How to Use Magnetic Contactor: Examples, Pinouts, and Specs

Design with Magnetic Contactor in Cirkit Designer

Design with Magnetic Contactor in Cirkit DesignerIntroduction

The Lauritz Knudsen MNX 9 Magnetic Contactor is an electrically controlled switch designed for high-current applications. It operates by using an electromagnet to close or open its contacts, enabling or interrupting the flow of current in a power circuit. Unlike standard relays, magnetic contactors are specifically engineered to handle higher loads, making them ideal for industrial and commercial applications.

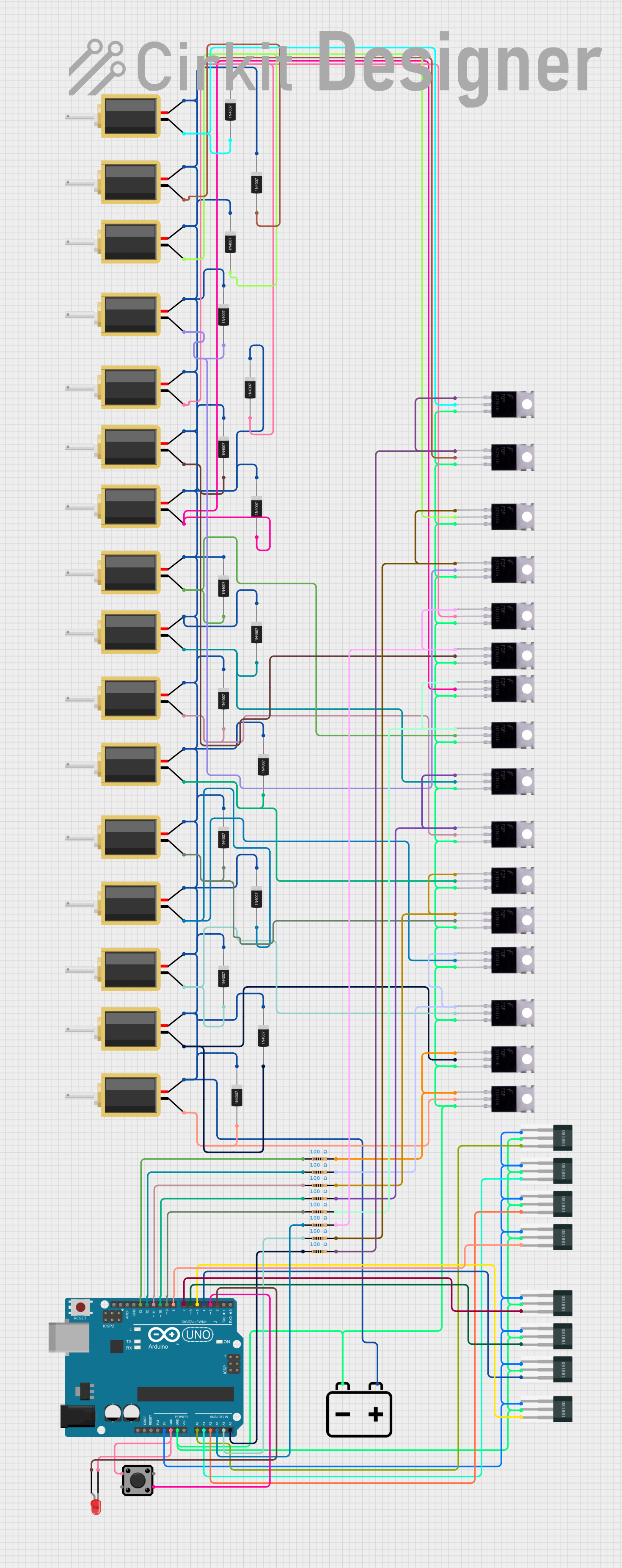

Explore Projects Built with Magnetic Contactor

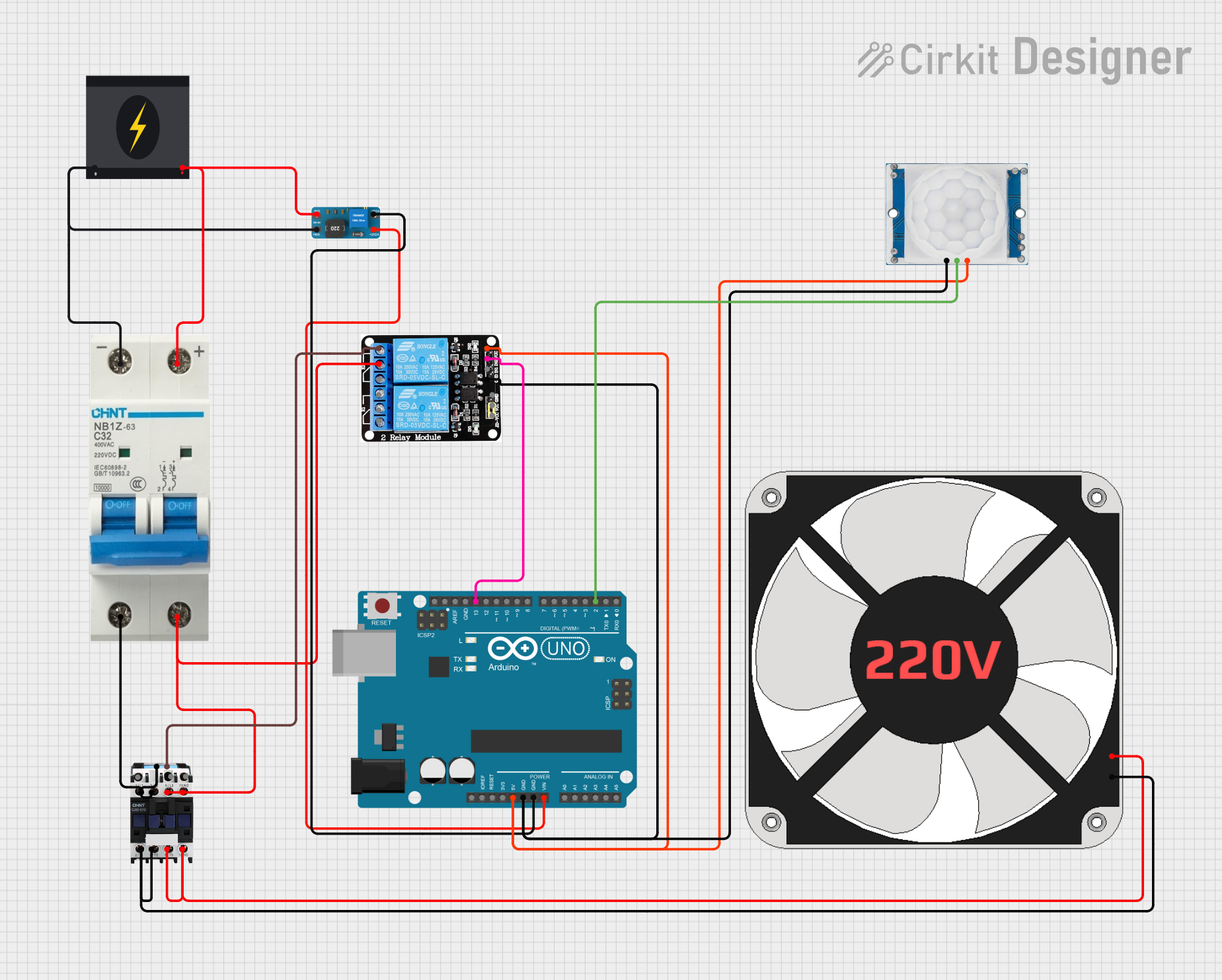

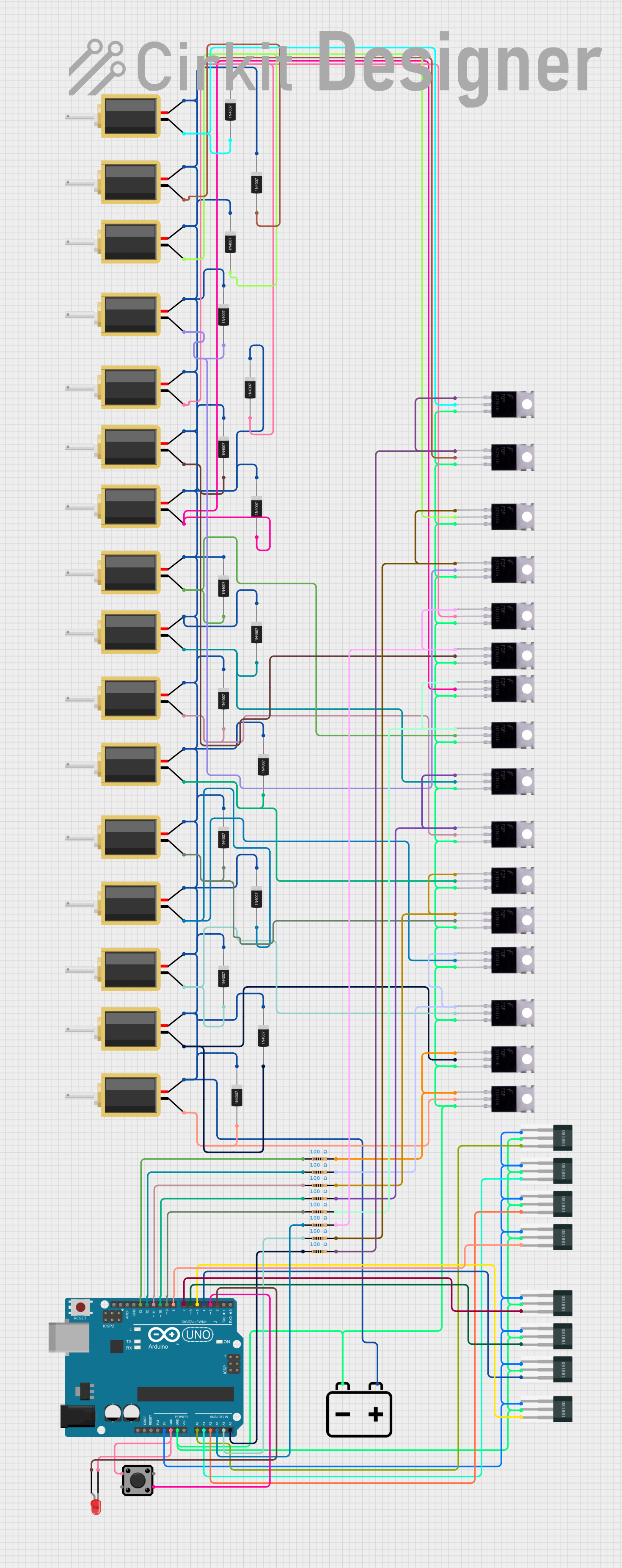

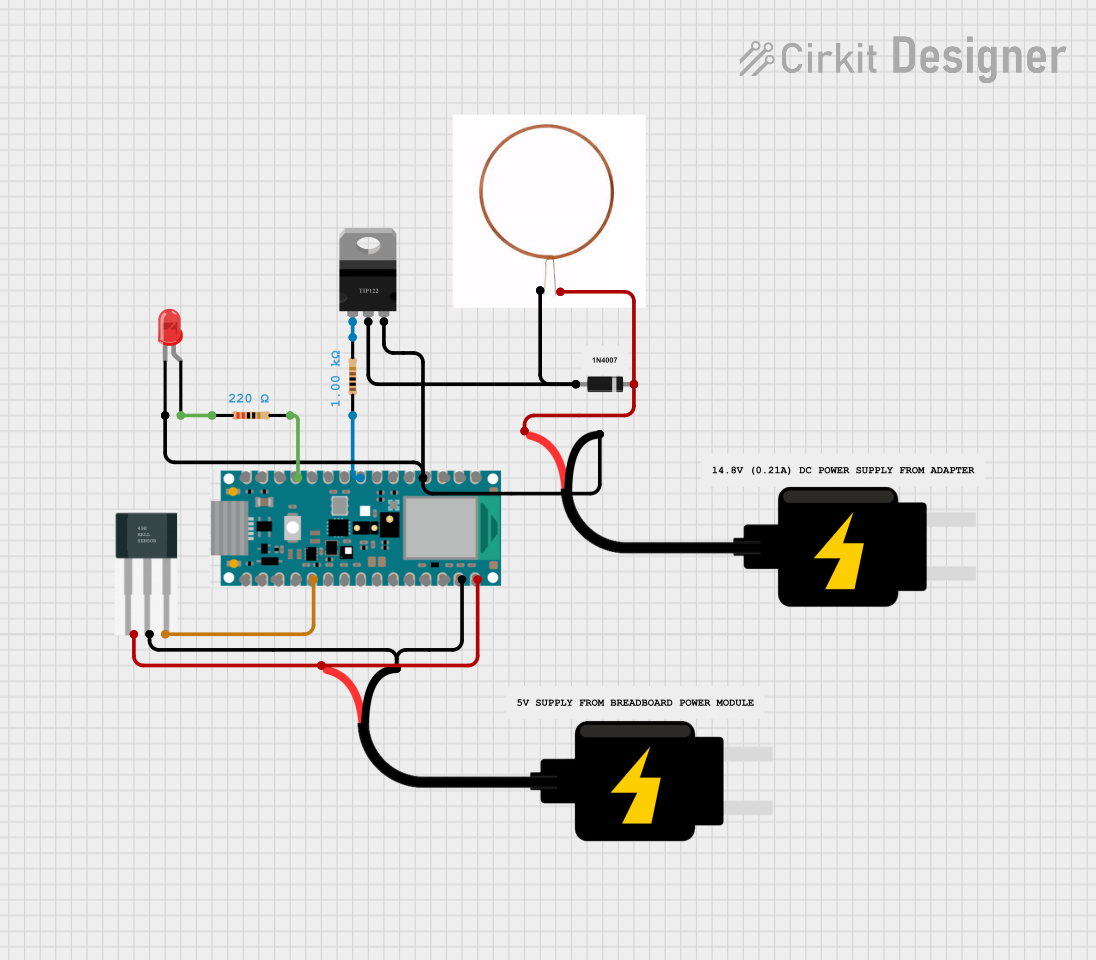

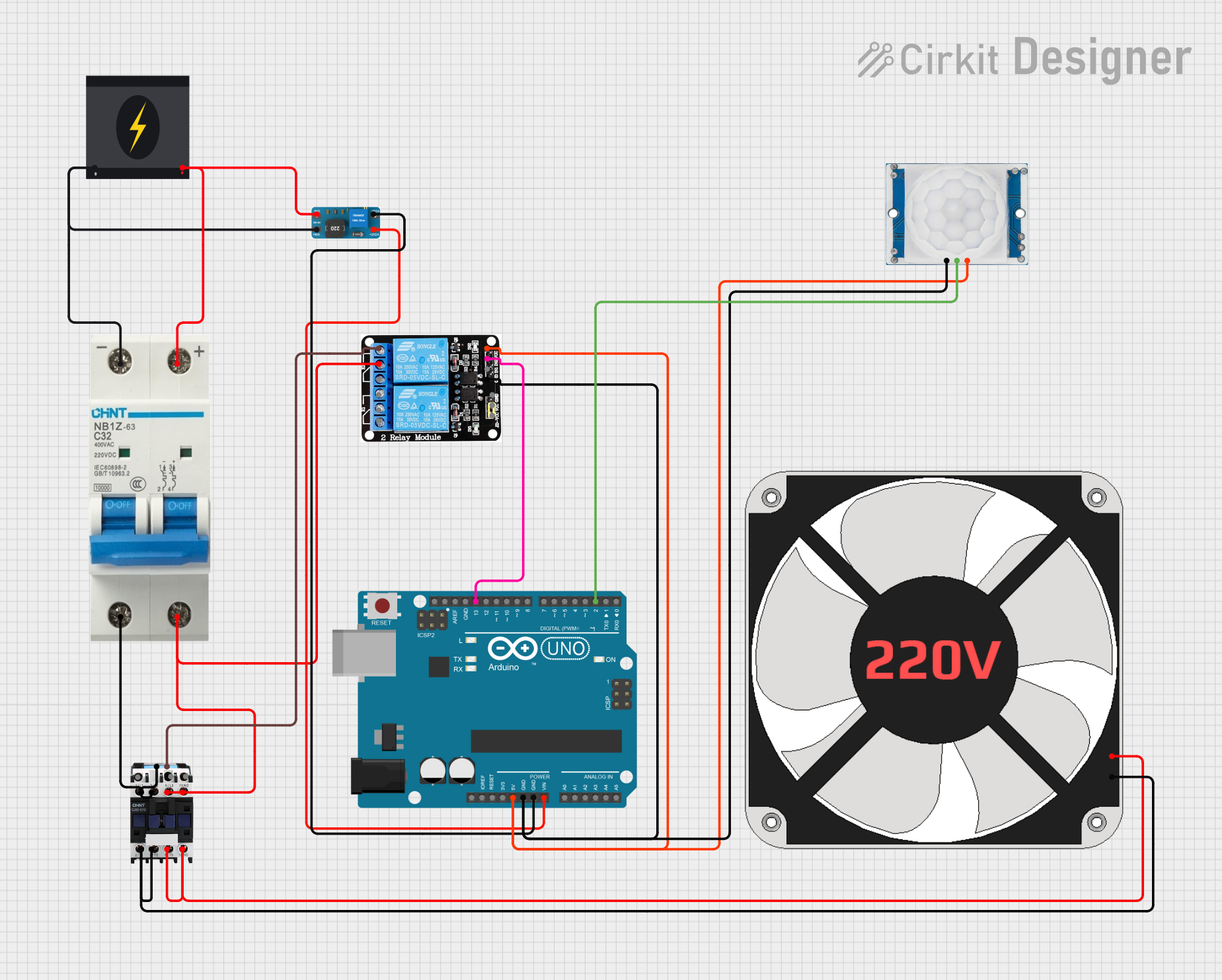

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Magnetic Contactor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Motor control in industrial machinery

- HVAC systems for controlling compressors and fans

- Lighting systems in commercial buildings

- Power distribution and automation systems

- Electric heating systems

Technical Specifications

The following table outlines the key technical details of the MNX 9 Magnetic Contactor:

| Parameter | Value |

|---|---|

| Manufacturer | Lauritz Knudsen |

| Part ID | MNX 9 |

| Rated Operational Voltage | 690V AC |

| Rated Current | 9A |

| Coil Voltage Options | 24V AC/DC, 110V AC, 230V AC |

| Frequency | 50/60 Hz |

| Number of Poles | 3 (Three-phase) |

| Contact Configuration | Normally Open (NO) |

| Mechanical Durability | 10 million operations |

| Electrical Durability | 1 million operations (at full load) |

| Operating Temperature | -25°C to +55°C |

| Mounting Type | DIN Rail or Panel Mount |

| Dimensions (H x W x D) | 77mm x 45mm x 85mm |

| Weight | 0.4 kg |

Pin Configuration and Descriptions

The MNX 9 Magnetic Contactor has the following terminal layout:

| Terminal | Description |

|---|---|

| L1, L2, L3 | Input terminals for the three-phase power supply |

| T1, T2, T3 | Output terminals for the load (e.g., motor) |

| A1, A2 | Coil terminals for energizing the contactor |

| Auxiliary Contacts | Optional terminals for control circuits (if equipped) |

Usage Instructions

How to Use the MNX 9 Magnetic Contactor in a Circuit

Power Supply Connection:

- Connect the three-phase power supply to the input terminals (L1, L2, L3).

- Ensure the voltage matches the rated operational voltage of the contactor.

Load Connection:

- Connect the load (e.g., motor, lighting system) to the output terminals (T1, T2, T3).

- Verify that the load current does not exceed the rated current of 9A.

Coil Connection:

- Connect the control voltage to the coil terminals (A1, A2). The coil voltage must match the specified voltage (e.g., 24V AC/DC, 110V AC, or 230V AC).

Auxiliary Contacts (Optional):

- If the contactor is equipped with auxiliary contacts, use them for control or signaling purposes in the circuit.

Mounting:

- Mount the contactor on a DIN rail or secure it to a panel using screws.

Testing:

- Energize the coil by applying the control voltage to A1 and A2. The contactor should close, allowing current to flow to the load.

- De-energize the coil to open the contacts and interrupt the current flow.

Important Considerations and Best Practices

- Overload Protection: Always use an appropriate overload relay in conjunction with the contactor to protect the load from overcurrent conditions.

- Voltage Matching: Ensure that the coil voltage and operational voltage match the specifications of the MNX 9.

- Wiring: Use appropriately rated wires for the current and voltage levels in the circuit.

- Maintenance: Periodically inspect the contactor for wear and tear, especially the contacts, to ensure reliable operation.

- Environment: Avoid installing the contactor in environments with excessive dust, moisture, or vibration.

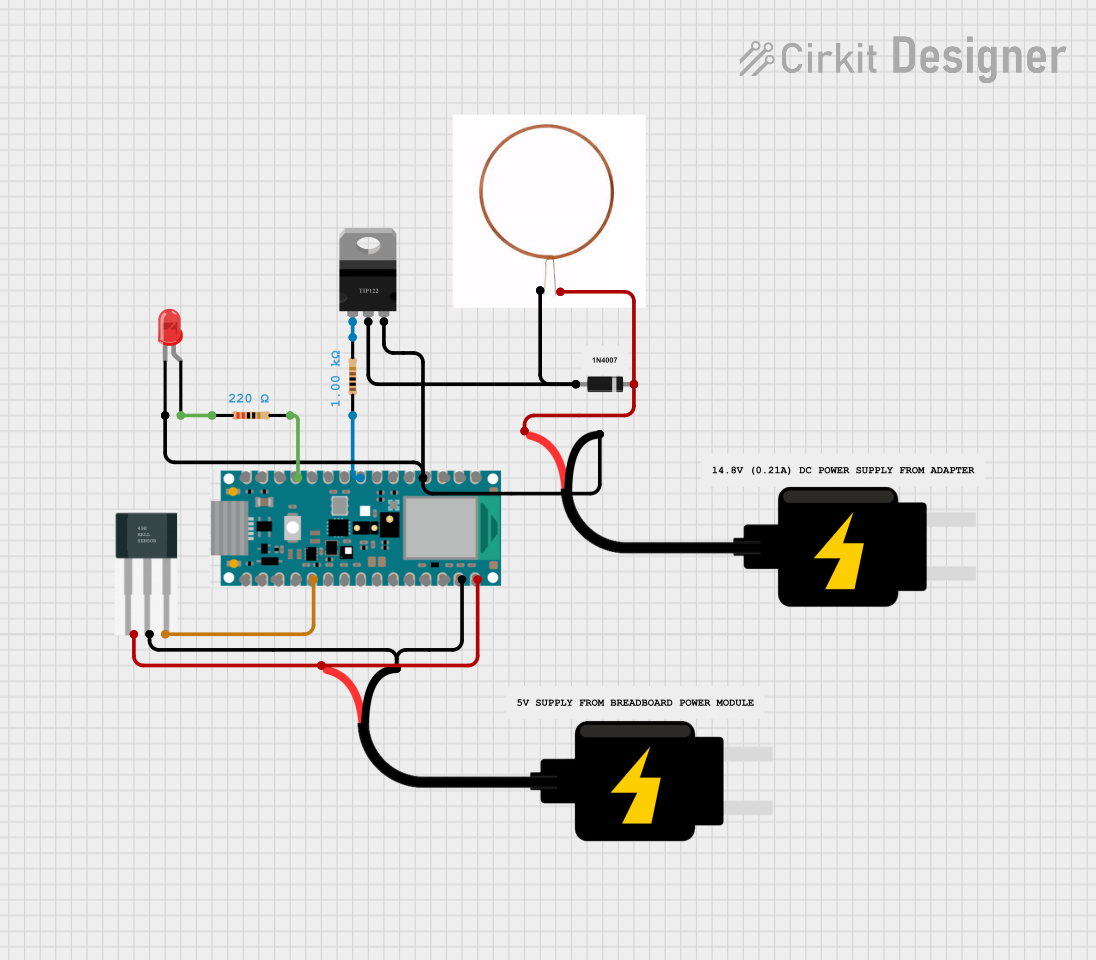

Example: Connecting the MNX 9 to an Arduino UNO

The MNX 9 can be controlled using an Arduino UNO by energizing its coil with a relay module. Below is an example code snippet:

// Example code to control the MNX 9 Magnetic Contactor using an Arduino UNO

// The Arduino controls a relay module, which energizes the contactor's coil.

const int relayPin = 7; // Pin connected to the relay module

void setup() {

pinMode(relayPin, OUTPUT); // Set the relay pin as an output

digitalWrite(relayPin, LOW); // Ensure the relay is off initially

}

void loop() {

// Turn the contactor ON

digitalWrite(relayPin, HIGH); // Energize the relay

delay(5000); // Keep the contactor ON for 5 seconds

// Turn the contactor OFF

digitalWrite(relayPin, LOW); // De-energize the relay

delay(5000); // Keep the contactor OFF for 5 seconds

}

Note: Use a relay module that can handle the coil voltage and current of the MNX 9. Ensure proper isolation between the Arduino and the high-voltage circuit.

Troubleshooting and FAQs

Common Issues and Solutions

Contactor Does Not Close:

- Cause: No control voltage applied to the coil.

- Solution: Check the coil voltage at terminals A1 and A2. Ensure the control circuit is functioning correctly.

Excessive Heating:

- Cause: Overcurrent or poor ventilation.

- Solution: Verify that the load current does not exceed 9A. Ensure adequate ventilation around the contactor.

Contacts Sticking:

- Cause: Worn or damaged contacts.

- Solution: Inspect and replace the contactor if the contacts are damaged.

Humming Noise:

- Cause: Loose or misaligned coil.

- Solution: Tighten the coil assembly and ensure proper alignment.

FAQs

Q: Can the MNX 9 be used for single-phase applications?

A: Yes, but only one pair of input and output terminals (e.g., L1 and T1) should be used.Q: What is the maximum switching frequency?

A: The MNX 9 can handle up to 1200 operations per hour under normal conditions.Q: Can I use the MNX 9 outdoors?

A: The MNX 9 is not weatherproof. Use it in a protected enclosure if installed outdoors.Q: How do I know if the contactor is faulty?

A: If the coil is energized but the contacts do not close, or if the contacts are visibly damaged, the contactor may need replacement.