How to Use Motor + Canister CO2: Examples, Pinouts, and Specs

Design with Motor + Canister CO2 in Cirkit Designer

Design with Motor + Canister CO2 in Cirkit DesignerIntroduction

The Motor + Canister CO2 by Robo Marine Indonesia is a compact and efficient propulsion system designed for small-scale robotics and marine applications. This component integrates a motor with a CO2 canister to provide thrust, making it ideal for underwater vehicles, small boats, and other robotic systems requiring controlled propulsion. Its lightweight design and ease of integration make it a popular choice for hobbyists and professionals alike.

Explore Projects Built with Motor + Canister CO2

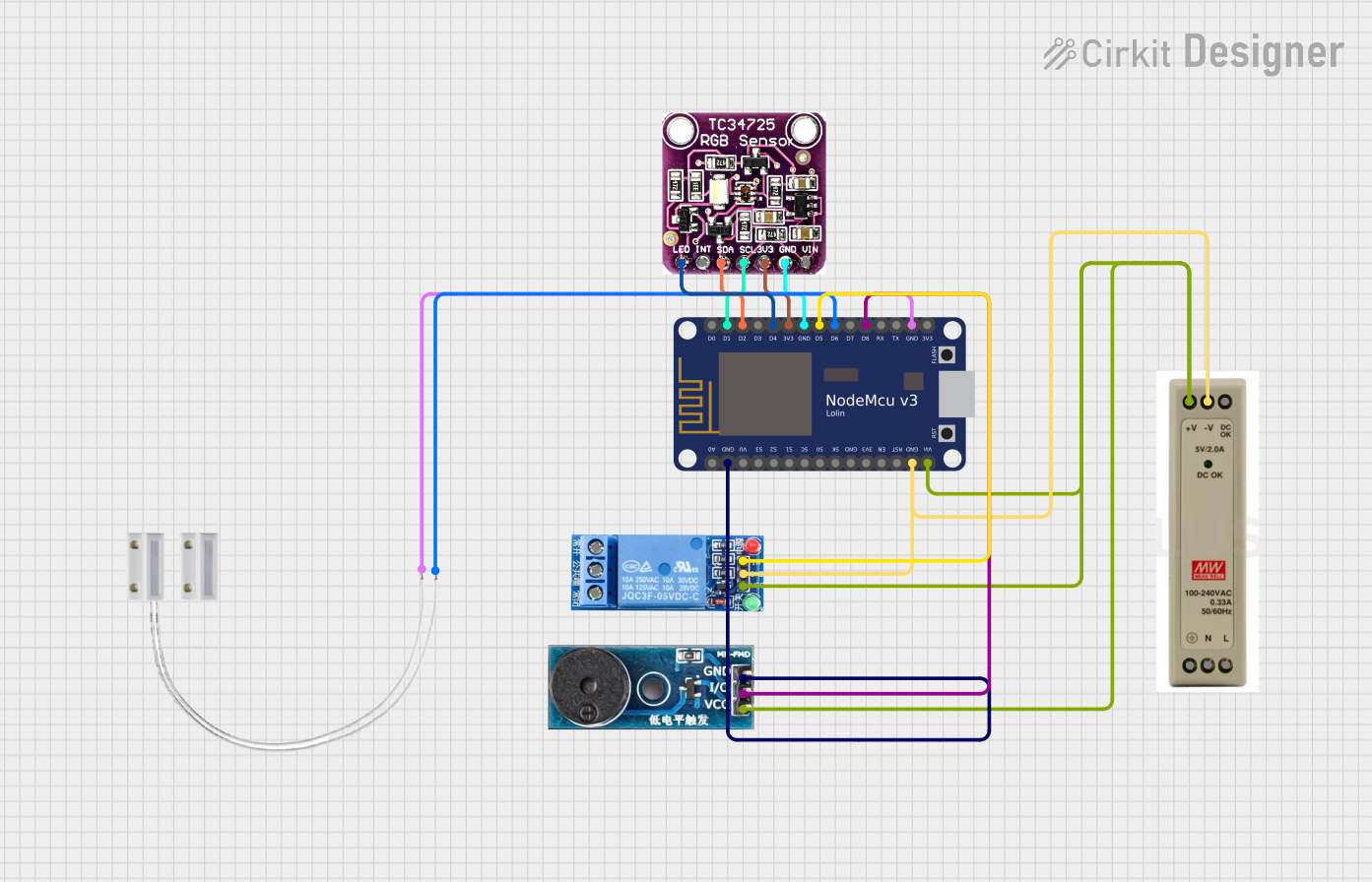

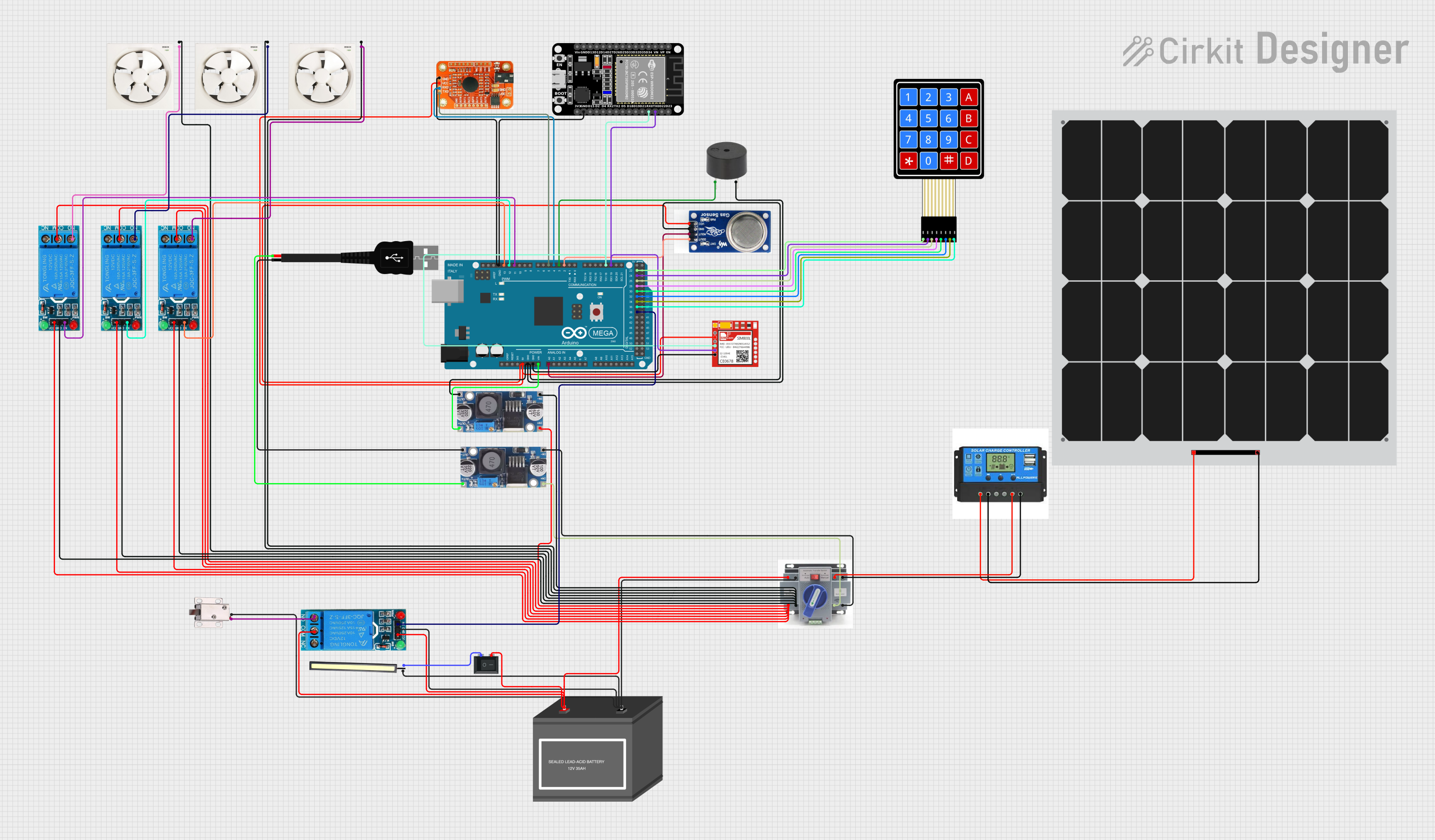

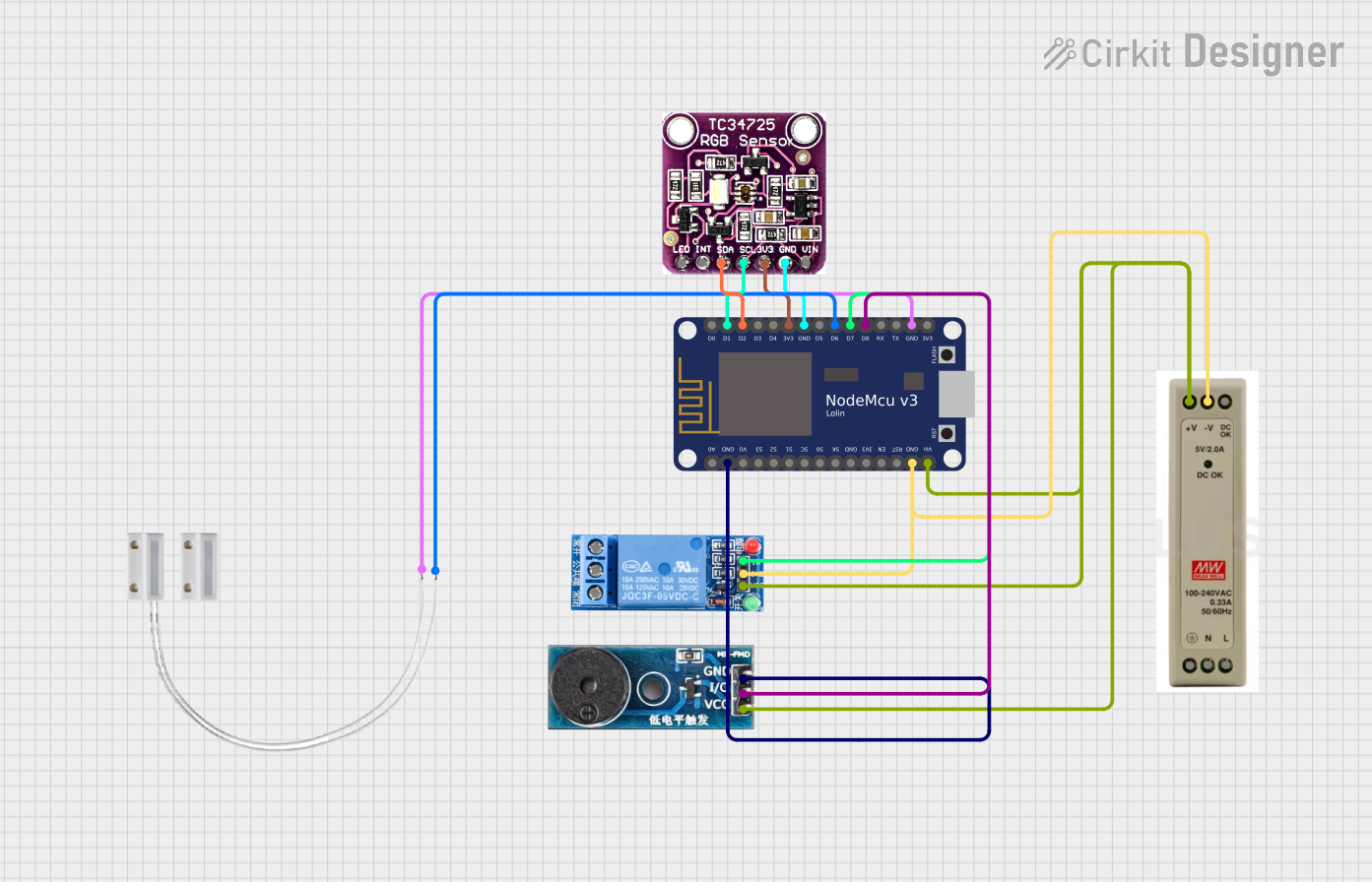

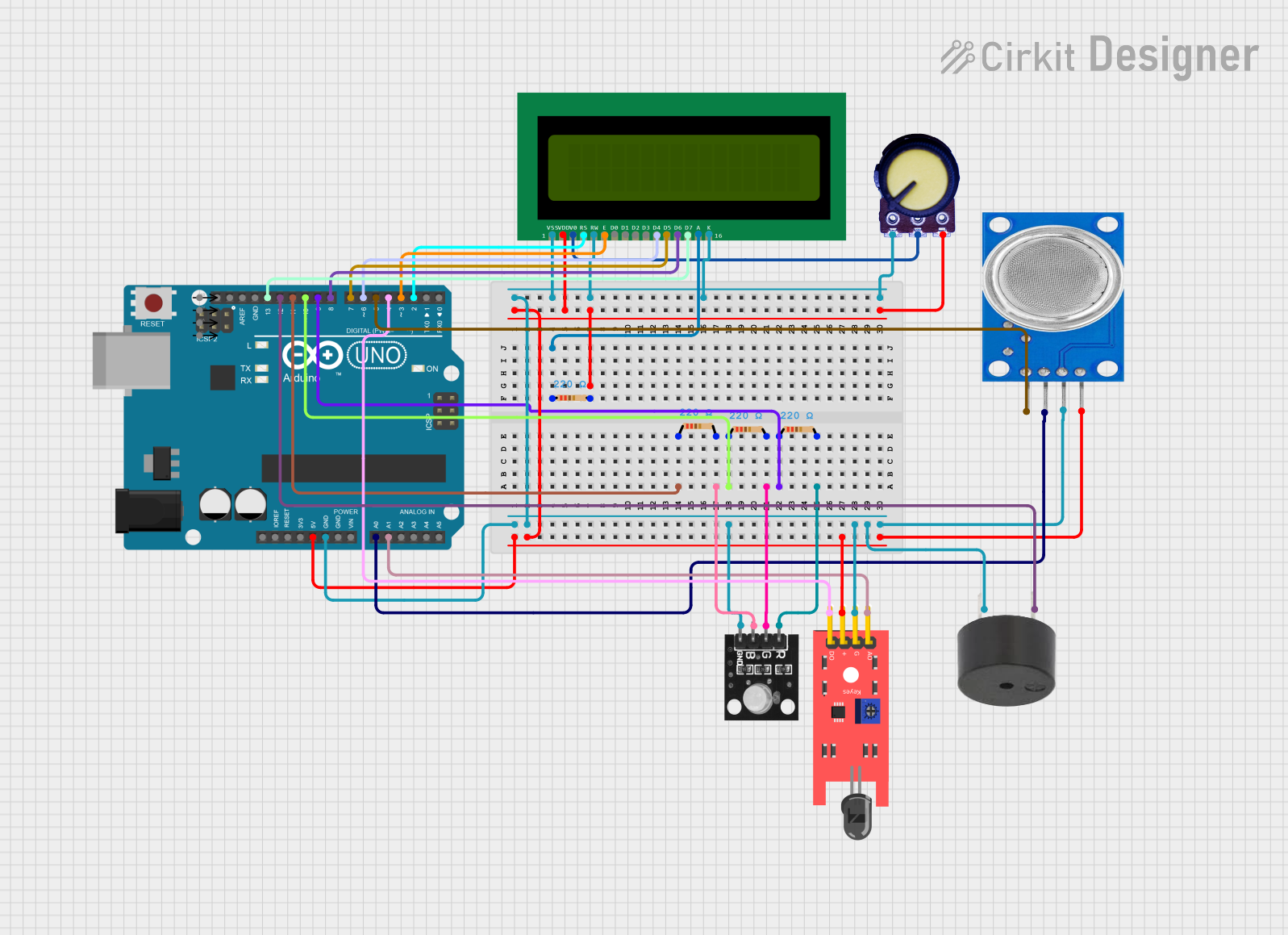

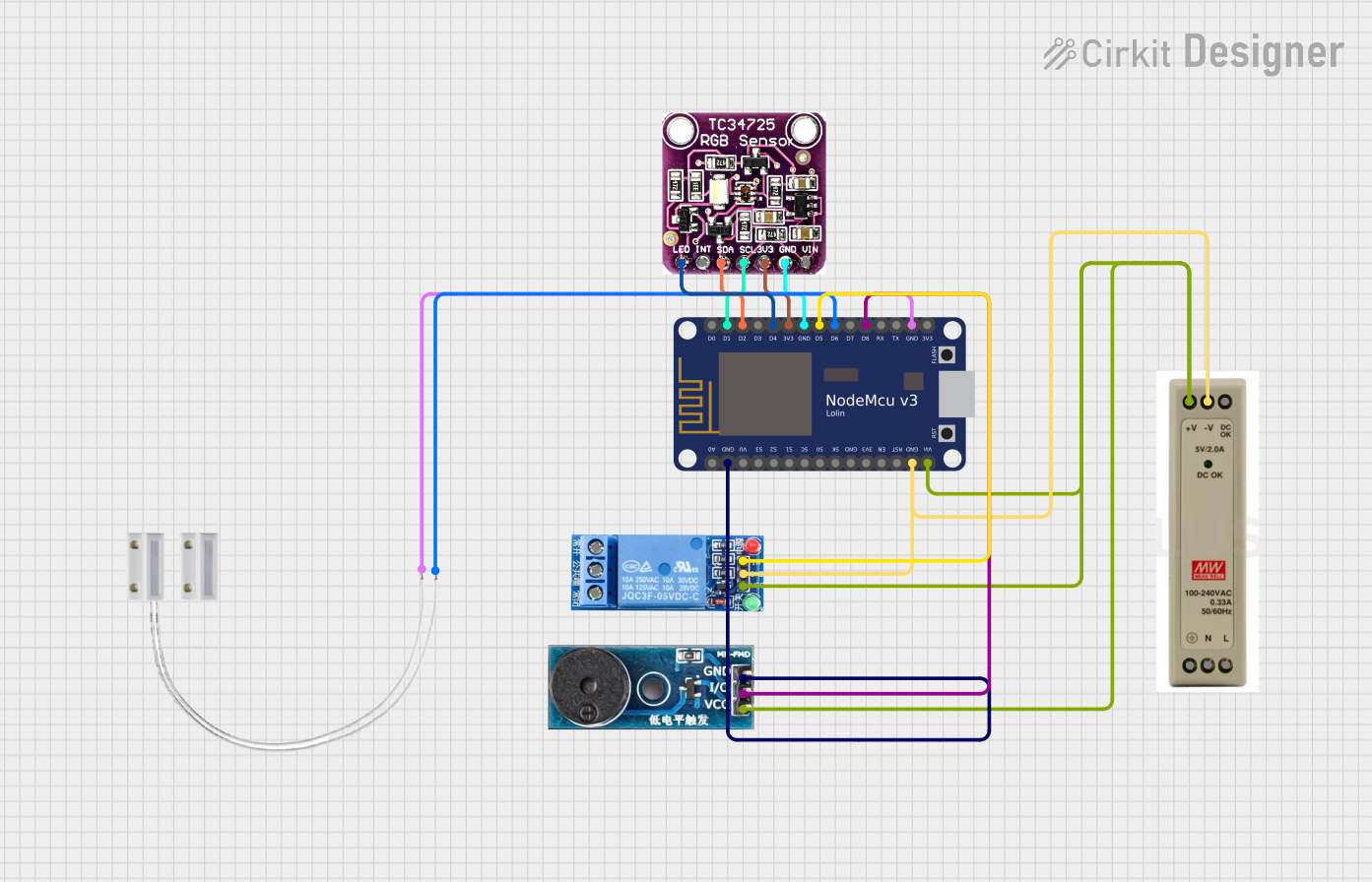

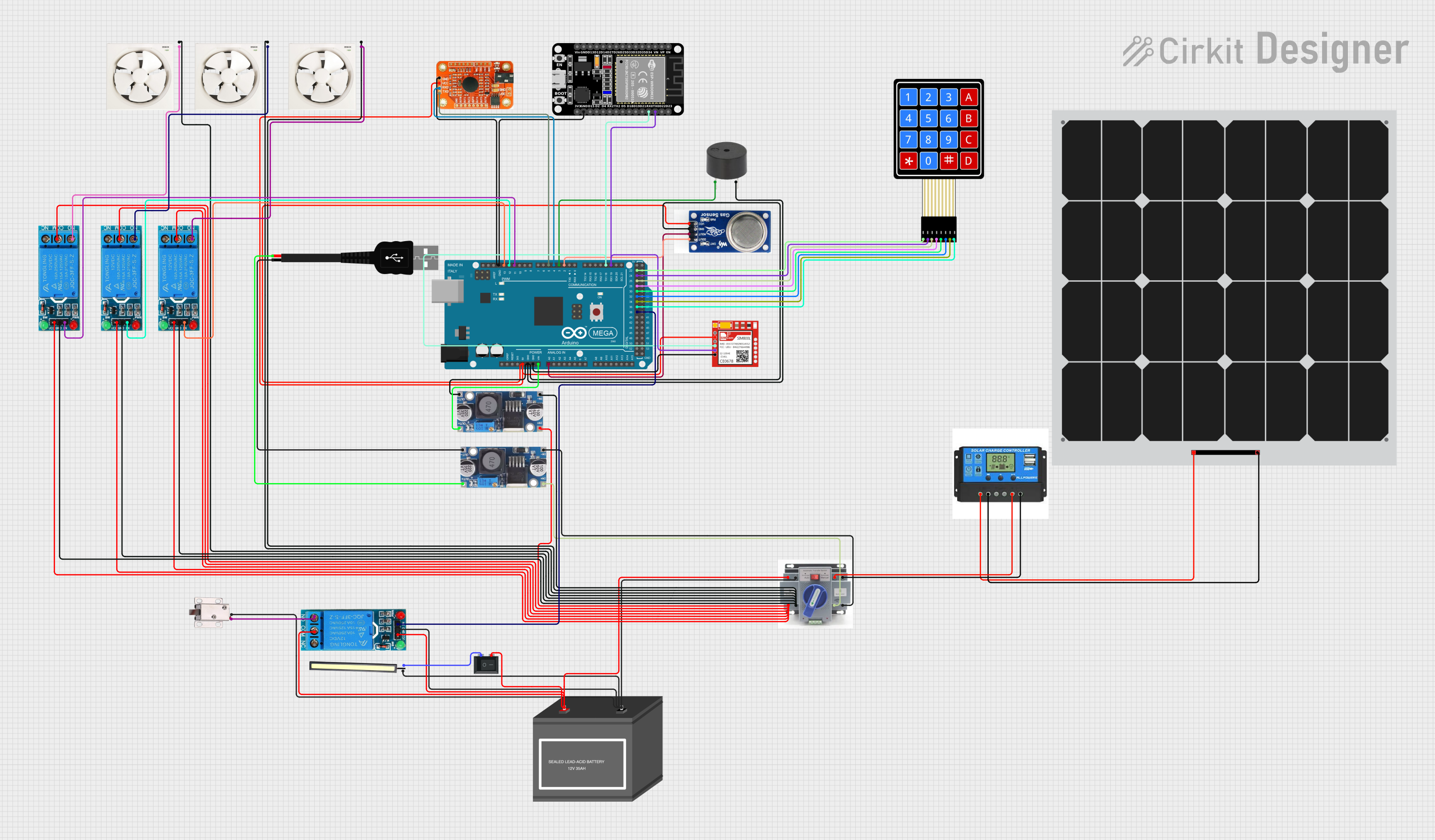

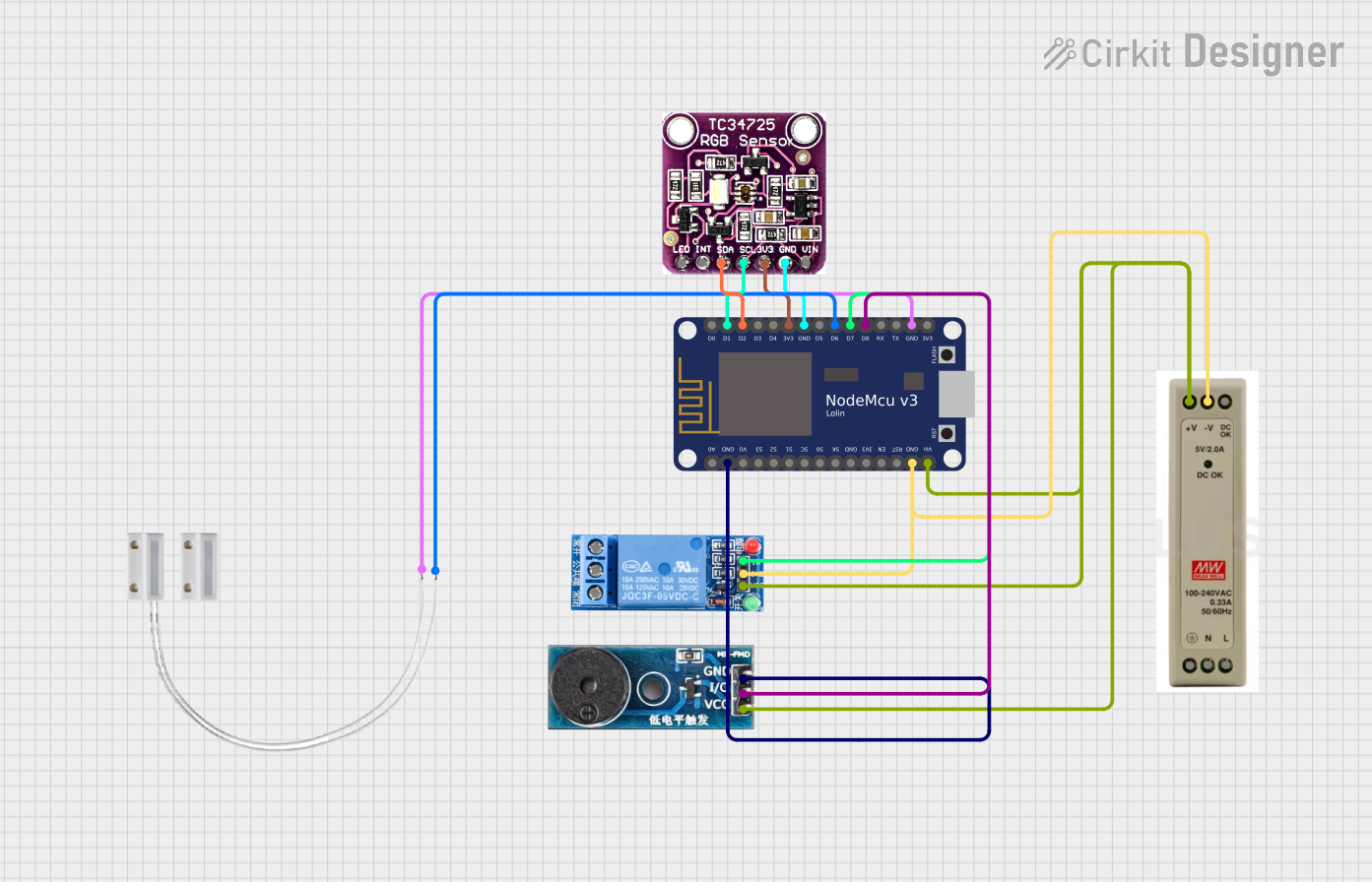

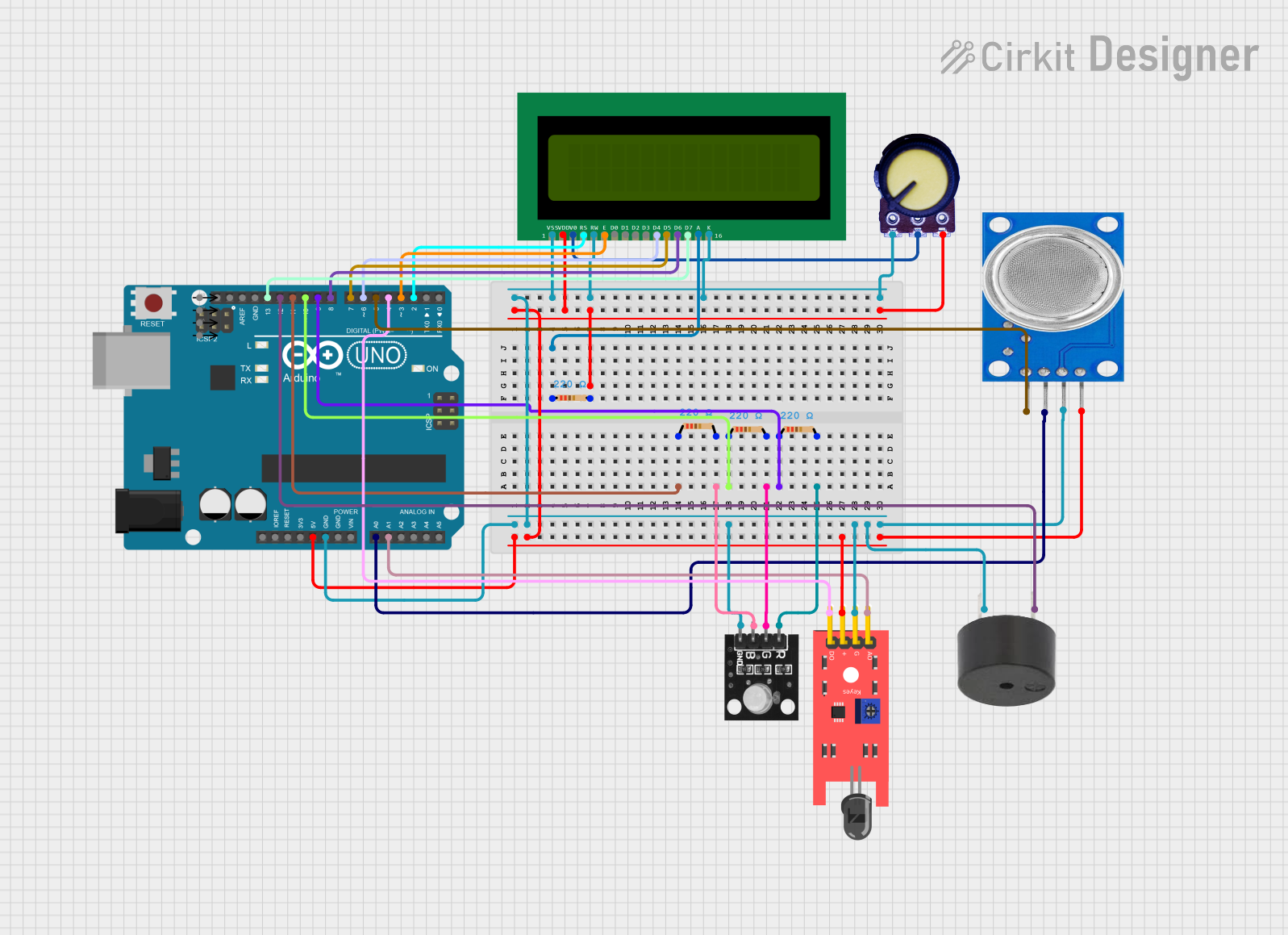

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Motor + Canister CO2

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Underwater drones and remotely operated vehicles (ROVs)

- Small-scale marine robotics

- Educational robotics projects

- Emergency flotation or propulsion systems

- Experimental propulsion systems for research

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Manufacturer | Robo Marine Indonesia |

| Motor Type | Brushed DC Motor |

| Operating Voltage | 6V - 12V |

| Maximum Current | 2A |

| Thrust Output (CO2) | Up to 5N |

| CO2 Canister Capacity | 16g |

| Motor Speed | 3000 RPM (at 12V) |

| Dimensions | 50mm x 30mm x 20mm |

| Weight | 150g (with canister) |

| Operating Temperature | -10°C to 50°C |

Pin Configuration and Descriptions

The motor has two terminals for electrical connections, and the CO2 canister is integrated into the system. Below is the pin configuration for the motor:

| Pin Number | Label | Description |

|---|---|---|

| 1 | V+ | Positive terminal for motor power input |

| 2 | V- | Negative terminal for motor power input |

The CO2 canister does not require electrical connections but is activated mechanically when the motor is powered.

Usage Instructions

How to Use the Component in a Circuit

- Power the Motor: Connect the motor terminals (V+ and V-) to a DC power source. Ensure the voltage is within the operating range (6V - 12V).

- Secure the CO2 Canister: Attach the CO2 canister to the designated slot on the motor assembly. Ensure it is tightly secured to prevent leaks.

- Control the Motor: Use a motor driver or an H-bridge circuit to control the motor's speed and direction. For Arduino users, a motor driver like the L298N is recommended.

- Test the System: Once connected, test the motor and CO2 canister in a safe environment. Ensure proper ventilation when testing the CO2 system.

Important Considerations and Best Practices

- Safety First: Always handle the CO2 canister with care. Avoid puncturing or exposing it to high temperatures.

- Voltage Regulation: Use a regulated power supply to prevent damage to the motor.

- Environmental Conditions: Avoid using the component in environments exceeding the specified temperature range.

- CO2 Refills: Replace the CO2 canister once depleted. Ensure compatibility with 16g canisters.

Arduino UNO Example Code

Below is an example of how to control the motor using an Arduino UNO and an L298N motor driver:

// Define motor control pins

const int motorPin1 = 9; // Connect to IN1 on L298N

const int motorPin2 = 10; // Connect to IN2 on L298N

const int enablePin = 11; // Connect to ENA on L298N

void setup() {

// Set motor pins as outputs

pinMode(motorPin1, OUTPUT);

pinMode(motorPin2, OUTPUT);

pinMode(enablePin, OUTPUT);

// Initialize motor in stopped state

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, LOW);

analogWrite(enablePin, 0); // Set speed to 0

}

void loop() {

// Example: Run motor forward at 50% speed

digitalWrite(motorPin1, HIGH);

digitalWrite(motorPin2, LOW);

analogWrite(enablePin, 128); // 50% duty cycle

delay(5000); // Run for 5 seconds

// Stop the motor

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, LOW);

analogWrite(enablePin, 0);

delay(2000); // Wait for 2 seconds

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Spin

- Cause: Insufficient power supply or loose connections.

- Solution: Check the power source and ensure all connections are secure.

CO2 Canister Does Not Release Thrust

- Cause: Canister not properly secured or depleted.

- Solution: Ensure the canister is tightly attached and replace it if empty.

Overheating

- Cause: Prolonged operation at high current.

- Solution: Operate the motor within the recommended voltage and current limits.

Irregular Thrust Output

- Cause: CO2 canister valve malfunction.

- Solution: Inspect the valve for blockages or damage and replace the canister if necessary.

FAQs

Q: Can I use a higher voltage than 12V for the motor?

A: No, exceeding 12V may damage the motor and void the warranty.

Q: How do I know when the CO2 canister is empty?

A: The thrust output will decrease significantly. Replace the canister when this occurs.

Q: Is the component waterproof?

A: The motor is not waterproof, but it is designed for use in controlled environments. Ensure proper sealing if used underwater.

Q: Can I refill the CO2 canister?

A: The canister is not refillable. Use compatible 16g replacement canisters.

By following this documentation, you can effectively integrate and operate the Motor + Canister CO2 in your projects.