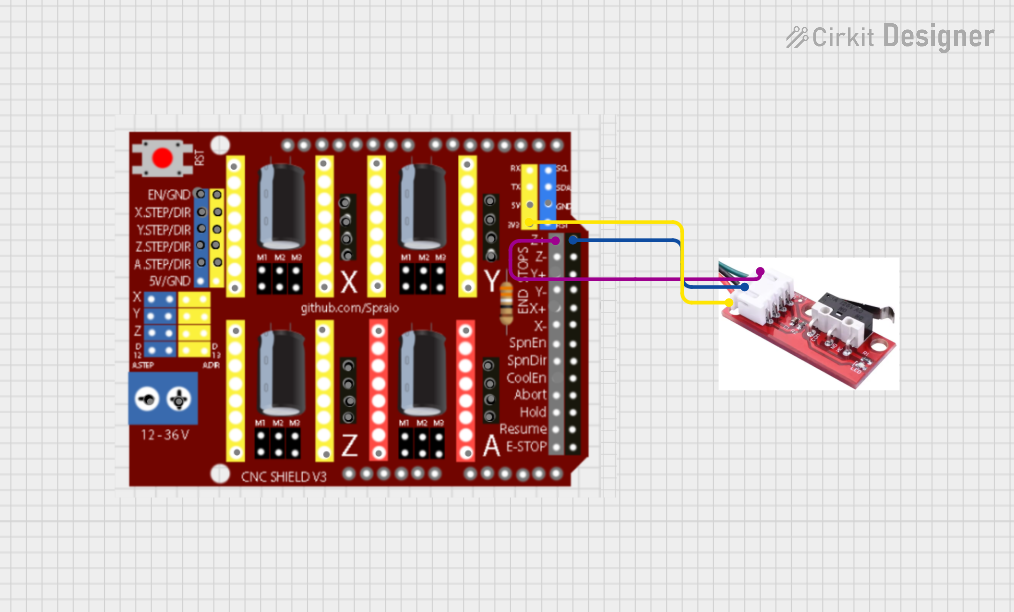

An endstop is a critical safety and precision device used in 3D printers, CNC machines, and other automated systems where precise control of motion is required. It serves as a limit switch that the machine's controller uses to determine the end of the travel range for a moving part, such as an axis of a 3D printer. When the moving part comes into contact with the endstop, it sends a signal to the controller to halt movement, preventing damage to the machine and ensuring the accuracy of the operation.

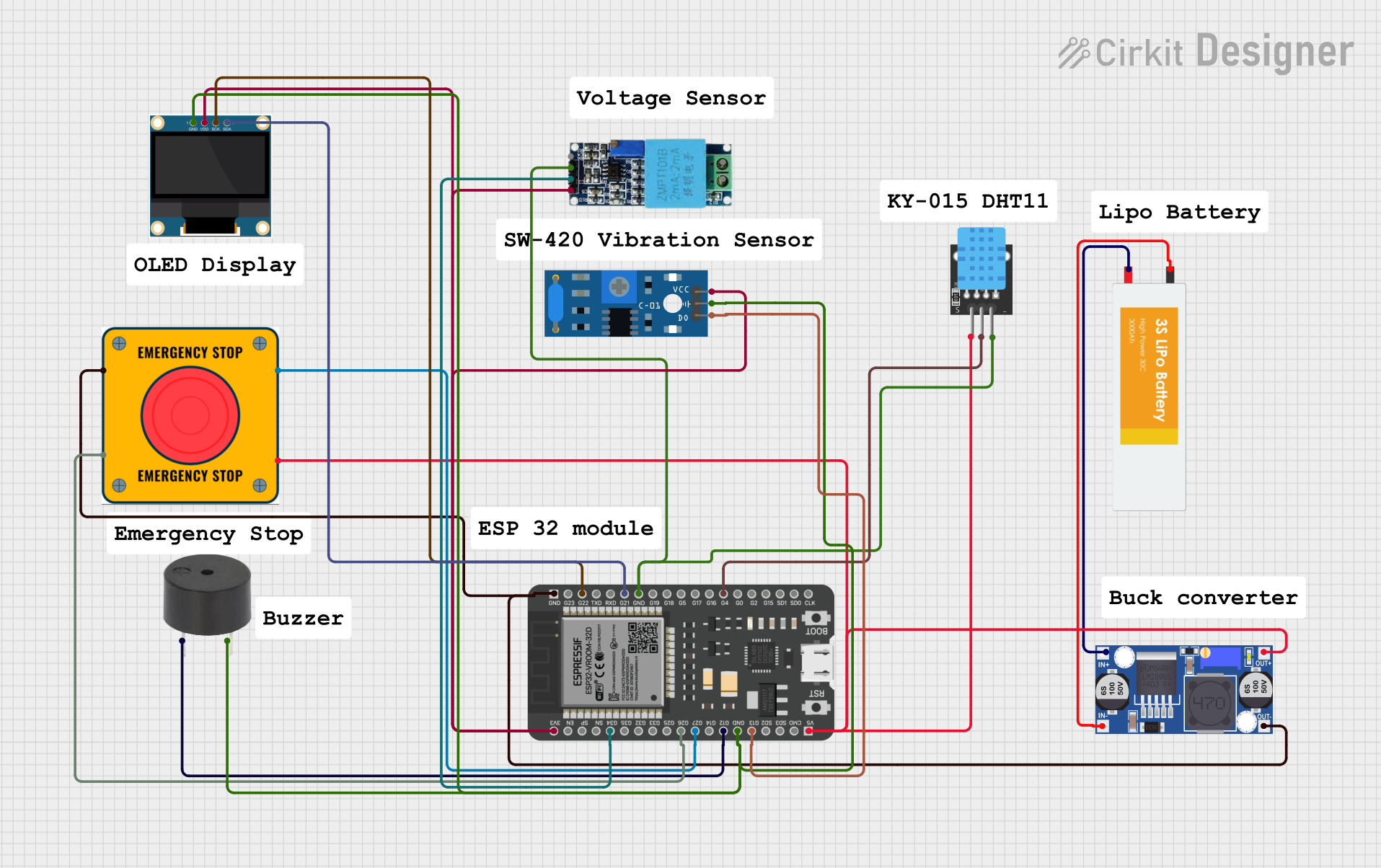

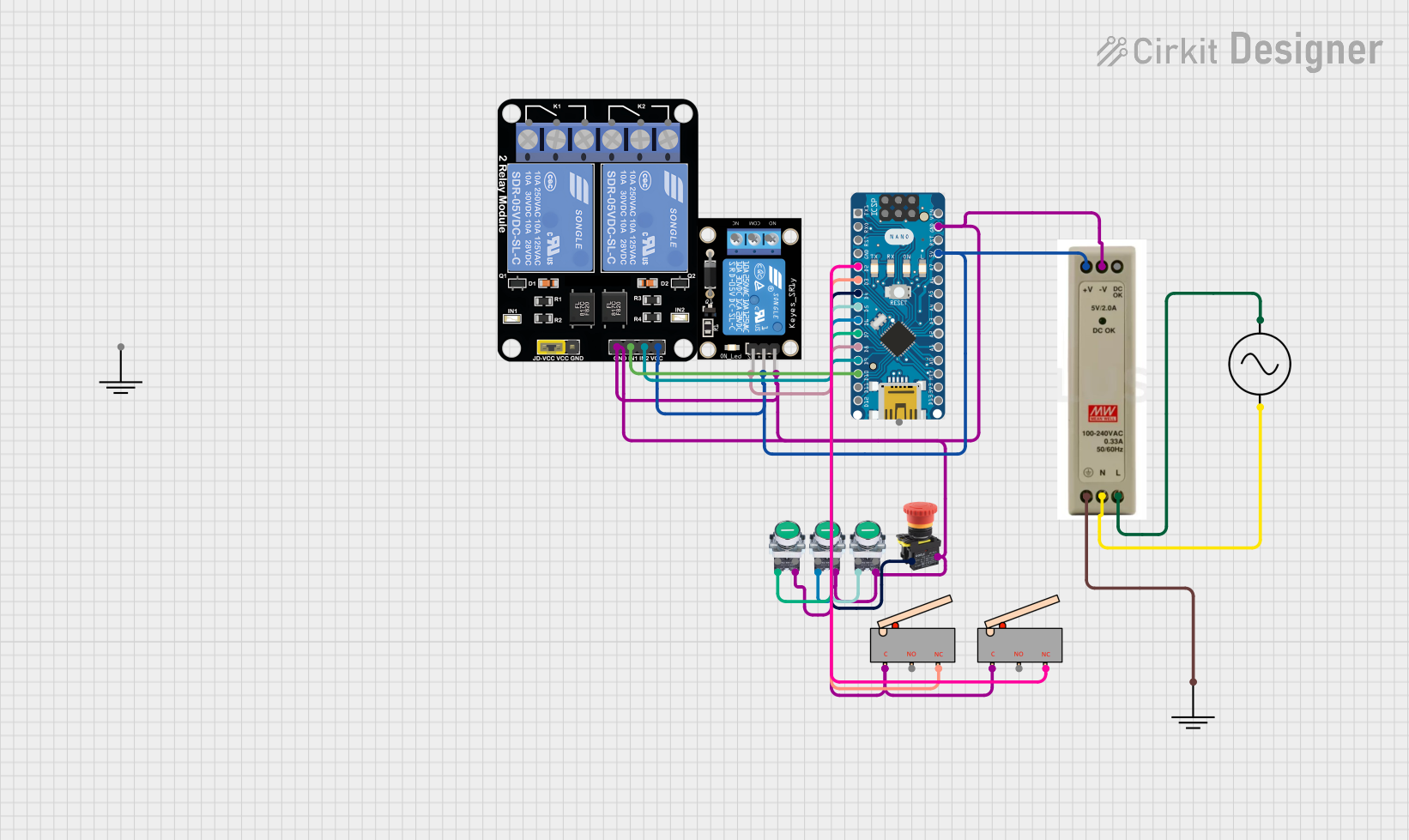

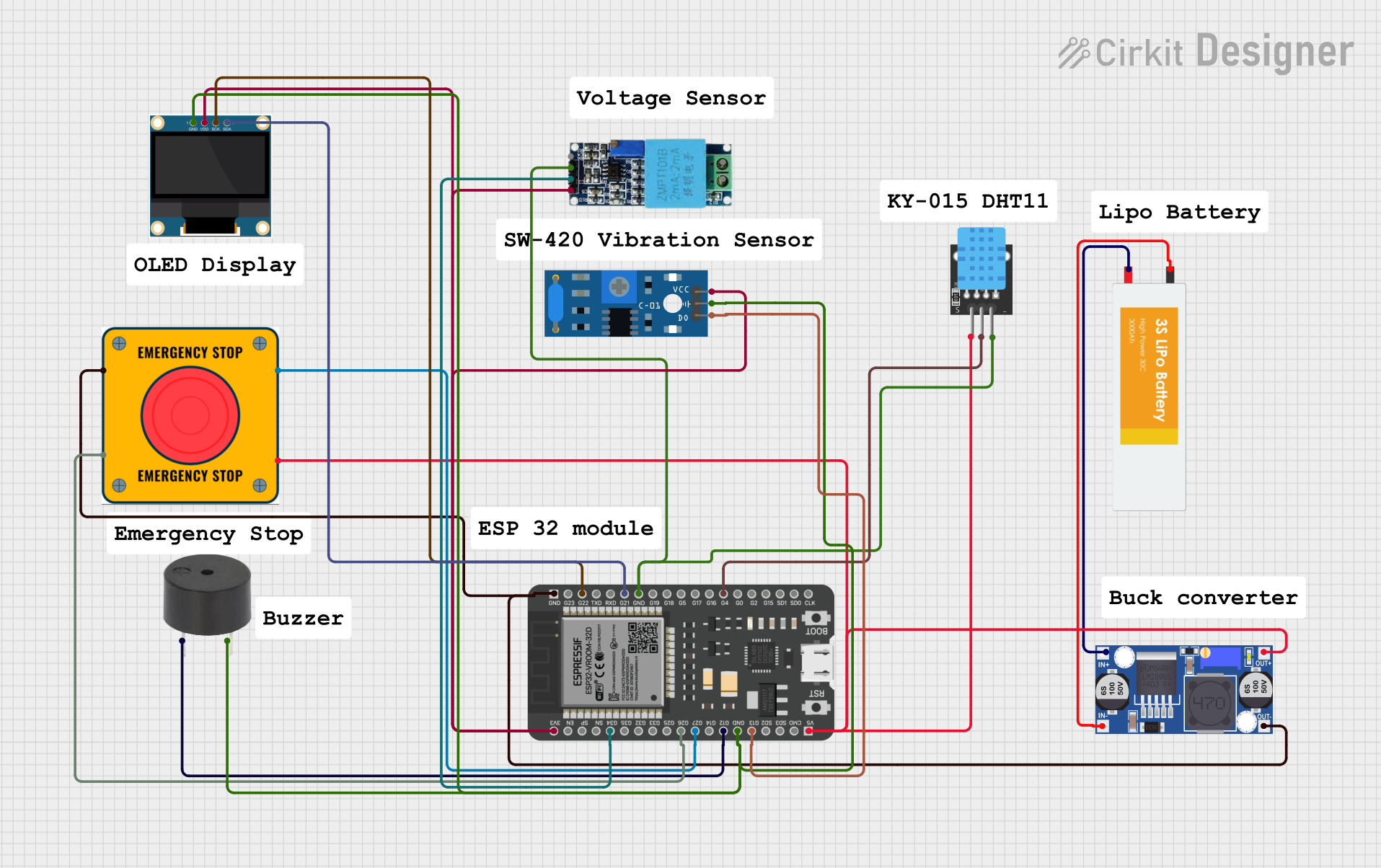

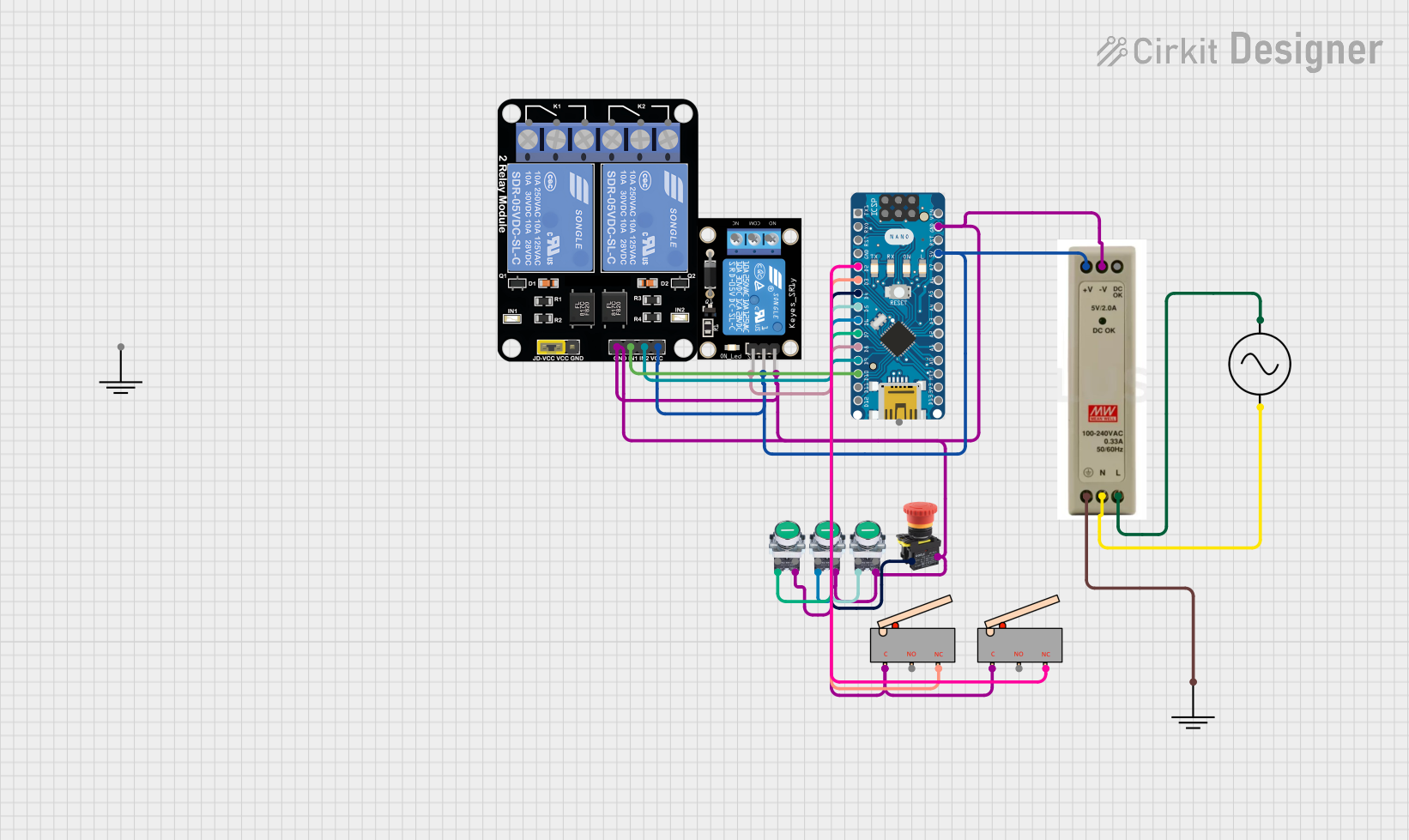

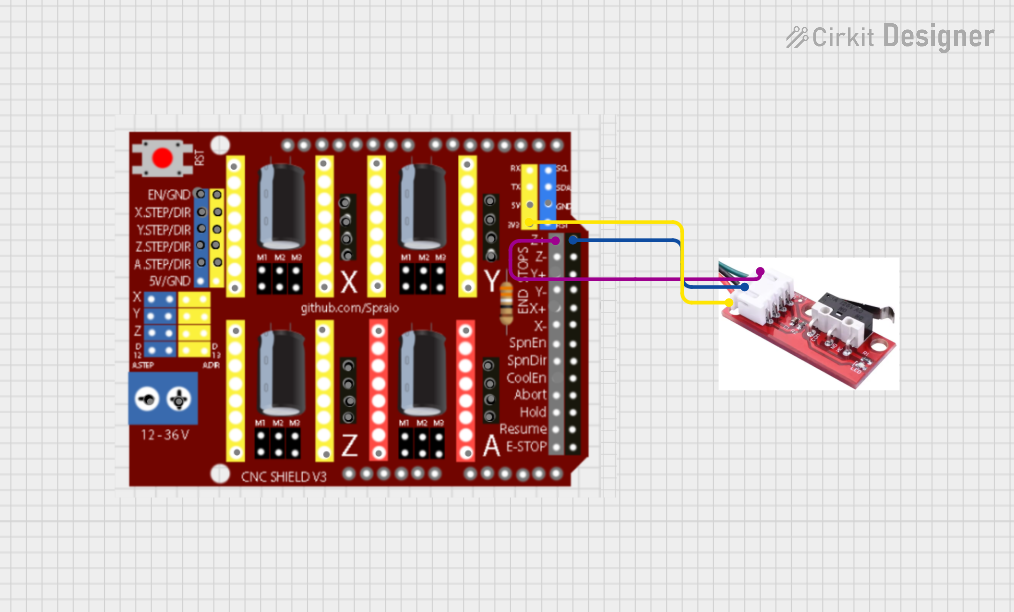

Explore Projects Built with Endstop

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Endstop

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Determining the home position in 3D printers

- Setting limits on CNC machine axes

- Position control in robotic arms

- Safety interlocks in automated systems

Technical Specifications

Key Technical Details

- Voltage Rating: 5V DC (typical for digital logic level compatibility)

- Current Rating: 10mA to 20mA (varies by model)

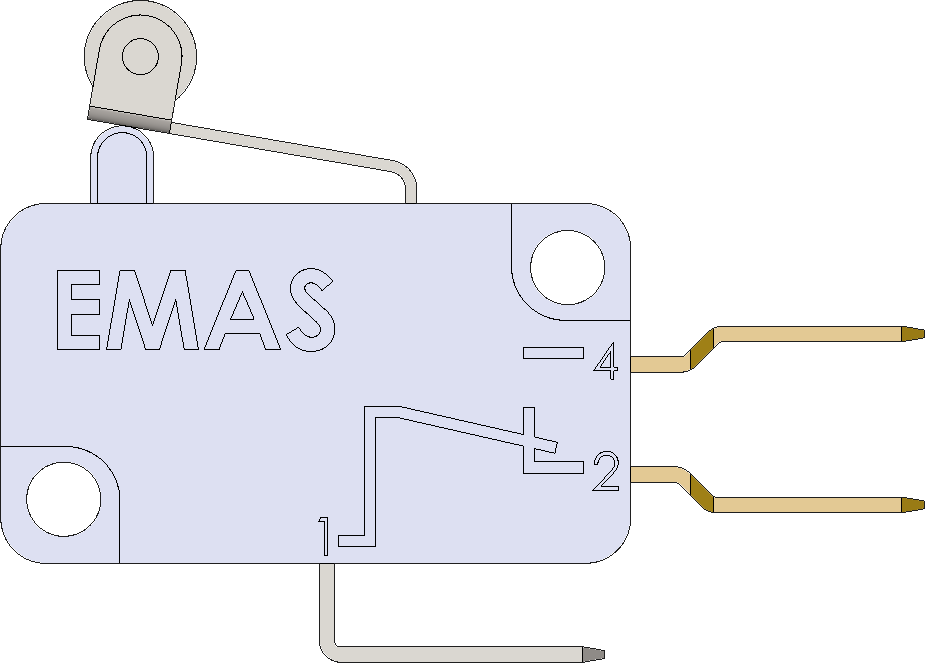

- Contact Type: Mechanical (microswitch) or Non-contact (magnetic or optical)

- Output Type: Digital signal (High or Low level)

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | Signal (SIG) | Outputs a digital signal |

| 2 | Ground (GND) | Connect to system ground |

| 3 | Power (VCC) | Connect to 5V power supply |

Usage Instructions

How to Use the Component in a Circuit

- Connect the Power (VCC) Pin: Connect the VCC pin to a 5V power supply from your controller board, such as an Arduino UNO.

- Connect the Ground (GND) Pin: Connect the GND pin to the ground on your controller board.

- Connect the Signal (SIG) Pin: Connect the SIG pin to a digital input pin on your controller board.

Important Considerations and Best Practices

- Ensure that the endstop is securely mounted so that it can accurately detect the moving part.

- Use pull-up or pull-down resistors as necessary to avoid floating inputs when the switch is open.

- Debounce the signal either through hardware or software to prevent false triggering due to mechanical vibrations.

- Test the endstop functionality before running the machine at full speed to ensure proper operation.

Example Code for Arduino UNO

// Define the pin connected to the endstop

const int endstopPin = 2;

void setup() {

// Set the endstop pin as an input

pinMode(endstopPin, INPUT_PULLUP);

// Initialize serial communication

Serial.begin(9600);

}

void loop() {

// Read the state of the endstop

int endstopState = digitalRead(endstopPin);

// Check if the endstop is triggered (assuming normally open)

if (endstopState == LOW) {

// Endstop is triggered, stop the motion

Serial.println("Endstop triggered!");

// Implement motion stop logic here

} else {

// Endstop is not triggered, continue motion

Serial.println("Endstop not triggered.");

// Implement motion logic here

}

// Small delay to reduce serial message frequency

delay(200);

}

Troubleshooting and FAQs

Common Issues Users Might Face

- Endstop Not Triggering: Check the wiring and ensure that the endstop is properly connected to the controller. Verify that the moving part is actually making contact with the endstop.

- False Triggering: This can be caused by noise or vibrations. Implement hardware debouncing with a capacitor or use software debouncing techniques.

- Endstop Always Triggered: Ensure that the endstop is not stuck in the triggered position and that there are no shorts in the wiring.

Solutions and Tips for Troubleshooting

- Testing the Endstop: Use a multimeter to check for continuity when the endstop is triggered.

- LED Indicator: Some endstops come with an LED indicator that lights up when triggered. This can be a quick visual aid for troubleshooting.

- Software Debugging: Use serial print statements to debug the state of the endstop in your code.

FAQs

Q: Can I use an endstop with a voltage rating different from 5V? A: It is essential to use an endstop with a voltage rating compatible with your controller board. Using a higher voltage may damage the board.

Q: How do I know if my endstop is normally open (NO) or normally closed (NC)? A: You can determine this by checking the continuity of the endstop in its resting state with a multimeter. NO endstops will not have continuity until triggered, while NC endstops will have continuity until triggered.

Q: Can I use multiple endstops on a single axis? A: Yes, you can use multiple endstops for added safety or to define multiple stopping points along an axis. Each endstop should be connected to a separate input pin on the controller.

This documentation provides a comprehensive guide to using an endstop with an electronic system. By following the instructions and best practices outlined above, users can ensure the safe and accurate operation of their machines.